Copper rod automatic forging and trimming equipment

A technology of edge trimming and copper rods, which is applied in other manufacturing equipment/tools, metal processing equipment, heating/cooling equipment, etc., can solve the problems of precise control of copper rod temperature, high labor cost, and poor flashing effect, etc. Achieve the effect of strengthening market competitiveness, reducing the probability of work-related injuries, and ensuring product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

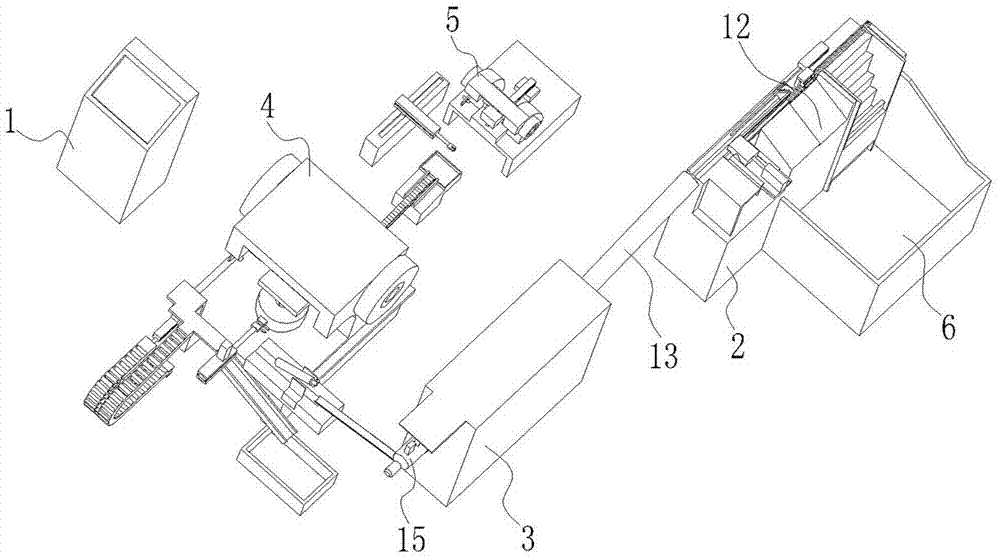

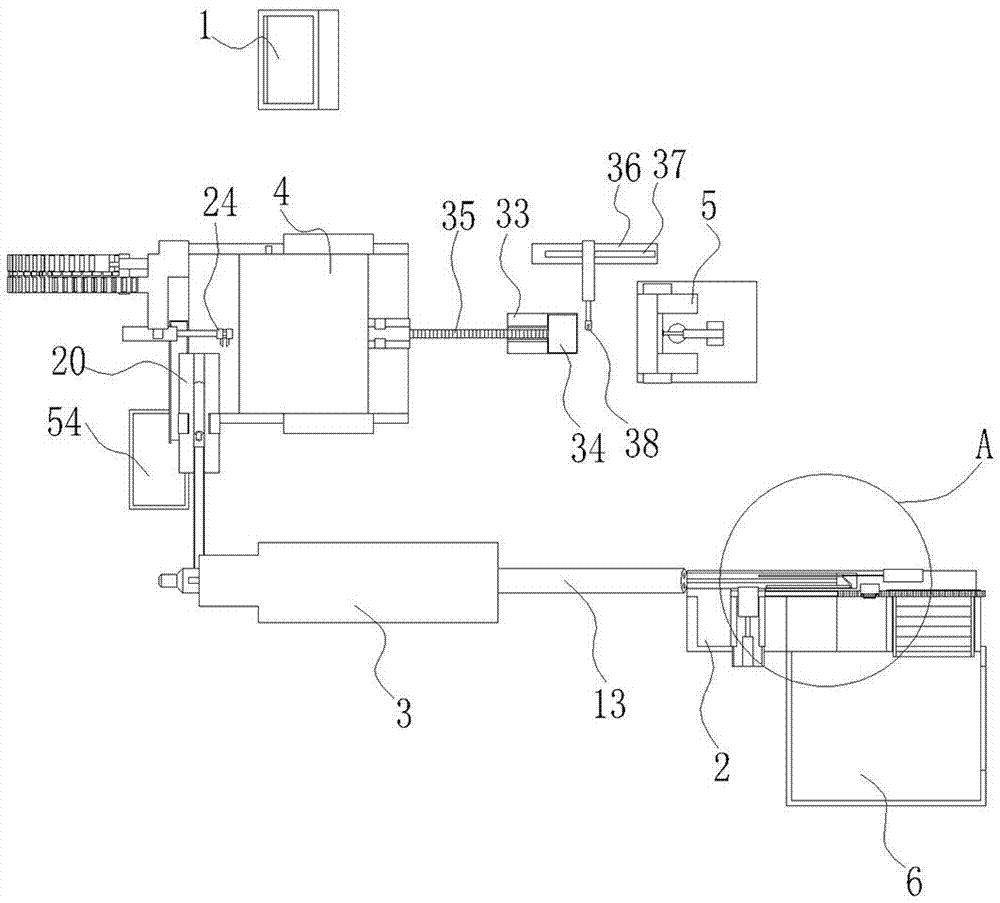

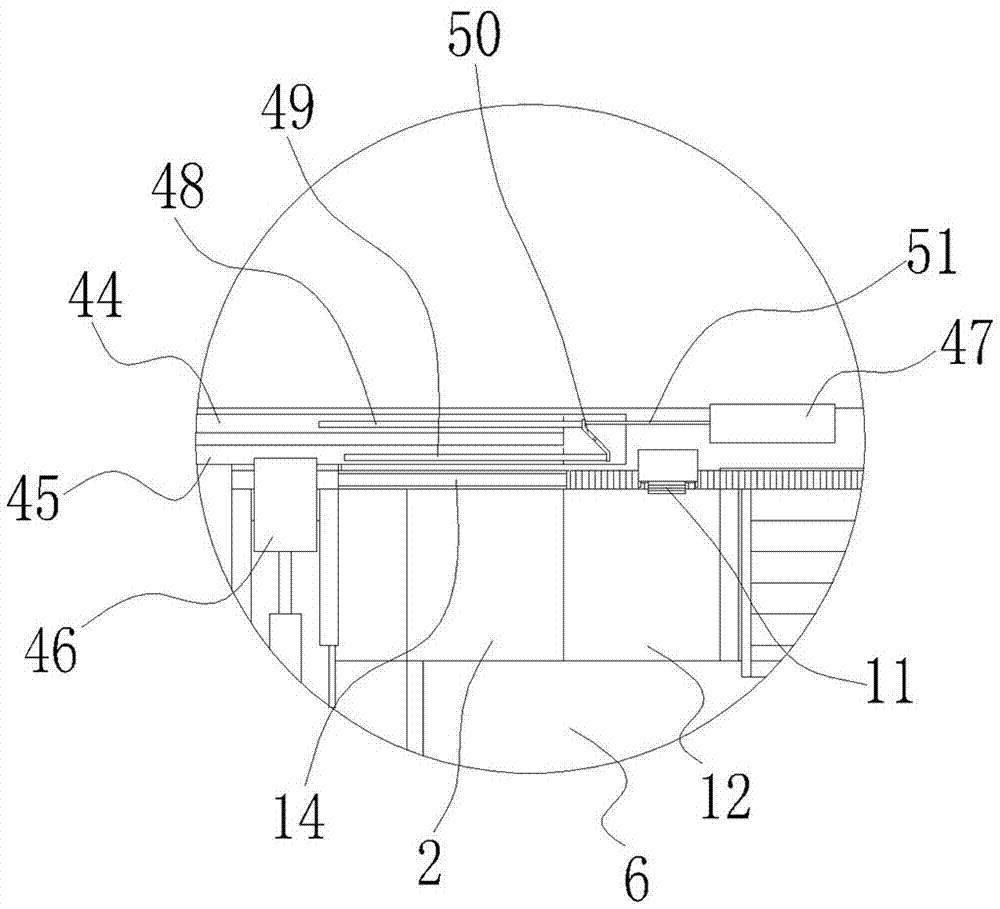

[0035] refer to Figure 1 to Figure 8 , a copper rod automatic forging trimming equipment, including a control box 1, and a fuselage 2, a heating furnace 3, a forging punch press 4 and a trimming punch press 5 arranged in sequence according to the process, the control box 1 is connected with the described The forging press 4 is electrically connected with the trimming punch 5, and the forging press 4 forges the copper bar into a semi-finished product, and the described trimming punch 5 processes the semi-finished product into a finished product;

[0036] One side of the fuselage 2 is provided with a material storage box 6, the inside of the described material storage box 6 is provided with a feeding area, and the upper end of the fuselage 2 is provided with a first conveying mechanism 7, and the described feeding area There are sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com