Patents

Literature

89results about How to "Meet stringent requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil-resistant, high-temperature-resistant and flame-retardant thermoplastic elastomer cable material and preparation method thereof

ActiveCN104629183ARaw material selection and proportioning are reasonableShort processRubber insulatorsPlastic/resin/waxes insulatorsChemistryPolypropylene

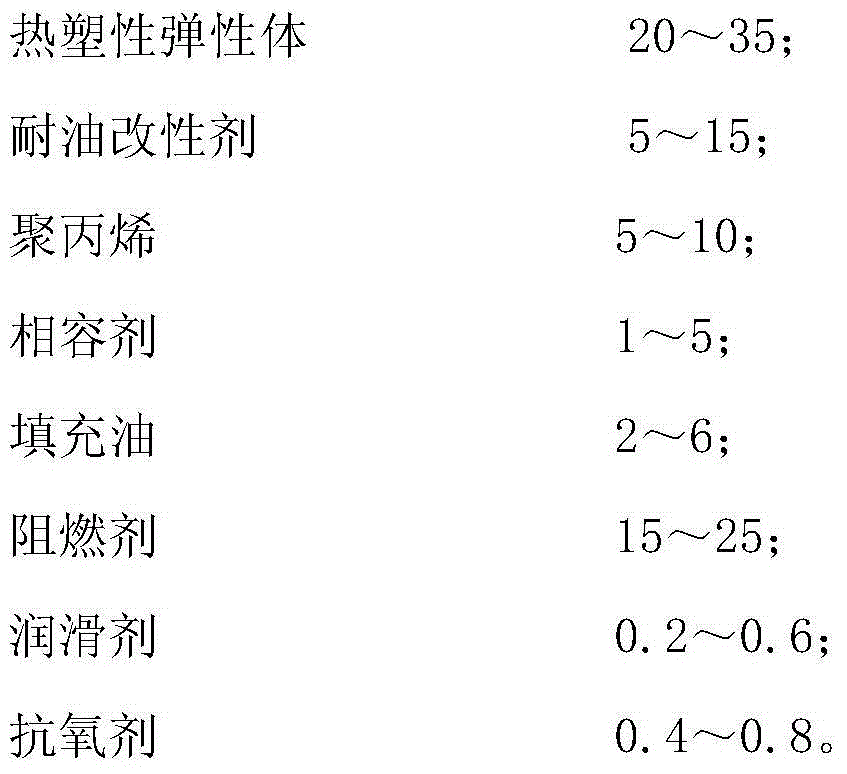

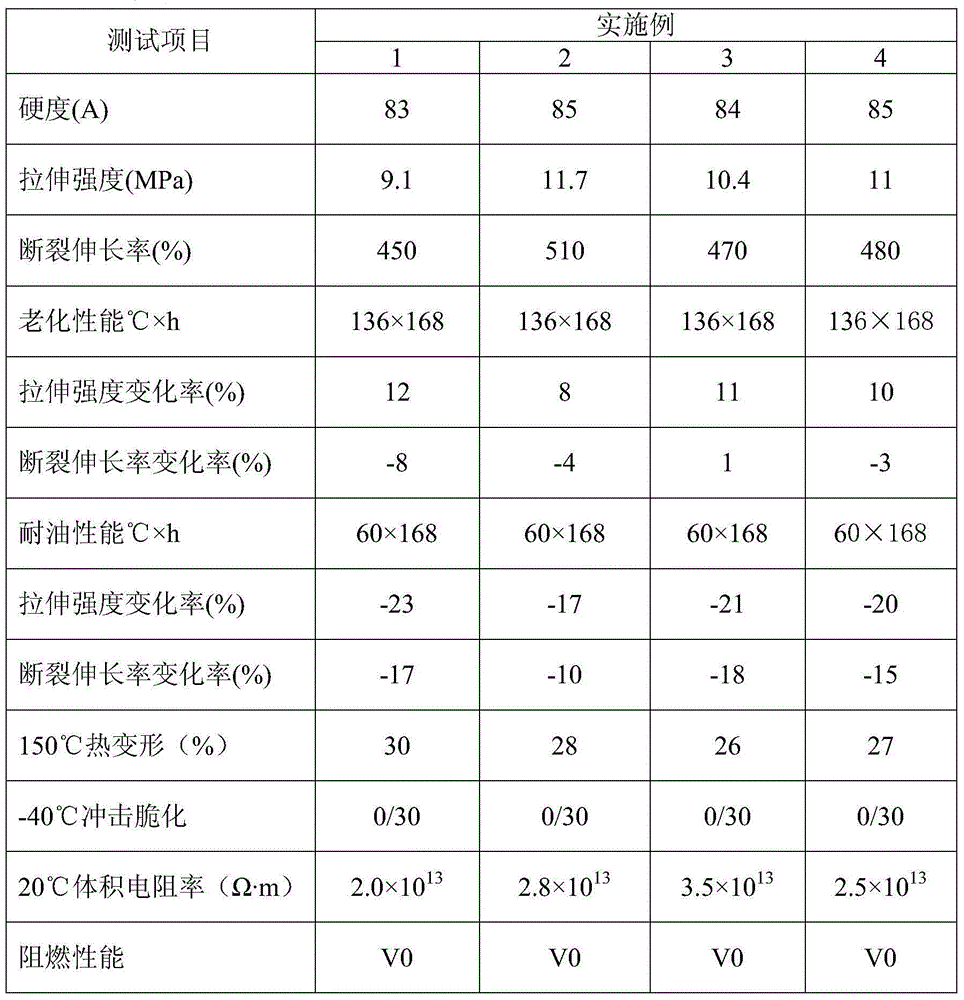

The invention relates to an oil-resistant, high-temperature-resistant and flame-retardant thermoplastic elastomer cable material and a preparation method thereof and belongs to the technical field of electric wires and cables and preparation thereof. The cable material is prepared from the following raw materials in parts by weight: 20-35 parts of a thermoplastic elastomer, 5-15 parts of an oil-resistant modifier, 5-10 parts of polypropylene, 1-5 parts of a compatilizer, 2-6 parts of extending oil, 15-25 parts of a flame retardant, 0.2-0.6 part of a lubricant and 0.4-0.8 part of an antioxidant. As raw materials are reasonably selected and proportioned, the mechanical property change rate of the material soaked in 902# oil for 168 hours at 60 DEG C is within 25%, the high-temperature-resistant deformation is 26-30% at 150 DEG C, and the flame-retardant performance reaches VO level, so that the stringent requirements of UL62 on the TPE material are fully satisfied. The preparation method provide is short in technical process, and the extruding temperature is within 100-200 DEG C. Compared with the prior art, the extruding temperature is remarkably reduced and an energy-saving effect is reflected.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +1

Method for Improving Oxidation Resistance of Graphite Electrodes by Chemical Vapor Deposition SIC/C Gradient Surface Coating

InactiveCN102277560AGood permeabilityStrong coating adhesionElectric discharge heatingChemical vapor deposition coatingOxidation resistantGraphite

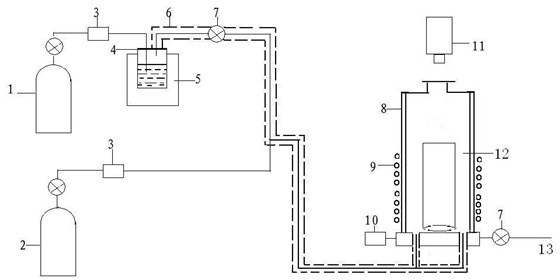

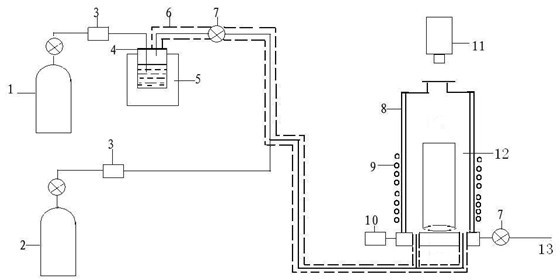

The invention discloses a method for improving the oxidation resistance of a graphite electrode by obtaining a SiC / C gradient surface coating through chemical vapor deposition. The method comprises the following steps of: performing surface pretreatment on the graphite electrode; fixing the graphite electrode which is subjected to surface pretreatment on a support in a water-cooled reaction furnace of chemical vapor deposition equipment, and vacuumizing in the furnace; heating the graphite electrode in the reaction furnace, and aerating CH4 gas to form a layer of pyrolytic carbon on the surface of the graphite electrode; keeping the temperature of a cavity unchanged, aerating carrier gas H2 to pass through boiling SiCl4 liquid, and reacting SiCl4 gas carried by the carrier gas H2 and the CH4 gas on the surface of the graphite electrode and depositing; and after the deposition is finished, keeping the temperature of the cavity unchanged, maintaining H2 atmosphere, performing in-situ heat treatment on the graphite electrode in the furnace, and cooling the graphite electrode to room temperature in the furnace after the heat treatment is finished so as to obtain the graphite electrodewith a SiC / C gradient functional surface protective layer. The invention has the advantages that: the permeability is high, the coating can permeate into any fine pores on the surface of a matrix of the graphite electrode, and a good effect of resisting the oxidation of surface voids can be achieved.

Owner:NANJING UNIV OF SCI & TECH +1

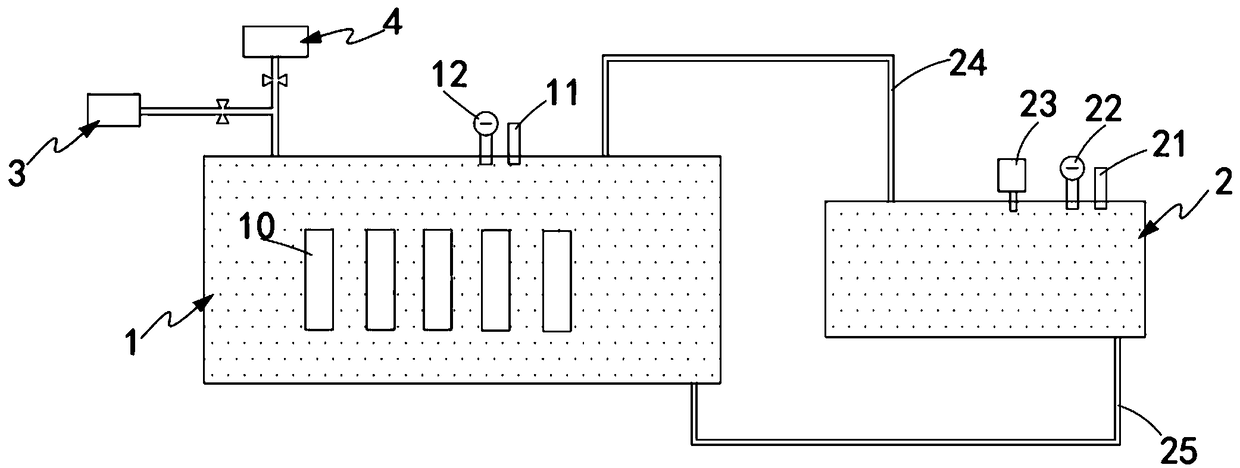

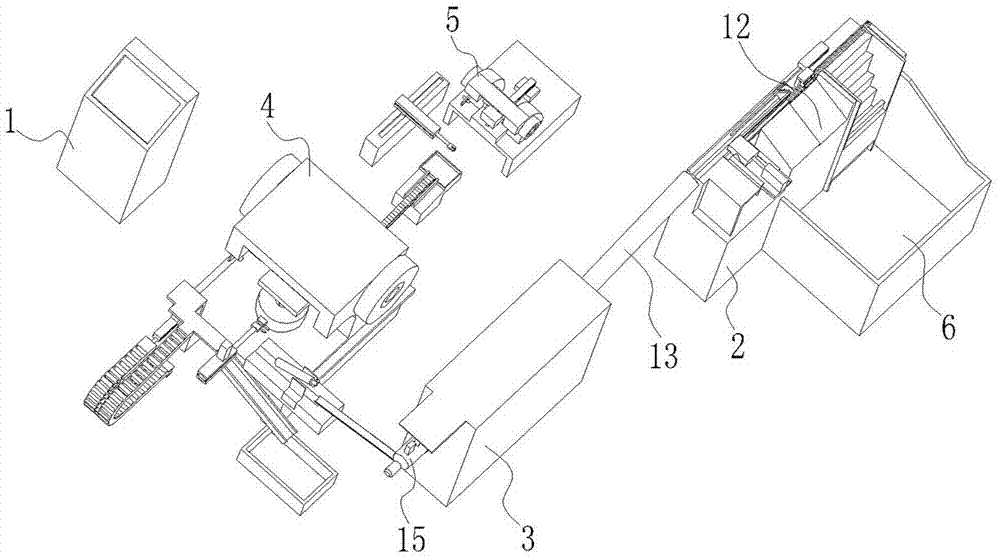

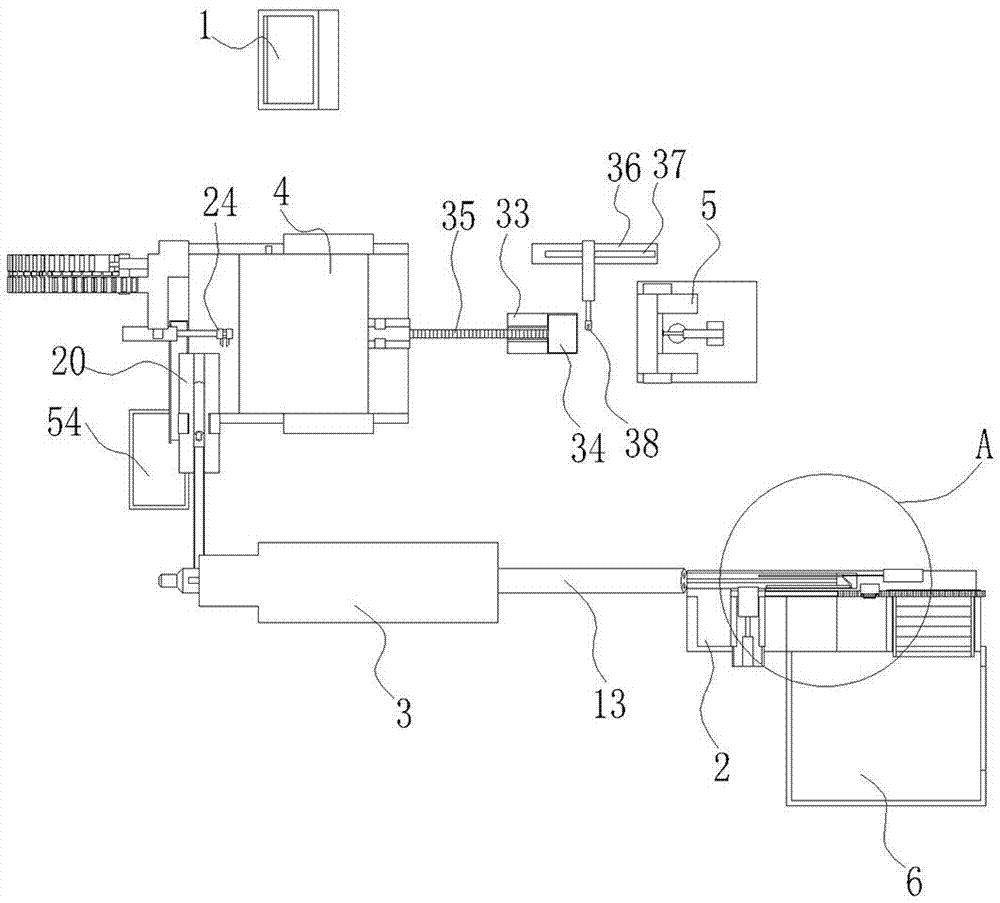

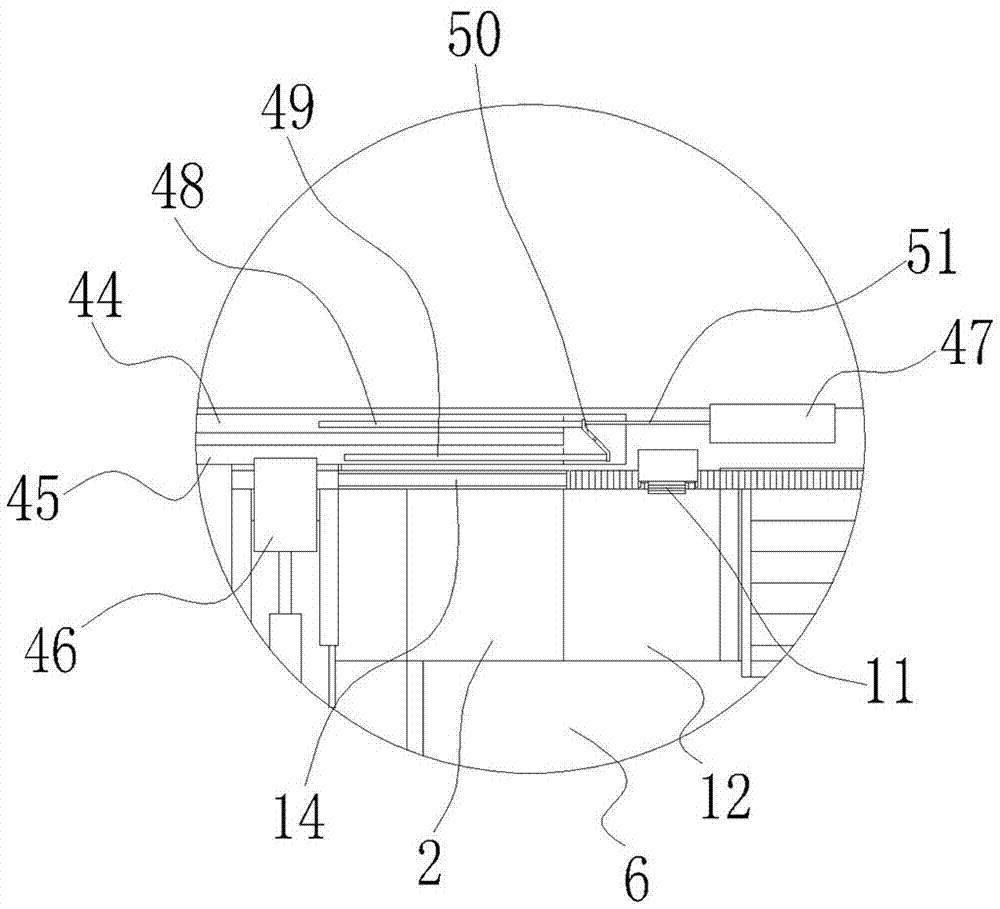

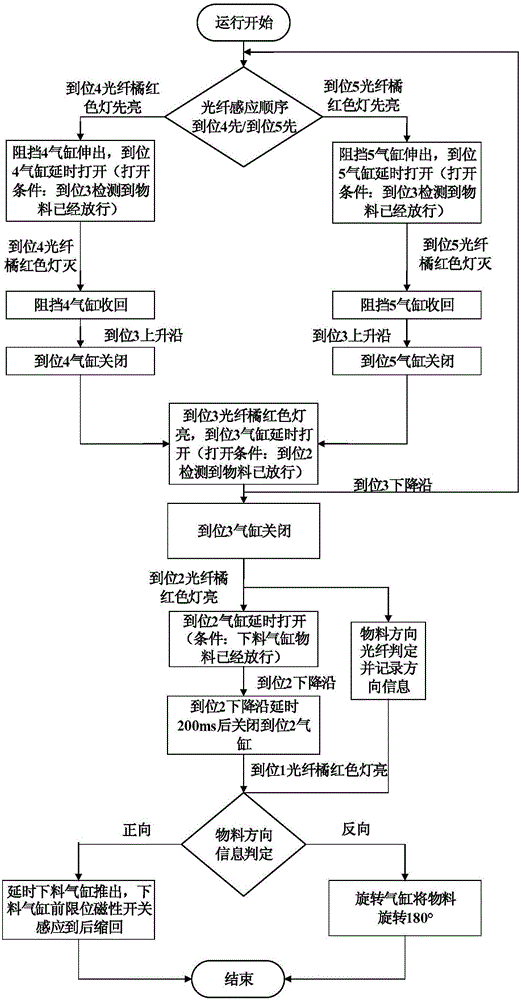

Article defect detection system and method based on machine vision

InactiveCN106153641AStable deliveryMeet stringent requirementsMaterial analysis by optical meansMachine visionImaging processing

The invention discloses an article defect detection system and method based on machine vision. The system comprises a feeding device, a conveying device, an image obtaining device and a control and image processing module. The feeding device and an inlet of the conveying device are in butt joint, the feeding device and the conveying device are installed on a rack, the feeding device is used for conveying an article to be detected to the conveying device, and the conveying device is used for conveying the article to be detected to a detection station. The action of the feeding device and the action of the conveying device are controlled by the control and image processing module. The image obtaining device is arranged on the rack and used for obtaining an image of the article to be detected at the detection station and transmitting the image into the control and image processing module for image processing so as to judge whether the corresponding article to be detected has a defect or not. The system is compact in structure, abundant in function, capable of detecting various defects of articles, ingenious in concept and capable of being easily implemented on a high-speed detection line.

Owner:余洪山

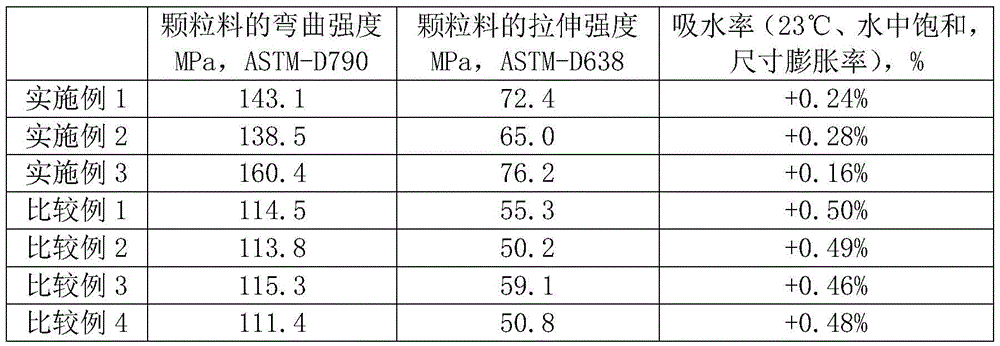

Granular material for injection-molded nylon-12-permanent magnetic ferrite and preparation method of granular material

The invention discloses a granular material for injection-molded nylon-12-permanent magnetic ferrite and a preparation method of the granular material. The granular material is prepared from the following components including permanent magnetic ferrite magnetic powder, nylon12, a reinforcing agent, a dispersant, a coupling agent and a lubricant through mixing granulation. The preparation method comprises specific steps as follows: (1), treatment of surfaces of the magnetic powder: the permanent magnetic ferrite magnetic powder is put into a powder mixing cylinder, and the dispersant and the coupling agent in a proper proportion are added; (2), addition of nylon12; (3), addition of the reinforcing agent and the lubricant; (4), granulation: the uniformly mixed nylon12 and permanent magnetic ferrite magnetic powder mixture is injected into a granulator for granulation. The granular material and the preparation method have the benefits as follows: by comparison with commercially available and universal granular materials for injection-molded nylon12-permanent magnetic ferrite, the bending strength and the tensile strength of the granular material can be improved by 20%-50%, and the granular material has high strength and high precision and can meet rigid requirements for injection-molded magnets for existing automobile motors, especially motors for high-grade new-energy powered automobiles and for high-grade household appliances.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

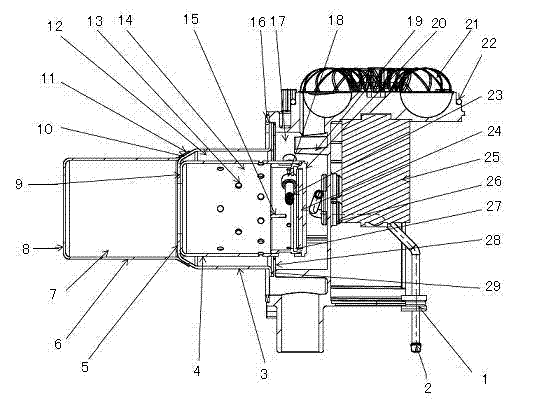

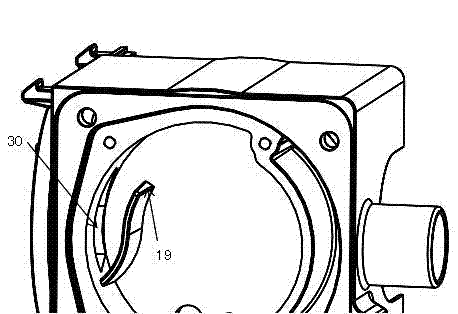

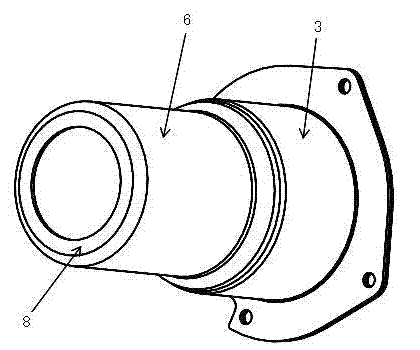

Burner for external spiral intake volatization and atomization type parking heater with flat cap and necking

InactiveCN102650253AAvoid the possibility of carbon depositionSuspension stabilityMachines/enginesEngine startersElectricityCombustor

The invention relates to a burner for external spiral intake volatization and atomization type parking heater with a flat cap and necking, which belongs to the field of burners. The technical scheme provided by the invention mainly adopts a compressed air chamber of an external spiral intake structure, an afterflaming barrel and a flat end cap, wherein an S-shaped diversion rib which corresponds to a compressed air outlet is fixedly arranged at the inner wall of the compressed air chamber; the afterflaming barrel is formed by stamping and drawing metal, and one end of the afterflaming barrel is contracted toward an inner plane; and one side of the flat end cap is provided with 3-5 long slant air inlets, and 5-15 auxiliary air inlets are uniformly arranged in the middle of the flat end cap. The burner has the advantages that the burner has a simple structure, a small volume and small noise, is easy to start and clean to burn, has high power density, and particularly saves the electricity quantity of an automobile storage battery; the burner stably burns and has high burning efficiency, the service life of a motor is greatly prolonged, and requirements on the automobile storage battery and the motor of a compressor are lowered; the burner can realize the common use of diesel, gasoline and kerosene, and can also be used on other heating devices except a fuel heater; and the burner has strong practicability.

Owner:李国莹 +1

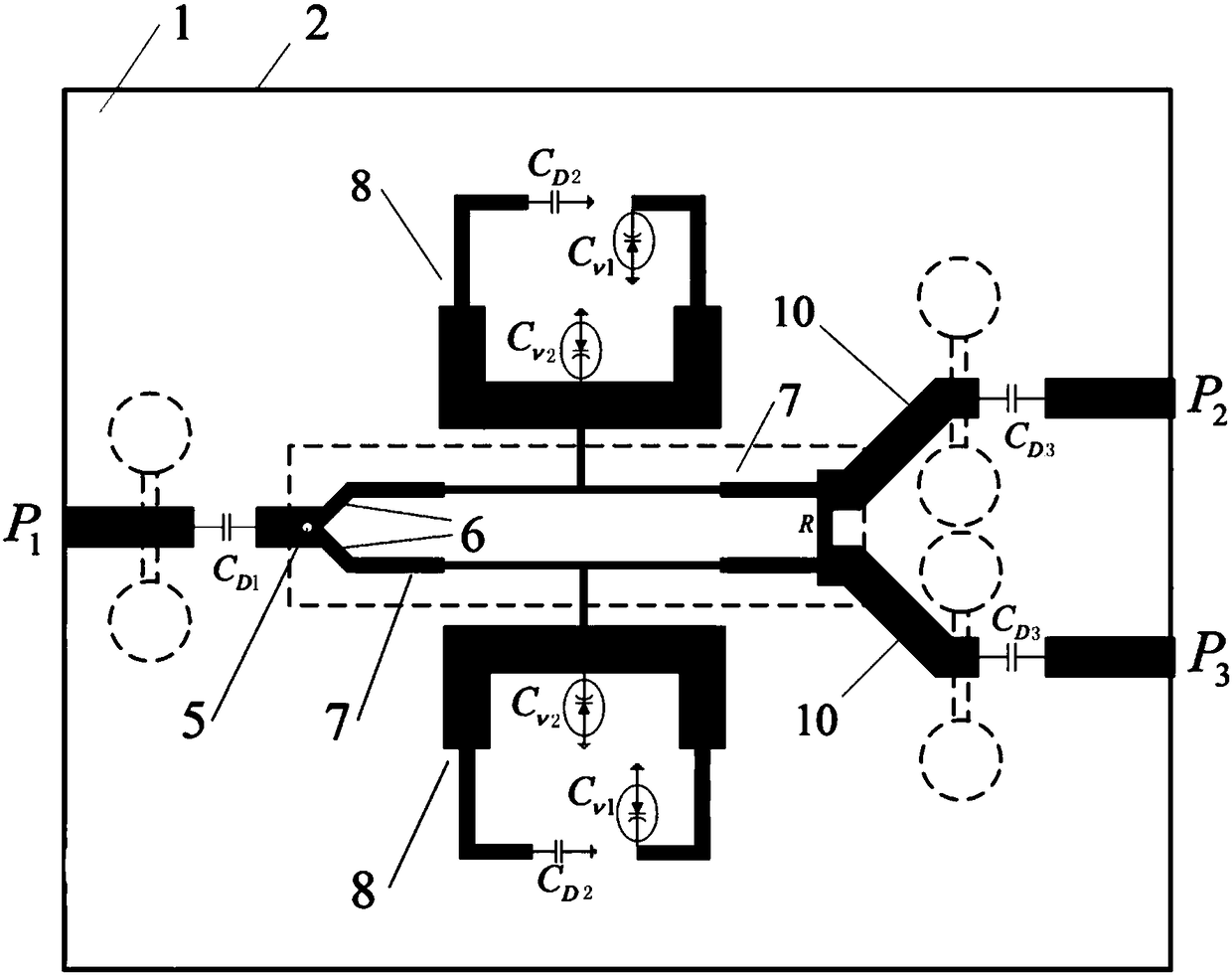

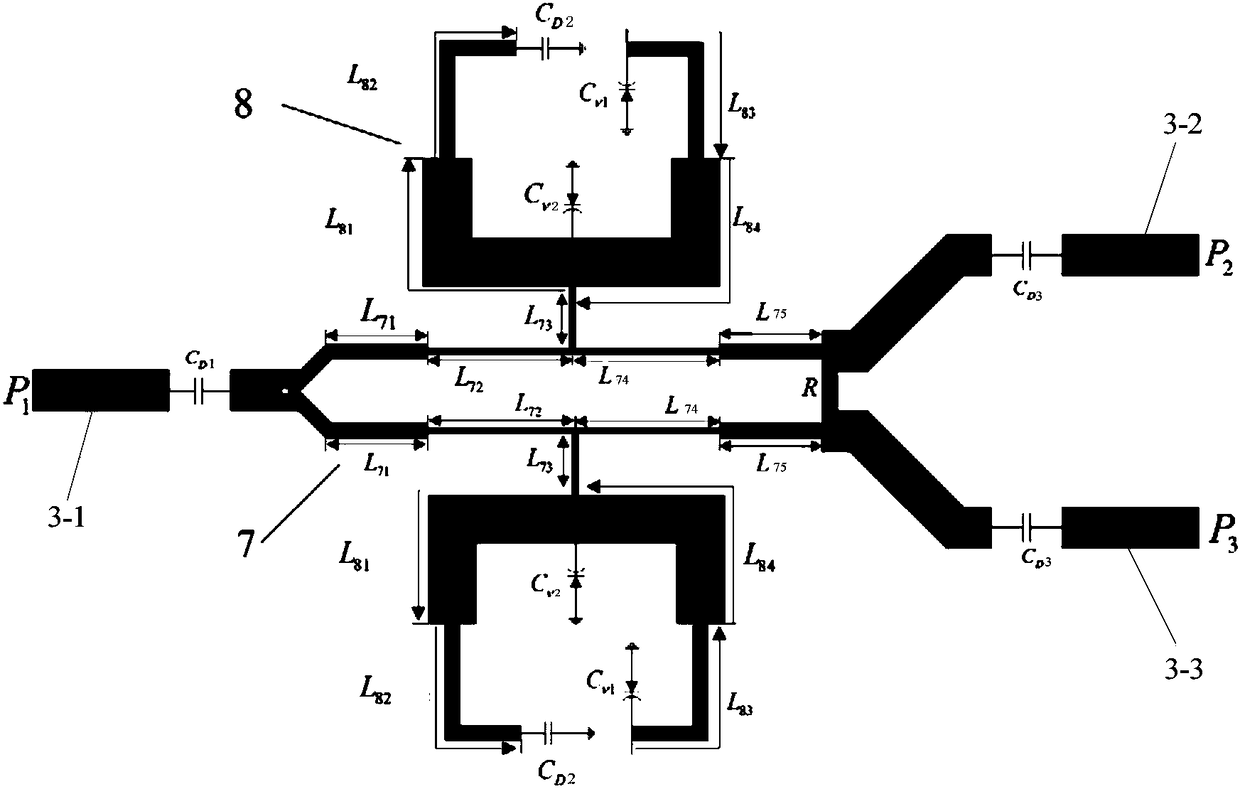

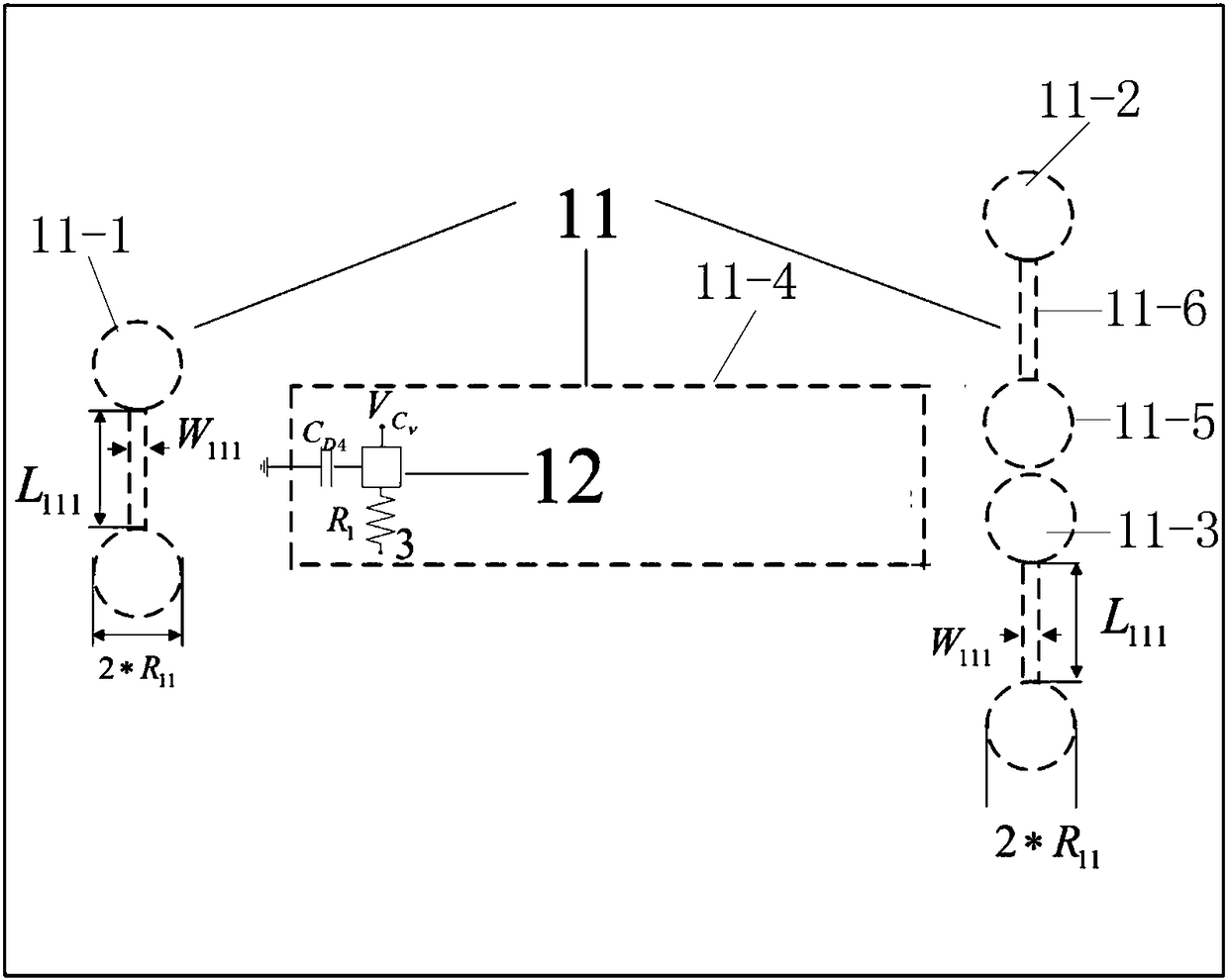

Wide-stop-band reconfigurable filter type power divider based on SIR and DGS structures

ActiveCN108493566AHarmonic suppressionReduce distractionsCoupling devicesCommunications systemHarmonic

The invention discloses a wide-stop-band reconfigurable filter type power divider based on SIR and DGS structures. SIR and DGS structures are set at a common power divider. One path of alternating-current signals entering the power divider is split into two paths and the two paths of signals are transmitted to two SIR resonators for processing by two SIR-T branches, thereby realizing harmonic filtering and frequency and bandwidth adjustment. An isolation resistor for isolating the two paths of signals is arranged behind the SIR-T branches, so that coupling of the two paths of signals during the transmission process is prevented. According to the invention, the DGS structure is arranged on the ground metal board, so that the power divider has the broadband group characteristic. The usage frequency band range of the power divider is extended; the functions of filtering and wide stop band are realized; and thus the strict requirement of the power divider by the modern communication systemis met.

Owner:XIDIAN UNIV

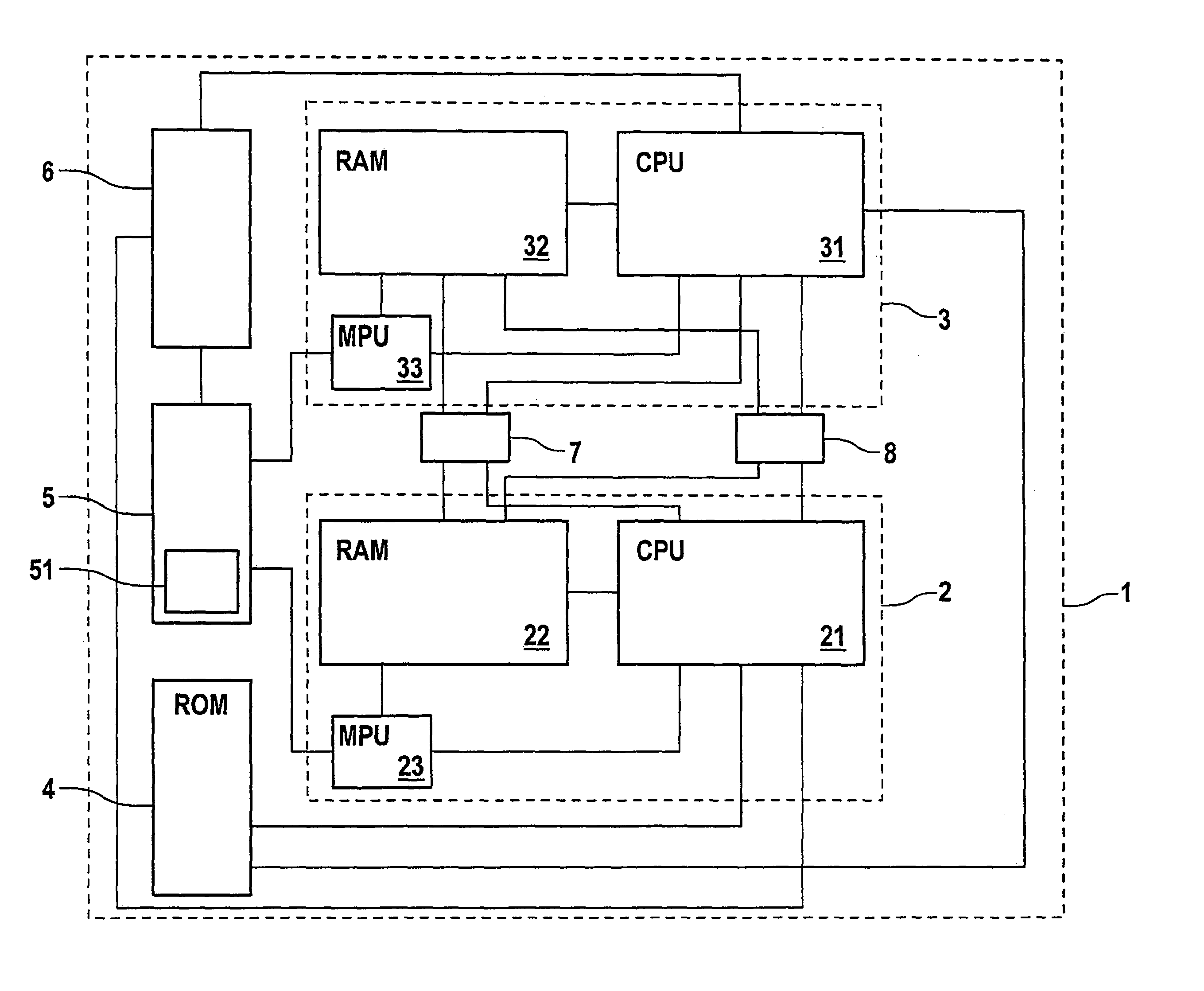

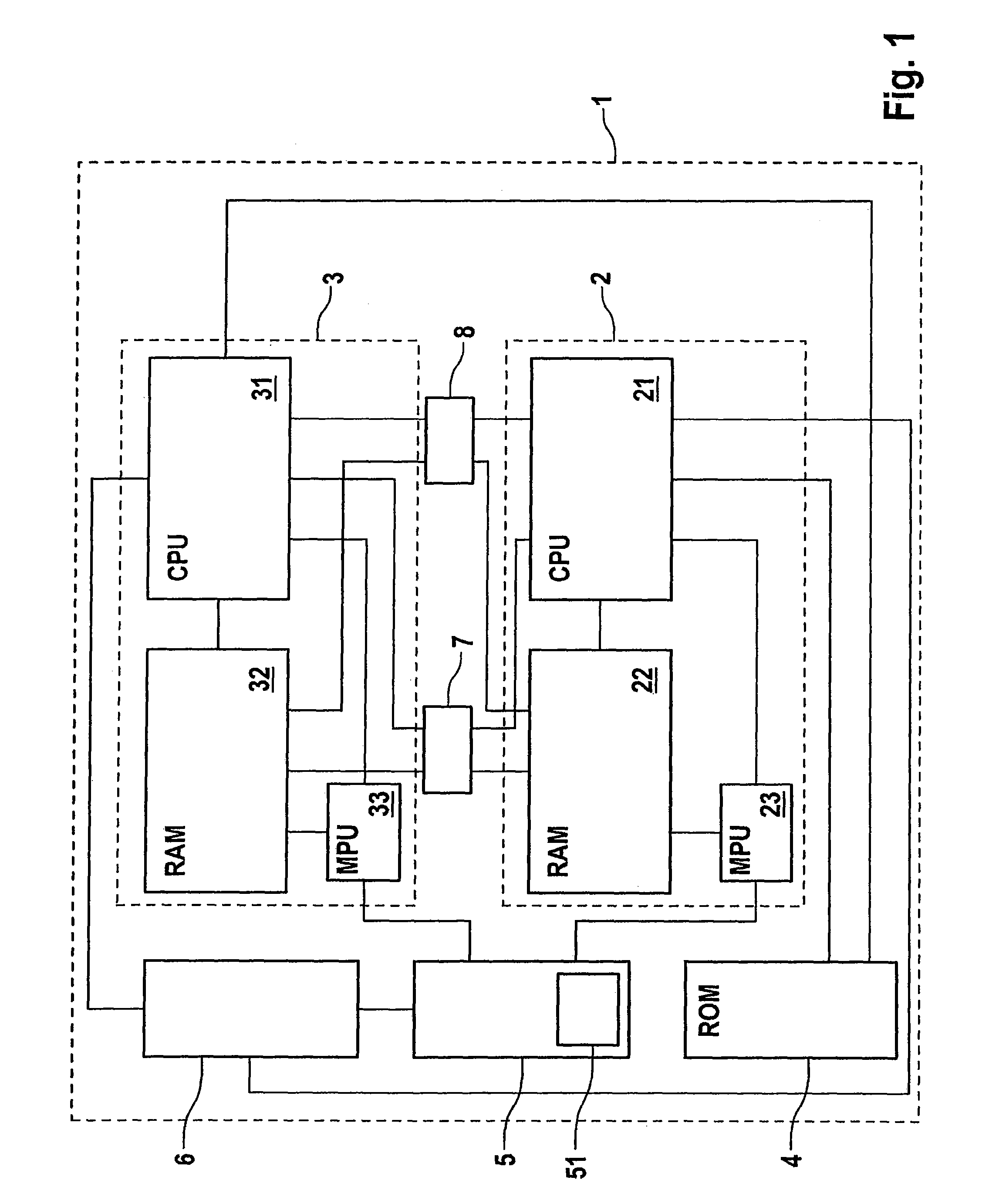

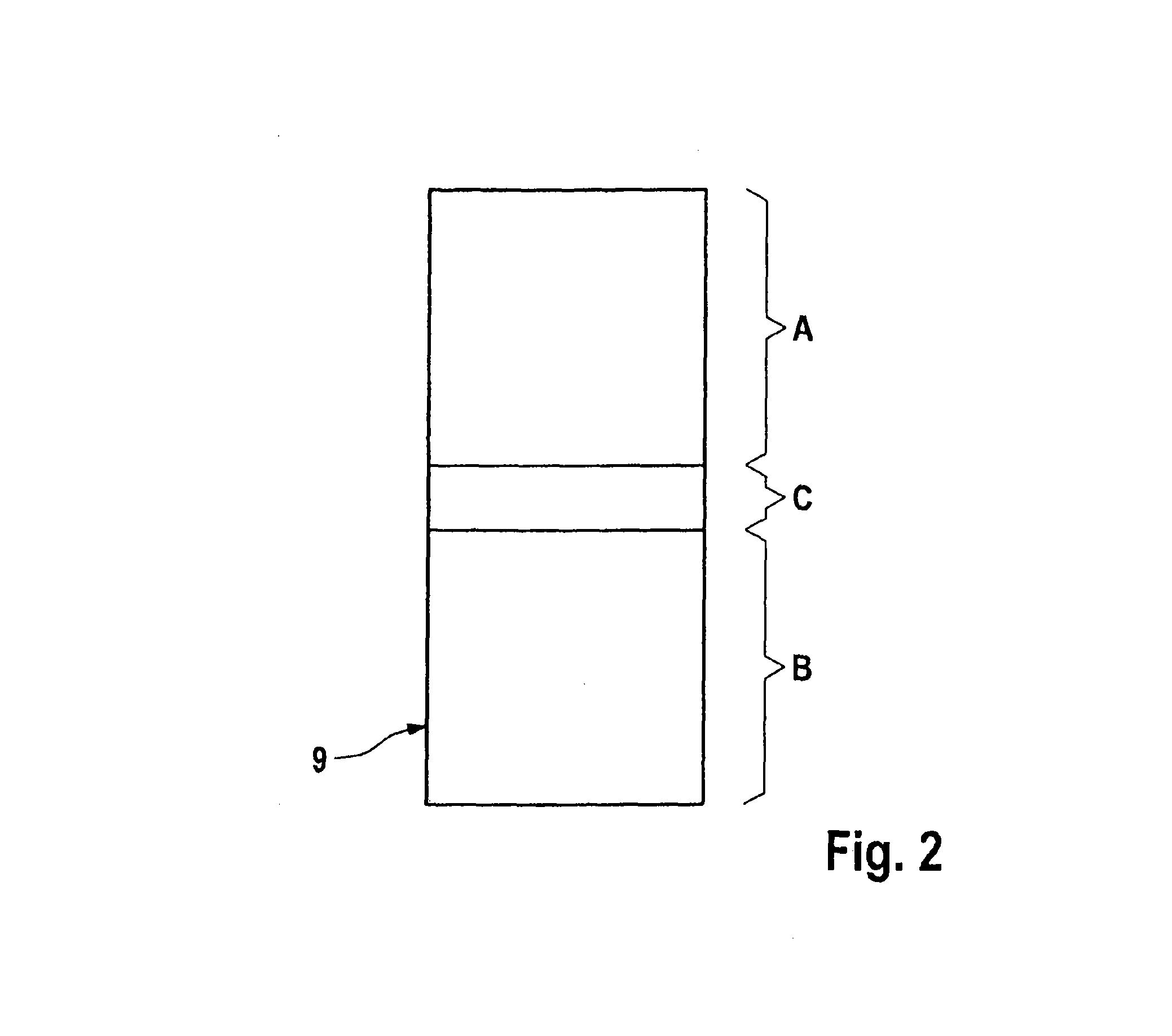

Integrated microprocessor system for safety-critical control systems including a main program and a monitoring program stored in a memory device

ActiveUS8549352B2Cost-effectiveStrict requirementsProgramme controlRedundant hardware error correctionControl systemComputer module

An integrated microprocessor system for safety-critical control systems, comprising at least two microprocessor system modules each comprising at least one processor core, a read / write memory and a memory protection unit, and a read-only memory which is jointly assigned to the processor cores of the microprocessor system modules. Each of the microprocessor system modules executes a main program and a monitoring program which may comprise a plurality of subprograms. If the memory protection unit detects unauthorized operations by one of the programs for accessing a separate address area (A, B) of another program, then the respective memory protection unit assigns a separate address area (A, B) of the read / write memory to the main program and to the monitoring program.

Owner:CONTINENTAL TEVES AG & CO OHG

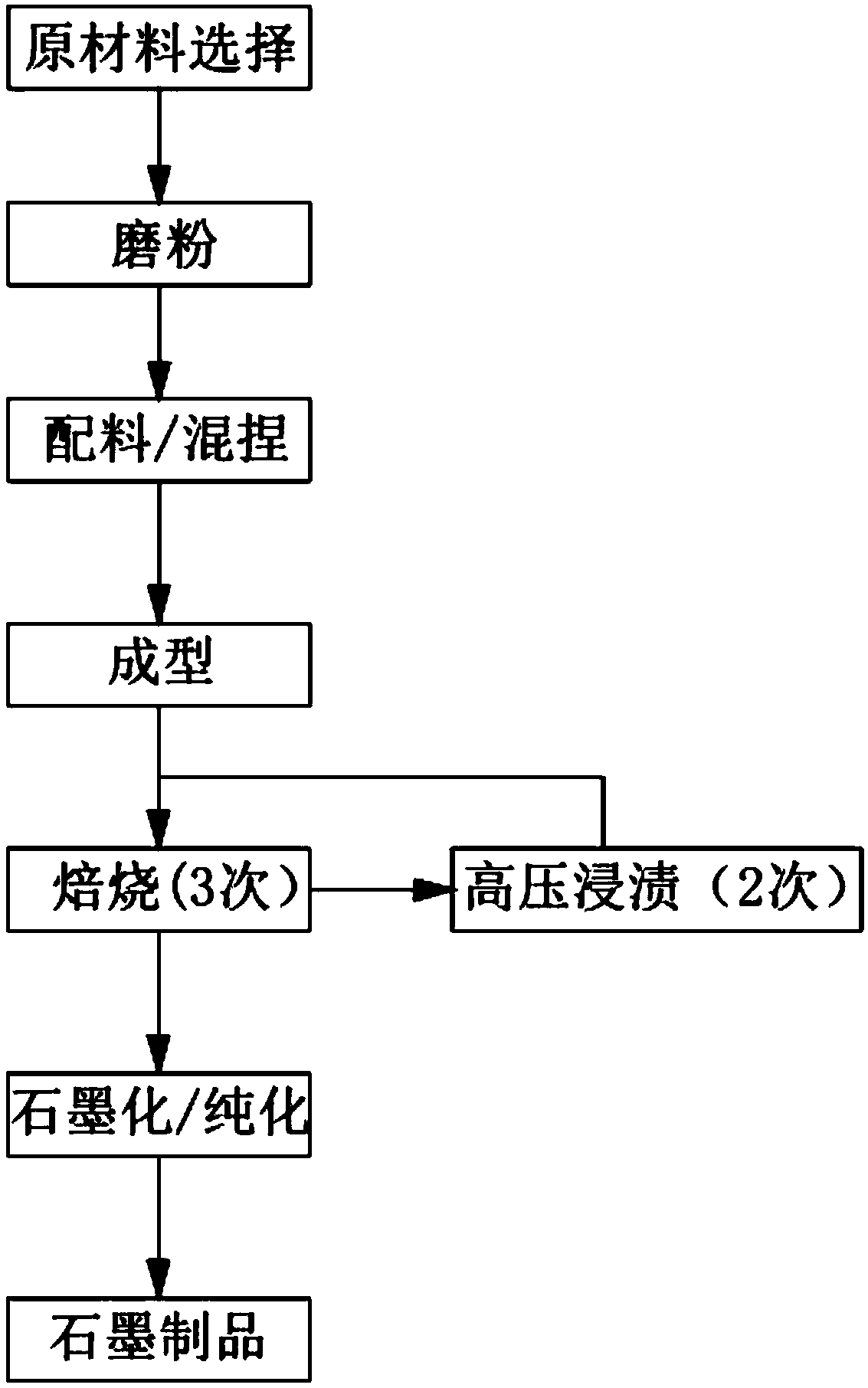

Preparation method of high-density ultrafine-aperture graphite

The invention provides a preparation method of high-density ultrafine-aperture graphite. The preparation method comprises the following steps: rotation of a raw material, stirring and hybrid kneading,compression molding, primary roasting, primary impregnation, secondary roasting, secondary impregnation, roasting for the third time and graphitization. A coke aggregate having an average particle size of 10 to 100 [mu]m and an adhesive are subjected to hybrid kneading, compression molding and roasting, and large pores of a product are blocked with an impregnant through two-times high-pressure impregnation, so that the large pores are turned into small pores, and the technical problem that large-particle aggregates cannot be used for preparing small-aperture graphite is solved; therefore, thelarge-particle aggregates can be used for preparing a small-aperture graphite material, and the aperture of the graphite material is less than or equal to 1 [mu]m; the particle specific surface areaand the surface energy of the graphite material are reduced; and furthermore, in the graphitization process, the purity of a graphite product is improved through purification.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

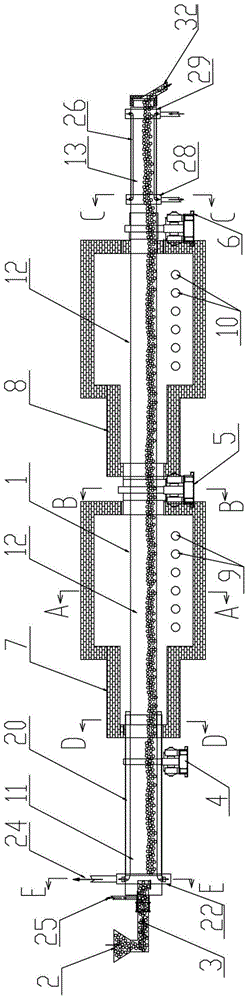

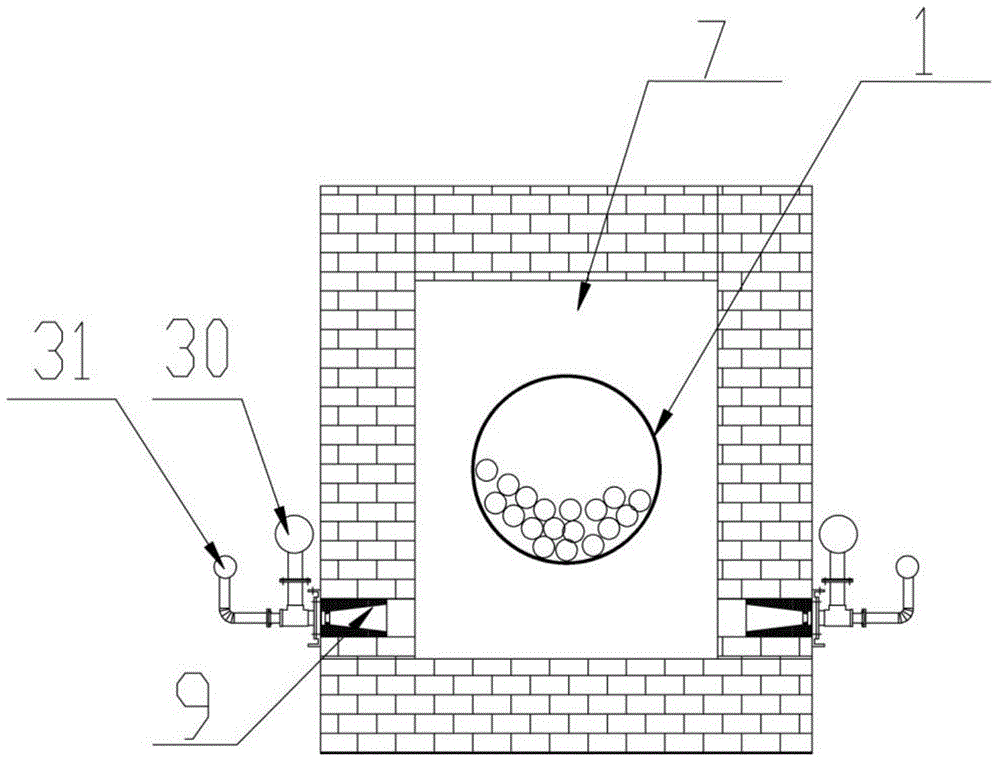

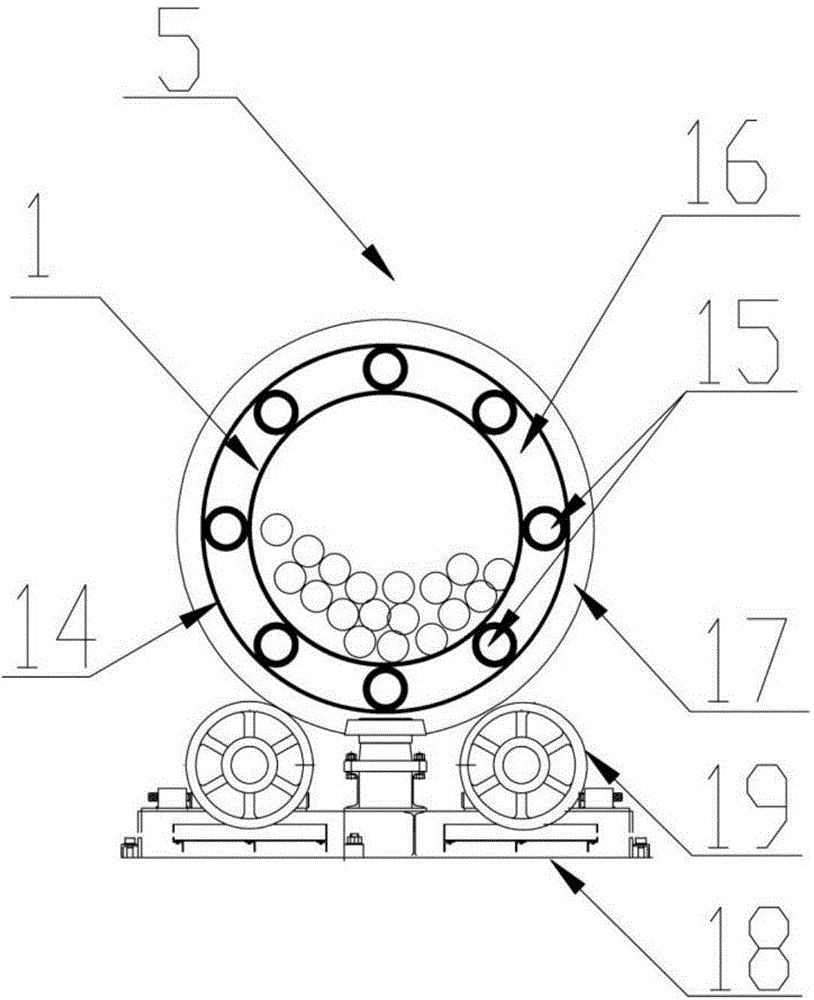

Whole-body type external-heating muffle type rotary kiln

InactiveCN104630407AContinuously stable temperatureReduced temperature required for reductionRotary drum furnacesRotary kilnLow graded

The invention belongs to the field of metallurgical equipment, and in particular relates to a whole-body type external-heating muffle type rotary kiln. A whole-body type continuous external heating muffle type coal-based rotary kiln device with a preheating section and a high-temperature section is adopted, the continuous stabilization of the temperature in a high-temperature area is realized, and a strict requirement on a reduction condition of reduced iron is met. By adopting a muffle-type heating mode, a reduction atmosphere in the rotary kiln is very full, the volatile gas is totally recycled, and the afterheat is fully utilized, so that the required reduction temperature of reduced materials can be greatly reduced, the reduction speed is greatly increased, the energy consumption is greatly reduced, and the carbon emission is reduced; by using non-caking coals with high granularity and high quality as reducing coals, the device is suitable for various iron raw materials with high grade, low grade and varieties, the reduction process is flexible, and the device has many advantages. According to a single production line of the device, the annual reduction treatment ore quantity can reach the maximum scale of 1,800,000-2,100,000 tons.

Owner:泉州寰锋冶金技术有限责任公司

Method for improving antioxidation performance of graphite electrode with surface modification

InactiveCN102497689AImprove the bonding strength of the interfaceIncreasing the thicknessMolten spray coatingElectric discharge heatingSteelmakingElectric arc furnace

The invention discloses a method for improving an antioxidation performance of a graphite electrode with surface modification. The method comprises: a graphite electrode is embedded in Si powder to carry out high-temperature reaction, so that a SiC surface protective layer is obtained; and a vacuum plasma spraying technology is applied to spray a fusing SiC coating on the surface of the obtained SiC protective layer, so that a surface defect of the SiC protective layer obtained by the embedding method is filled up and modified and thus the quality of the surface protective layer is improved. According to the method provided in the invention, surface modification processing is carried out on the graphite electrode, so that the high-temperature antioxidation performance of the graphite electrode can be substantially improved. Moreover, the method can be widely applied to the manufacturing industry of graphite electrodes used for steelmaking of an arc furnace and external refinement.

Owner:NANJING UNIV OF SCI & TECH +1

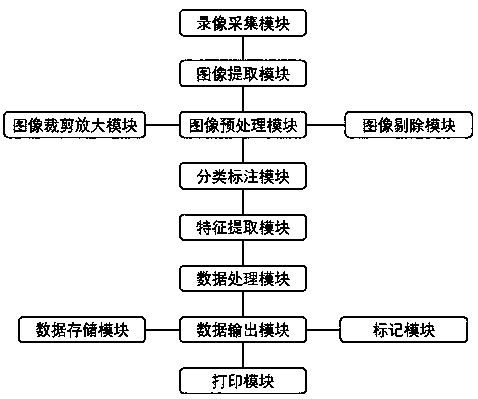

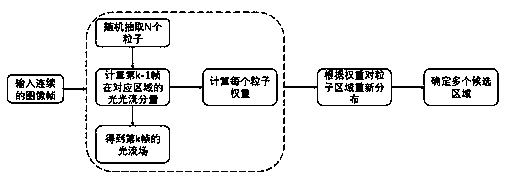

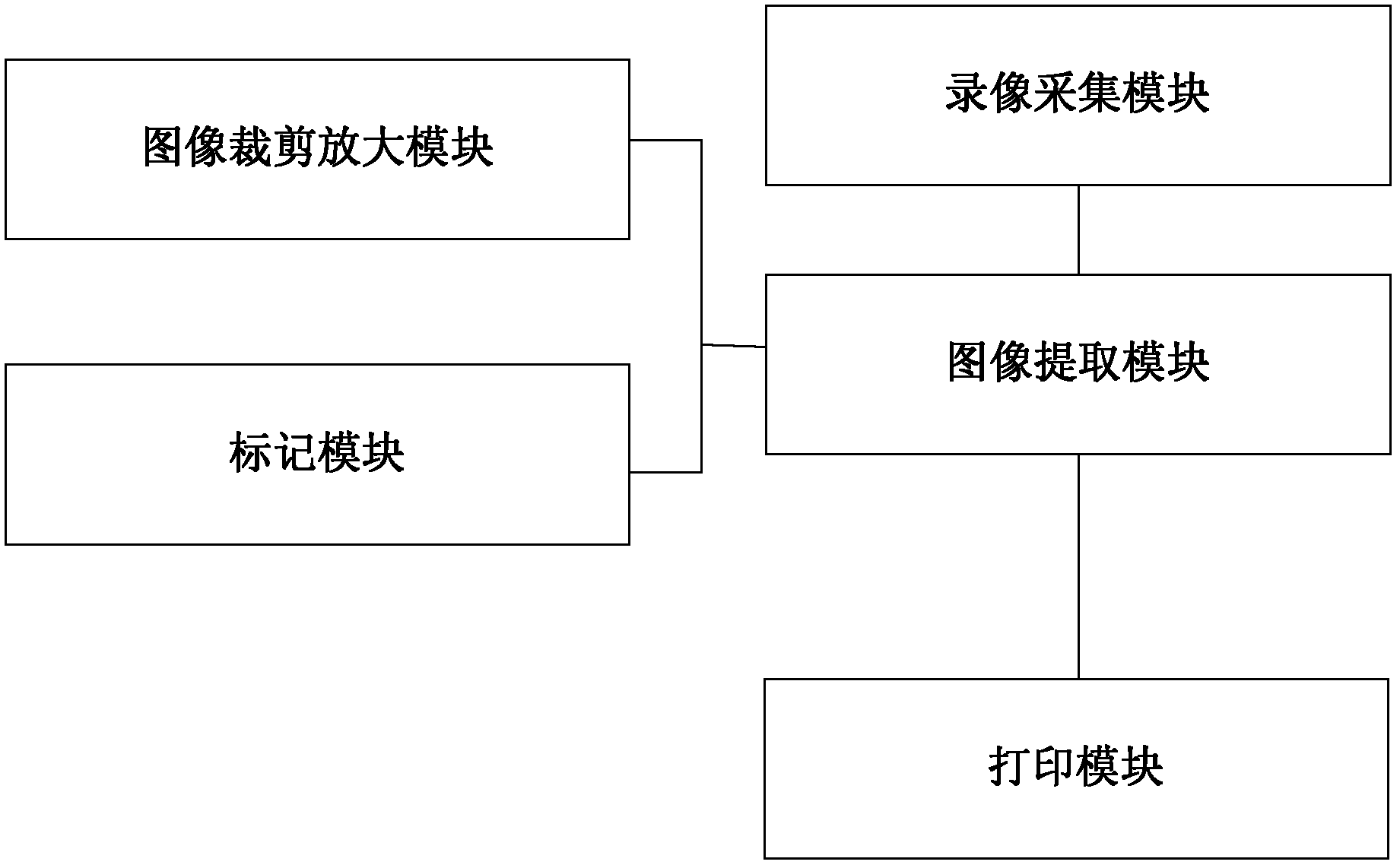

System for identifying focal liver lesions based on contrast-enhanced ultrasonography

InactiveCN110772286AEnhance useful informationReasonable Quantification ParametersOrgan movement/changes detectionInfrasonic diagnosticsHistogramFocal lesion

The invention discloses a system for identifying focal liver lesions based on contrast-enhanced ultrasonography. The system includes a video acquisition module, an image extraction module, an image pre-processing module, a classification labeling module, a feature extraction module, a data processing module, and a data output module, a mode based on combination of edge enhancement and color balance is used firstly for performing denoising and enhancement processing on a contrast image to enhance useful information of the image while retaining the color of the contrast image, then based on a gray level histogram of the image, feature extraction is performed on the contrast image to obtain reasonable quantitative parameters, so that the diagnostic errors caused by probe movement and lesion movement caused by breathing movements of a patient can be inhibited to the greatest extent, so that the features of the lesion is reflected scientifically, objectively, clearly, and effectively, so that accuracy rate and efficiency of feature identification of the focal liver lesions by a contrast-enhanced ultrasonography technology is improved, and thus a novel way is provided for the faster andbetter development of the contrast-enhanced ultrasonography technology.

Owner:王瑛

High-performance piston manufacturing material

InactiveCN102212726AExcellent high temperature mechanical strengthHigh tensile strengthPlungersTrunk pistonsChemical compositionHardness

The invention relates to a machine manufacturing material, in particular to a high-performance piston manufacturing material. The material contains the following elements in percentage by mass: 11.0 to 13.0 percent of Si, 2.8 to 3.6 percent of Cu, 2.0 to 2.6 percent of Ni, 0.8 to 1.2 percent of Mg, 0 to 0.7 percent of Fe, 0.05 to 0.2 percent of Ti, 0 to 0.3 percent of Mn, 0.05 to 0.2 percent of Zr, 0.05 to 0.18 percent of V and the balance of Al. By proportioning the chemical components of the conventional piston manufacturing material more reasonably, the piston manufacturing material has qualitative leap; and compared with the conventional similar products, the piston manufactured by using the material has more excellent high-temperature mechanical strength, tensile strength and fatigue resistance and higher thermal stability and hardness, and meets various strict requirements of the conventional engine on the piston.

Owner:于建华

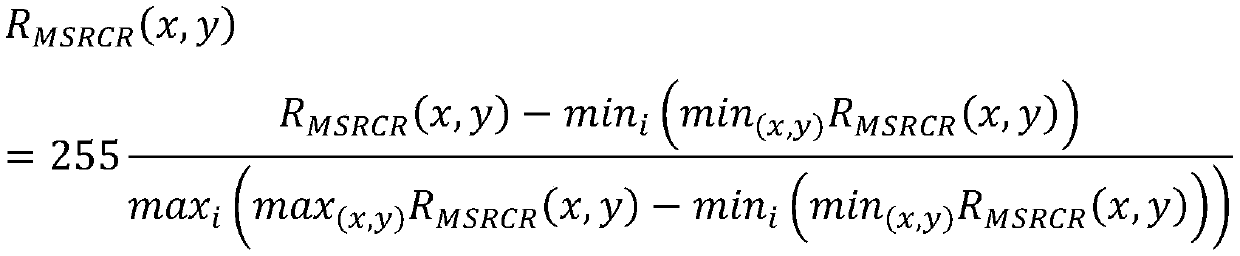

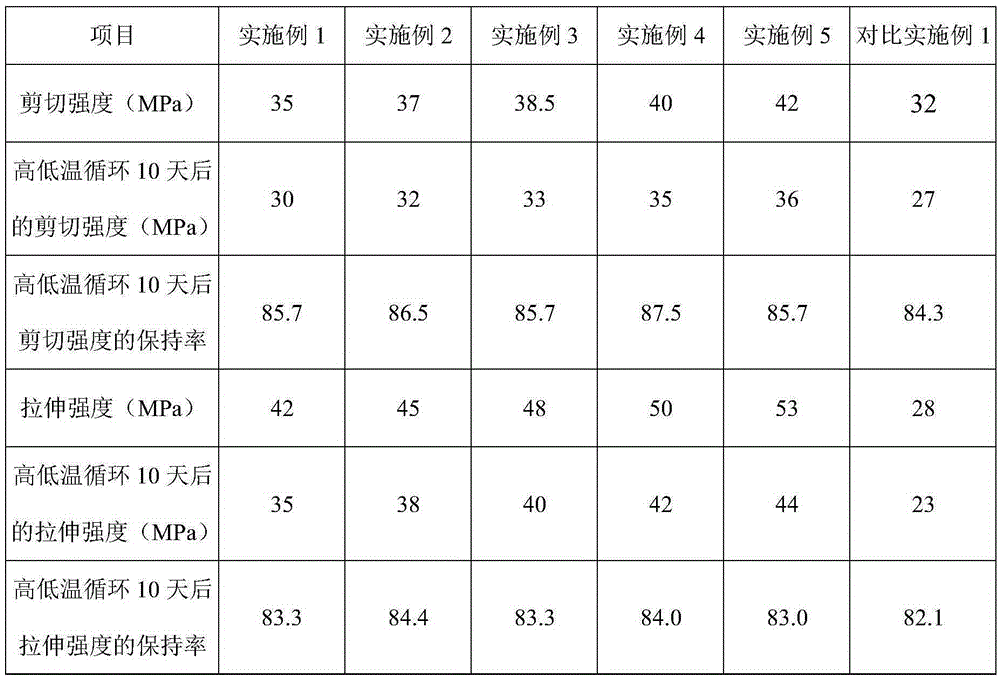

Novel thermosetting epoxy resin used for carbon fiber composite material

The invention provides novel thermosetting epoxy resin used for a carbon fiber composite material. The novel thermosetting epoxy resin used for the carbon fiber composite material comprises the following components in parts: 40-60 parts of epoxy resin / polybutadiene rubber polymer, 40-60 parts of mixed type epoxy resin, 0.1-0.5 part of graphene, 5-10 parts of SBM / MAM copolymer, 4-8 parts of a toughening agent, 0.1-0.5 part of a dispersing agent, 1-5 parts of attapulgite, 1-5 parts of a thixotropic agent, 0.1-0.5 part of a wetting agent, 5-12 parts of dicyandiamide, 1-5 parts of a latent accelerator and 0.5-1.0 part of a coupling agent. By adopting the thermosetting epoxy resin, pre-treatment can be carried out on a carbon fiber body, so that good compatibility and permeability between resin and carbon fibers can be guaranteed, the prepared carbon fiber composite plate has high shear strength and tensile strength, and stringent requirements of aerospace, war industry, rail transit, water traffic, automobiles and sports equipment can be met.

Owner:SHENCAI TECH SHENZHEN CO LTD

Copper rod automatic forging and trimming equipment

PendingCN107214518AGuaranteed high qualityEnsure product consistencyMetal-working feeding devicesForging/hammering/pressing machinesEngineeringHeating furnace

The invention discloses an automatic forging and trimming equipment for copper rods, which comprises a control box, a fuselage, a heating furnace, a forging press and a trimming punch arranged in sequence according to the process, and the control box is connected with the forging press and the trimming press respectively. The trimming punch is electrically connected, the forging punch forges the copper bar into a semi-finished product, and the trimming punch processes the semi-finished product into a finished product. The invention realizes fully automatic production from copper rods (raw material) to finished copper products. By precisely controlling the temperature of the heating furnace, the high quality and consistency of copper products can be ensured, labor costs can be reduced, and the probability of work-related injuries can be greatly reduced. The market competitiveness of copper products meets the strict requirements of customers in all aspects of products.

Owner:岑攀益

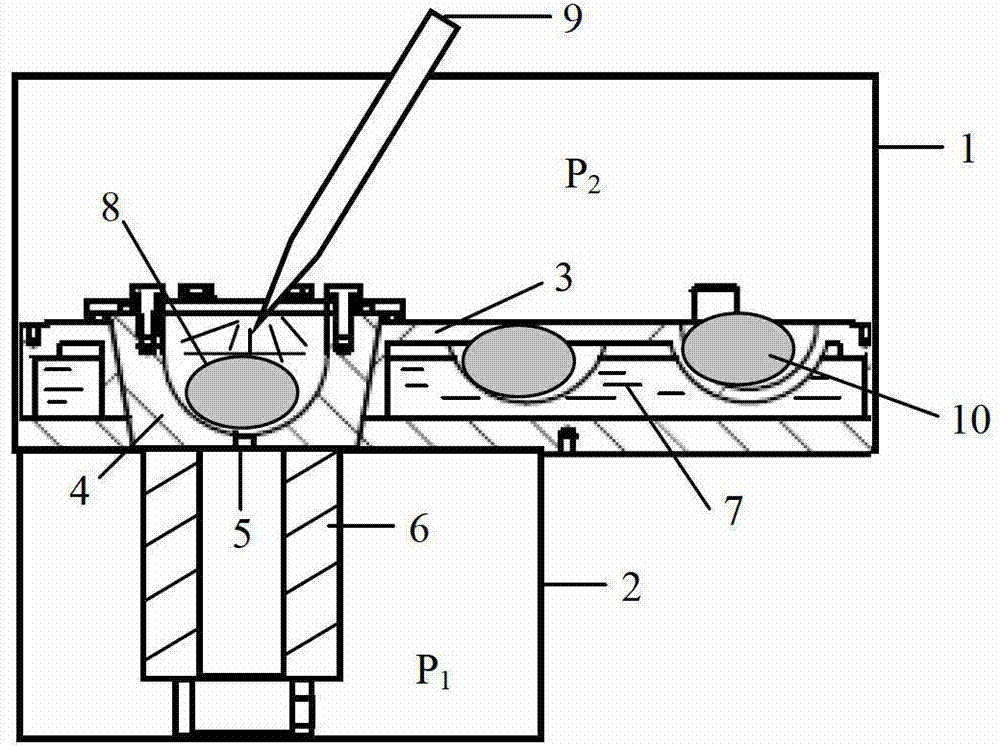

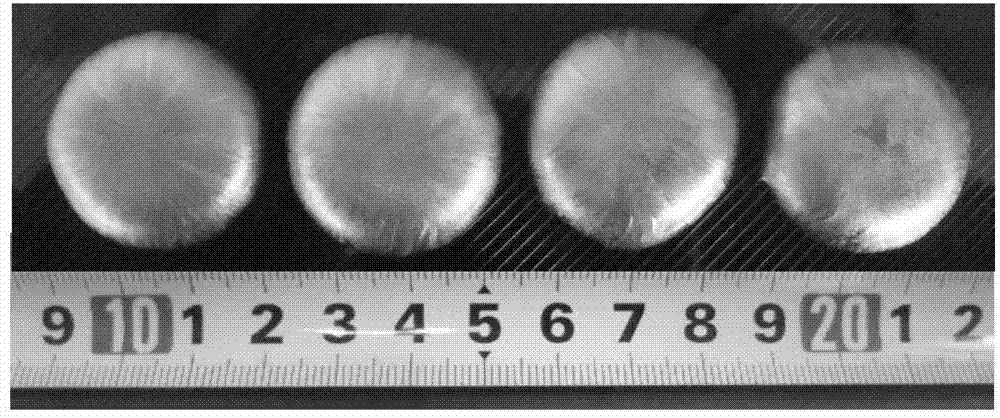

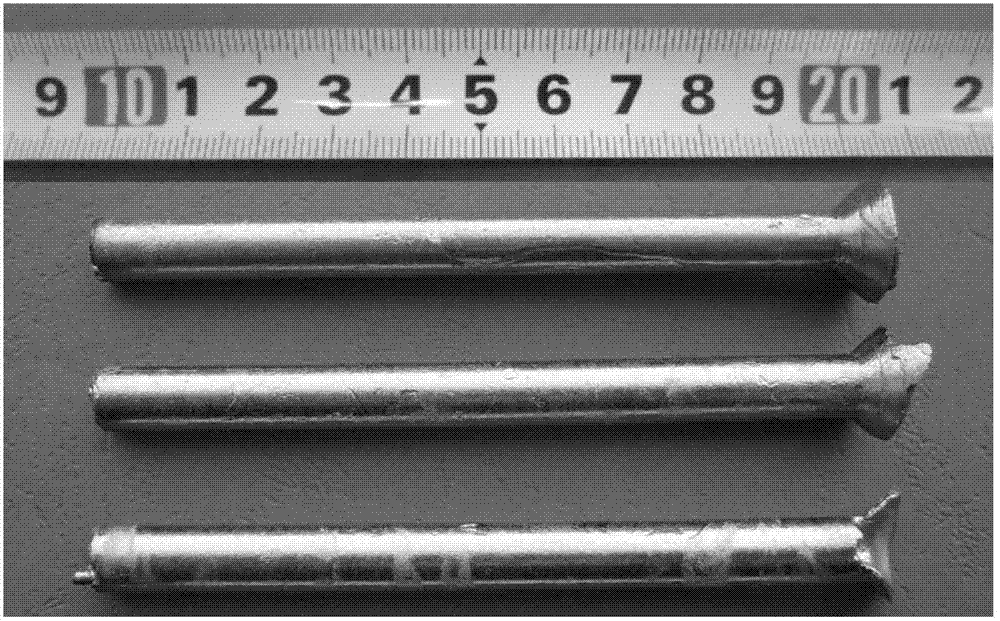

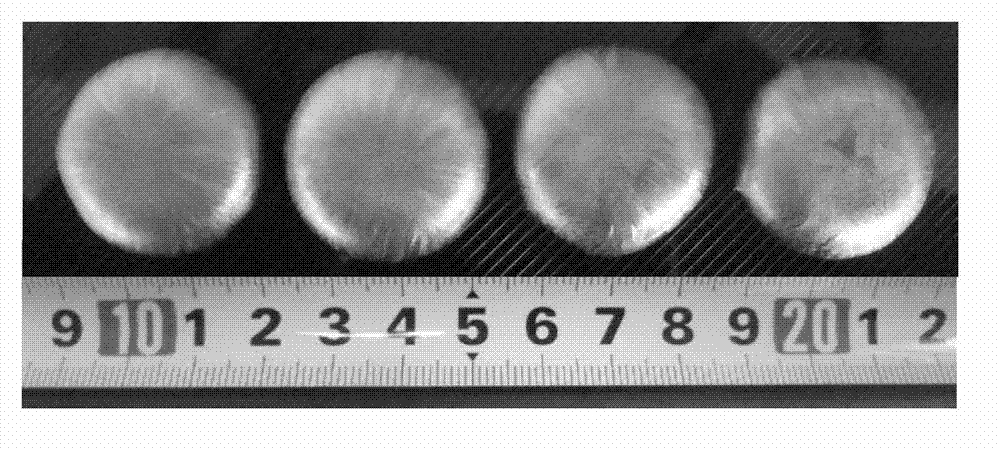

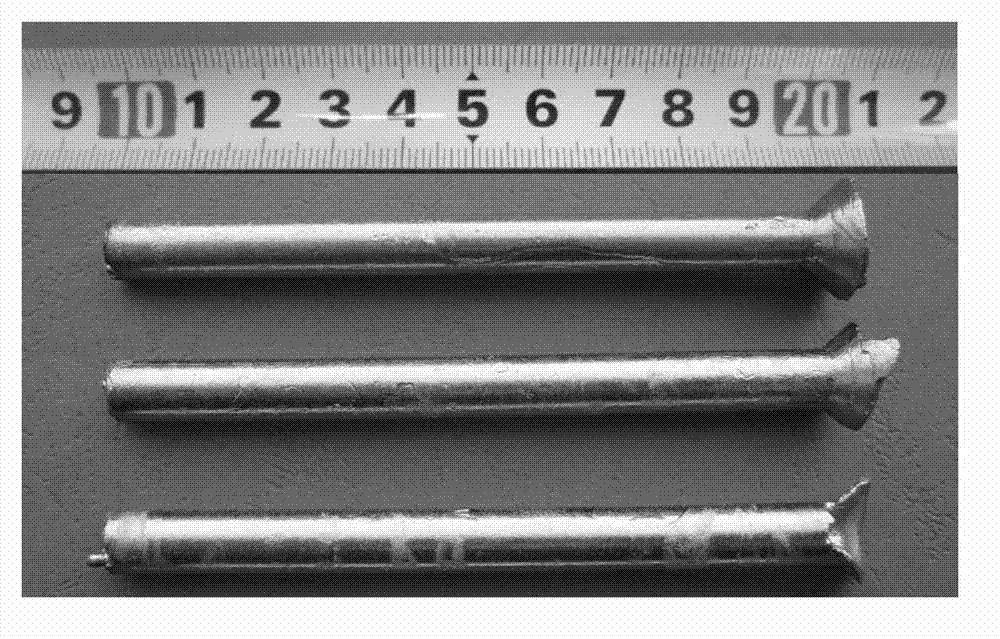

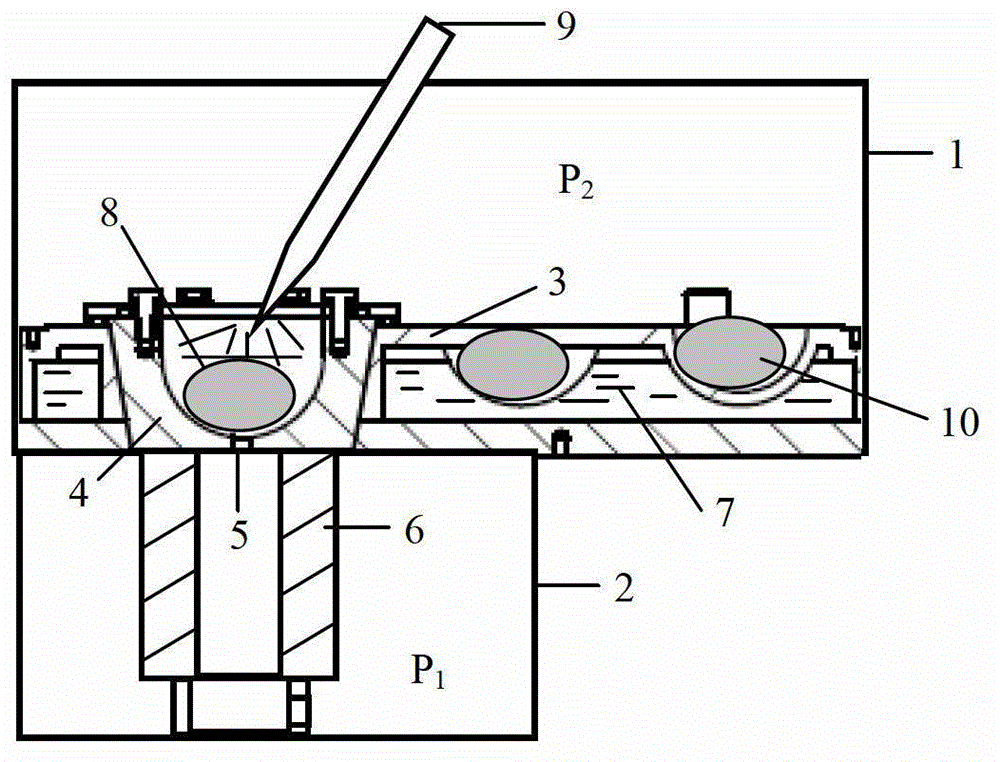

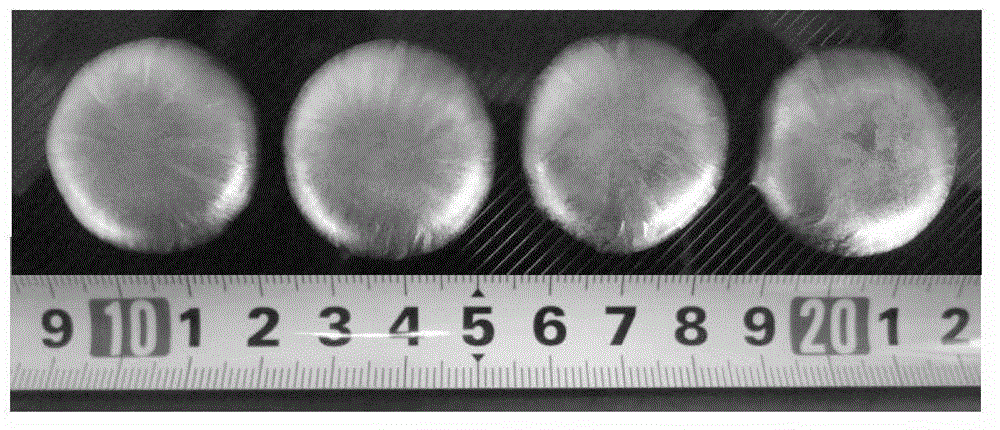

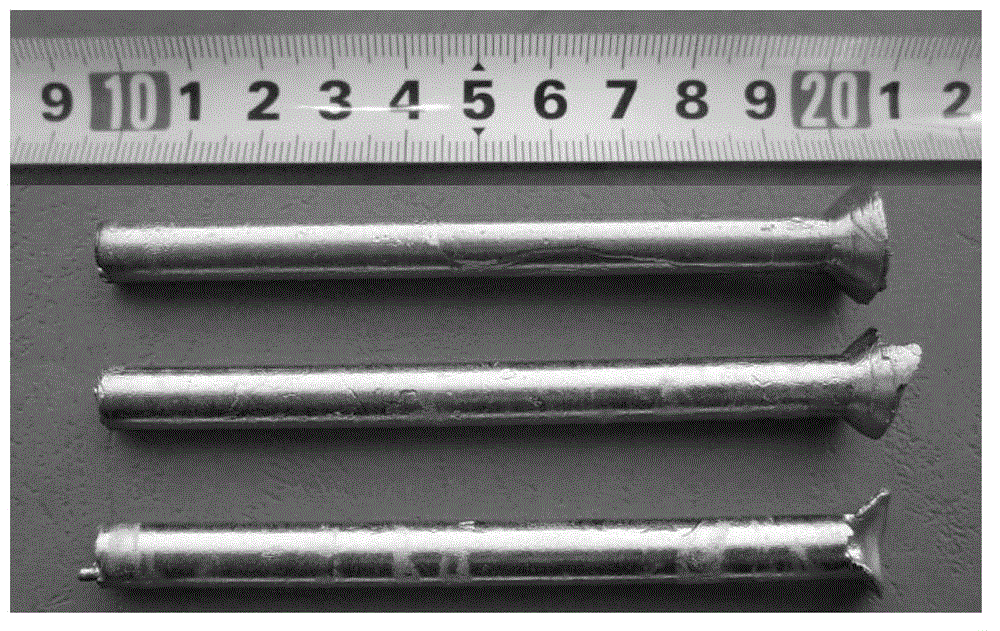

Preparation method for metal alloy test rod

InactiveCN102901659AAvoid pollutionImprove uniformityPreparing sample for investigationDifferential pressureVacuum chamber

The present invention relates to the field of metal alloy test rod production, and provides a metal alloy test rod preparation method. According to the method, a vacuum suction casting device is adopted, wherein a vacuum chamber is filled with high purity argon to achieve pressure P1 of 0.02-0.06 MPa; when a button ingot surface layer is completely melted and a through hole on the bottom of an alloy ingot crucible is sealed through a liquid sealing manner, the vacuum chamber is continuously filled with high purity argon to increase pressure to P2, wherein pressure difference between the P2 and the P1 is 0.01-0.1 MPa; and pressure difference suction casting molding is adopted. The preparation method has the following characteristics that: high cleaning and high efficiency are provided; high uniformity and high accuracy of the components can be achieved; a size of the test rod can be phi 12 mm*120 mm; disadvantages of uniform component, difficult oxygen content control, long period or complex process, and the like of powder metallurgy, mold melting casting, extrusion molding, ingot processing and other test rod preparation methods are overcome; and strict requirements on the ideal alloy test rod by standard sample preparation, alloy design, performance testing, material feeding rod preparation and other processes can be met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

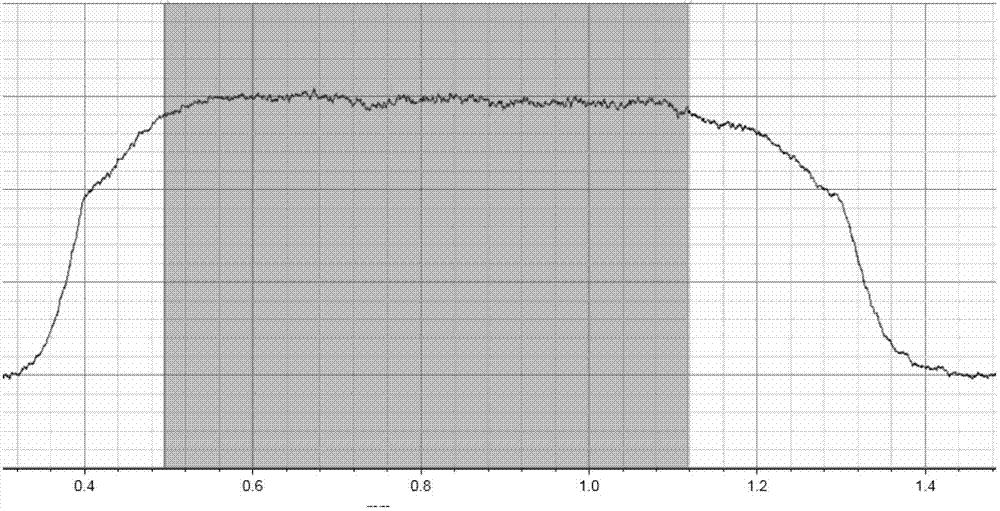

Fine steel wire production method used for cutting solar-energy-grade silicon wafer

InactiveCN104646441AReduce generationImprove production stabilityExtrusion cleaning devicesEconomic benefitsWaste product

The invention provides a fine steel wire production method used for cutting a solar-energy-grade silicon wafer, belonging to the technical field of a steel wire drawing process. The fine steel wire production method is used for producing fine steel wires. According to the technical scheme, the fine steel wire production method comprises the following steps: carrying out three times of acid washing, two times of coating, two times of multi-pass continuous dry type drawing and two times of sorbitic heat treatment by using a special phi5.5mm high sorbite rate disc strip; electroplating brass; and wetly drawing until the length is 0.08-0.12mm. According to the invention, a more fine control method is used for realizing the continuous and stable control of a whole technical process, the production stability and the quality consistency are improved, and waste products are reduced. According to the fine steel wire production method, a process link is increased so that the control stability of the process is improved; the stable drawing of the steel wires with the diameters of 0.08-0.12mm is realized, and the requirements that the cutting of the solar-energy-grade silicon wafer to a steel wire carrier is more and more strict are met; the wafer yield of a silicon rod is improved when the silicon wafer is cut; and the resources are sufficiently utilized, the production cost is reduced and the economic benefits of enterprises are improved.

Owner:邢台钢铁线材精制有限责任公司

Packaging technology of tail cover of unmanned plane

ActiveCN102826235AImprove reliabilityFirmly connectedLine/current collector detailsAircraft assemblyElectricityEngineering

The invention discloses a packaging technology of a tail cover of an unmanned plane. The packaging technology comprises the following steps of: (1) according to the process document requirements, preserving welding allowance for a backup wire core in a cable subassembly in elements after getting the elements, cutting, blowing corresponding heat shrinkable tubes, and strapping the corresponding heat shrinkable tubes and other leads; (2) welding or pressing each element; (3) cleaning welding spots, and removing redundancy; (4) packaging the tail cover, and cladding the connector tail cover until no gap is generated by insulating leather; (5) carrying out coating and sealing on the tail cover; (6) screwing the tail cover and removing bad stress of a cable; and (7) fastening a screw on a hoop, and plugging an opening or through hole which is open to an electric connector and communicated with the external part after the step (2). According to the invention, the packaging technology of the tail cover is improved, the reliability of an aerospace cable product is improved, the cable is firmer, and the appearance is more beautiful; and the packaging mode of the tail cover is improved, so that the space is sealed and no gap is generated, and invasion of the redundancy and influences of humidity and salt mist are effectively prevented.

Owner:BEIJING AEROSPACE YILIAN TECH DEV

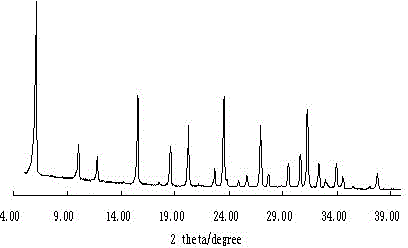

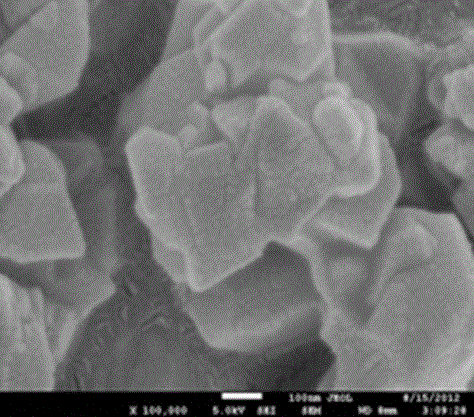

Synthetic method for small-crystal-size high-silicon Y-type molecular sieve

ActiveCN104556127ALower synthesis costConducive to industrial productionFaujasite aluminosilicate zeoliteMolecular sieveCrystallite

The invention provides a synthetic method for a small-crystal-size high-silicon Y-type molecular sieve. The method comprises the following steps: stirring water, inorganic base, an aluminum source and part of a silicon source for 2-4 days; then adjusting the basicity of the system with acid; and adding a silicon source, and finally synthesizing the Y-type molecular sieve by hydrothermal crystallization. The small-crystal high-silicon Y-type molecular sieve synthesized by the method provided by the invention has the characteristics of small crystal size and high silicon-aluminum ratio, is suitable for serving as an adsorbent for separation of a gas and liquid mixture and can also serve as a catalyst carrier or an acid catalyst component.

Owner:CHINA PETROLEUM & CHEM CORP +1

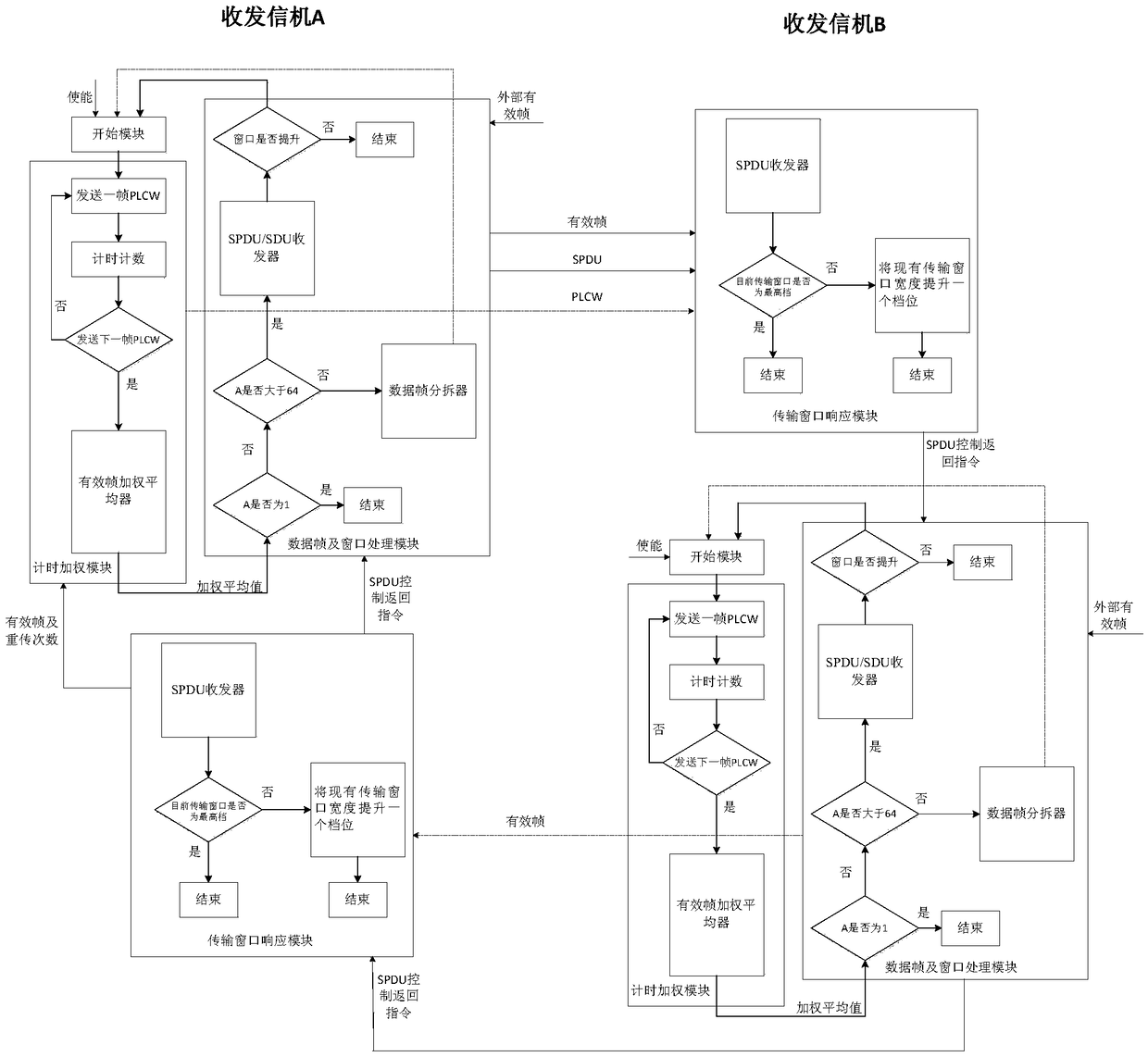

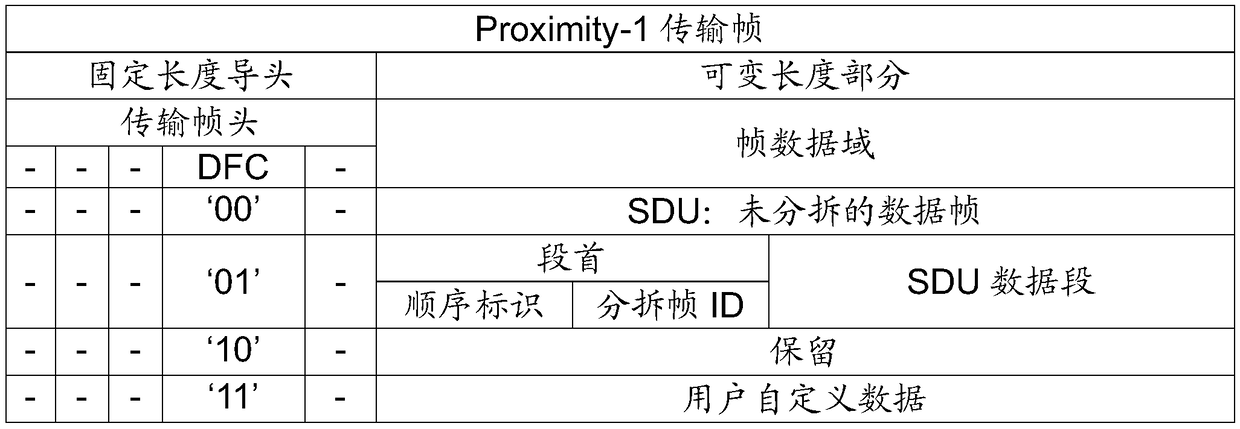

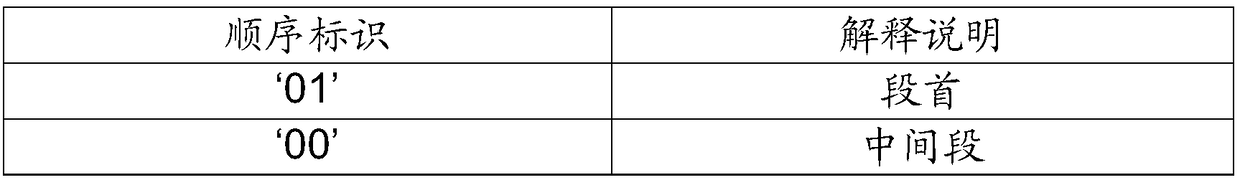

Full-duplex high-throughput bidirectional ARQ communication system and method based on CCSDS protocol

ActiveCN109495157AAvoid the risk of working in a low-efficiency state for a long timeImprove communication efficiencyError prevention/detection by using return channelTransmission monitoringWindow WidthSelf adaptive

The invention discloses a full-duplex high-throughput bidirectional ARQ communication system and method based on a CCSDS protocol. The system comprises a timing weighting module, a data frame and window processing module, a transmission window response module, and a starting module. According to the full-duplex high-throughput bidirectional ARQ communication system and method based on a CCSDS protocol, the adaptive adjustment of the transmission data frame length and the transmission window width under the full-duplex bidirectional ARQ (Automatic Repeat Queuing) working state is realized, andthe problem that communication parties in CCSDS Proximity-1 protocol may cause the forward, backward or two-way communication throughput to decrease under the conditions of specific communication parameters(including the data frame length, the transmission window, a forward and backward rate, and encoding mode), so that the forward and backward link can achieve the maximum communication throughputwhile ensuring error-free transmission.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

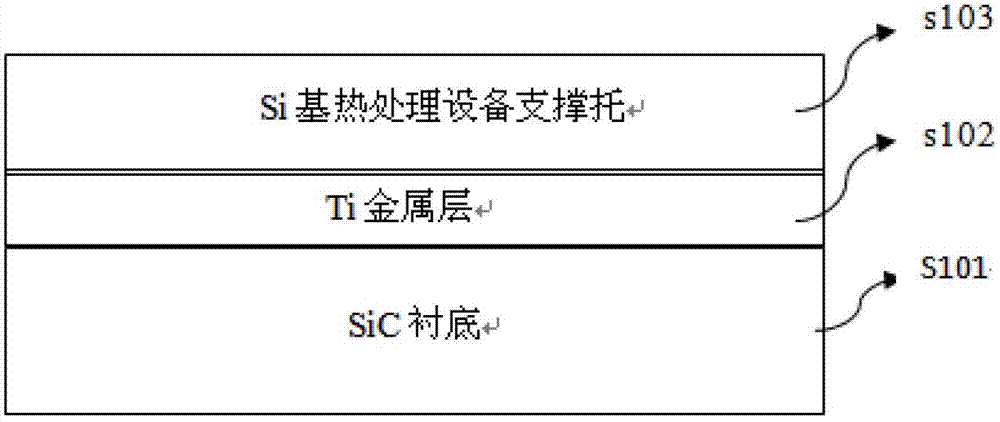

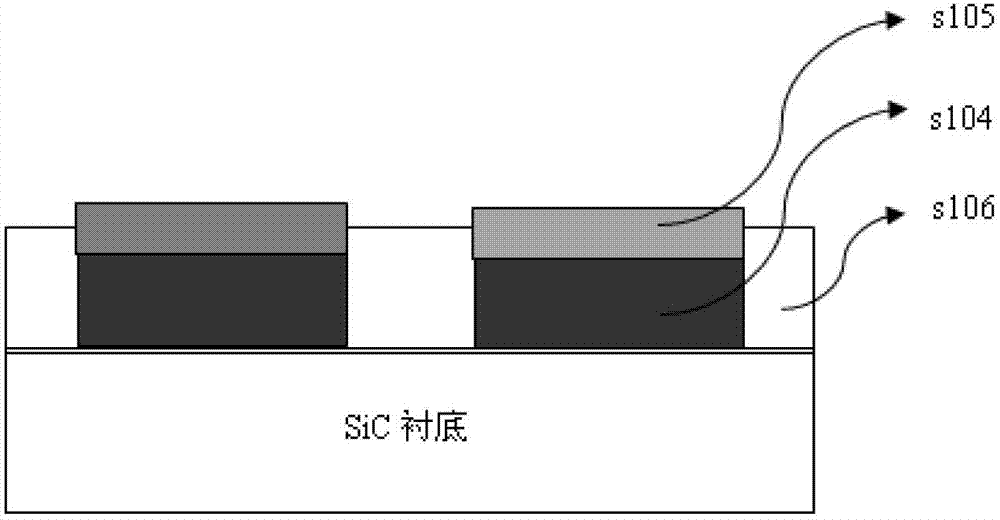

Preparation method of semi-insulating silicon carbide substrate titanium ohmic contact electrode

InactiveCN103094073AShort processImprove yieldSemiconductor/solid-state device manufacturingTitanium electrodeOhmic contact

The invention relates to a preparation method of a semi-insulating silicon carbide substrate titanium ohmic contact electrode. The preparation method is characterized by comprising the following steps that a 4H-SiC substrate is prepared; vacuum magnetron sputtering equipment is utilized, Ti electrode thin film is deposited on the 4H-SiC substrate through the magnetron sputtering equipment to form a titanium electrode; the titanium electrode is closely attached to an annealing furnace support Si base to carry out annealing heat treatment, so an alloy compound electrode with gradually varied Si, Ti and SiC components is achieved; a layer of Au is plated on the outer side of the alloy compound electrode with the gradually varied Si, Ti and SiC components and serves as electrode protection; and an SiO2 insulating layer is arranged between electrodes.

Owner:SHANGHAI NORMAL UNIVERSITY

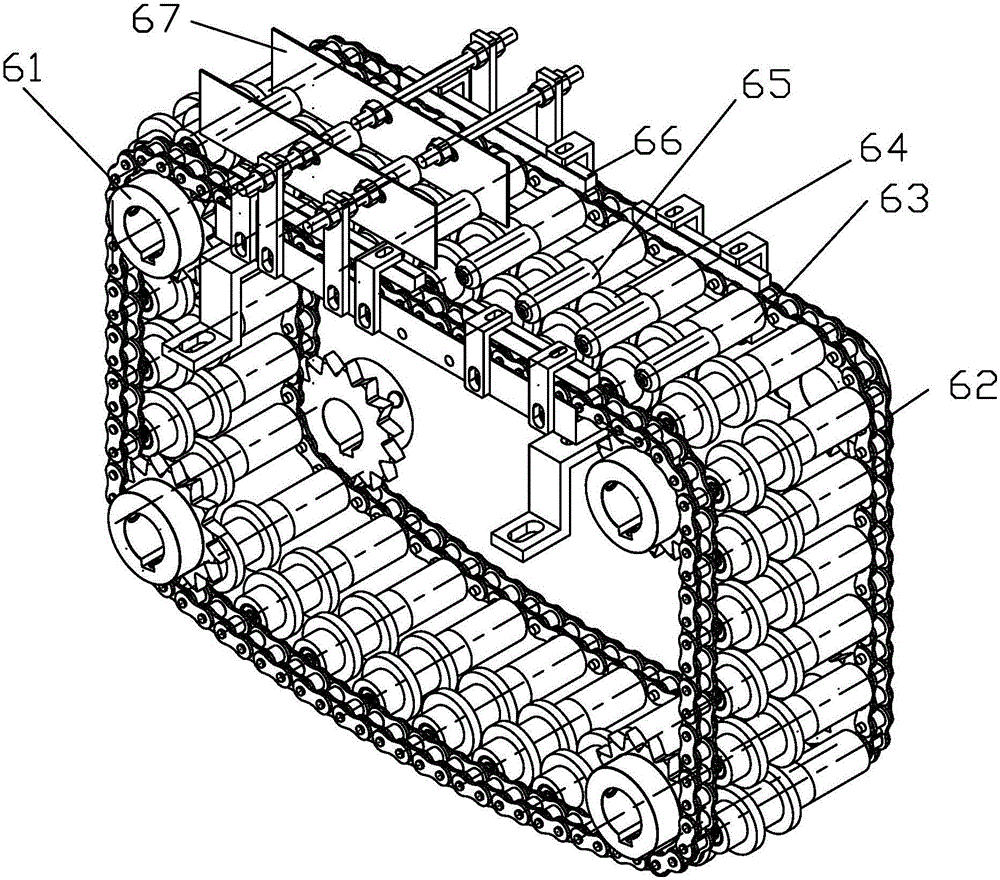

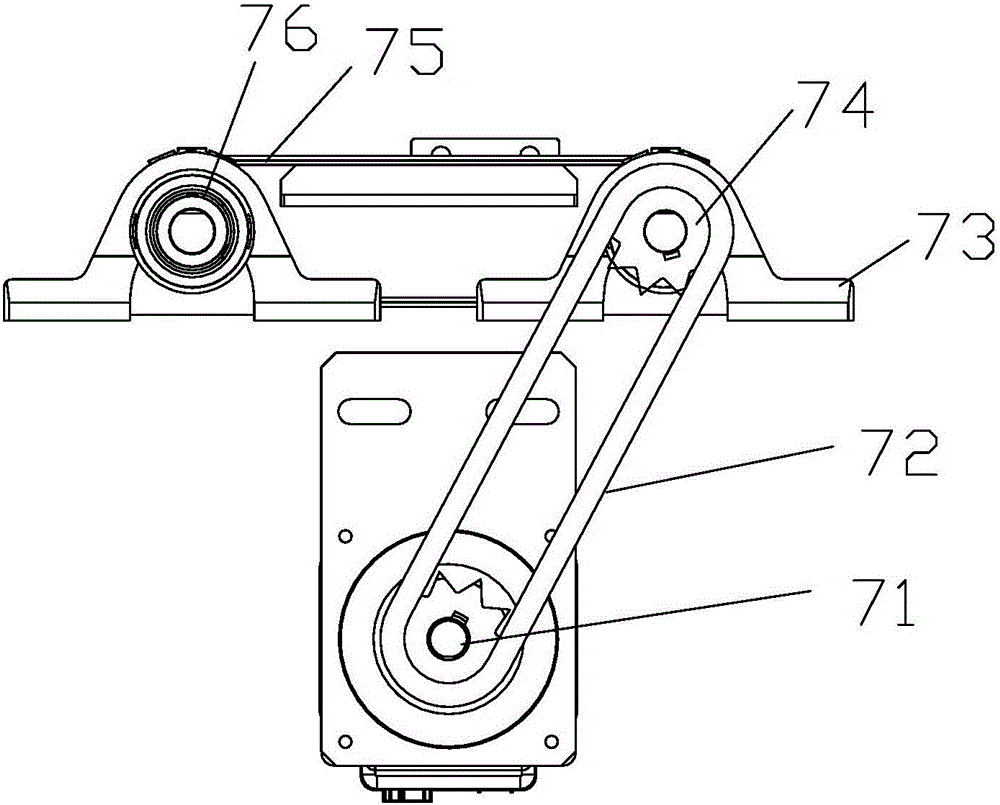

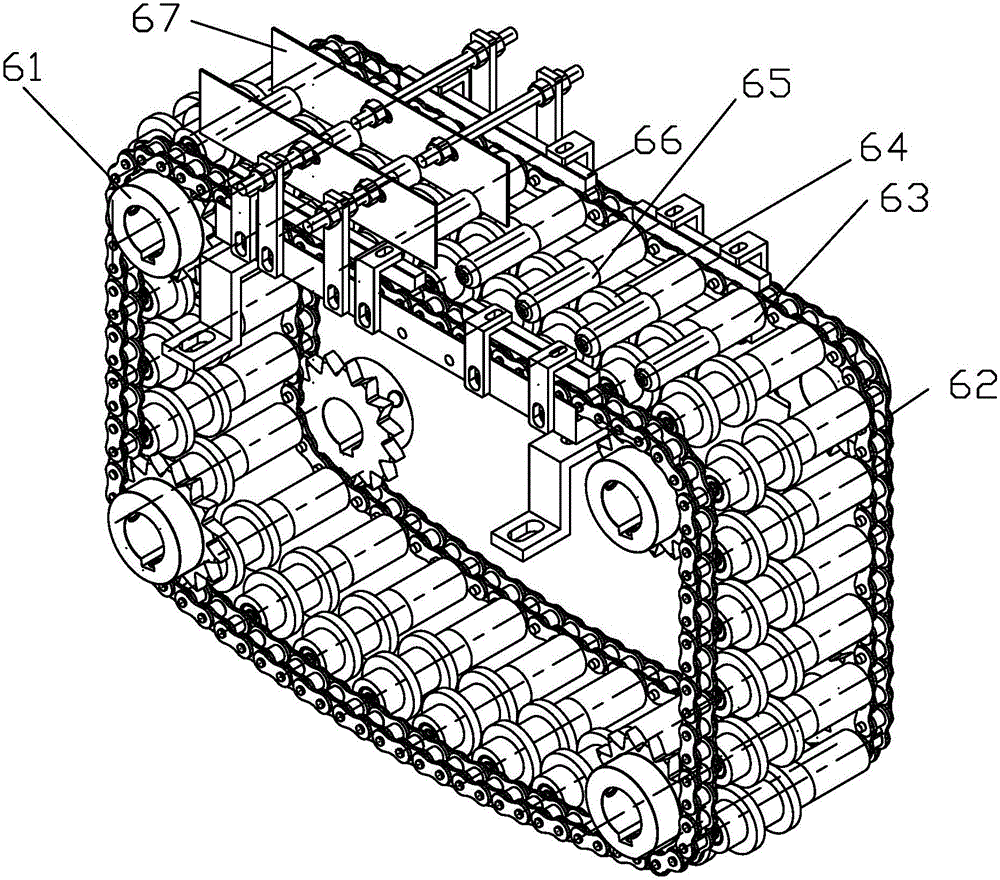

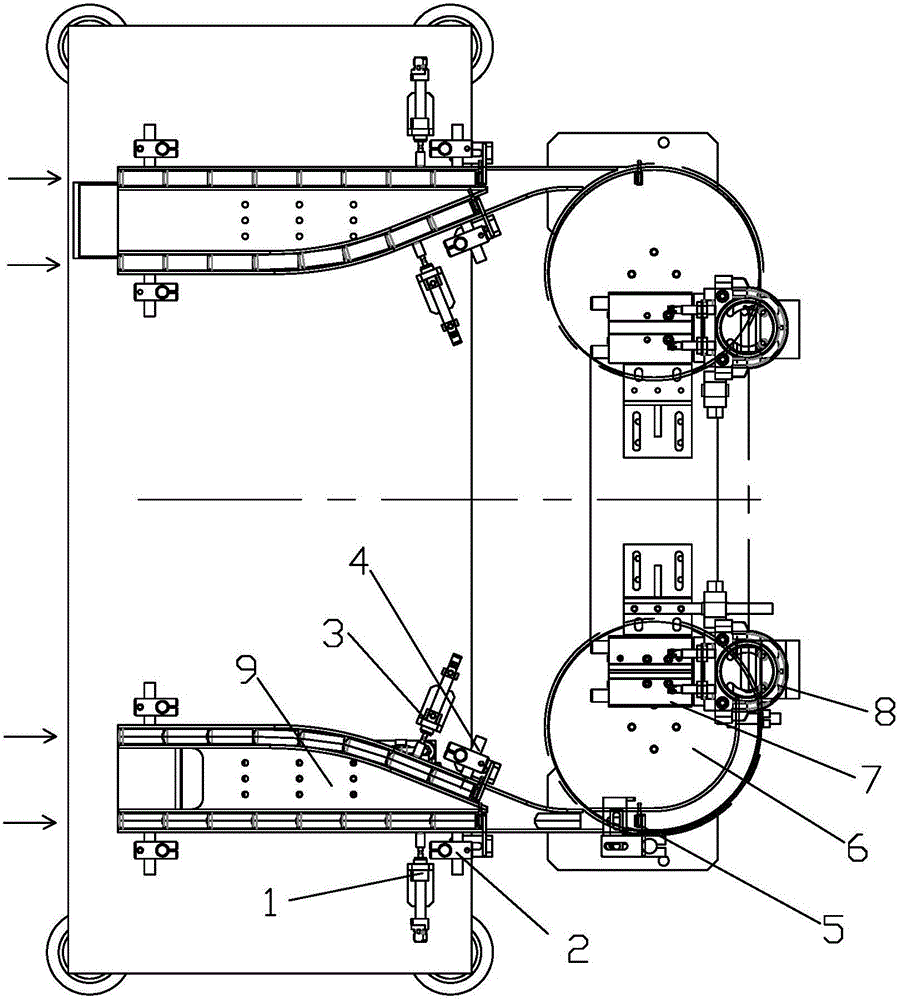

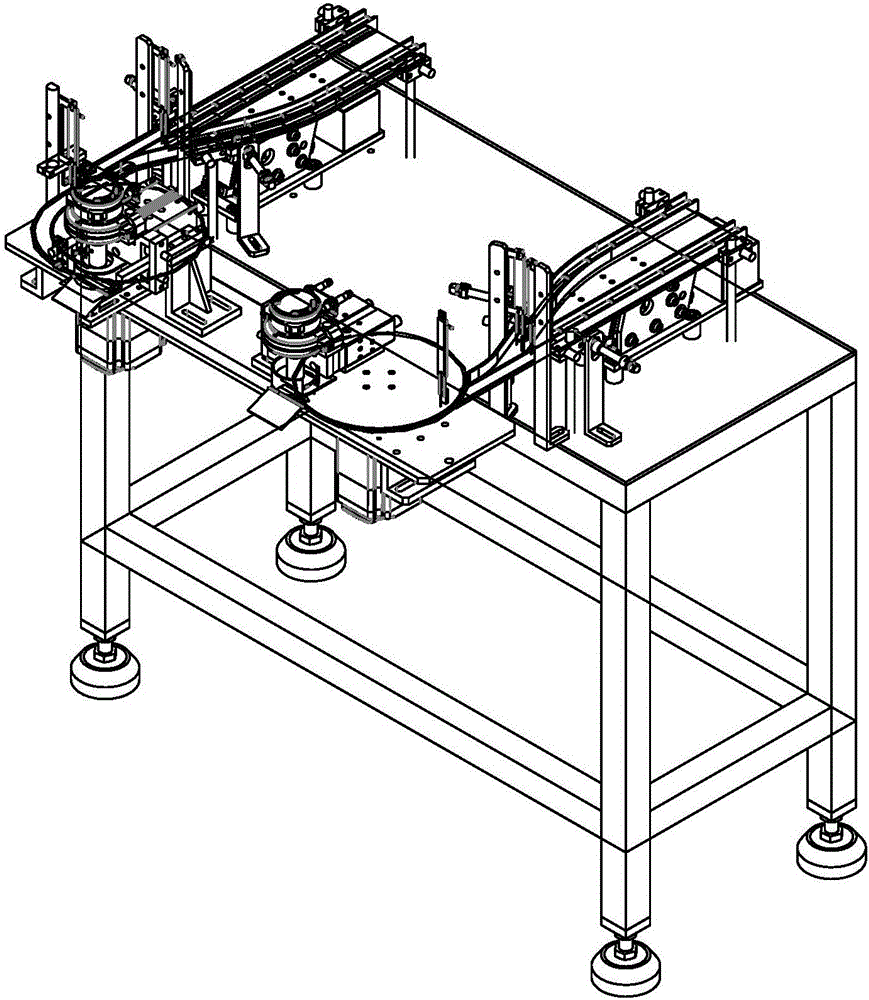

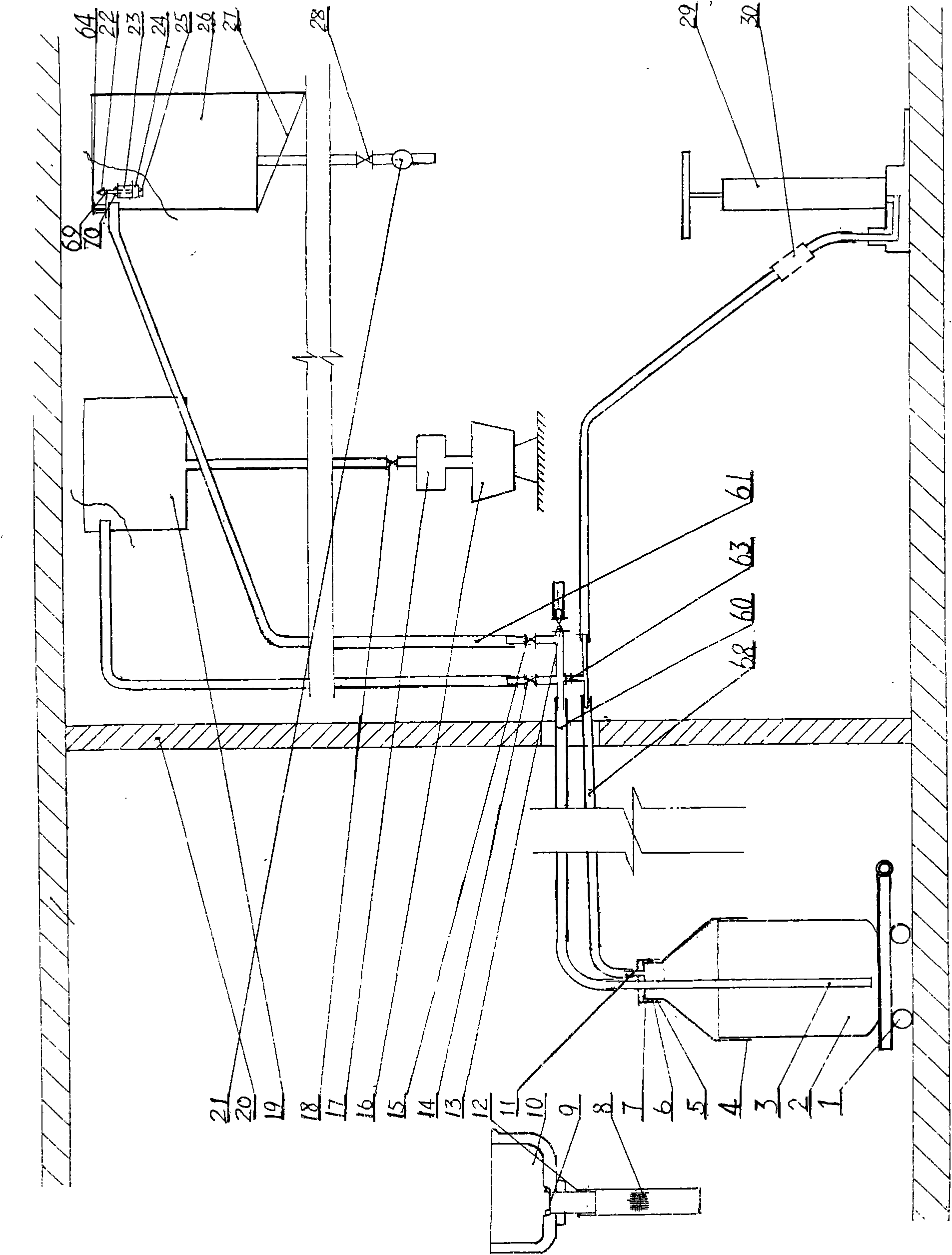

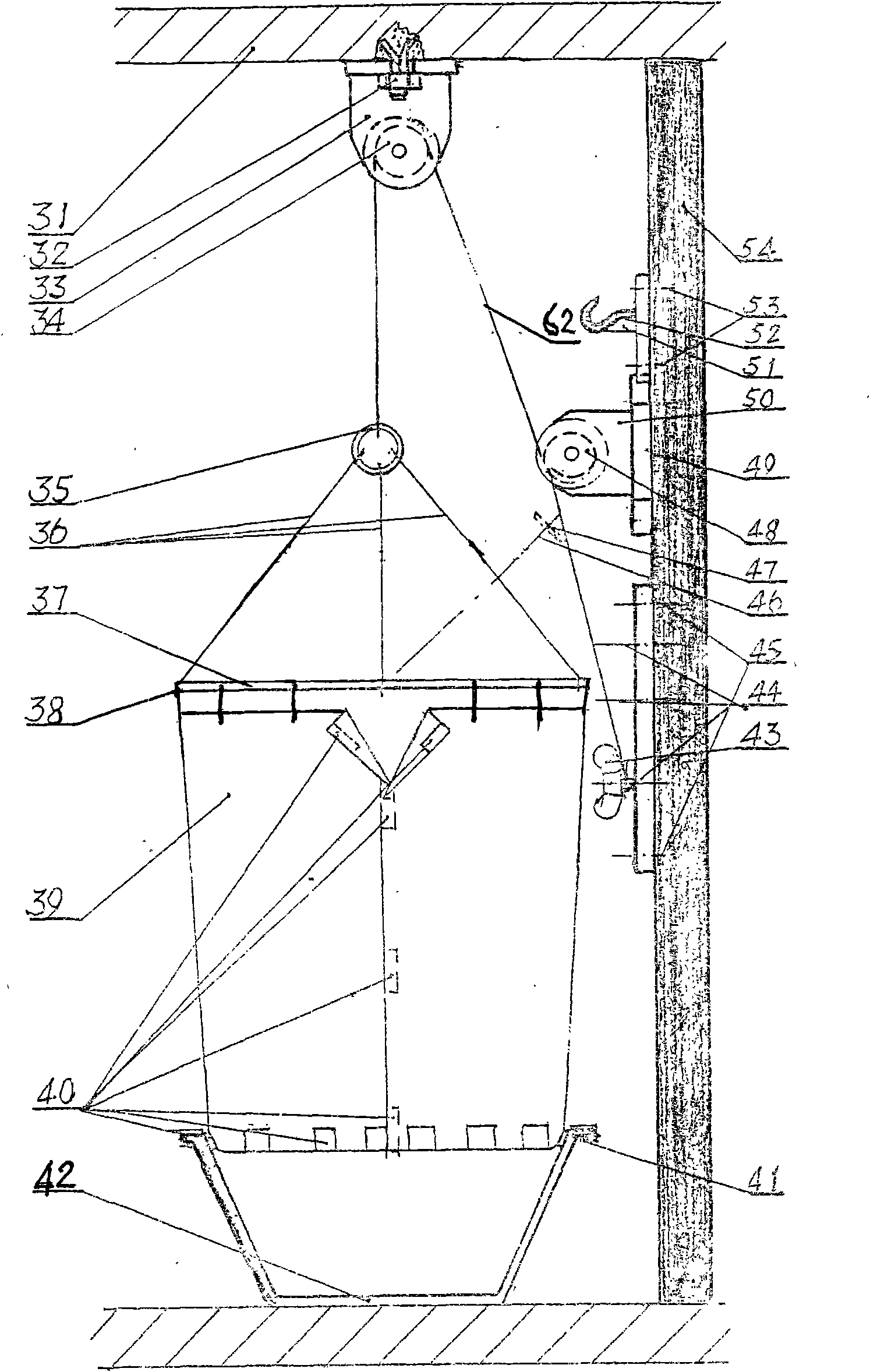

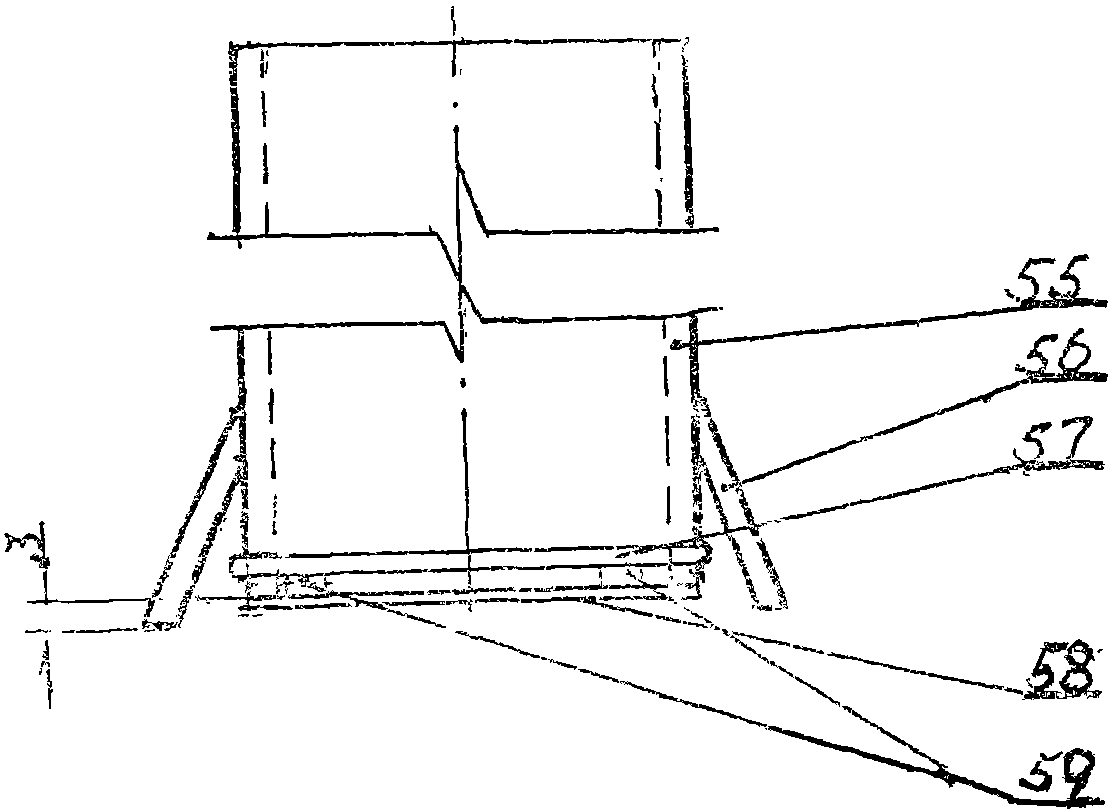

Conveying and self-rotating device and method for cylindrical or columnar object

InactiveCN106044060AStable working distanceRealize all-round continuous detectionConveyorsConveyor partsDrive wheelChain type

The invention discloses a conveying and self-rotating device and method for a cylindrical or columnar object. The conveying and self-rotating device comprises a chain type conveying mechanism. The chain type conveying mechanism comprises chains (62), chain drive wheels (61), axles and conveying rollers (63). The chain drive wheels are installed on a rack through the axles. The two chains are arranged, the multiple conveying rollers are arranged between the two chains, the arrangement direction of the conveying rollers is perpendicular to the moving direction of the chains, one to-be-conveyed cylindrical or columnar object can be contained between every two adjacent conveying rollers, and at least two sets of chain drive wheels are arranged. The two chain drive wheels are arranged in each set, the two chains are tensioned on the chain drive wheels, and the chain drive wheels drive the two chains so that the conveying rollers can be driven to cyclically move so as to convey the cylindrical or columnar object. The conveying and self-rotating device further comprises a self-rotation drive mechanism used for driving the cylindrical or columnar object to rotate by itself. The conveying and self-rotating device can guarantee that the cylindrical or columnar object can smoothly enter a detection station, and the structure is novel and compact.

Owner:蔺薛菲

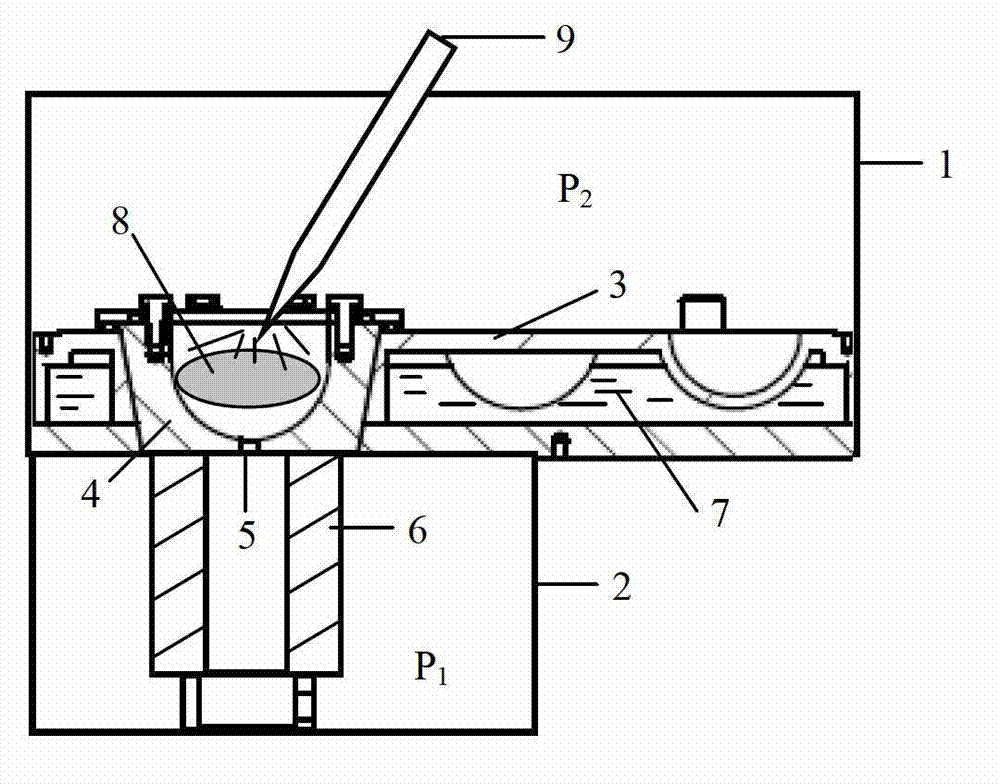

Vacuum suction casting equipment and method of high-activity, high-purity and high-melting-point alloy

The invention discloses vacuum suction casting equipment and a method of high-activity, high-purity and high-melting-point alloy. The equipment comprises an upper vacuum chamber and a lower vacuum chamber which are arranged up and down; an electric arc gun is arranged at the top end of the upper vacuum chamber; a plurality of station copper crucibles are arranged at the bottom end to tightly separate the upper vacuum chamber and the lower vacuum chamber; the peripheries of the copper crucibles are cooled by circulating water; an alloy ingot crucible is tightly matched and embedded in one station copper crucible; a through hole is preserved at the bottom, and the upper vacuum chamber and the lower vacuum chamber are communicated. Nozzles such as graphite and the like are replaced by a high-melting-point alloy ingot which has good conduction performance and large heat capacity and comprises a hole at the bottom, and embedded into the copper crucibles to form an indirect water cooling structure. Automatic suction casting is carried out by combining with a differential-pressure method; the problems of pollution and low success ratio of the alloy in the existing suction casting equipment are solved; the clean suction casting process of the alloy is effectively achieved; the melting point of the suction casting alloy can be up to 1600-1800 DEG C, and the pollution degree is smaller than or equal to 0.01wt %.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

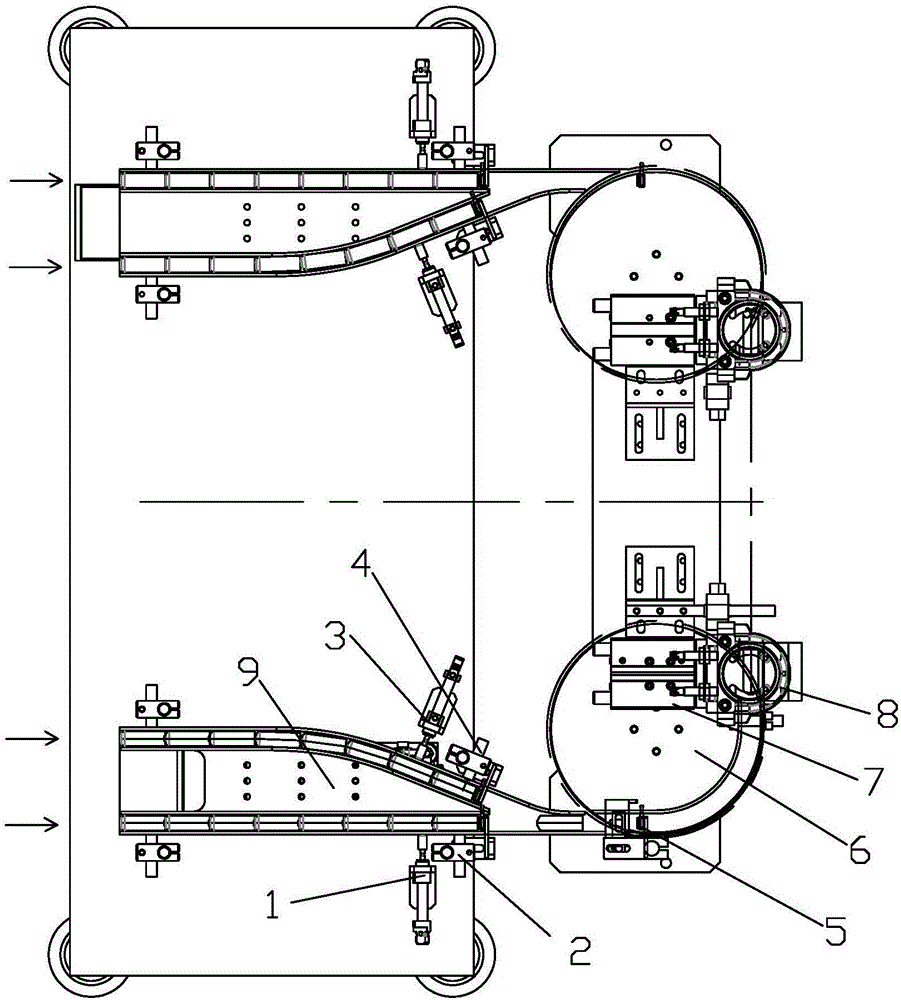

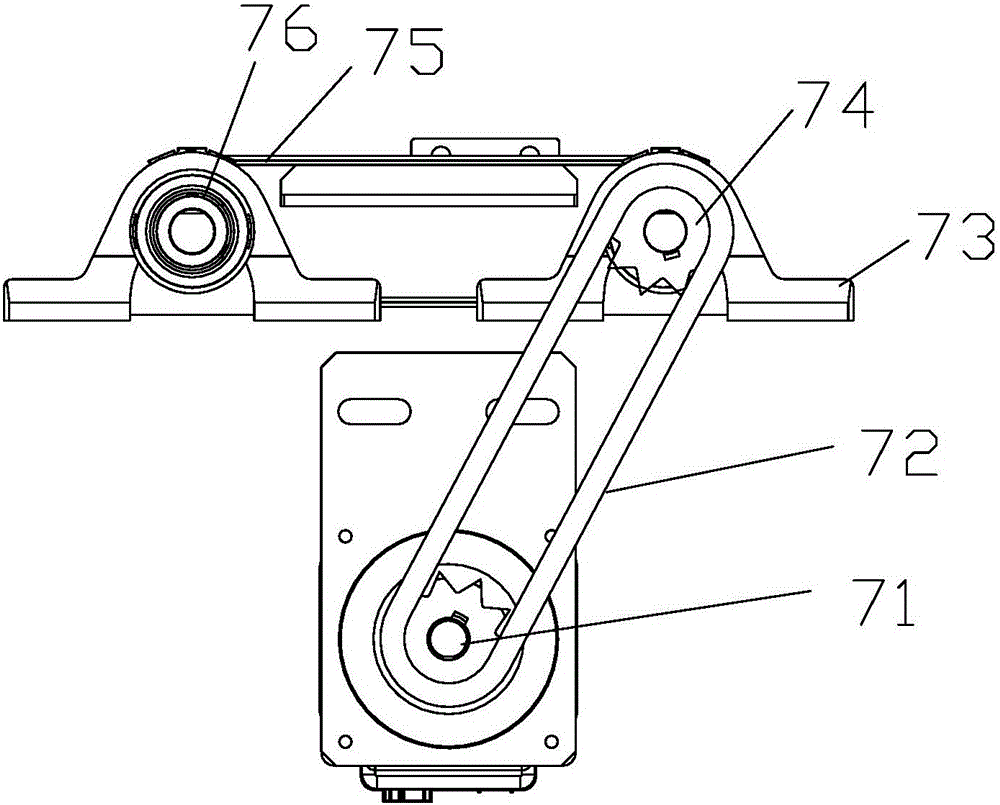

Automatic feeding device for industrial production line and control method

InactiveCN106044119AImprove reliabilityHigh degree of automationConveyorsControl devices for conveyorsVibration basedTesting equipment

The invention discloses an automatic feeding device for an industrial production line and a control method. The feeding device comprises a feeding platform and a feeding mechanism, wherein the feeding mechanism comprises a straight vibration base, a feeding channel, a blocking cylinder, a turntable and a pushing mechanism, wherein the feeding channel is arranged on the straight vibration base mounted on the feeding platform; the blocking cylinder is located at the outlet end of the feeding channel; the edge of the turntable is provided with a circumferential arc-shaped channel, and the central angle where the arc section of the arc-shaped channel is relative to the circle center of the turntable is 90 DEG; an inlet of the arc-shaped channel is abutted with the outlet end of the feeding channel; and an outlet of the arc-shaped channel is provided with the pushing mechanism used for pushing materials output from the arc-shaped channel to detecting equipment. The feeding device is novel and compact in structure, capable of realizing automatic feeding of the materials and high in efficiency and automation degree.

Owner:蔺薛菲

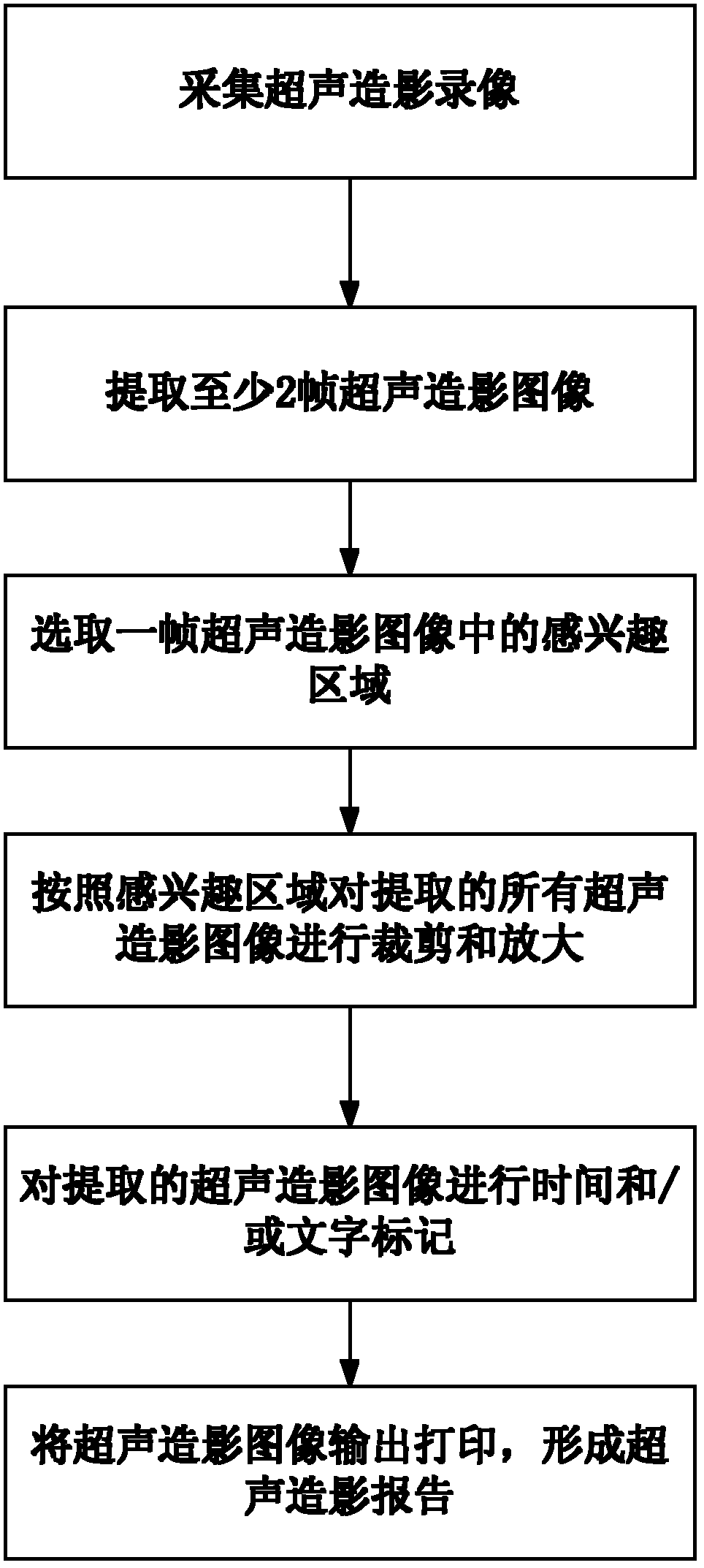

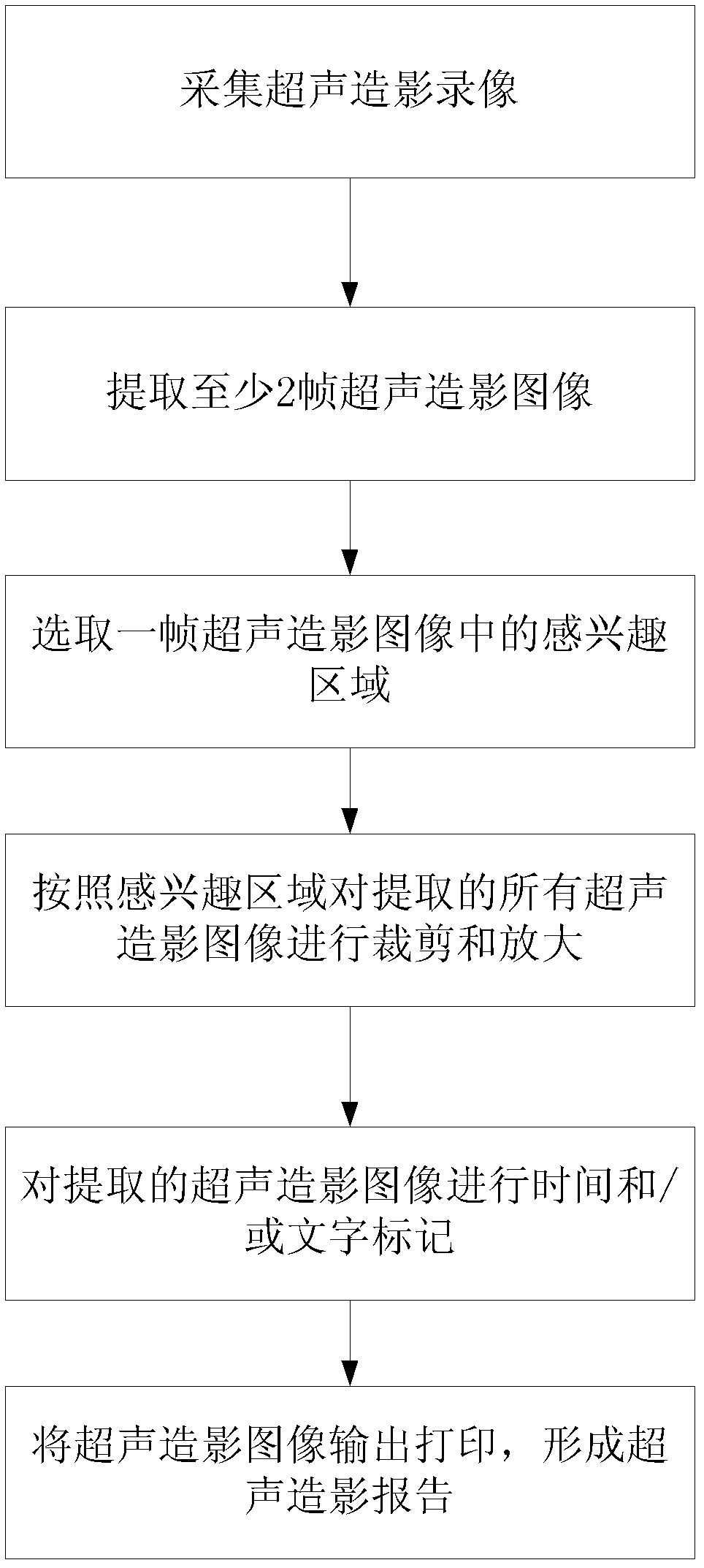

Ultrasonic contrast report generation method and generation system thereof

InactiveCN102525561AImprove recognitionRealize analysisUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsImage extractionSonification

The invention relates to the technical field of ultrasonic contrast, in particular to an ultrasonic contrast report generation method and a generation system thereof. The method comprises the following steps of: (1) acquiring an ultrasound contrast video; (2) extracting at least two frames ultrasound contrast images from the ultrasound contrast video acquired in the step (1) according to a time sequence; and (3) outputting and printing the ultrasound contrast images to form an ultrasonic contrast report. The system comprises a video acquisition module, an image extraction module and a printing module. With the adoption of the ultrasonic contrast report generation method and the generation system thereof, the analysis on an ultrasound contrast video file can be achieved, and the requirements of the ultrasound contrast on the strictness of time series are met; the image change of areas of interest can still be ensured to be clearly observed when a plurality of images are printed through cutting and zooming the areas of interest in the images; and through marking each image by using time and texts, the strict requirements of the ultrasonic contrast on the clear marking of time are met, and the degree of recognition of the ultrasonic contrast in clinical medicine is increased.

Owner:CHONGQING AMBITION TECH

Ultralow-carbon glassed steel for ultra-deep bathtub and production method of ultralow-carbon glassed steel

InactiveCN111411303ARough surface morphologyUniform colorManufacturing convertersSteel platesBathtub

The invention relates to ultralow-carbon glassed steel for an ultra-deep bathtub and a production method of the ultralow-carbon glassed steel. The ultralow-carbon glassed steel comprises, by weight percent, 0.0015%<=C<=0.0040%, 0.10%<=MN<=0.30%, not larger than 0.020% of Si, not larger than 0.015% of P, 0.020%<=S<=0.040%, 0.02%<=Als<=0.050%, 0.10%<=Ti<=0.13%, 0.0040%<=N<=0.0120% and the balance Feand other residual micro elements. The production method of the ultralow-carbon glassed steel for the ultra-deep bathtub comprises the steel making procedure, the hot rolling procedure, the acid pickling procedure and the continuous annealing procedure. A cleaning control unit, a temperature control unit and a leveling control unit are included in the continuous annealing procedure. Good flexibility resistance, scale blasting resistance, enamel adherence and other comprehensive prosperities are achieved, and the rigid requirements of a glassed steel plate for the ultra-deep bathtub are met. In the whole process, the manufacturing cost is low, and the production process is simple and easy to control.

Owner:SD STEEL RIZHAO CO LTD

Process for recycling reclaimed water in residential buildings and manpower driving device thereof

InactiveCN101967846AStable hoistingRinse smoothlySewerage structuresFlushing devicesWater savingHigh elevation

The invention discloses a process for recycling reclaimed water in residential buildings and a manpower driving device thereof, and belongs to the technical field of reclaimed water recycling. At present, a process and a device capable of well and comprehensively recycling reclaimed water are absent. The technical scheme is that: the used reclaimed water is subjected to filtration and classified collection, and is continuously pumped to different water consumption containers such as water tanks and the like at a higher elevation from a lower elevation by means of air pressure and the capacity of an air lift pump of pumping the reclaimed water, and finally, the excessive reclaimed water is totally used for washing toilets and kitchen drainage with more oil can be directly used for washing the toilets. The invention has the advantages that: the process for recycling the reclaimed water in the residential buildings has novelty, creativeness and practicability, and is perfect combination of advanced combination technology and a simple process device; and the process device can be completely driven by manpower without other energy, and is an energy-saving water-saving device.

Owner:韩晓东

Preparation method of pancreatin

ActiveCN108795920AAchieve the purpose of inactivationEnhanced Virus SecurityPancreatinVirus inactivationVirus safety

The invention relates to a preparation method of pancreatin. The preparation method comprises following steps: pancreas is subjected to grounding, hydrogen peroxide is added so as to obtain a mixture,wherein the mass ratio of hydrogen peroxide in the mixture is controlled to be 0.1 to 2%; the mixture is stirred for 1 to 8h, catalase is added for 0.5 to 2h of reaction, and degreasing, activating,deposition, and drying are carried out so as to obtain pancreatin. In the preparation method, hydrogen peroxide is capable of realizing full contact with virus in a relatively short time, so that virus inactivation is realized; the residual hydrogen peroxide is degraded by catalase into water and oxygen, so that no hydrogen peroxide is left in pancreatin, the drug virus safety is improved greatly,and the obtained pancreatin product is capable of satisfying the strict requirements of pharmacopeia and animal-sourced biochemical medicine standards of different states.

Owner:苏州良辰生物医药科技有限公司

Preparation method for metal alloy test rod

InactiveCN102901659BAvoid pollutionImprove uniformityPreparing sample for investigationDifferential pressureVacuum chamber

The present invention relates to the field of metal alloy test rod production, and provides a metal alloy test rod preparation method. According to the method, a vacuum suction casting device is adopted, wherein a vacuum chamber is filled with high purity argon to achieve pressure P1 of 0.02-0.06 MPa; when a button ingot surface layer is completely melted and a through hole on the bottom of an alloy ingot crucible is sealed through a liquid sealing manner, the vacuum chamber is continuously filled with high purity argon to increase pressure to P2, wherein pressure difference between the P2 and the P1 is 0.01-0.1 MPa; and pressure difference suction casting molding is adopted. The preparation method has the following characteristics that: high cleaning and high efficiency are provided; high uniformity and high accuracy of the components can be achieved; a size of the test rod can be phi 12 mm*120 mm; disadvantages of uniform component, difficult oxygen content control, long period or complex process, and the like of powder metallurgy, mold melting casting, extrusion molding, ingot processing and other test rod preparation methods are overcome; and strict requirements on the ideal alloy test rod by standard sample preparation, alloy design, performance testing, material feeding rod preparation and other processes can be met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

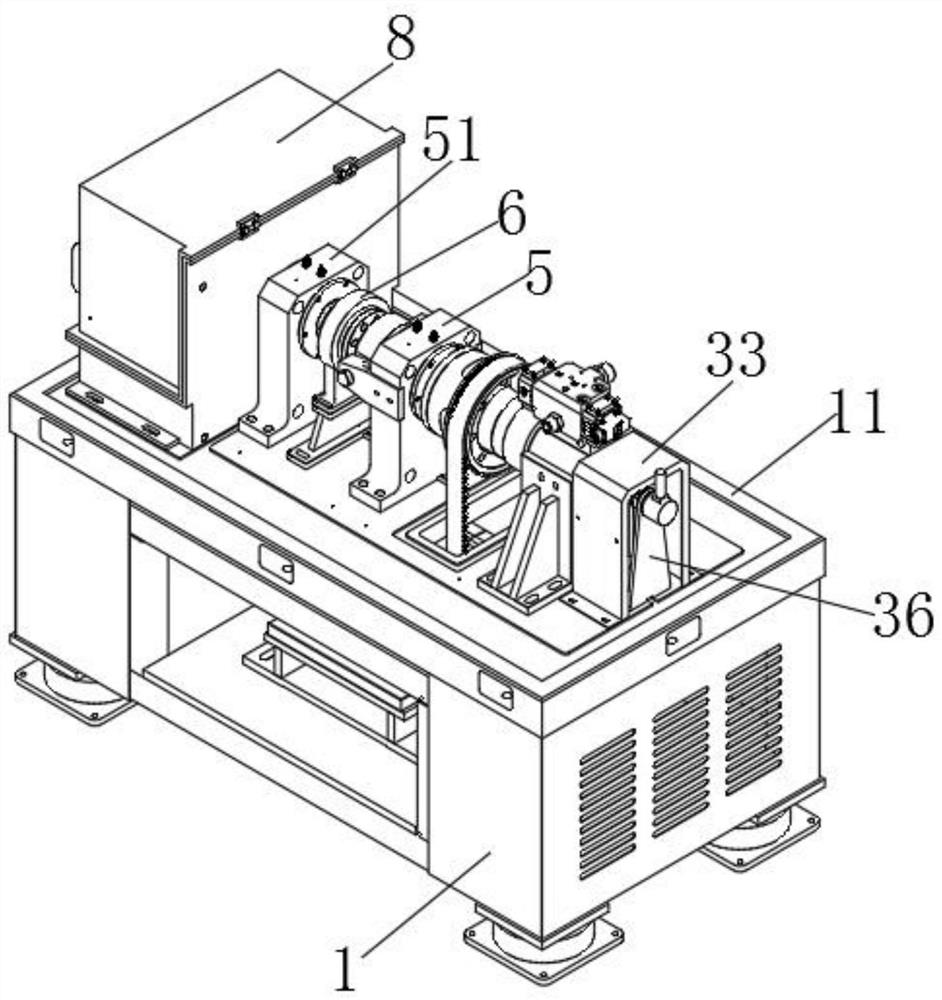

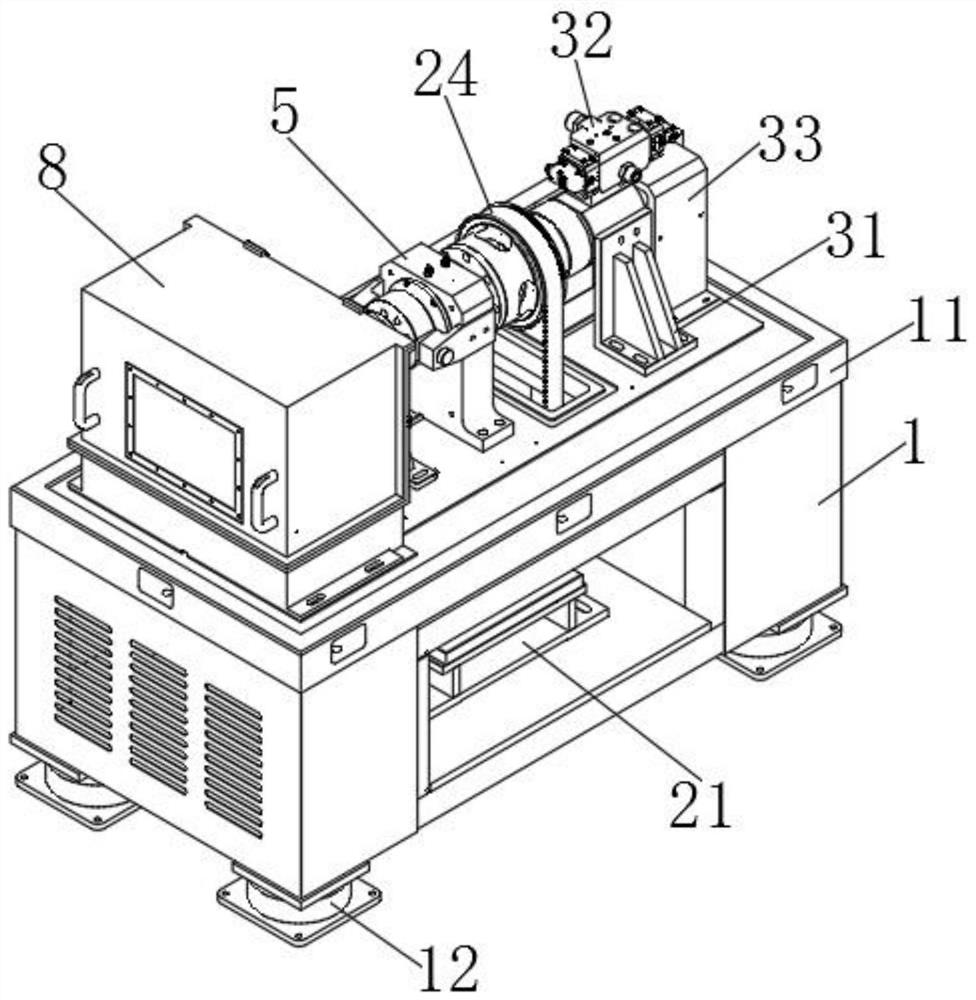

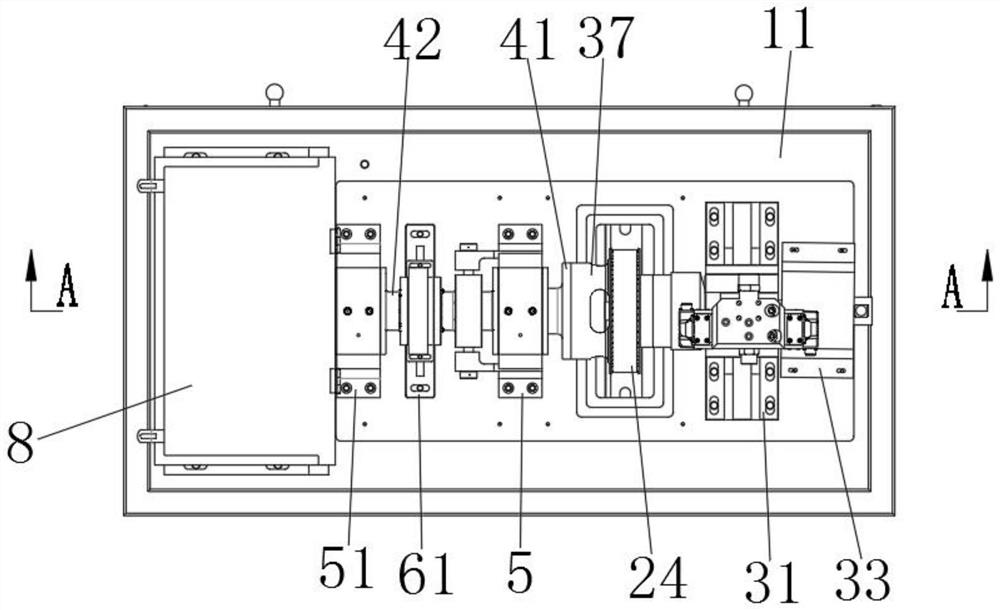

Mechanical closed shock absorber rotation torsion test bench

InactiveCN113405789AMeet stringent requirementsImprove shock absorptionMachine part testingTemperature measurement of moving solidsTorsion testElectric machinery

The invention relates to the technical field of shock absorber testing, in particular to a mechanical closed type shock absorber rotation torsion test bench which comprises a base support with a motor installed in an inner cavity and a rotation torque exciter arranged on the base support. A torsion shaft and a rotating cylinder arranged on the outer ring wall of the torsion shaft in a sleeving mode are rotationally connected to the axis of the rotating torque exciter, the rotating cylinder seals the torsion shaft in an inner cavity of the rotating cylinder, and an oil pressure cavity is formed between the rotating cylinder and the torsion shaft. In the invention, the motor is used for driving the rotating cylinder to finally enable the friction ring of the outer ring of the test piece to rotate, and then the electro-hydraulic servo valve is used for driving the inner long shaft to finally enable the inner ring of the test piece to generate advanced and lagged cyclic torsional vibration relative to the outer ring, so that the inner ring and the outer ring generate advanced and lagged phase torsional vibration when the test piece rotates at a high speed; the torque performance of the driven disc hub of the inner ring of the test piece can be tested in the rotating process of the friction ring, and the strict requirements of shock absorber testing are met.

Owner:安徽精科检测技术有限公司

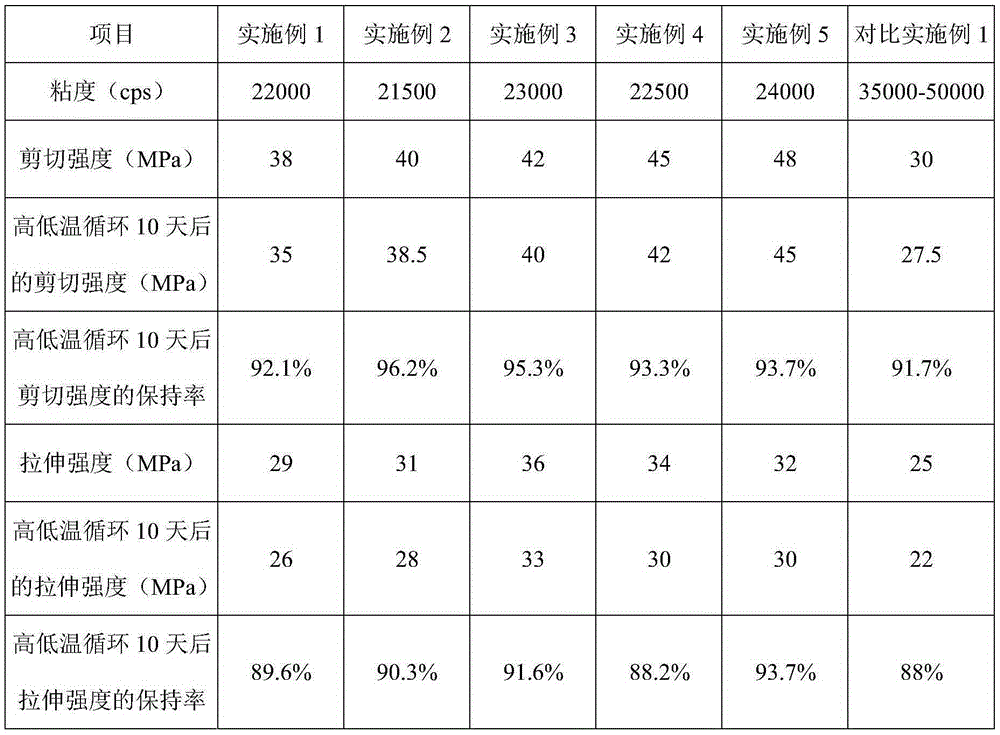

High-strength epoxy structural adhesive for adhering carbon fiber composite materials

ActiveCN105238313AHigh bonding strengthAchieve the effect of destructionNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyGas phase

The invention provides a high-strength epoxy structural adhesive for adhering carbon fiber composite materials. The high-strength epoxy structural adhesive consists of A component and B component; the A component comprises the following components in parts by weight: 40-60 parts of epoxy resin / polybutadiene rubber polymer, 40-60 parts of mixed type epoxy regin, 0.2-0.5 part of graphene, 5-10 parts of SBM / MAM copolymer, 6-10 parts of flexibilizer, 1-5 parts of attapulgite, 1-5 parts of gas-phase method silicon dioxide and 0.5-1.5 parts of coupling agent; and the B component comprises the following components in parts by weight: 85-95 parts of polyamide, 5-15 parts of flexible polyamide, 3-8 parts of ATBN reactive liquid polymer and 1-5 parts of gas-phase method silicon dioxide. The adopted epoxy structural adhesive in the technical scheme of the invention is high in adhesion strength when being used between the carbon fiber composite materials, and achieves the effect that adhered surface of the carbon fiber composite materials is destroyed.

Owner:SHENCAI TECH SHENZHEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com