Conveying and self-rotating device and method for cylindrical or columnar object

A columnar and article technology, which is applied in the field of conveying and spinning devices for cylindrical or columnar articles, can solve the problems of large space occupation, insufficient compactness, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

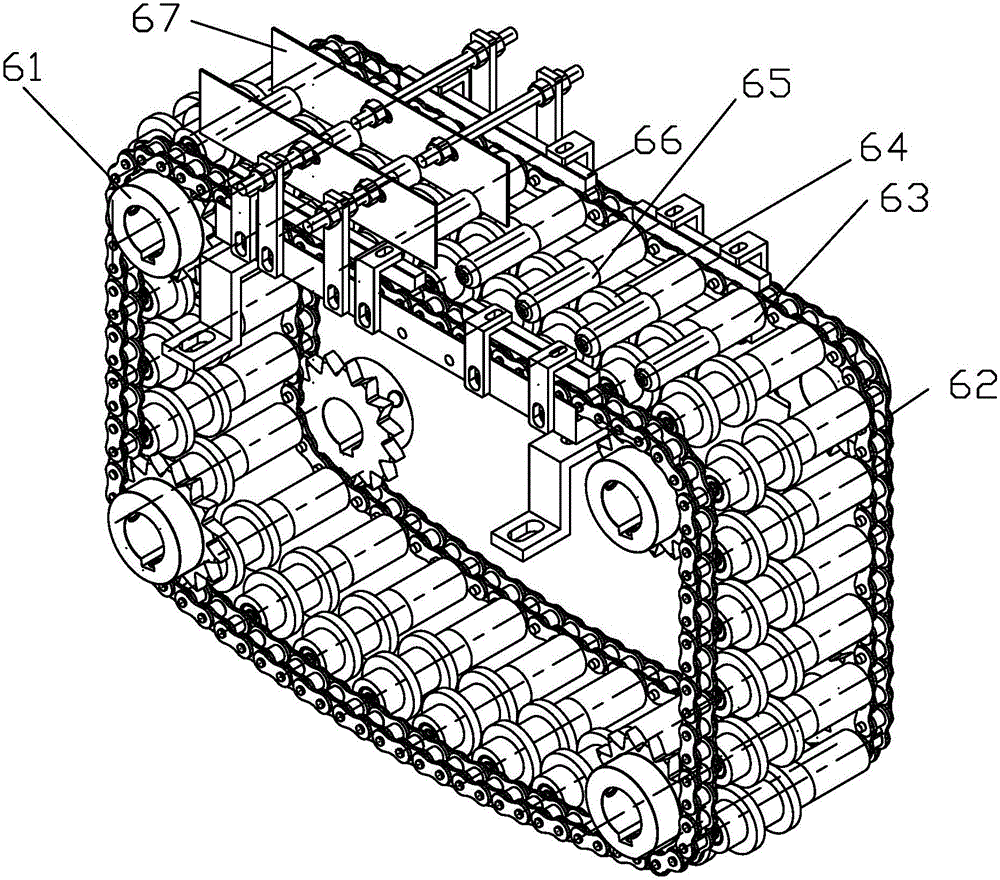

[0033] Embodiment 1: as Figure 1-2 , a transmission and spin device for cylindrical or columnar articles, including a chain transmission mechanism, the chain transmission mechanism includes a chain 62, a chain drive wheel 61, a wheel shaft and a transmission roller 63; the chain drive wheel is installed on the frame through the wheel shaft ;

[0034] There are 2 chains, and a plurality of said conveying rollers are arranged between the 2 chains, the setting direction of the conveying rollers is perpendicular to the moving direction of the chains, and a cylindrical or For columnar articles, there are at least two sets of chain drive wheels; each set of chain drive wheels has 2 pieces;

[0035] The two chains are stretched on the chain driving wheel, and the chain driving wheel drives the two chains so as to drive the conveying roller to move circularly to convey the cylindrical or columnar articles, and the stretching refers to the tension setting.

[0036] There are 4 group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com