Machine vision-based method for detecting end defectives of transparent object

A defect detection and machine vision technology, applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of large amount of calculated data, inability to adapt to high-speed production lines, complex detection methods, etc., and achieve the effect of easy consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

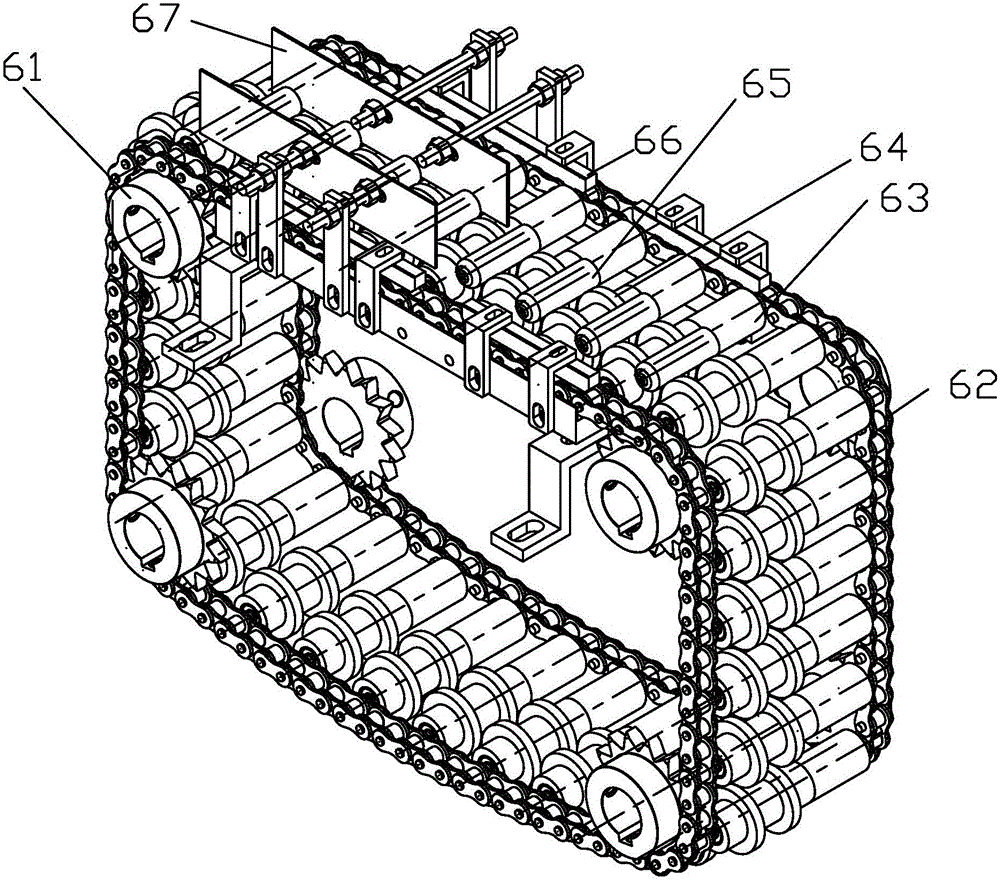

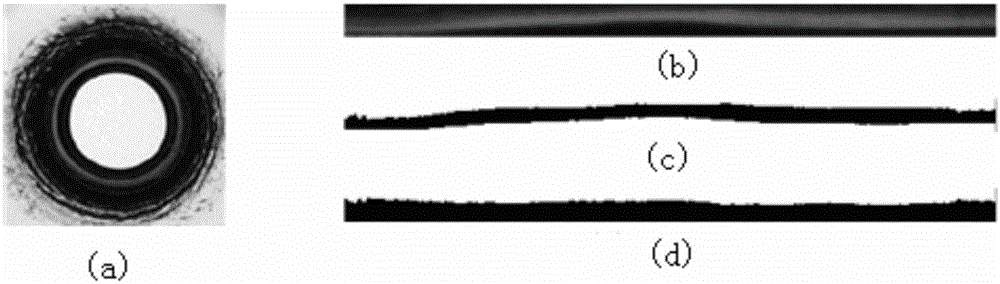

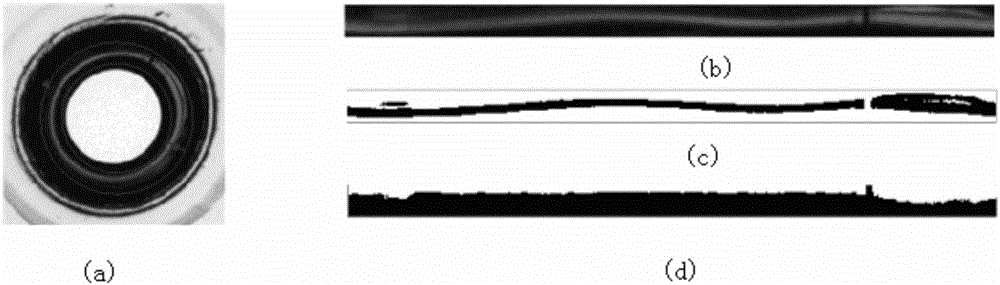

[0042] Embodiment 1: as Figure 1-4 , taking the glass bulb as an example, a method for detecting defects on the end face of a transparent object based on machine vision, including the following steps:

[0043] Step 1: Obtain the end face image of the transparent object; the end face image of the transparent object is a grayscale image;

[0044] Step 2: For the end surface image of the transparent object, the vertical integral projection method is used to detect the crack of the transparent object;

[0045] Described step 2 comprises the following steps:

[0046] Step 21: Locate the white ring in the end face image of the transparent object; (corresponding to the white ring in the bright image of the end face of the transparent object, which can be seen in the bright image of the transparent object)

[0047] Step 22: Transform the white circle into a rectangular image; the n*m size image of the rectangular image; where n and m are the number of pixels corresponding to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com