Granular material for injection-molded nylon-12-permanent magnetic ferrite and preparation method of granular material

A technology of permanent ferrite and granules, applied in the field of injection molding nylon 12-permanent ferrite granules and its preparation, can solve the problem that the strength and precision of injection molding nylon 12-permanent ferrite granules are not high enough, and cannot meet the strict requirements of automobile motors. requirements, etc., to achieve the effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

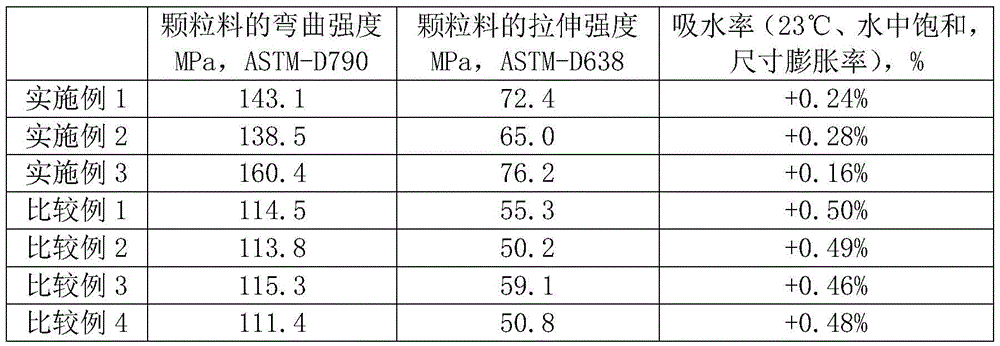

Examples

Embodiment 1

[0025] A kind of injection molding nylon 12-permanent ferrite granular material, by 100kg permanent magnetic Sr ferrite magnetic powder, 10kg nylon 12, 0.90kg chopped glass fiber, 0.25kg sodium metaphosphate, 0.50kg silane coupling agent, 0.25kg hard Calcium fatty acid is mixed and granulated.

[0026] Prepare as follows:

[0027] 1) Surface treatment of magnetic powder: Put 100kg of permanent magnet Sr ferrite magnetic powder in the powder mixing tank, add 0.25kg of sodium metaphosphate, 0.50kg of silane coupling agent (dissolved in 5L of isopropanol in advance), at a temperature of 120°C Mix the powder for 30 minutes;

[0028] 2) Add 10kg of nylon 12, and continue to mix the powder for 15 minutes at a temperature of 120°C;

[0029] 3) Add 0.90kg of chopped glass fiber and 0.25kg of calcium stearate, continue mixing powder at 120°C for 15 minutes, and raise the temperature to 150°C, and continue mixing powder for 15 minutes;

[0030] 4) Granulation: inject the mixed nylon ...

Embodiment 2

[0033] A kind of injection molding nylon 12-permanent ferrite pellets, consisting of 100kg permanent magnet Sr ferrite magnetic powder, 9.8kg nylon 12, 0.90kg chopped mica sheet, 0.25kg sodium metaphosphate, 0.50kg silane coupling agent, 0.40kg Silicone oil is mixed and granulated.

[0034] Prepare as follows:

[0035] 1) Surface treatment of magnetic powder: Put 100kg of permanent magnet Sr ferrite magnetic powder into the powder mixing tank, add 0.25kg of sodium metaphosphate, 0.5kg of silane coupling agent (dissolved in 5L of isopropanol), and mix the powder at 110°C for 20 minutes ;

[0036] 2) Add 9.8kg of nylon 12, and continue mixing for 10 minutes at a temperature of 110°C;

[0037] 3) Add 0.9kg of chopped mica flakes and 0.40kg of silicone oil, continue mixing for 10 minutes at a temperature of 110°C, and raise the temperature to 160°C, and continue mixing for 10 minutes;

[0038] 4) Granulation: inject the mixed nylon 12-permanent ferrite magnetic powder mixture i...

Embodiment 3

[0041] A kind of injection molding nylon 12-permanent ferrite pellets, consisting of 100kg permanent magnet Sr ferrite magnetic powder, 10.3kg nylon 12, 0.60kg chopped potassium titanate fiber, 0.25kg sodium tripolyphosphate, 0.50kg silane coupling agent , 0.20kgEBS mixed granulation made.

[0042] Prepare as follows:

[0043] 1) Surface treatment of magnetic powder: Put 100kg of permanent magnet Sr ferrite magnetic powder in the powder mixing tank, add 0.25kg of sodium tripolyphosphate, 0.50kg of silane coupling agent (dissolved in 5L of isopropanol), and mix the powder at a temperature of 100°C 40min;

[0044] 2) Add 10.3kg of nylon 12, and continue mixing for 30 minutes at a temperature of 100°C;

[0045] 3) Add 0.60kg chopped potassium titanate fiber and 0.20kg EBS, continue mixing powder at 100°C for 20 minutes, and raise the temperature to 140°C, and continue mixing powder for 30 minutes;

[0046] 4) Granulation: inject the mixed nylon 12-permanent ferrite magnetic po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com