Patents

Literature

207 results about "Nylon 12" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nylon 12 is a polymer with the formula [(CH₂)₁₁C(O)NH]ₙ. It is made from ω-aminolauric acid or laurolactam monomers that each have 12 carbons, hence the name ‘Nylon 12’. It is one of several nylon polymers.

Laser sinter powder with a metal salt and a fatty acid derivative, process for its production, and moldings produced from this laser sinter powder

InactiveUS20050027050A1Improve the immunityMaintain good propertiesAdditive manufacturing apparatusFibre treatmentSelective laser sinteringPolyamide

The present invention relates to a sinter powder composed of polyamide which also comprises metal salts of weak acids, in particular metal carbonates, and fatty acid derivatives, in particular fatty acid esters or fatty acid amides, to a process for laser sintering, and also to moldings produced from this sinter powder. The moldings formed using the powder of the invention have marked advantages in appearance and in surface finish when compared with conventional products, especially when recyclability in the selective laser sintering (SLS) process is taken into account. Moldings produced from recycled sinter powder of the invention moreover also have markedly improved mechanical properties when compared with moldings based on recycled conventional nylon-12 powders, in particular in terms of modulus of elasticity and tensile strain at break. These moldings also have a density approaching that of injection moldings.

Owner:EVONIK DEGUSSA GMBH

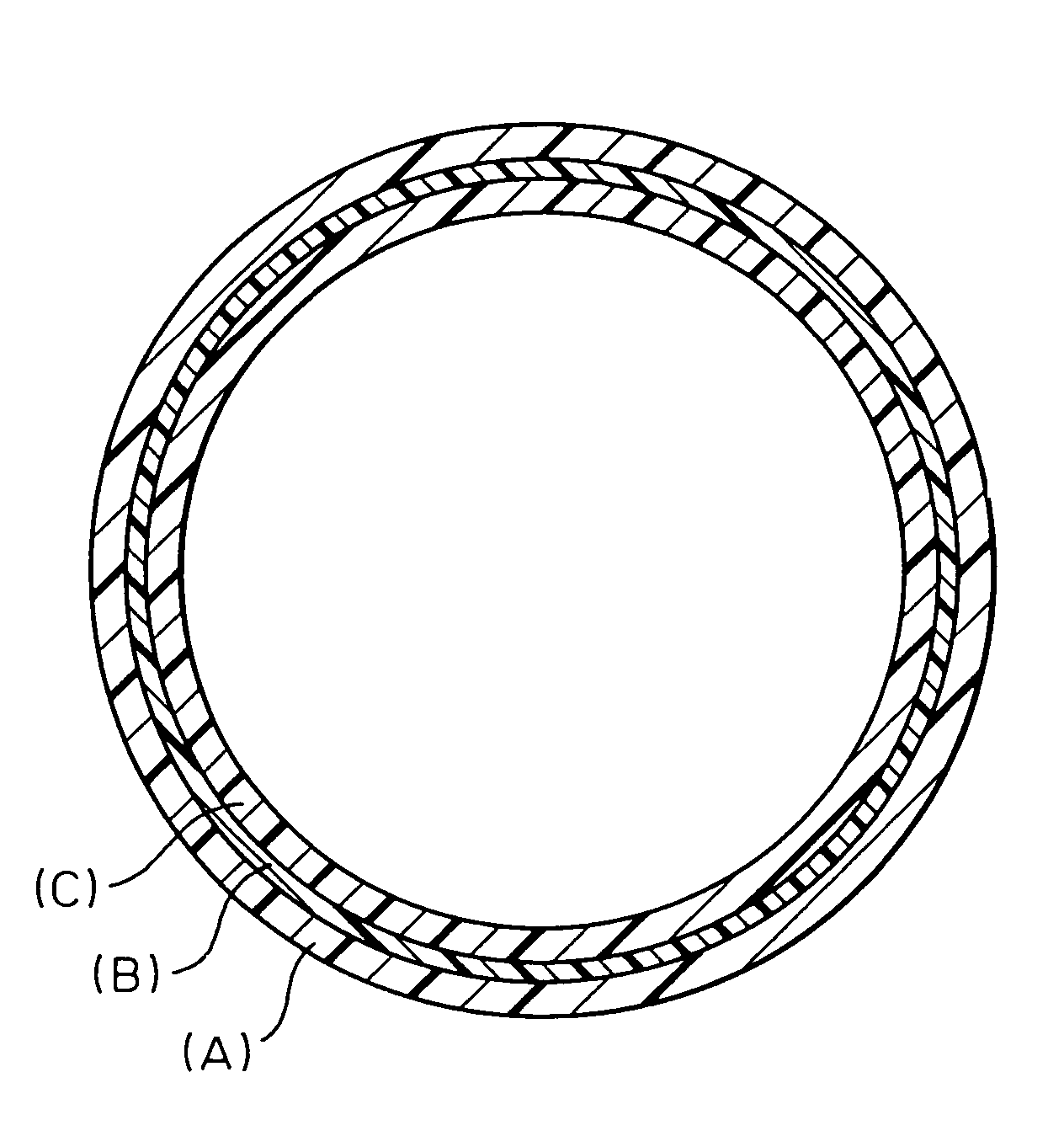

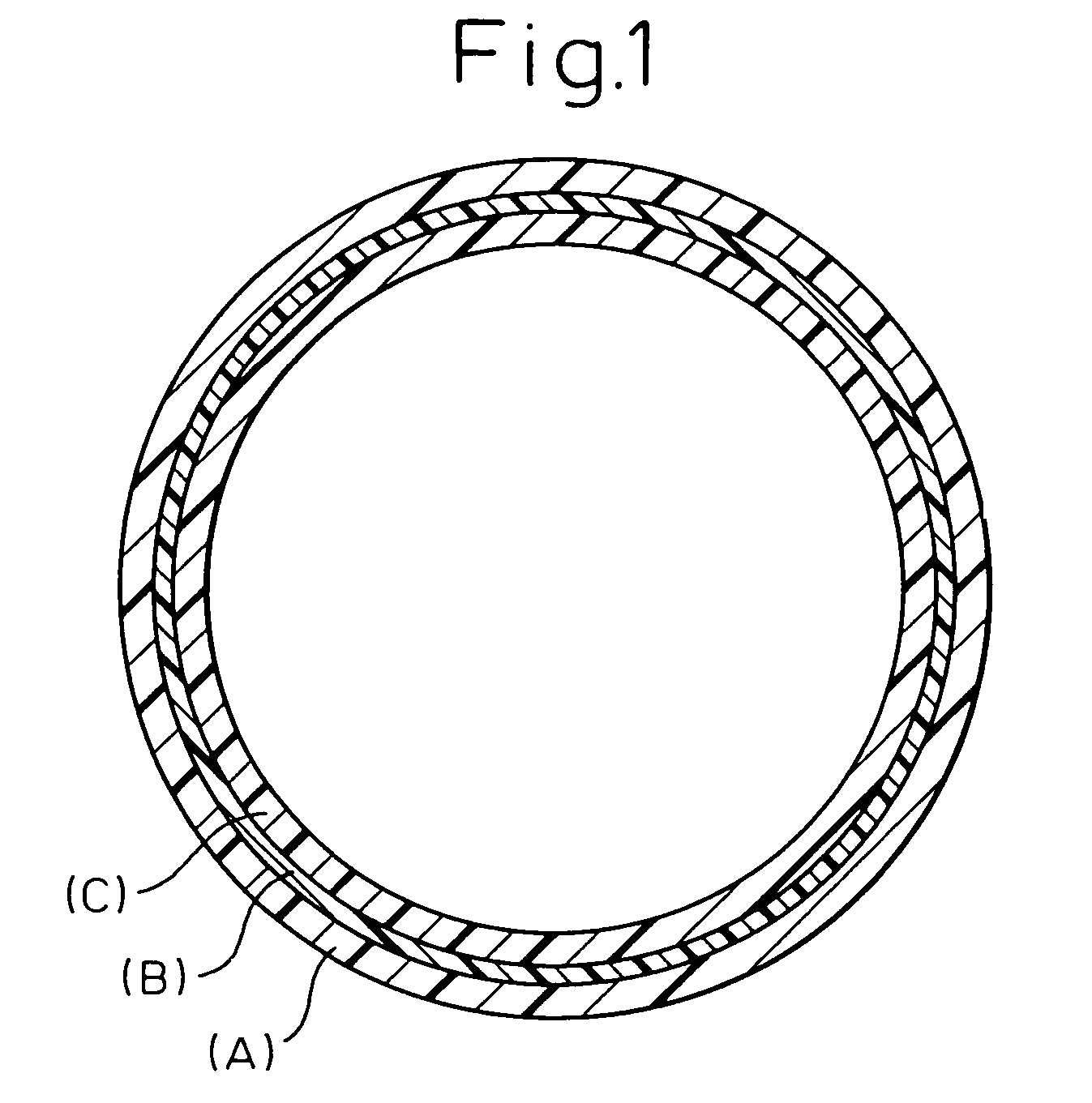

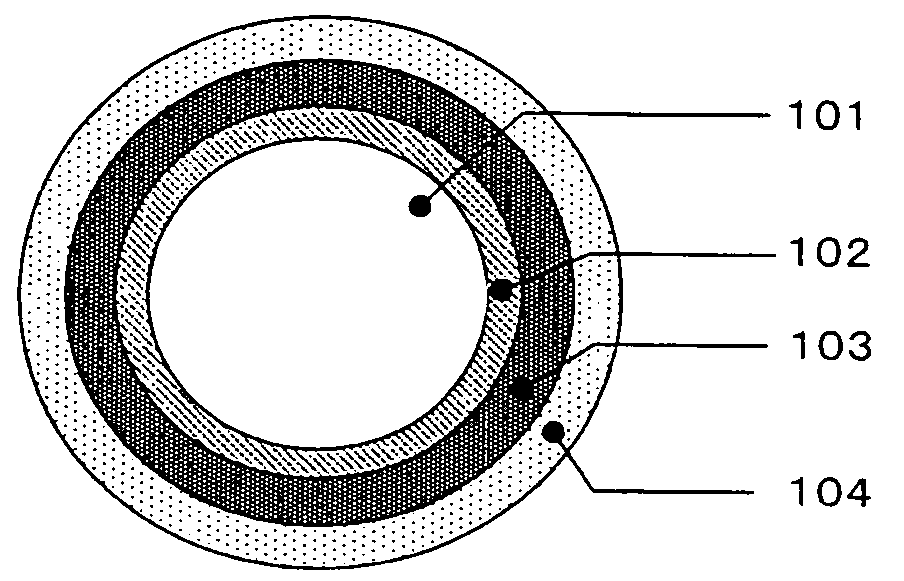

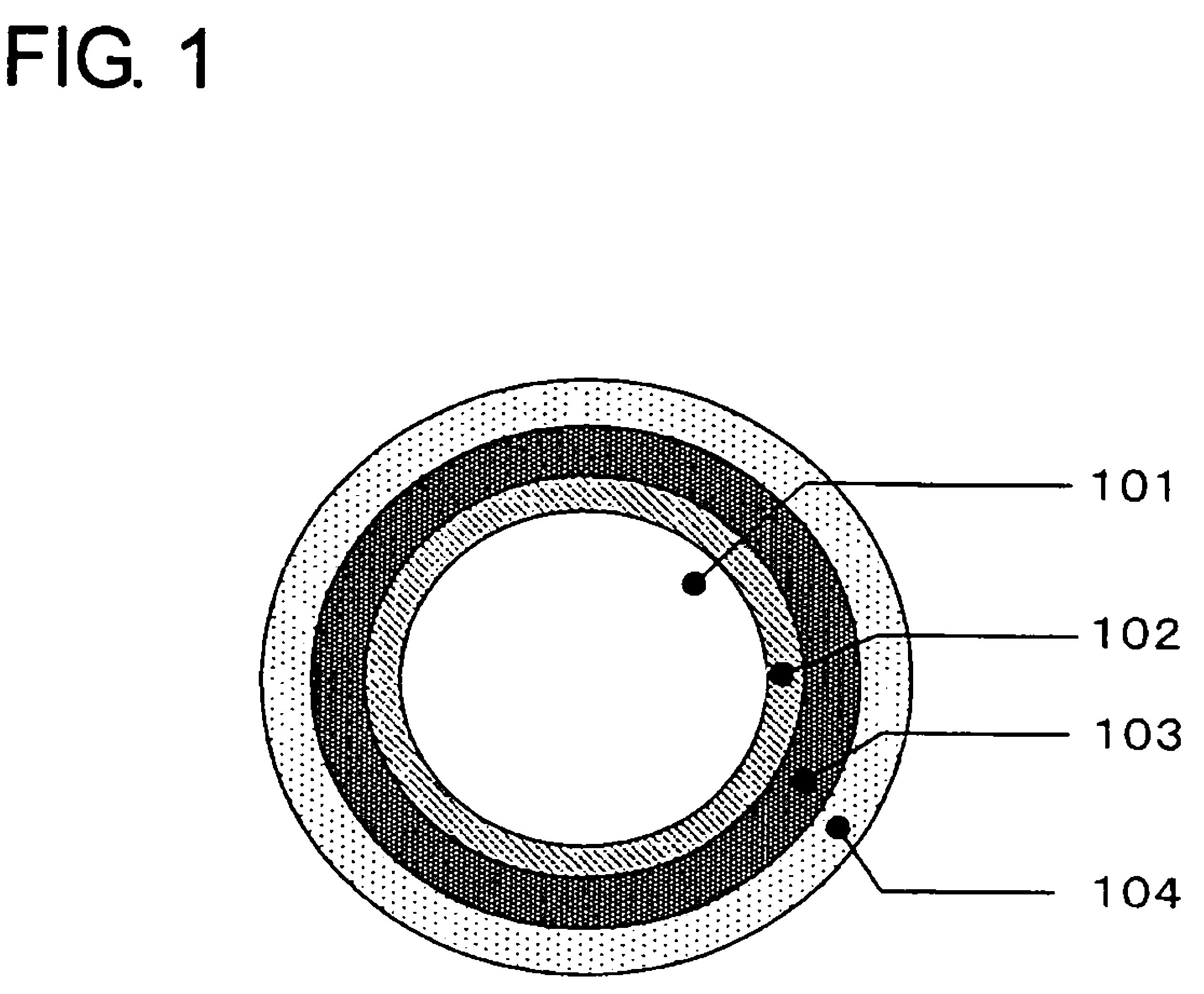

Multi-layer structure

ActiveUS6989198B2Improve penetration resistanceLarge containersRefuse receptaclesCarboxylic acidNylon 11

A multi-layer structure excellent in the barrier properties against alcohol gasoline, particularly hydrocarbon components, and also excellent in the interlayer adhesion, low-temperature impact resistance, heat resistance and chemical resistance is provided. The stractive is a multi-layer structure comprising two or more layers including at least a layer (a) comprising (A) nylon 11 and / or nylon 12 and a layer (b) comprising (B) a polyamide resin (nylon 9T) consisting of a dicarboxylic acid component and a-diamine component, with 60 to 100 mol % of the dicarboxylic acid component being a terephthalic acid and 60 to 100 mol % of the diamine component being a diamine component selected from 1,9-nonanediamine and 2-methyl-1,8-octanediamine, and preferably further including a layer (c) comprising (A) nylon 11 and / or nylon 12 or (C) nylon 6.

Owner:KURARAY CO LTD +1

Laser-sintering powder with PMMI, PMMA, and/or PMMI-PMMA copolymers, process for its preparation, and moldings produced from this laser-sintering powder

InactiveUS7135525B2High resolutionFlat surfacePretreated surfacesGlass/slag layered productsSelective laser sinteringNylon 12

The present invention relates to a sinter powder composed of polyamide which also comprises PMMI, PMMA, or copolymers with PMMI, in particular PMMI-PMMA copolymers, to the use of this sinter powder for laser-sintering, and also to moldings produced from this sinter powder. The moldings made from the powder of the invention have marked advantages over conventional products in their appearance and in their surface quality, especially as far as roughness and dimensional stability during selective laser sintering (SLS) are concerned. In addition, moldings produced from the sinter powder of the invention also have better mechanical properties than moldings based on conventional nylon-12 powders, in particular in terms of modulus of elasticity and tensile strength. These moldings also have a density close to that of injection moldings.

Owner:EVONIK DEGUSSA GMBH

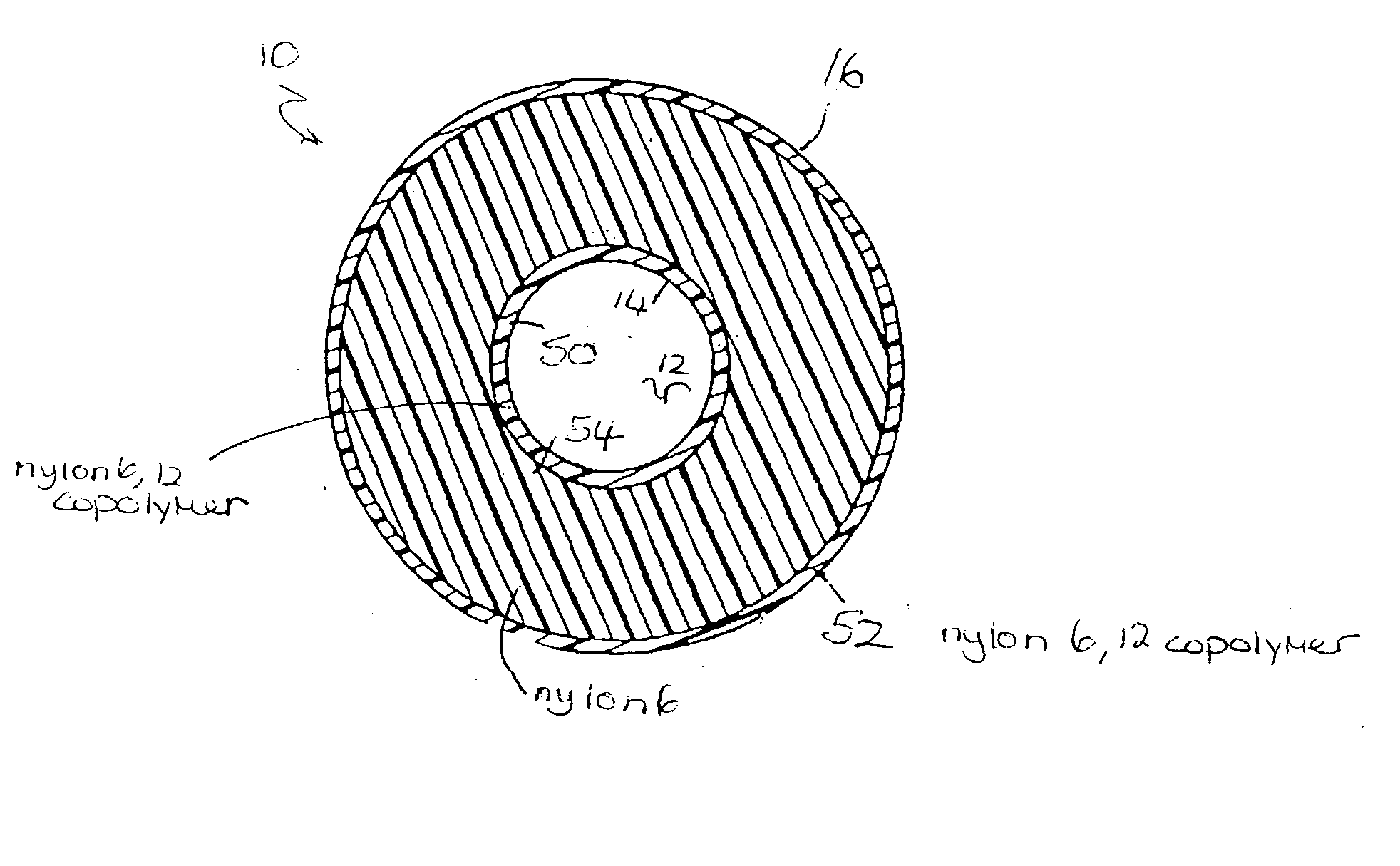

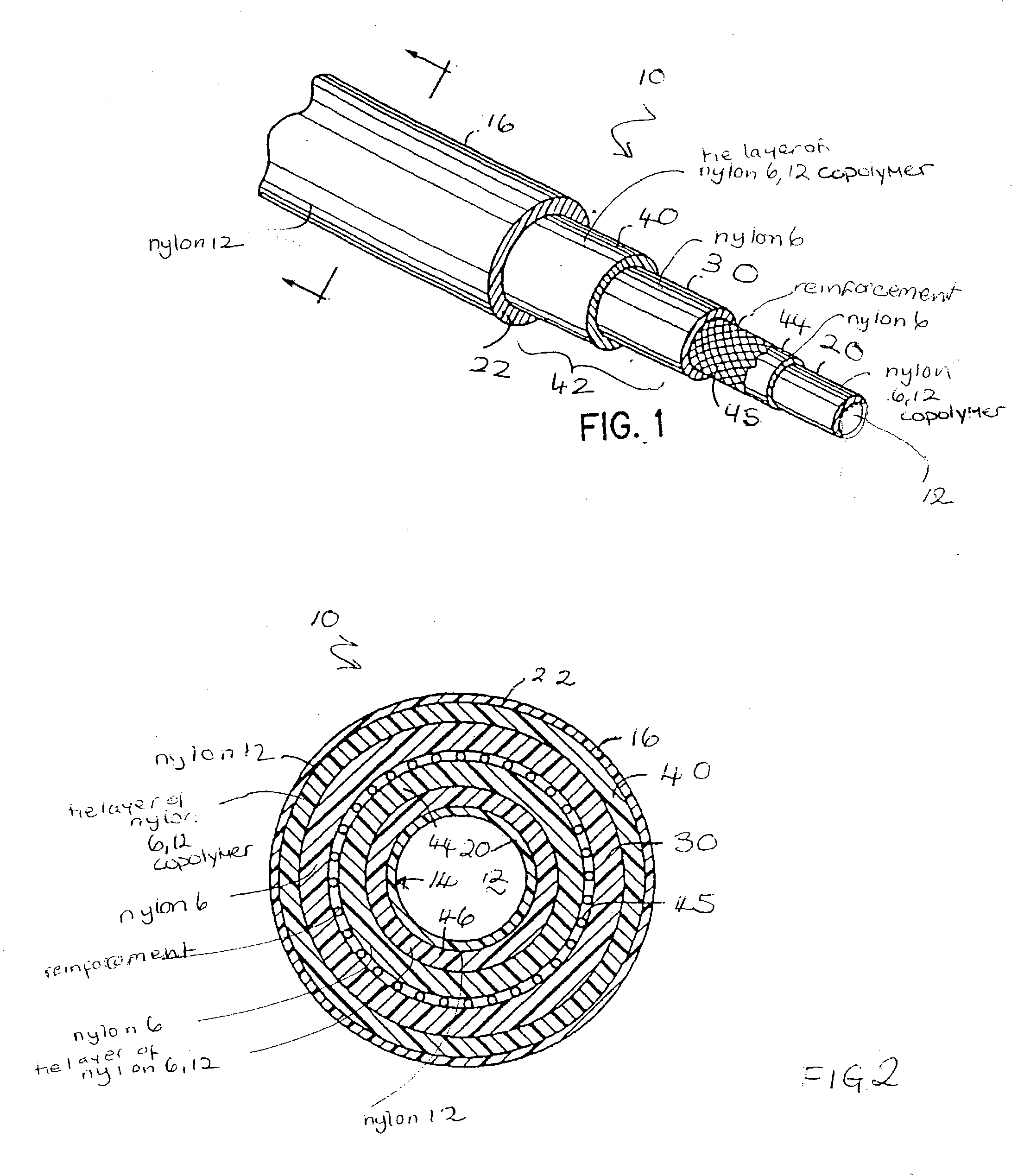

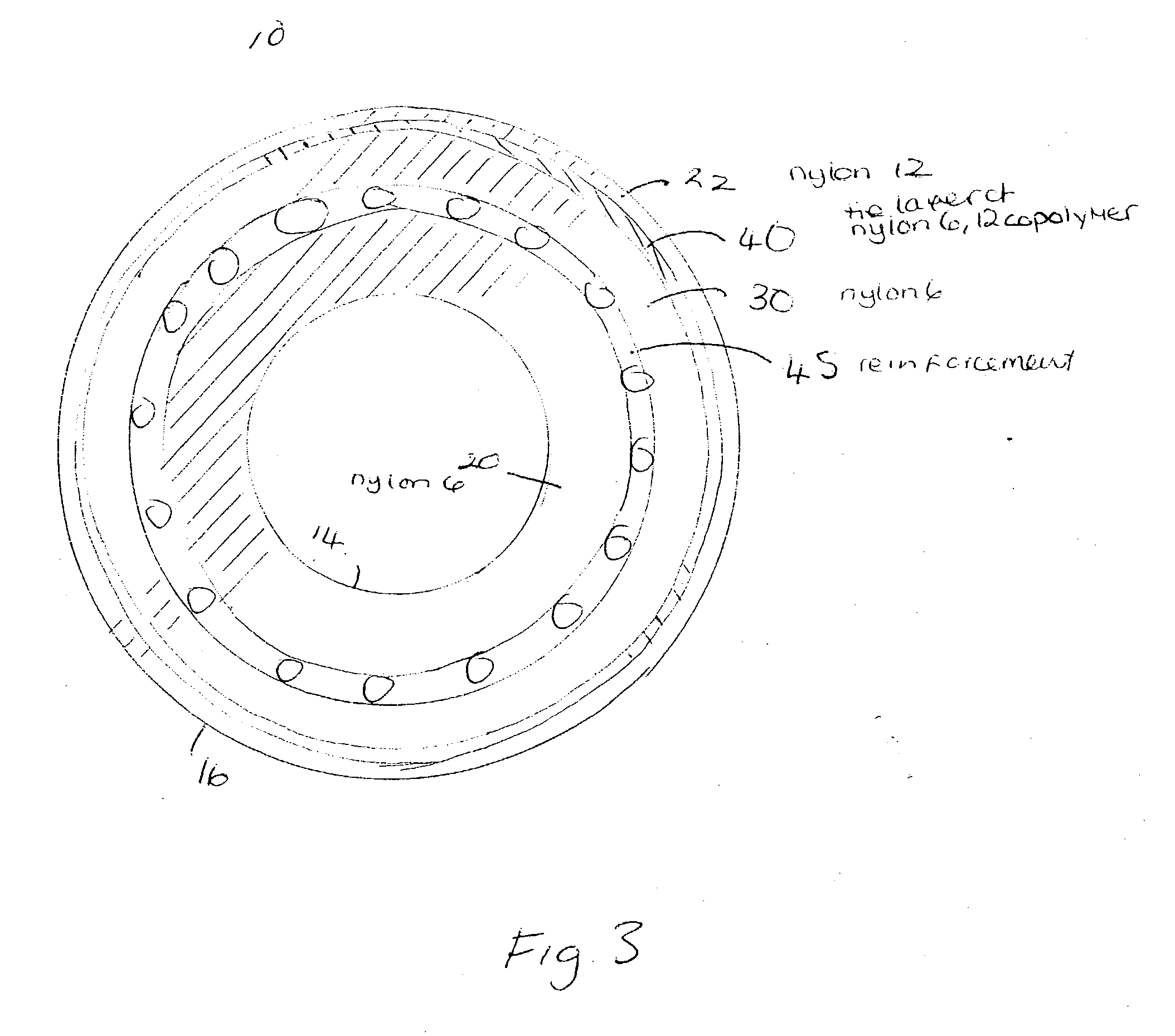

Hose comprising modified nylon 6,12 material

InactiveUS20040096615A1Improve mechanical propertiesSynthetic resin layered productsFlexible pipesPolyamideNylon 11

A copolymer of nylon 6 (caprolactam mer units) and nylon 12 (dodecanolactam mer units) and / or nylon 11 (undecanolactam mer units), which has been modified to provide improved physical properties, such as flex modulus, elastic modulus, and yield strength, serves as a layer of a hose suited to use in airbrake applications. The modified copolymer is resistant to degradation by zinc chloride and moisture and thus may be used as a peripheral layer of the hose in place of a conventional protective layer comprising a pure polyamide, such as nylon 11 or 12. Alternatively, the modified copolymer may be used as a tie layer for rendering a peripheral layer comprising nylon 12 or 11 compatible with a layer of nylon 6, allowing the less expensive nylon 6 material to comprise the bulk of the hose thickness. The layer includes a compatibilizer, such as a maleic anhydride grafted polyethylene, and may also include plasticizers and impact modifiers.

Owner:EATON CORP

High-temperature resistant PTC electroconductive composition, high-temperature resistant PTC device containing composition and manufacturing method thereof

ActiveCN101560325ALower resistanceImprove PTC StrengthCurrent responsive resistorsPositive temperature coefficient thermistorsMetallurgyOrganic polymer

The invention relates to a high-temperature resistant PTC electroconductive composition, which comprises 20 to 70 percent of organic polymers, 25 to 75 percent of electroconductive filler, 1 to 30 percent of inorganic filler and 0.1 to 10 percent of additive, wherein the preferred melting point of the organic polymers is more than 150 DEG C; the organic polymers are one or more crystalline or semi-crystalline polymers and made of one or more of nylon 11, nylon 12, polyvinylidene fluoride, soluble poly(tetrafluoroethylene), ethylene-tetrafluoroethylene copolymers, perfluoroethylene-propylene, ethylene-chlorotrifluoroethylene and copolymers thereof. The invention also provides a high-temperature resistant PTC device containing the composition and a manufacturing method thereof. The high-temperature resistant PTC device containing the composition has low resistance, high PTC strength and superior resistance stability, so that the high-temperature resistant PTC device can be used for overcurrent protection of circuits in high-temperature environments such as automobile motors and the like. Moreover, the high-temperature resistant PTC device is simple and convenient to manufacture and has high efficiency.

Owner:SHANGHAI KETER POLYMER MATERIAL

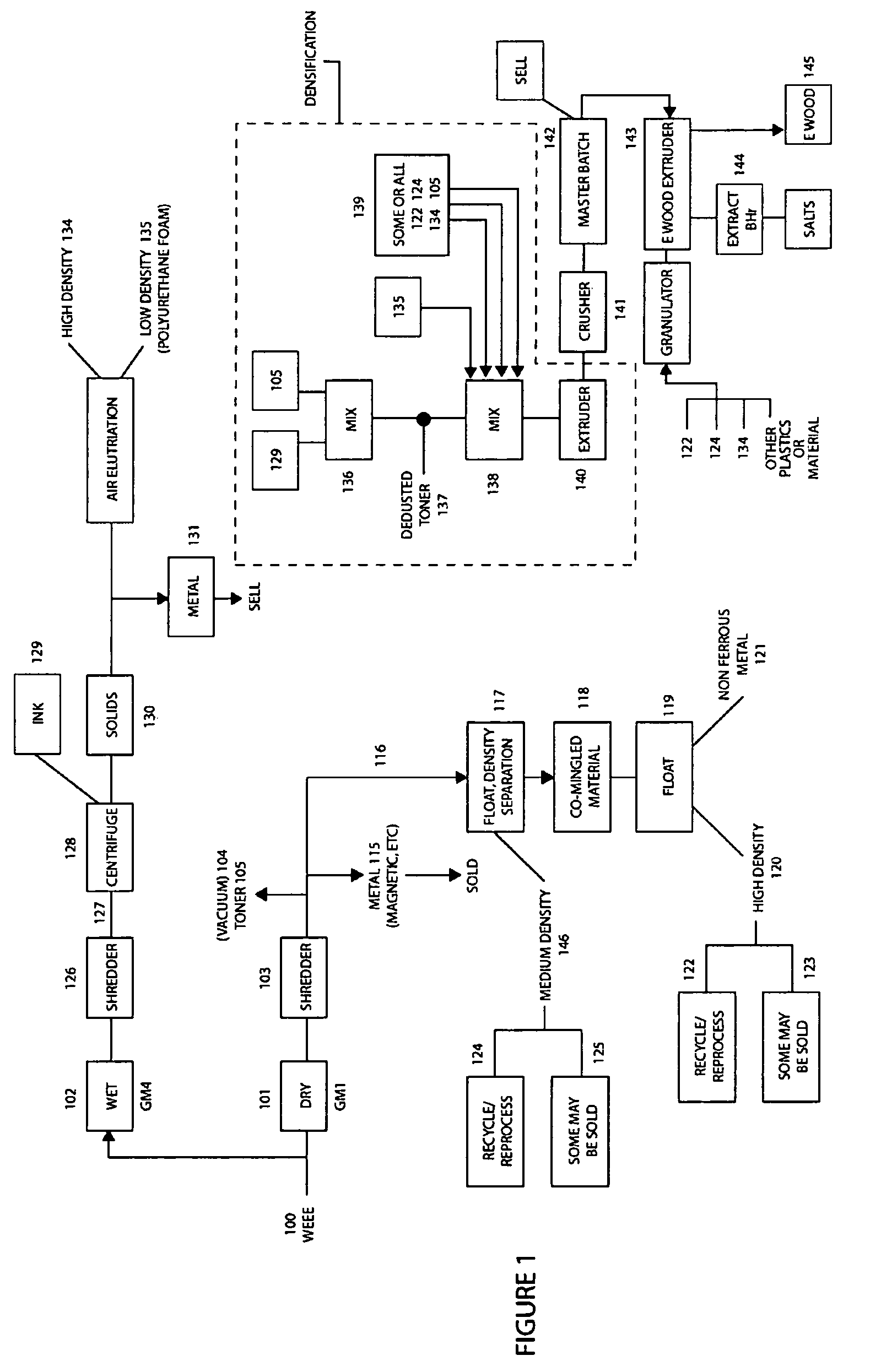

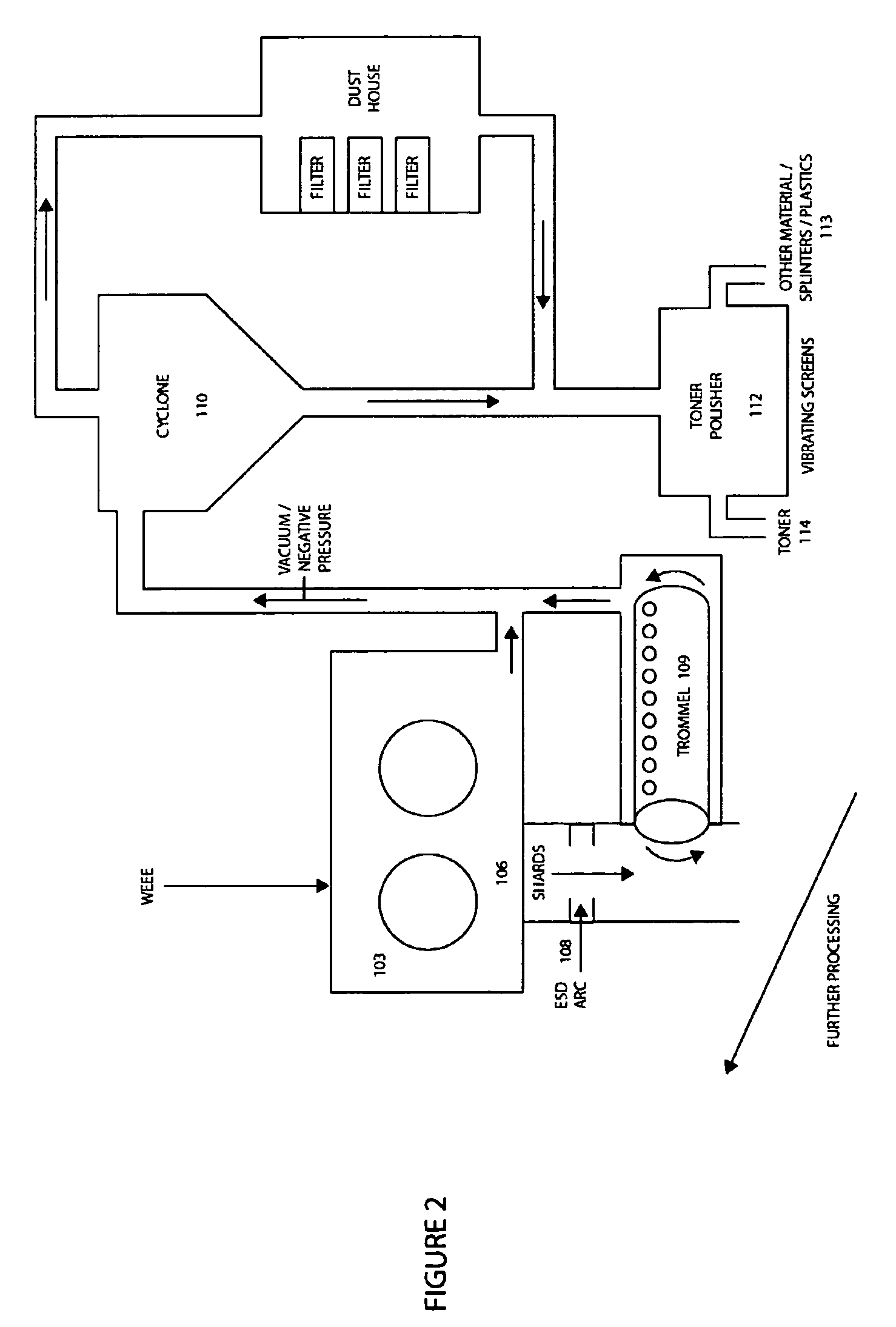

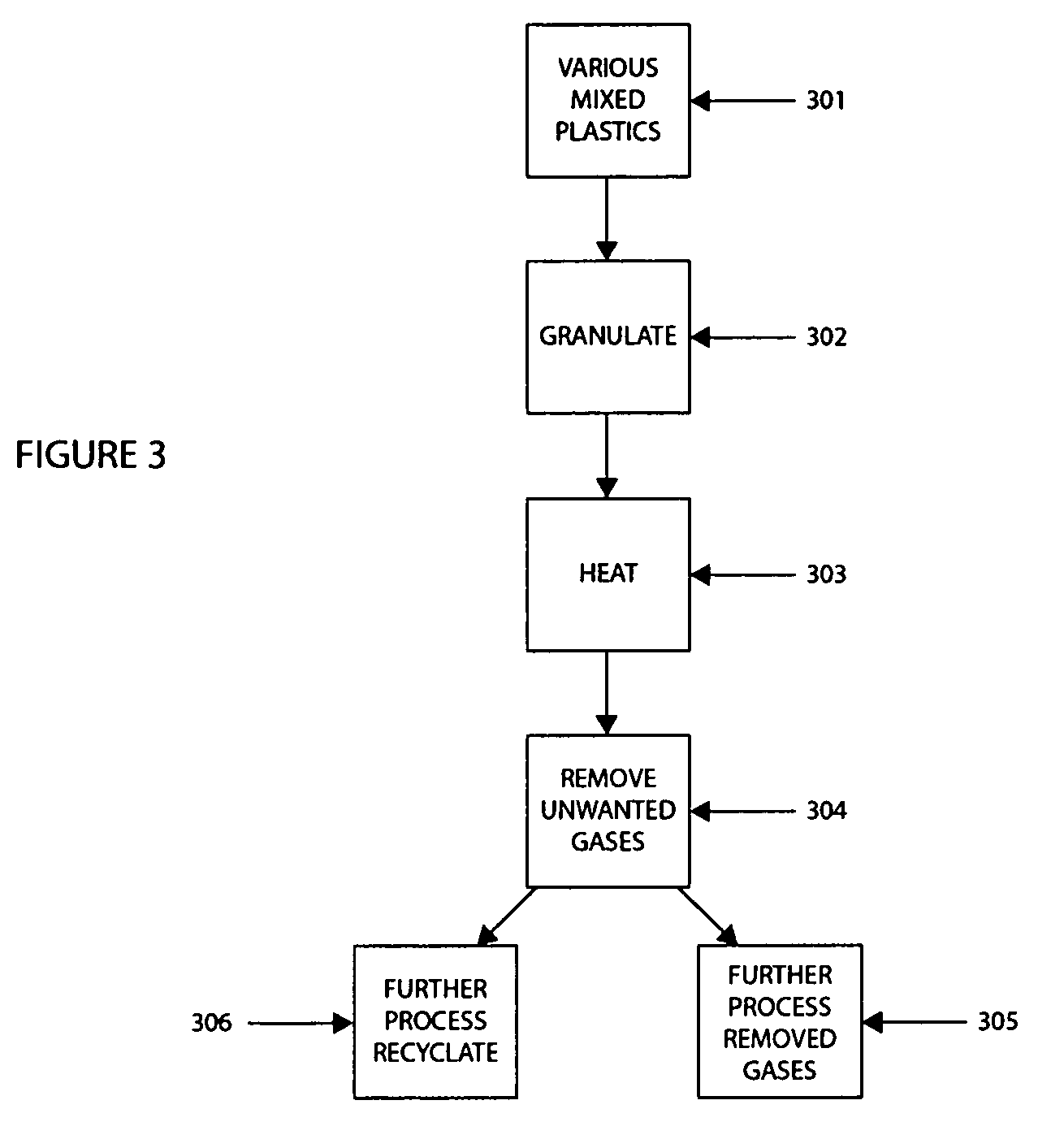

Method of recycling mixed streams of ewaste (WEEE)

The present invention relates to the recycling of waste electrical and electronic equipment (WEEE). Preferably, the present invention relates to the substantial recycling of all material forming the WEEE, thus providing substantially zero landfill. In yet another form, the invention relates to an additive and / or method of providing an additive. In still another form, the invention relates to recycling ink, toner, and / or PU foam from imaging consumables, forming part of the WEEE. In another form, the invention relates to the recycling of plastic materials containing flame retardants, including the recycling of plastics materials, such as plastics materials containing brominated flame retardants generally based on styrenics (e.g. PS, HIPS, ABS, PPO / PS, PPE / PS, ABS / PC) and polyamides (Nylon 6, nylon 6,6, nylon 12) and other engineering plastics such as polyacetal, polycarbonate, PET, PBT, liquid crystal polymers.

Owner:CLOSE THE LOOP TECH

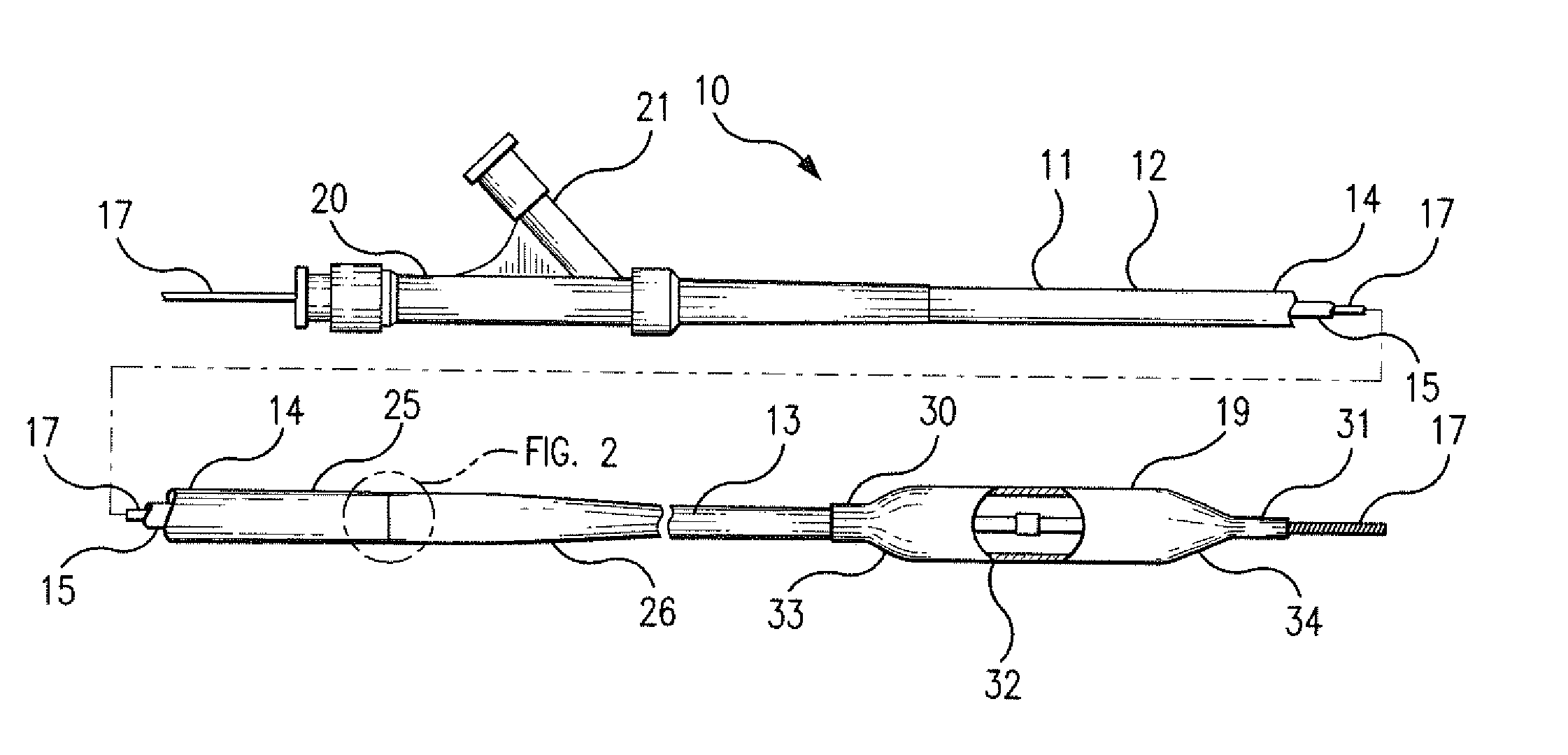

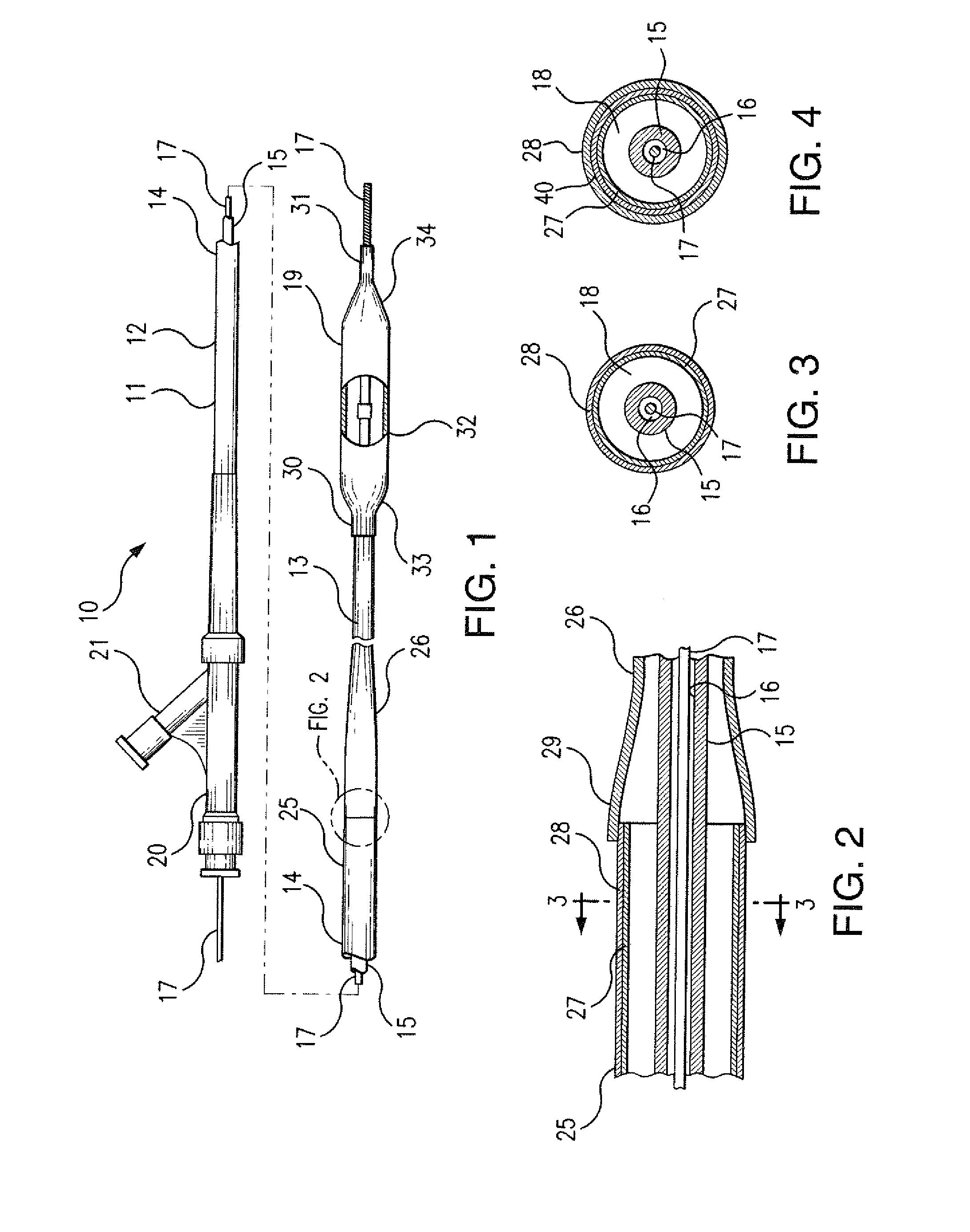

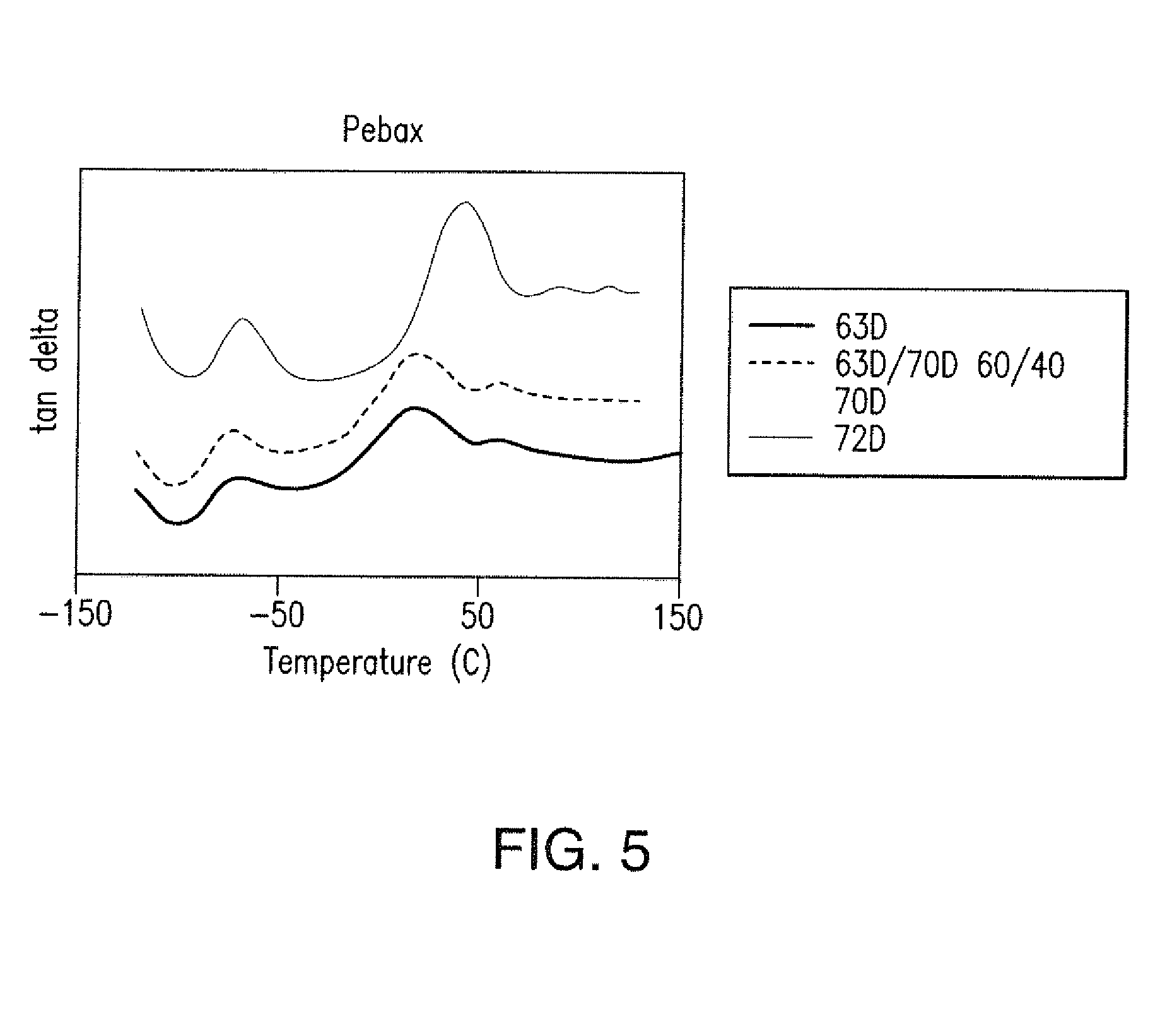

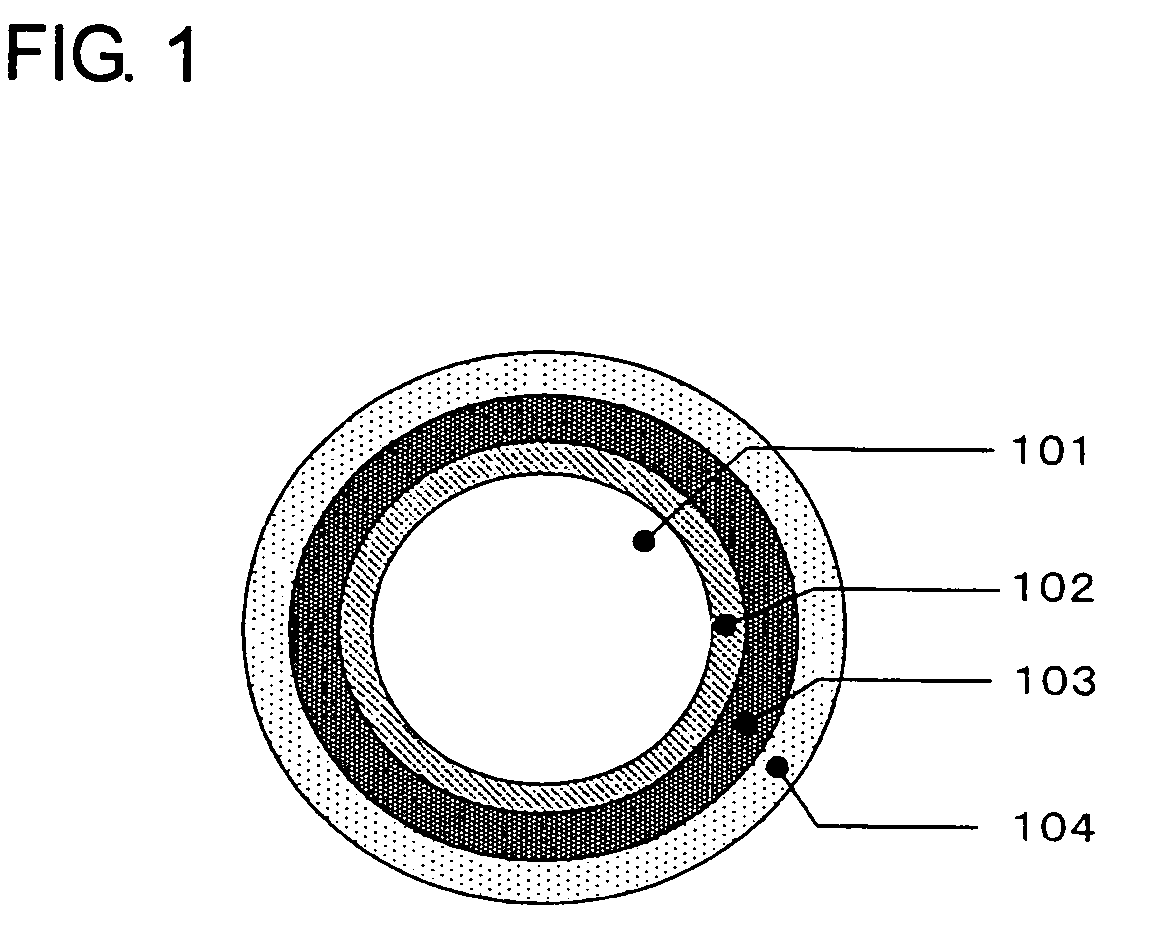

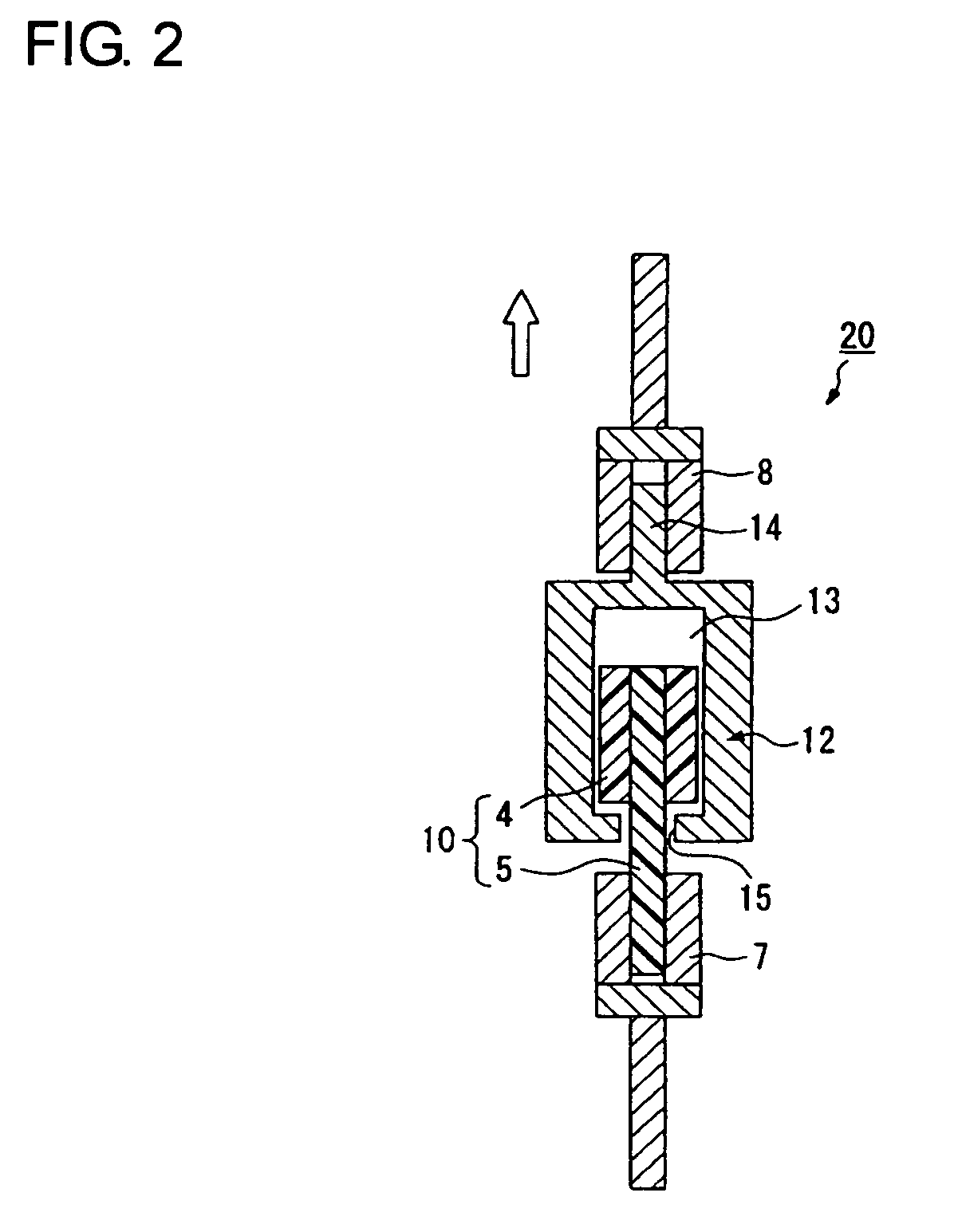

Catheter Shaft and Method of Forming Same

InactiveUS20140276401A1Increase thrustBalloon catheterSurgeryPolytetramethylene terephthalateHeat deflection temperature

Elongate, flexible catheter includes an elongated shaft having a proximal end, a distal end, and a lumen defined therein. The shaft includes a tubular member having an outer layer and an inner layer. The outer layer includes a first polymer selected from the group consisting of nylon 12, polyether block amide, and combinations thereof. The inner layer includes a second polymer having a heat deflection temperature greater than about 53° C. selected from the group consisting of nylon 11, nylon 6, nylon 6,6, nylon 6,12, polyamide-imide, polyetherimide, polypropylene, polyethylene terephthalate, polybutylene terephthalate, polyethereetherketone, and combinations thereof. Method of making an elongate, flexible catheter is also provided.

Owner:ABBOTT CARDIOVASCULAR

Stone-plastic composite powder for laser sintering 3D manufacturing technology and preparation method of stone-plastic composite powder

ActiveCN103881371ALow costReduce consumptionAdditive manufacturing apparatus3D object support structuresManufacturing technologyNylon 12

The invention provides stone-plastic composite powder for laser sintering 3D manufacturing technology and a preparation method of the stone-plastic composite powder, and relates to composite powder for laser sintering 3D manufacturing technology as well as a preparation method and a use method of the composite powder. The stone-plastic composite powder provided by the invention is used for solving the technical problems of low strength of a sintered workpiece prepared from a wood-plastic composite material and a rice husk powder-hot melt adhesive composite material for the existing laser sintering, and high cost of a sintered workpiece prepared from metal powder or ceramic powder. The stone-plastic composite powder for laser sintering 3D manufacturing technology provided by the invention is composed of nylon 12 powder and limestone powder. The preparation method comprises the steps of adding the nylon 12 powder and the limestone powder into a ceramic grinding tank for grinding and mixing to obtain the stone-plastic composite powder. During laser sintering, a laser beam scans a sub-region in a manner of scanning on a horizontal plane, and the laser power is 15-20 W, so that the laser power is low. The stone-plastic composite powder provided by the invention is applied to the laser sintering 3D manufacturing field.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

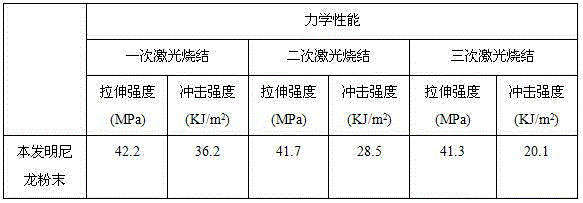

Nylon powder composition for 3D printing, and preparation method and application thereof

ActiveUS20170253702A1Improve liquidityImprove accuracyAdditive manufacturing apparatusAdditive manufacturing with solidsAntioxidantMechanical property

This invention relates to a high molecular weight nylon powder composition for 3D printing, its preparation method and use. The composition comprises: 100 parts by weight of high-viscosity nylon powder, 1-5 parts by weight of a flow agent, and 0.1-1 parts by weight of an antioxidant; the high-viscosity nylon powder is one or more selected from nylon 6, nylon 66, nylon 11, nylon 12, nylon 612 and nylon 610; or the powder composition is obtained via polymerization reaction of the raw materials comprising the following components, based on the weight parts of lactam monomers or amide monomers: 100 parts by weight of lactam monomers or amide monomers, 0.005-1 parts by weight of a catalyst, and 0.1-1 parts by weight of an antioxidant. The high molecular weight nylon powder composition prepared in the present invention has a particle diameter in the range of 20-100 micrometers, good powder spreading performance, and is suitable for the 3D printing process, and the product of the high molecular weight nylon powder composition has good mechanical properties, good dimensional stability and low manufacturing cost.

Owner:INST OF CHEM

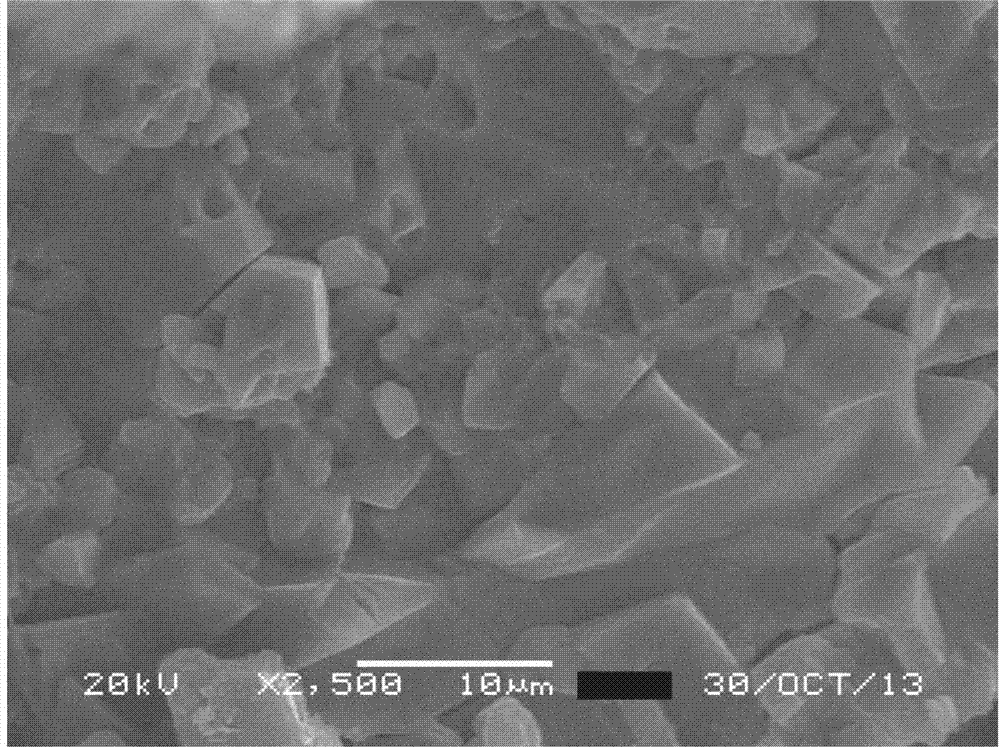

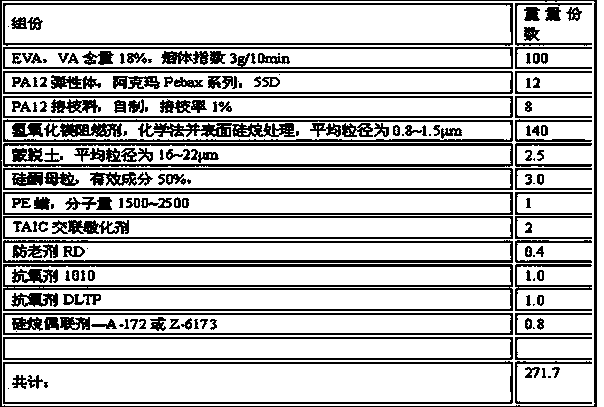

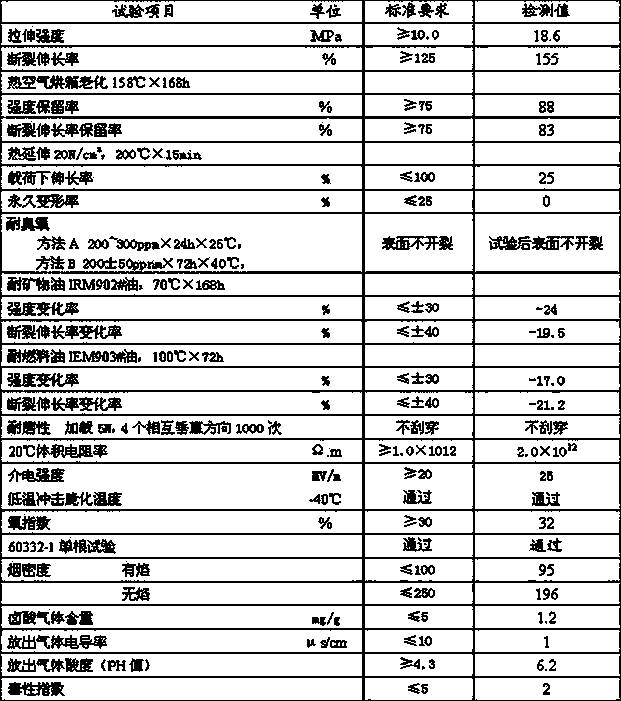

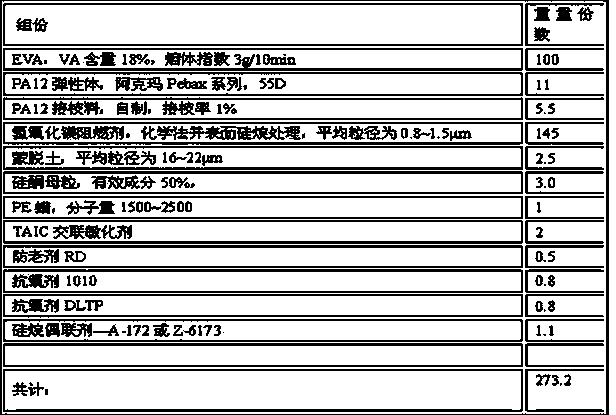

125 DEG C irradiation crosslinking oil-resistant low-smoke halogen-free flame retardant cable material and preparation method thereof

ActiveCN103937086AGood oil resistanceImprove wear resistancePlastic/resin/waxes insulatorsInsulated cablesElastomerChemistry

The invention discloses a 125 DEG C irradiation crosslinking oil-resistant low-smoke halogen-free flame retardant cable material which is characterized in that a raw material formula consists of the following materials in parts by weight: 100 parts of ethylene vinyl acetate copolymer EVA, 5-15 parts of nylon 12 elastomer, 4-12 parts of nylon 12 grafted maleic anhydride copolymer, 120-165 parts of a magnesium hydrate flame retardant, 1.5-6.0 parts of a montmorillonoid synergic flame retardant, 2-4 parts of silicone master batch, 0.8-1.2 parts of a lubricant, 2-3 parts of a crosslinking sensitizing agent triallyl isocyanuric acid ester TAIC, 0.7-1.5 parts of a silane coupling agent, 0.7-1.2 parts of an antioxidant 1010, 0.7-1.2 parts of an antioxidant DLTP and 0.3-0.8 part of an anti-aging agent RD. By adopting the scheme, a halogen-free flame retardant insulating mixture material and a sheath mixture material which meet the EN50264 standard can be produced, the materials are good in comprehensive properties such as oil resistance, wearing resistance, flame retardancy, a machining process of a locomotive cable is simplified, and social values are achieved when the oil-resistant locomotive cable is used.

Owner:中广核三角洲(江苏)塑化有限公司

Polyamide-based composition for flexible pipes containing oil or gas

A composition comprising by weight:[0001]70 to 96% of at least one polyamide chosen from PA-11, PA-12, aliphatic polyamides resulting from the condensation of an aliphatic diamine having from 6 to 12 carbon atoms and an aliphatic diacid having from 9 to 12 carbon atoms, and 11 / 12 copolyamides having either more than 90% of nylon-11 units or more than 90% of nylon-12 units;[0002]4 to 10% of a plasticizer;[0003]0 to 25% of an NBR or H-NBR elastomer; and[0004]the sum of the amount of plasticizer and the amount of elastomer is between 4 and 30%;can be manufactured by melt-blending the various constituents using standard techniques for thermoplastics. The composition is particularly useful for pipes used in the operation of offshore oil and gas fields. They exhibit very good ageing resistance. They are also useful for simpler pipes in motor vehicles, these compositions withstanding the ageing caused by the temperature under the bonnet of motor vehicles and the nature of the fluids transported. Pipes which comprise at least one layer of this composition are useful for offshore uses and for simpler pipes used in motor vehicles.

Owner:ATOFINA

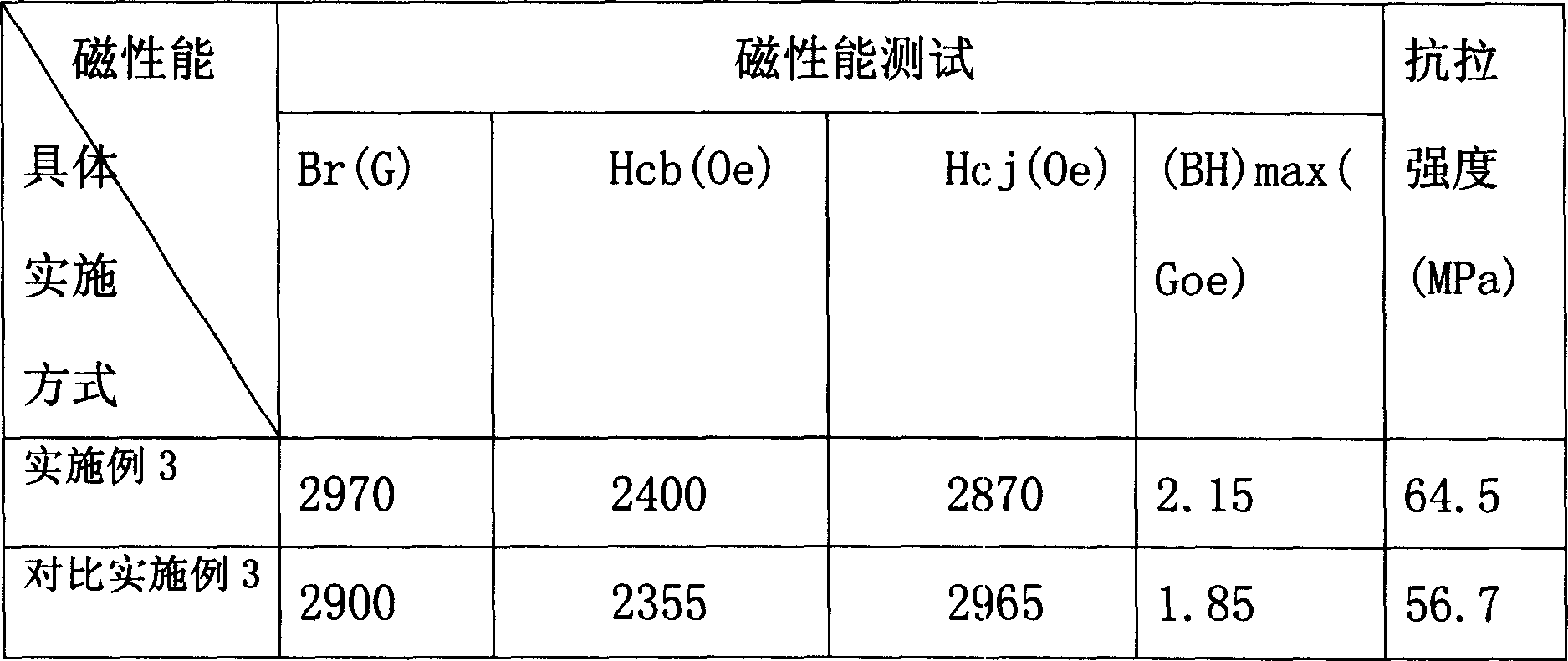

Injecting ferrite permanent magnet material formula

ActiveCN1645526AImprove flow magnetismIncrease usage contentInorganic material magnetismNylon 12Additive ingredient

The invention composed of following component: ferrite magnetic powder, 80.0wt%-95.0wt%; nylon 12, 4.0wt%-20.0wt%; additive, 0.01wt%-3.0wt%; Its feature is:The additive consists of organic outside lubricant and inorganic inner lubricant, which can increase the fluidity of ingredients in tube, reduce decompose and oxidation of nylon 12 and palletizing temperature.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

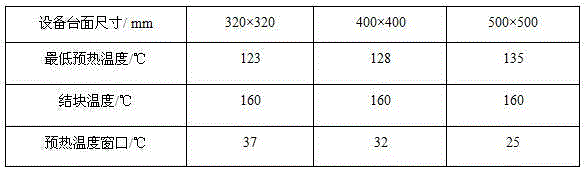

Low-temperature nylon powder material for selective laser sintering and preparation method thereof

ActiveCN104910616AReduced precision requirementsImprove recycling ratesAdditive manufacturing apparatusAdditive manufacturing with solidsSelective laser sinteringPolyethylene glycol

The invention relates to the technical field of polymer composites and particularly relates to a low-temperature nylon powder material for selective laser sintering. The low-temperature nylon powder material mainly comprises nylon 12 particles, dodecanedioic acid, double amino-terminated polyethylene glycol, deuterated trifluoroacetic acid, an antioxidant, a solvent, a nucleating agent, a plasticizer and a silane coupling agent. The low-temperature nylon powder material is prepared by the following steps: uniformly mixing the dodecanedioic acid and nylon 12 particles and putting into a reaction kettle; adding the double amino-terminated polyethylene glycol and deuterated trifluoroacetic acid into the reaction kettle; heating and starting stirring to obtain a product; putting the product together with the antioxidant, solvent, nucleating agent, plasticizer and silane coupling agent into the reaction kettle, and closing the kettle with a cover; vacuumizing the reaction kettle and introducing nitrogen displacement for protection; starting stirring and reducing the temperature of the kettle body to room temperature; taking out the materials, drying and performing ball milling; and drying the powder to obtain powder with good sphericity and fluidity. The low-temperature nylon powder material provided by the invention has the characteristics of low preheating temperature, wide preheating window, good aging resistance and adaptability to table boards of various specifications.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

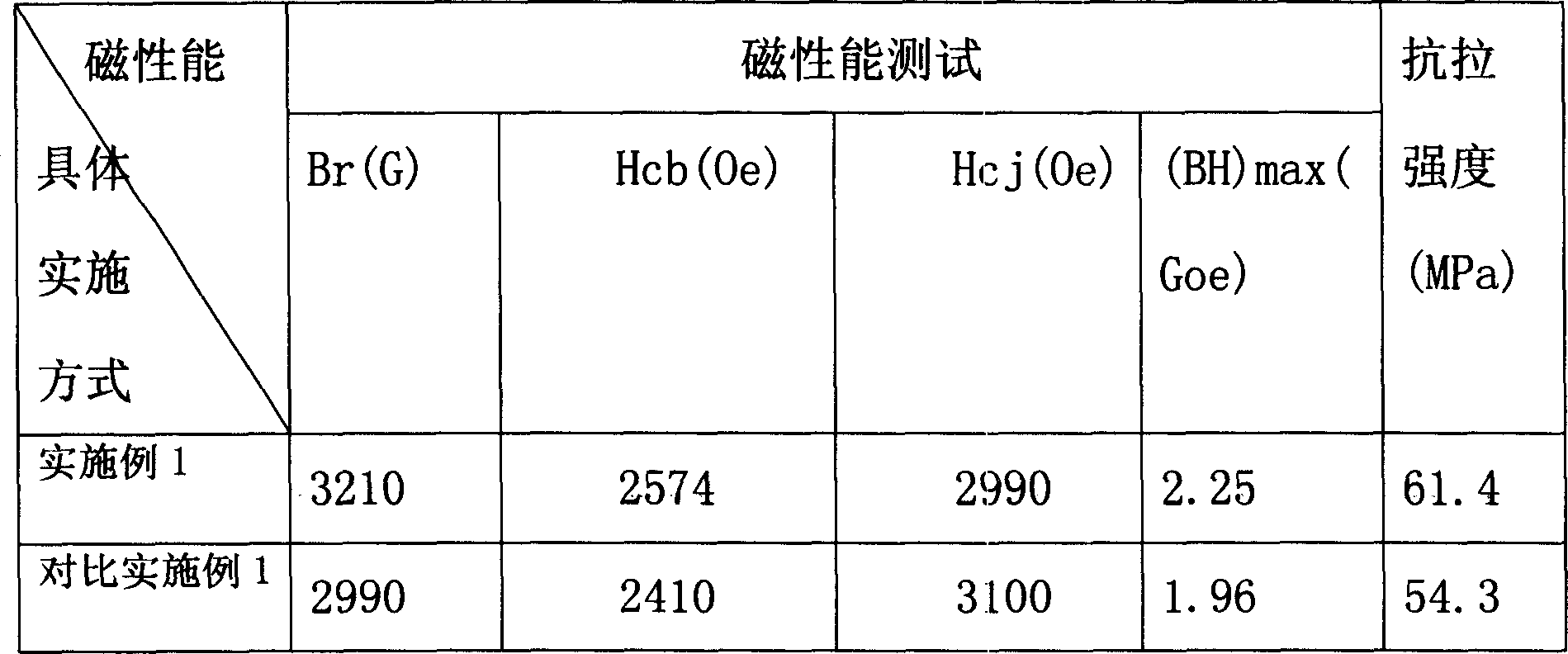

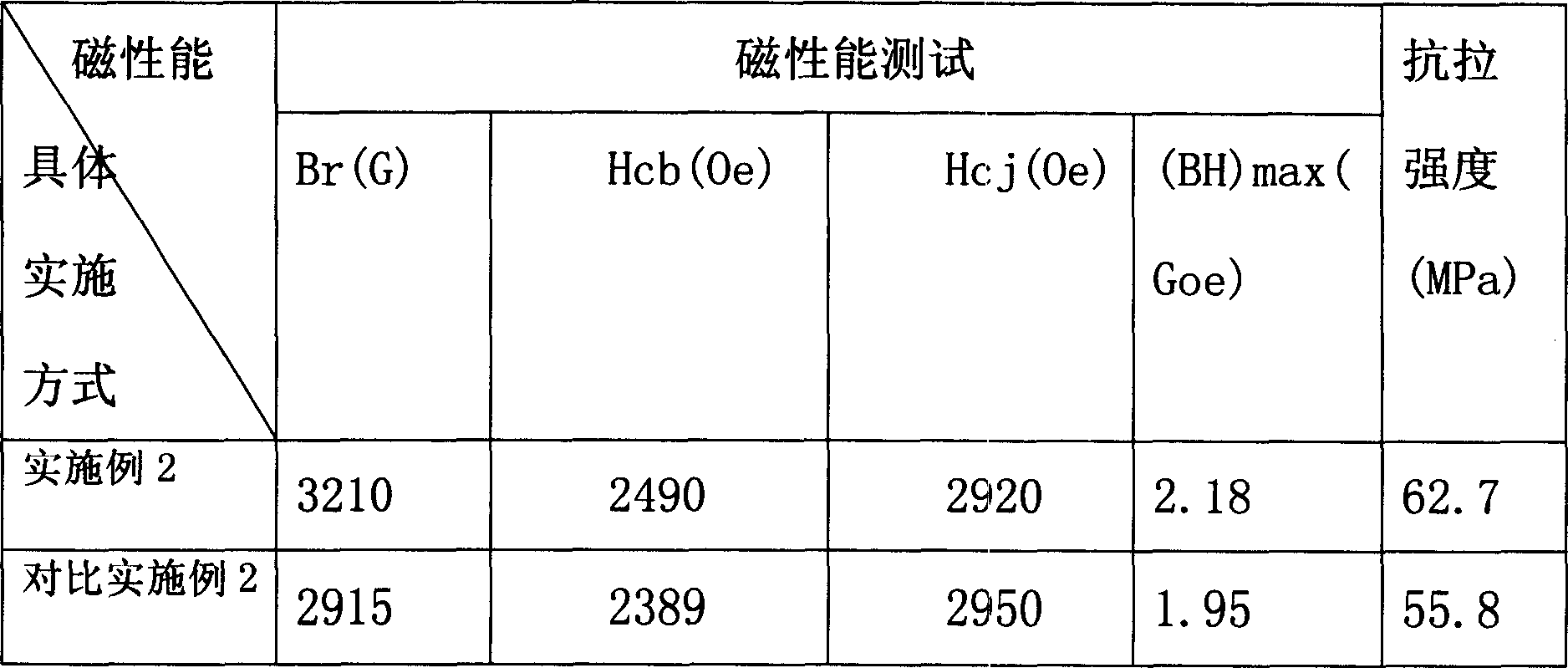

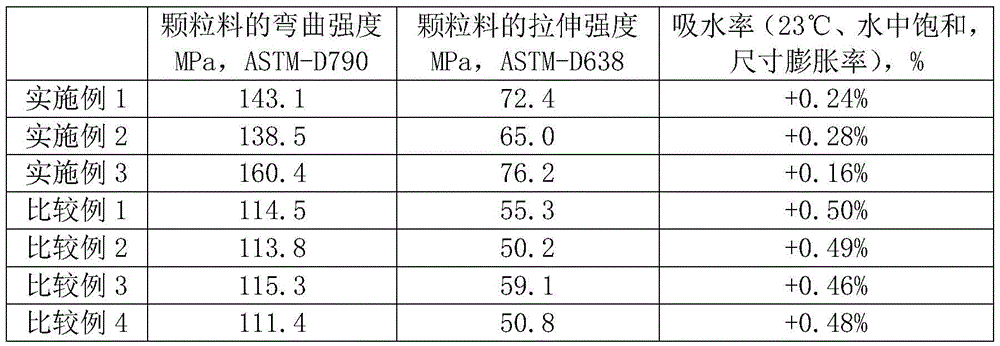

Granular material for injection-molded nylon-12-permanent magnetic ferrite and preparation method of granular material

The invention discloses a granular material for injection-molded nylon-12-permanent magnetic ferrite and a preparation method of the granular material. The granular material is prepared from the following components including permanent magnetic ferrite magnetic powder, nylon12, a reinforcing agent, a dispersant, a coupling agent and a lubricant through mixing granulation. The preparation method comprises specific steps as follows: (1), treatment of surfaces of the magnetic powder: the permanent magnetic ferrite magnetic powder is put into a powder mixing cylinder, and the dispersant and the coupling agent in a proper proportion are added; (2), addition of nylon12; (3), addition of the reinforcing agent and the lubricant; (4), granulation: the uniformly mixed nylon12 and permanent magnetic ferrite magnetic powder mixture is injected into a granulator for granulation. The granular material and the preparation method have the benefits as follows: by comparison with commercially available and universal granular materials for injection-molded nylon12-permanent magnetic ferrite, the bending strength and the tensile strength of the granular material can be improved by 20%-50%, and the granular material has high strength and high precision and can meet rigid requirements for injection-molded magnets for existing automobile motors, especially motors for high-grade new-energy powered automobiles and for high-grade household appliances.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

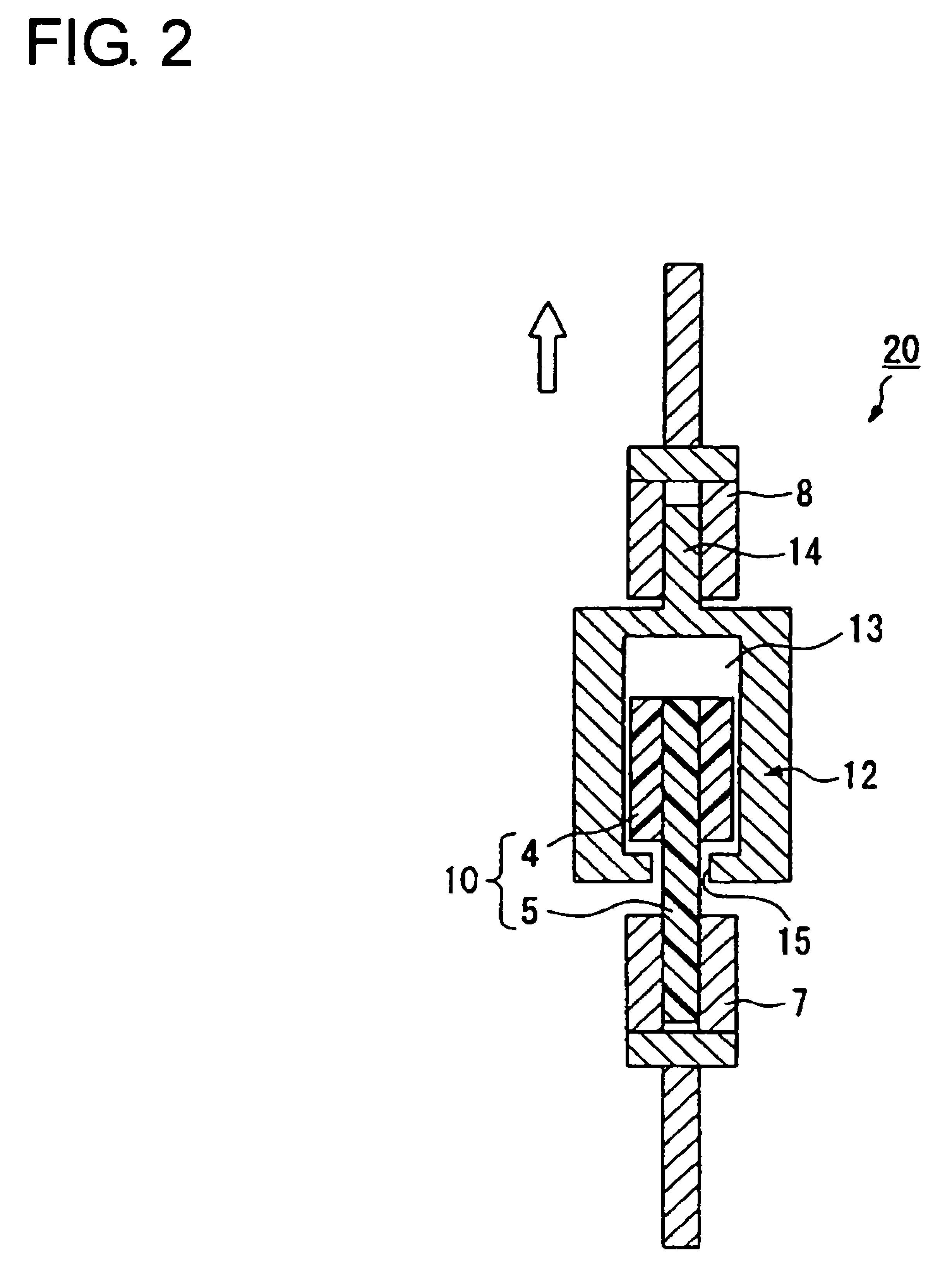

Plastic optical fiber cable and method of signal transmission using the same

ActiveUS20090279837A1Improve transmission lossExcellent long-term heat resistanceOptical fibre with multilayer core/claddingFibre mechanical structuresBare fiberPolymethyl methacrylate

A plastic optical fiber cable includes: a bare optical fiber including a core made of a poly(methyl methacrylate) or a copolymer including methyl methacrylate as a major component and a cladding layer including, at least in the outermost layer, a layer made of a certain fluorine-containing olefin-based resin; and a coating layer provided on the outer surface thereof. The coating layer includes a protective coating layer, a light blocking coating layer, and a functional coating layer, the layers being provided in the order mentioned from inner side. The protective coating layer is made of a certain resin material. The light blocking coating layer is made of a nylon-based resin including, as a major component, nylon 11 or nylon 12, the nylon-based resin containing monomer and oligomer compounds derived from the nylon-based resin in an amount of a certain range. The functional coating layer is made of a nylon-based resin composition having a crystalline melting point within a certain range, the nylon-based resin composition containing a certain amount of melamine cyanurate or bromine atoms and further containing a certain amount of inorganic chromatic pigments, or the layer is made of a nylon-based resin composition having a crystalline melting point of within a certain range and an oxygen transmission rate within a certain range.

Owner:MITSUBISHI CHEM CORP

Polyamide-based composition for flexible pipes containing oil or gas

A composition comprising by weight:70 to 96% of at least one polyamide chosen from PA-11, PA-12, aliphatic polyamides resulting from the condensation of an aliphatic diamine having from 6 to 12 carbon atoms and an aliphatic diacid having from 9 to 12 carbon atoms, and 11 / 12 copolyamides having either more than 90% of nylon-11 units or more than 90% of nylon-12 units;4 to 10% of a plasticizer;0 to 25% of an NBR or H-NBR elastomer; andthe sum of the amount of plasticizer and the amount of elastomer is between 4 and 30%;can be manufactured by melt-blending the various constituents using standard techniques for thermoplastics. The composition is particularly useful for pipes used in the operation of offshore oil and gas fields. They exhibit very good ageing resistance. They are also useful for simpler pipes in motor vehicles, these compositions withstanding the ageing caused by the temperature under the bonnet of motor vehicles and the nature of the fluids transported. Pipes which comprise at least one layer of this composition are useful for offshore uses and for simpler pipes used in motor vehicles.

Owner:ARKEMA PATENT

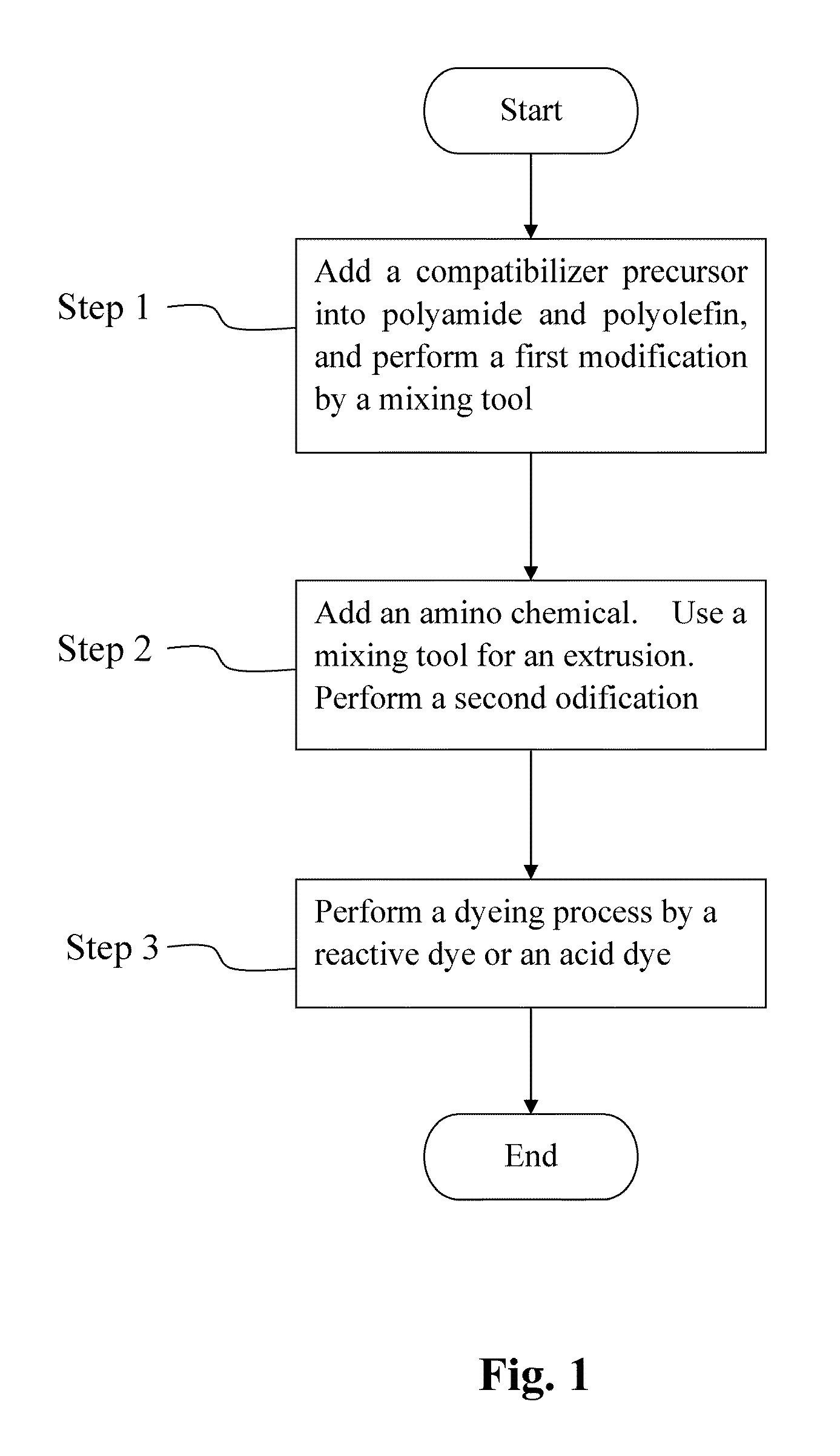

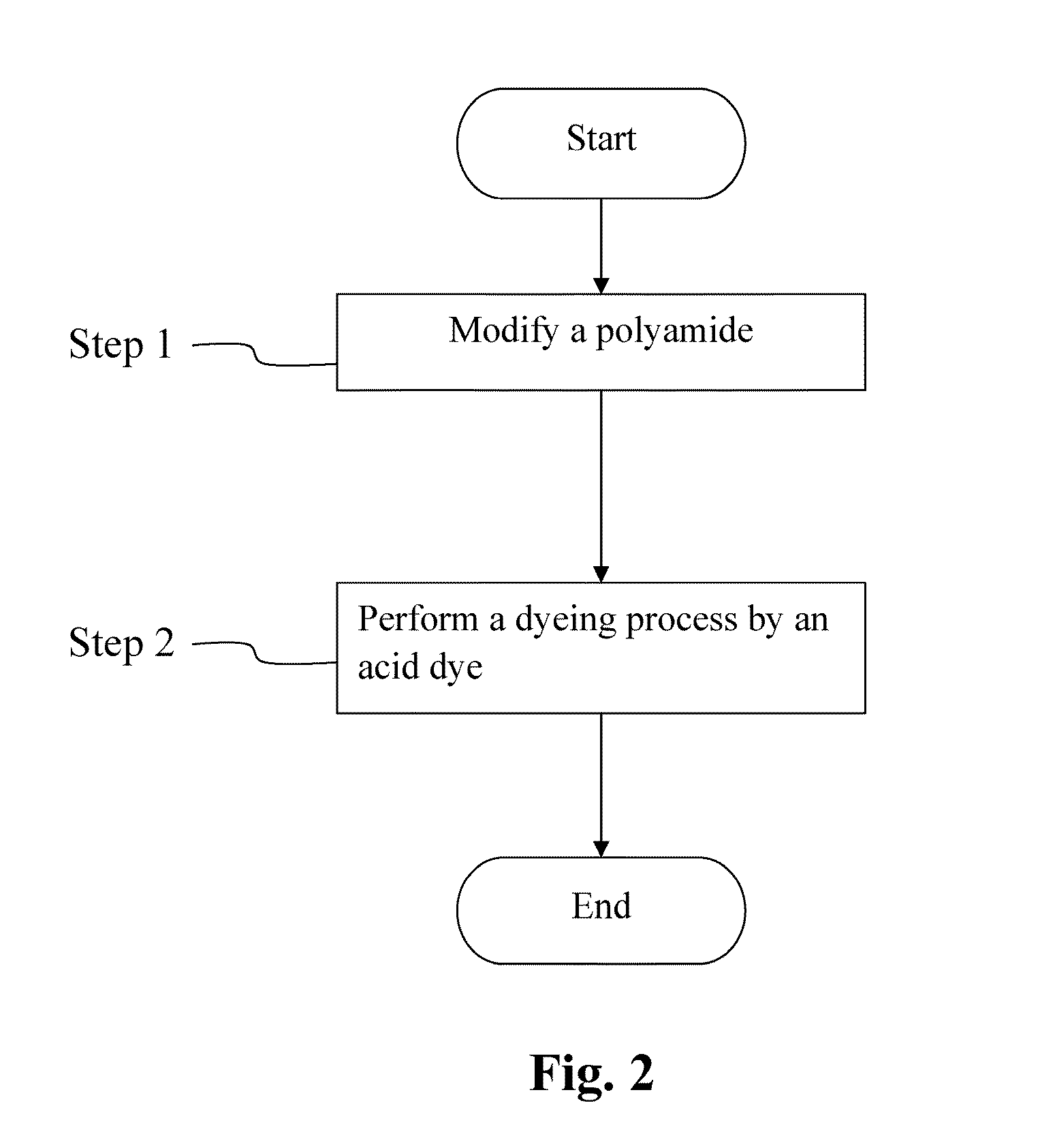

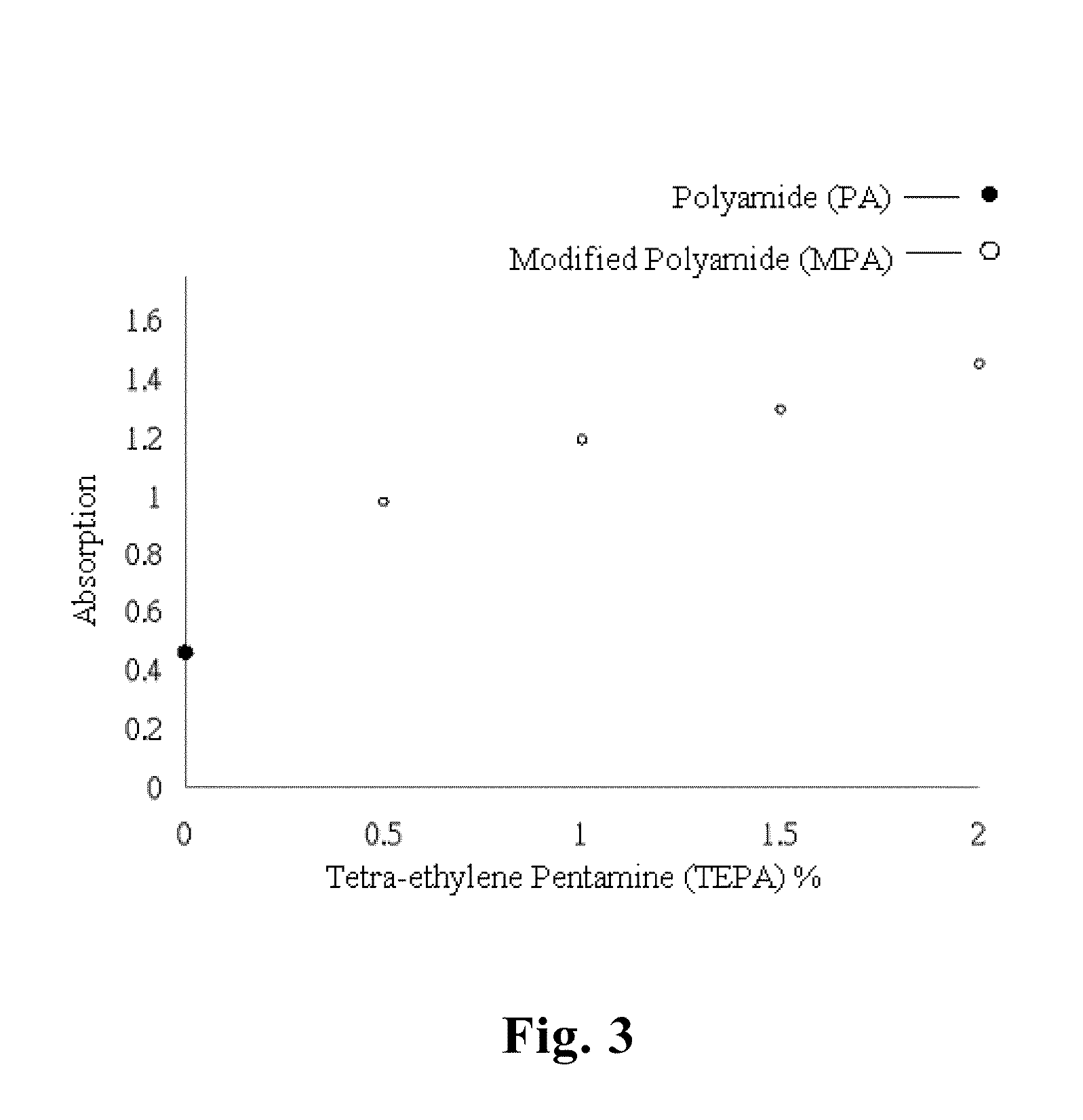

Deep Dyeing Process of Polyamide and Polyolefin

In a deep dyeing process of a polyamide (PA) including Nylon 4, Nylon 6, Nylon 46, Nylon 66, Nylon 7, Nylon 8, Nylon 9, Nylon 610, Nylon 1010, Nylon 11, Nylon 12, Nylon 13, Nylon 612, Nylon 9T, Nylon 13, MC Nylon, Nylon MXD6, and all polyamide derivatives, and a polyolefin (PO) including ethylene copolymer, propylene copolymer and their derivatives, a compatibilizer precursor is used for modifying the polyamide and polyolefin of an amino, hydroxyl or epoxy group containing chemical, and then a reactive dye and / or an acid dye is used for dyeing the polyamide and polyolefin, so that the dyed polyamide and polyolefin have excellent dye fastness, light fastness, rubbing fastness, washing fastness and low-temperature dyeability to overcome the shortcomings of conventional nylon fibers including a poor dyeing effect, a non-level dyeing quality, a high dyeing temperature (100° C. to 120° C.) and a high cost.

Owner:YEH JEN TAUT +1

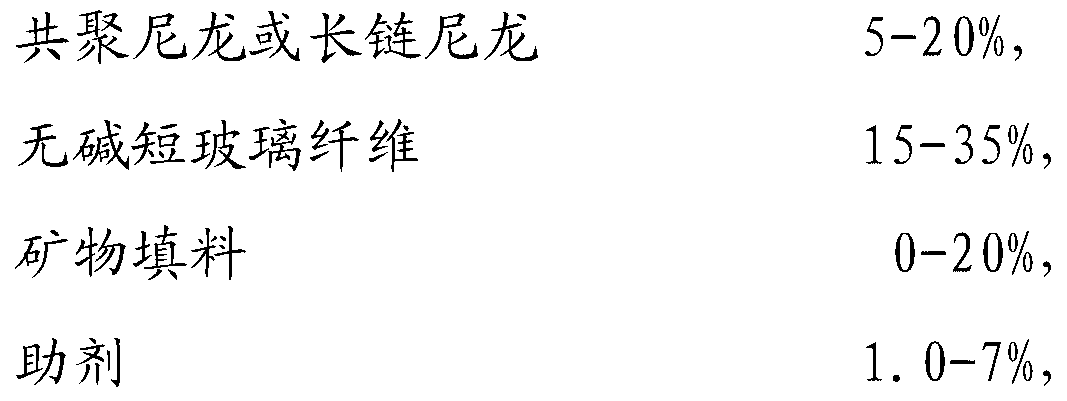

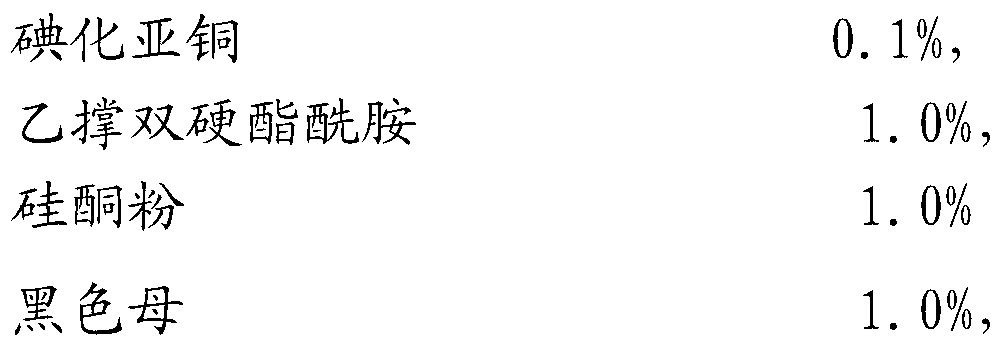

Special nylon 66 composition for automobile engine hood and preparation method thereof

The invention provides a special nylon 66 composition for an automobile engine hood. The composition contains the following components by weight percent: 18-79% of nylon 66, 5-20% of copolymer nylon or long-chain nylon, 15-35% of alkali-free short glass fiber, 0-20% of mineral filler and 1.0-7% of auxiliaries, wherein the copolymer nylon is a polymer which is prepared through reaction, dehydration and polymerization of two or more monomer units, contains an amide group and is selected from one of or the mixture of more of a nylon6 / 66 copolymer, a nylon 6 / 12 copolymer and a nylon 6 / 10 copolymer; and the long-chain nylon is a polymer which is prepared through polymerization of monomers with carbon contents greater than or equal to 10 in polymer monomer units and other monomer units, contains an amide group and is selected from one of or the mixture of more of a nylon 11, a nylon 12 and a nylon 1010. The invention provides the special nylon 66 composition for the automobile engine hood and a preparation method thereof. The composition has the beneficial effects that the composition has quite high impact resistance and super strength and excellent chemical properties and dimensional stability; and products have smooth and clean surfaces and are cheap.

Owner:辰东意普万新材料(广东)有限公司

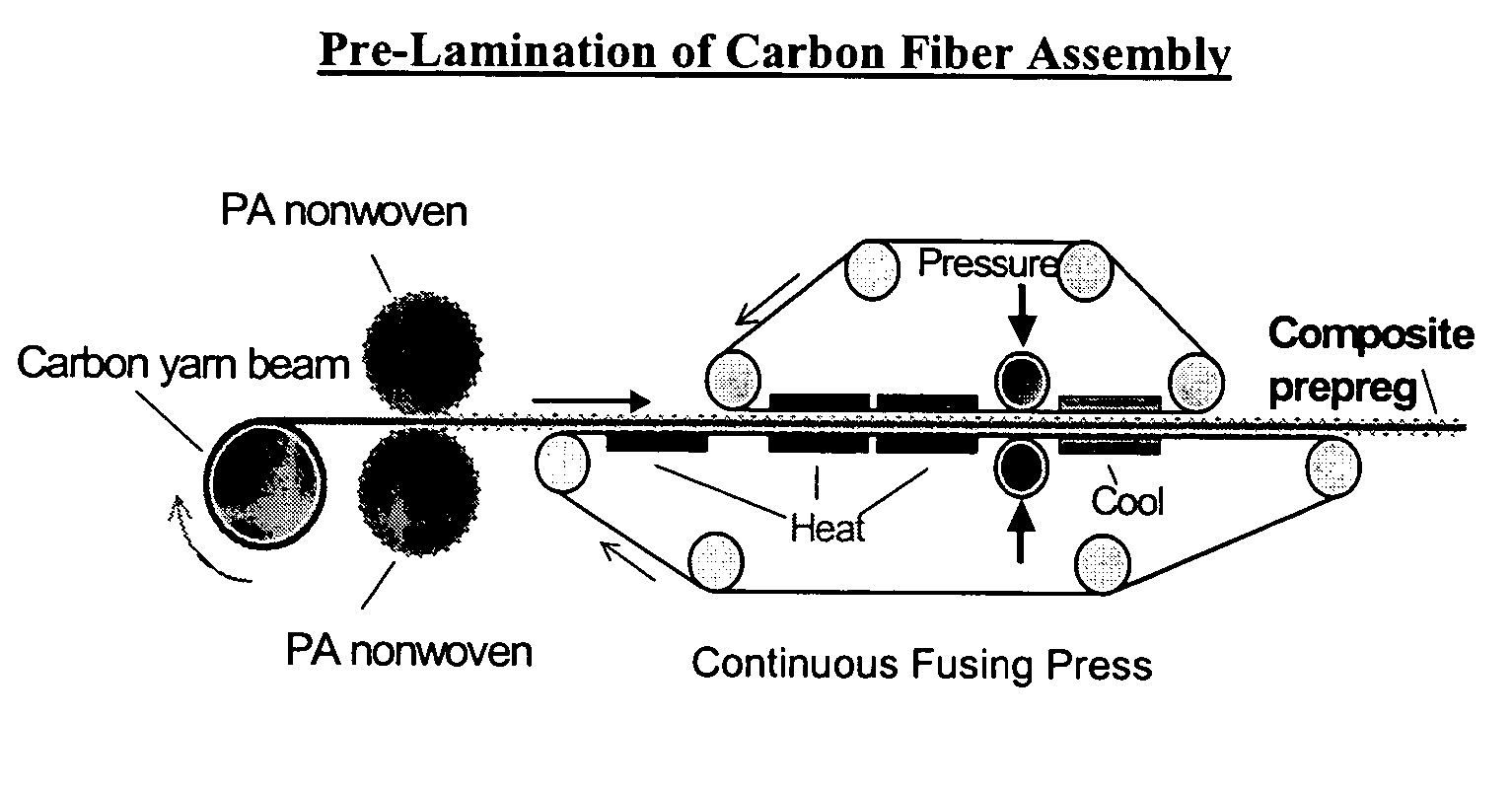

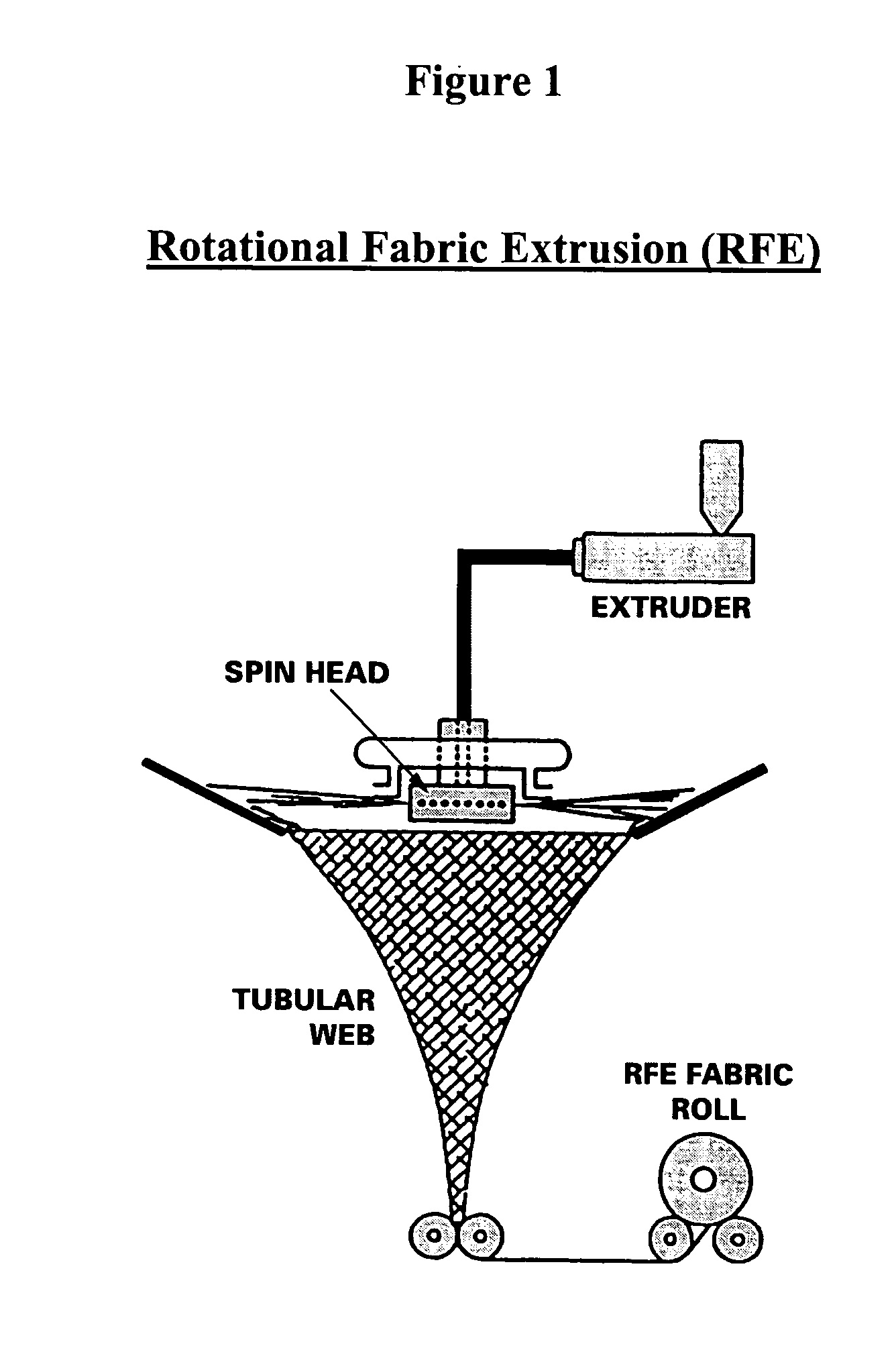

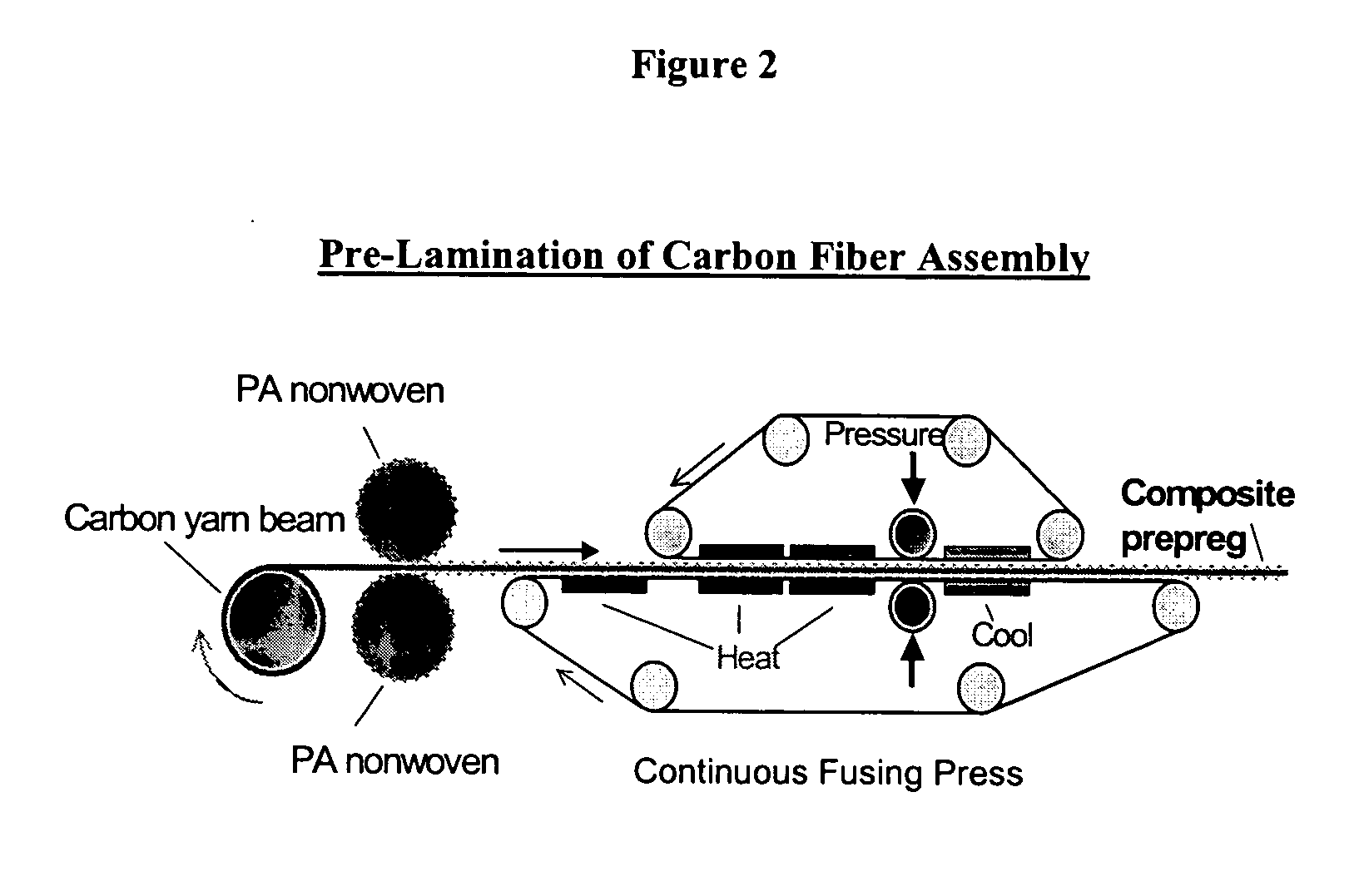

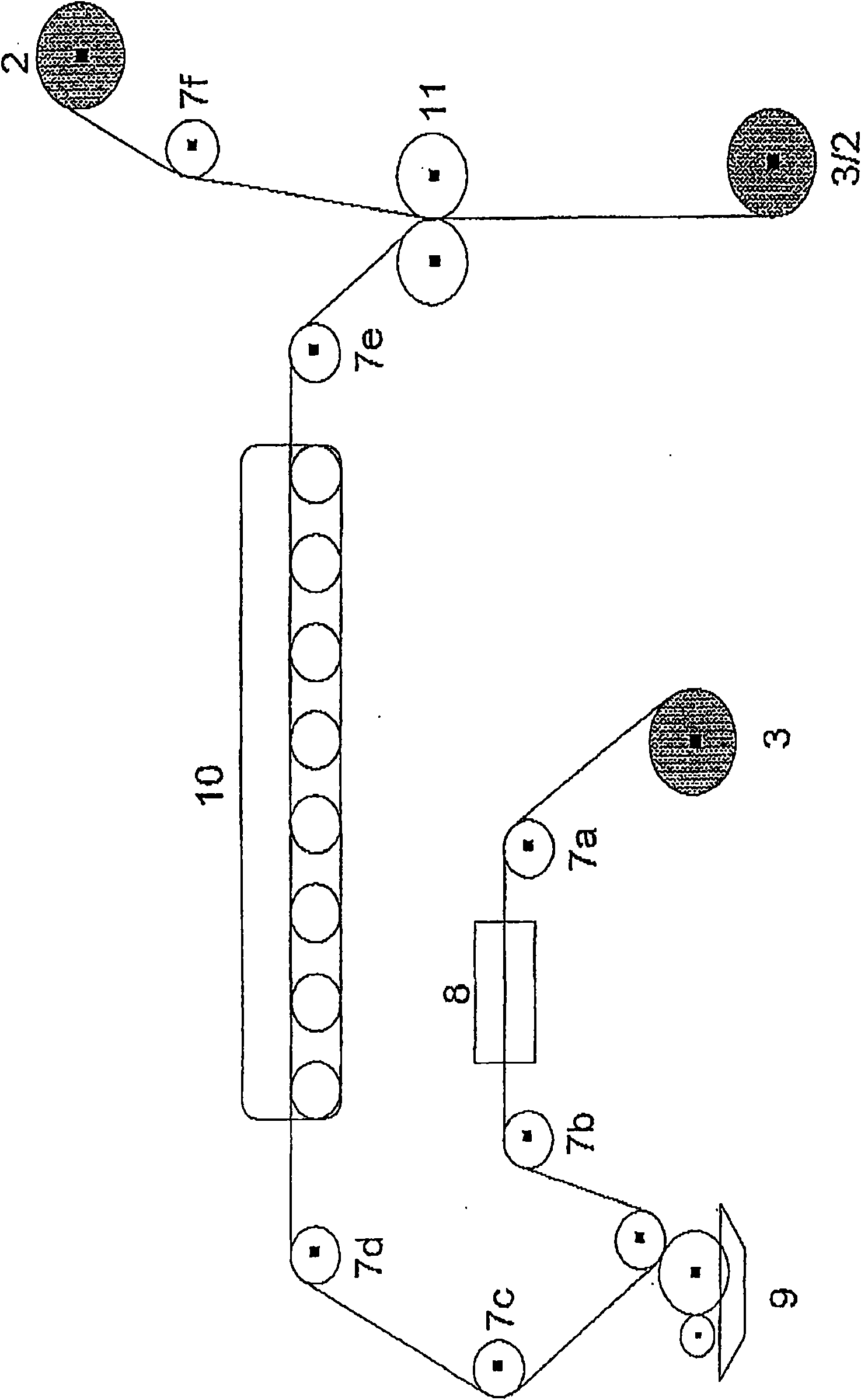

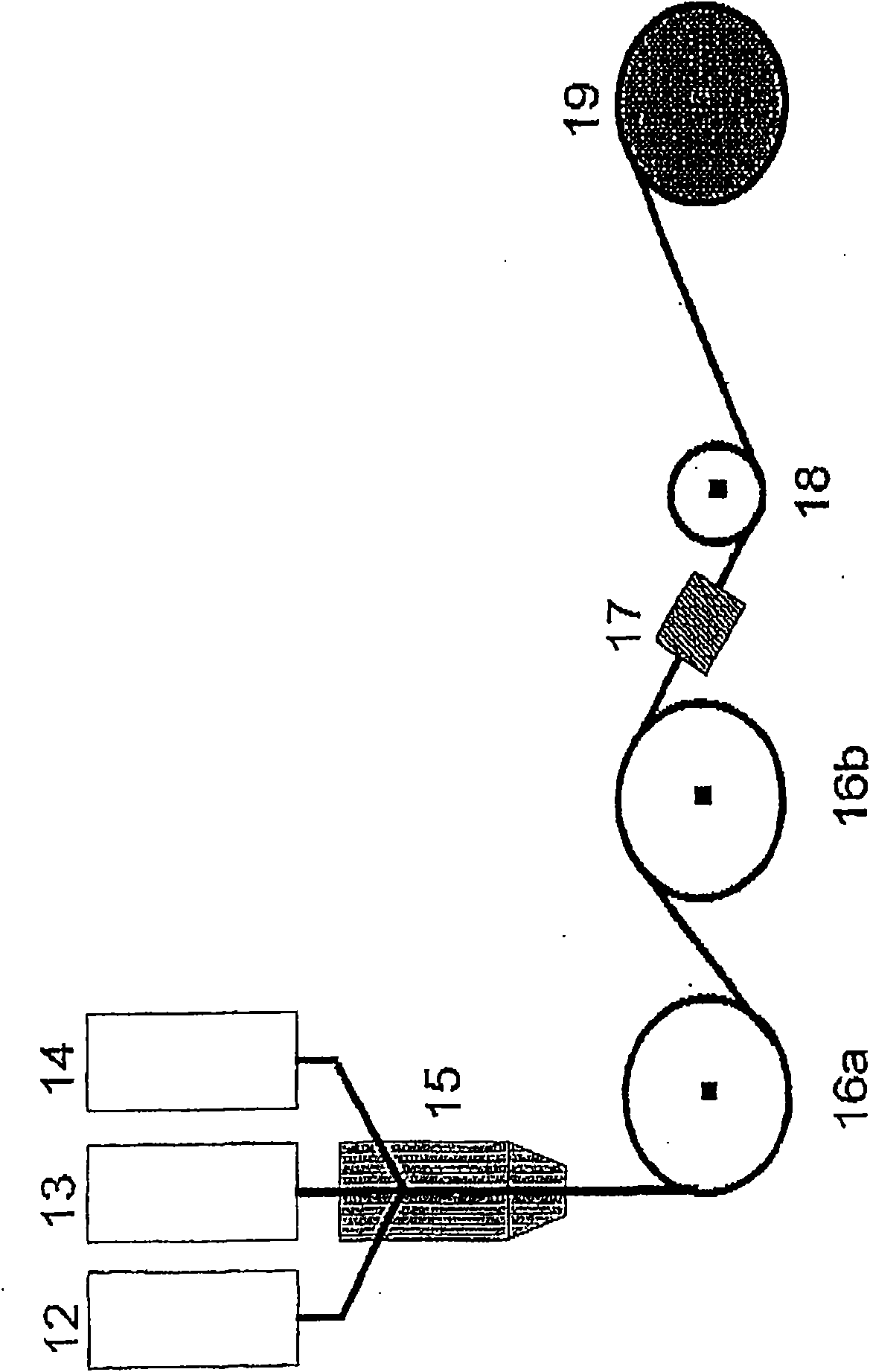

Thermoplastic nylon adhesive matrix having a uniform thickness and composite laminates formed therefrom

InactiveUS20050197026A1Enable productionSynthetic resin layered productsWoven fabricsThermoplasticAdhesive

Owner:KEUCHEL KENNETH +1

Plastic optical fiber cable and method of signal transmission using the same

ActiveUS8023789B2Improve transmission lossExcellent long-term heat resistanceOptical fibre with multilayer core/claddingFibre mechanical structuresPoly(methyl methacrylate)Engineering

Owner:MITSUBISHI CHEM CORP

Polyamide Composition Containing Ionomer

InactiveUS20130171394A1Poor salt stress crack resistanceExcellent salt stress crack resistanceLayered productsPretreated surfacesIonomerCrack resistance

Disclosed is a composition comprising polyamide comprising nylon-6 and optionally nylon-6,66, nylon-66, nylon-610, nylon-612, nylon-11, nylon-12 and an ionomer comprising an ethylene carboxylic acid copolymer, wherein 30 to 90% of the total carboxylic acid functionalities are neutralized to salts with a mixture of zinc cations and cations of a second metal selected from Group 1 of the Periodic Table of the Elements wherein the salts comprise from 20 to 90% equivalents of zinc. Articles prepared from the composition have improved salt stress crack resistance when exposed to zinc chloride solutions.

Owner:EI DU PONT DE NEMOURS & CO

Preparation method of enamel conductor environment-friendly type hot melt self-adhesive paint

InactiveCN101007924AAvoid it happening againImprove thermal stabilityInsulated cablesPolyamide coatingsSolubilitySolvent

The invention discloses a method for preparing environment-friendly thermo-activatable self-adhesive paint. It takes dimethylbenzene, natural methyl phenol and butyl alcohol as solvent, takes nylon 12, coploymerized nylon and phenoxy resin as main raw material, takes parting compound, levelling agent and lubricating agent as addictive auxiliary, prepares intermediate product by adding nylon 12 and ploymerized nylon into solvent, then adds additive auxiliary agent and phenoxy resin into solvent to produce final product. The invention is characterized in that it takes dimethylbenzene, natural methyl phenol and butyl alcohol as solvent, which avoids peculiar smell generation, all raw material possess good thermal stability and volatize lttle smell, which meets environment- friendly RoHS standard promulgated by European Union; the solubility between phenoxy resin and nylon is pretty good, and it is convenient for japanning in enamelcovered wire preparation process; the added proper addictive auxiliary ensures excellent demoulding for wire shaping and metal.

Owner:溧阳市佳禾电子材料有限公司

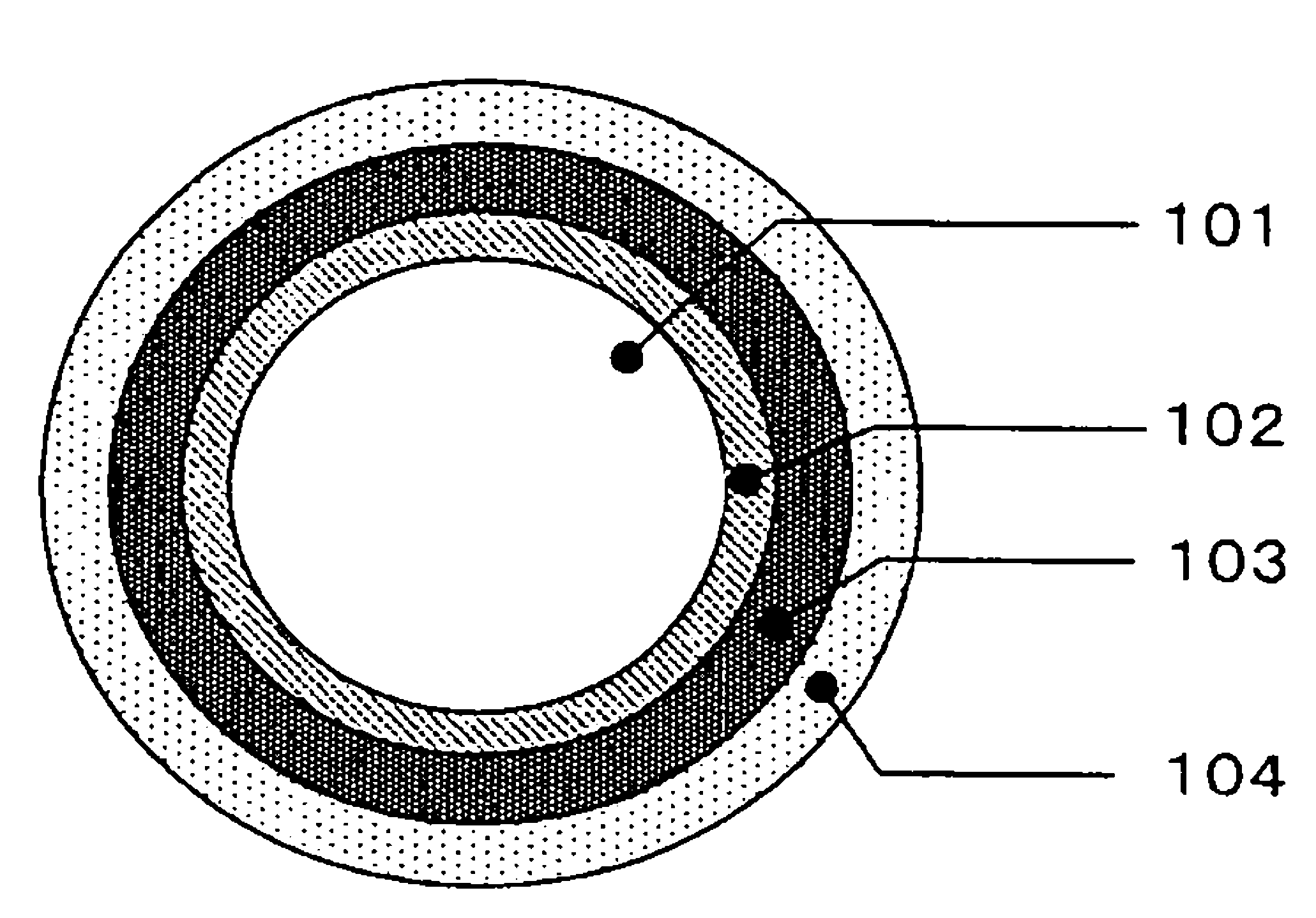

Polyamide-based multilayer tube for transferring fluids

ActiveUS20070059469A1Good resistance to fuelGood to to engine lubrication oilSynthetic resin layered productsFlexible pipesFluid transportNylon 12

The present invention relates to a multilayer tube comprising, in its radial direction from the outside inwards: an optional layer (1) made of nylon-11 or nylon-12 polyamide; an intermediate layer (2) comprising by weight, the total being 100%: 50 to 100% of at least one polyamide A1 of formula X,Y / Z or 6,Y2 / Z, in which X denotes residues of an aliphatic diamine having from 6 to 10 carbon atoms, Y denotes residues of an aliphatic dicarboxylic acid having from 10 to 14 carbon atoms, Y2 denotes residues of an aliphatic dicarboxylic acid having from 15 to 20 carbon atoms, Z denotes at least one unit chosen from residues of a lactam, residues of an α,Ω-aminocarboxylic acid, the unit X1,Y1, in which X1 denotes residues of a diamine and Y1 denotes residues of a diacid, the weight ratios Z / (X+Y+Z) and Z / (6+Y2+Z) being between 0 and 15%, and 0 to 50% of nylon-11 or nylon-12 polyamide; an optional layer (3) made of nylon-11 or nylon-12 polyamide, with the condition that at least one of the layers (1) and (3) is present; the layers being successive and adhering to one another, the inner layer being the layer in contact with the fluid transported.

Owner:ARKEMA FRANCE SA

High barrier laminated body

ActiveUS20090269533A1Improve compatibilityIncrease flexibilitySynthetic resin layered productsFlexible pipesCarboxylic acidNylon 11

A laminated body having a thermoplastic resin layer (I) and a polyamide resin layer (II) which is made of nylon 11 and / or nylon 12. The thermoplastic resin layer (I) includes 100 parts by weight of a polyamide resin composition (A) and 0.1 to 10 parts by weight of a carbodiimide compound (B) having two or more carbodiimide groups. The polyamide resin composition (A) contains a polyamide resin (a-1) having diamine units 70 mol % or more of which are derived from m-xylylenediamine and dicarboxylic acid units 70 mol % or more of which are derived from a C4 to C20 α,ω-linear aliphatic dicarboxylic acid and a nylon 12 and / or nylon 11 component (a-2) in an amount of 5 to 95% by weight of the component (a-1) and 95 to 5% by weight of the component (a-2) each based on a total weight of the components (a-1) and (a-2). The laminated body is excellent in the barrier property, peeling resistance and mechanical properties such as strength, impact resistance and elongation, particularly in the barrier property to alcohol-containing fuels.

Owner:MITSUBISHI GAS CHEM CO INC

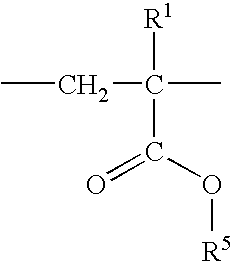

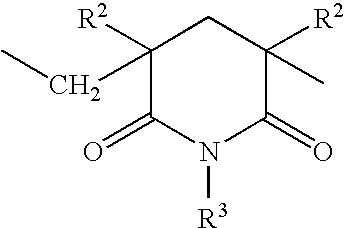

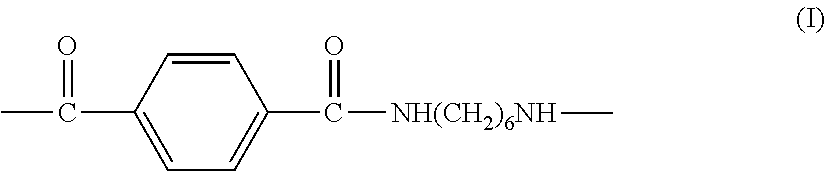

Polyamide composition containing ionomer

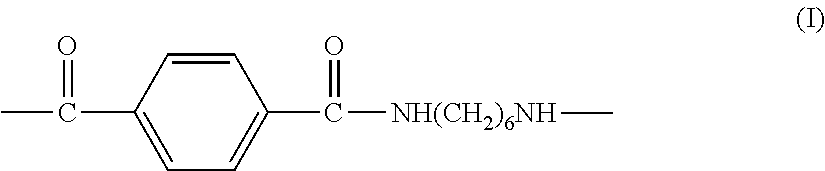

Disclosed is a composition comprising polyamide comprising nylon-6 / 12 or a polyamide comprising a first repeat unit of formula (I)and a second repeat unit of formula (II)—C(O)(CH2)nC(O)NH(CH2)6NH— (II);wherein n is an integer selected from 8, 10, 12, or 14, and optionally nylon-6,66, nylon-66, nylon-610, nylon-612, nylon-11, nylon-12 and an ionomer comprising an ethylene carboxylic acid copolymer, wherein 30 to 90% of the total carboxylic acid functionalities are neutralized to salts with zinc cations or a mixture of zinc cations and cations of a second metal selected from Group 1 of the Periodic Table of the Elements wherein the salts comprise from 20 to 90% equivalents of zinc. Articles prepared from the composition have improved salt stress crack resistance when exposed to zinc chloride solutions.

Owner:EI DU PONT DE NEMOURS & CO

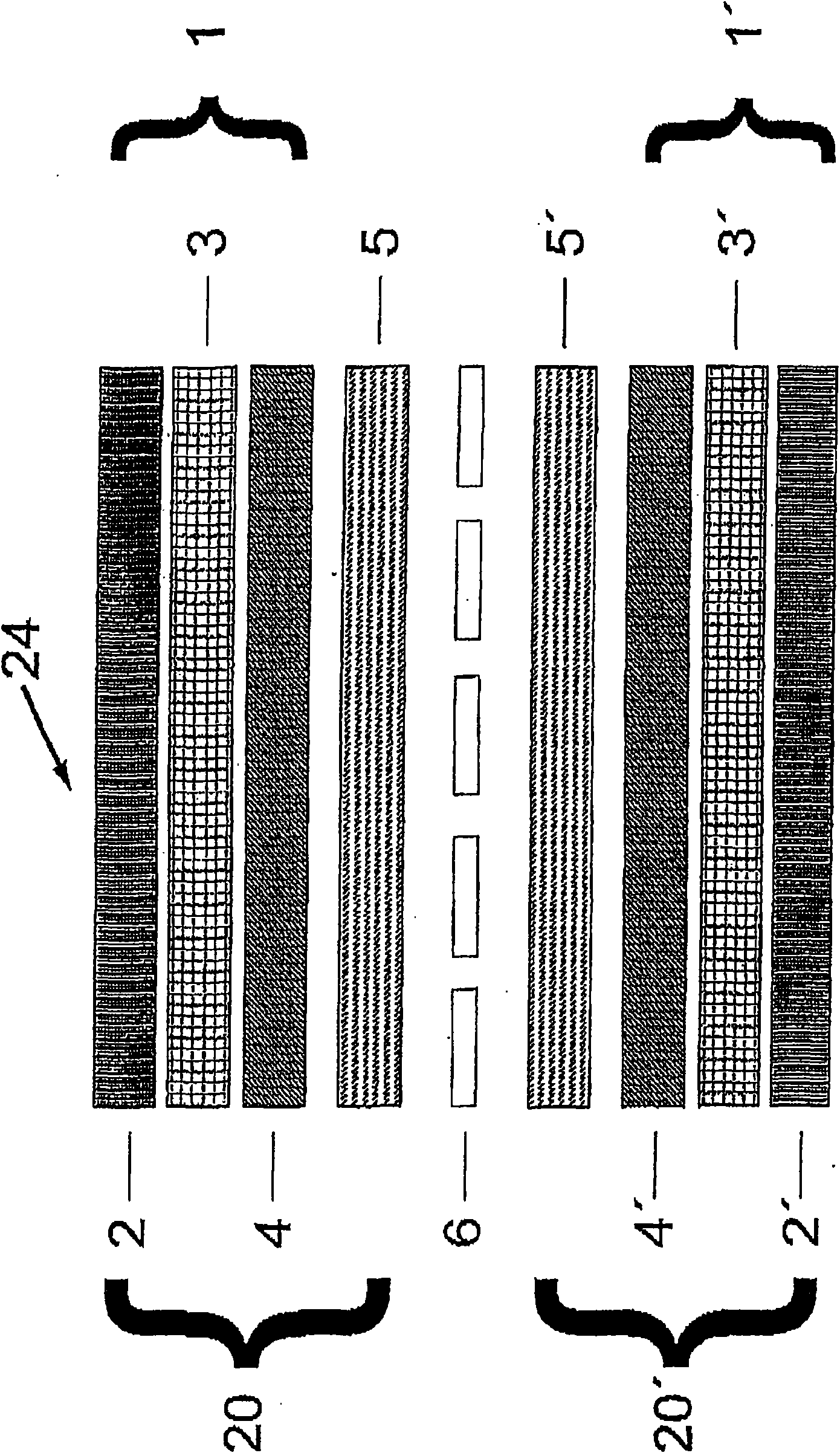

Use of a polymer composite for the production of photovoltaic modules

InactiveCN101669214ASynthetic resin layered productsPhotovoltaic energy generationTetrafluoroethyleneNylon 12

The invention relates to the use of a polymer composite (1, 1'), comprising a backing material (3, 3'), selected from the group made up of polyethylene terephthalate (PET), polyethylene naphthenate (PEN) and ethylene-tetrafluoroethylene copolymer (ETFE), and layers of nylon 12 (2, 2', 4, 4') adjacent to the backing material on both sides, for producing photovoltaic modules.

Owner:ISOVOLTA OSTE ISOLIERSTOFFWERKE AG

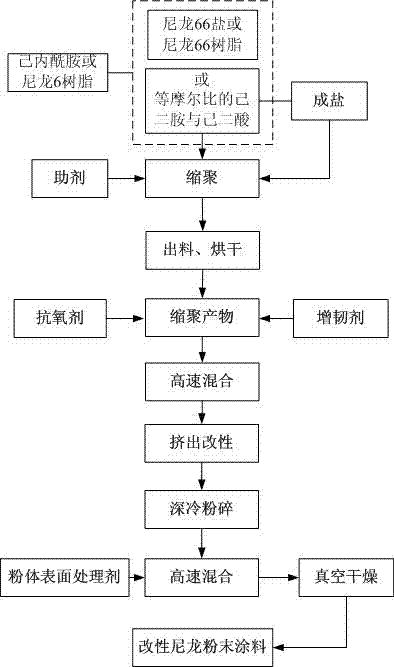

Modified nylon powder coating and preparation method thereof

InactiveCN102898941AFull play to the melting pointReduce regulationPowdery paintsPolyamide coatingsPolymer scienceNylon 12

The invention discloses a modified nylon powder coating and a preparation method thereof. The preparation method comprises the following steps of: firstly preparing a polymerization product by performing polymerization reaction on the following main synthetic materials in parts by mass: 50 to 80 parts of caprolactam or nylon 6 resin, 20 to 50 parts of nylon 66 salt, nylon 66 resin or equal mole ratio of hexamethylene diamine and hexanedioic acid, and 0.02 to 1.7 parts of an auxiliary agent; and then preparing the modified nylon powder coating through the processes of extrusion modification, deep cooling crushing and treatment with a powder surface treatment agent. The auxiliary agent comprises an antioxidant, a nucleating agent and a molecular weight adjusting agent. The modified nylon powder coating prepared by the method is lower in melting point, simple in process control and stable in product quality, can partially substitute nylon 11 and nylon 12 powder products, can effectively reduce the using cost of nylon powder, is favorable for application popularization of the nylon powder, and has a great market potential.

Owner:NANJING INST OF TECH

Thermoplastic resin composition excellent in barrier property

InactiveUS20100004406A1Improve compatibilityIncrease flexibilityEnvelopes/bags making machinerySynthetic resin layered productsNylon 12Alcohol

A thermoplastic resin composition comprising 100 parts by mass of a polyamide resin composition (A) and 0.1 to 10 parts by mass of a carbodiimide compound (B) having two or more carbodiimide groups. The polyamide resin composition (A) contains a polyamide resin (a-1) and nylon 11 and / or nylon 12 (a-2) in an amount of 5 to 95% by mass of the component (a-1) and 95 to 5% by mass of the component (a-2) each based on a total amount of the components (a-1) and (a-2). The polyamide resin (a-1) is constituted by diamine units 70 mol % or more of which are derived from m-xylylenediamine and dicarboxylic acid units 70 mol % or more of which are derived from a C4 to C20 α,ω-linear aliphatic dicarboxylic acid. The thermoplastic resin composition is excellent in barrier property, strength and impact resistance, in particular, barrier property to alcohol-containing fuels, and suitably used as various shaped articles such as fuel containers, tubes and parts.

Owner:MITSUBISHI GAS CHEM CO INC

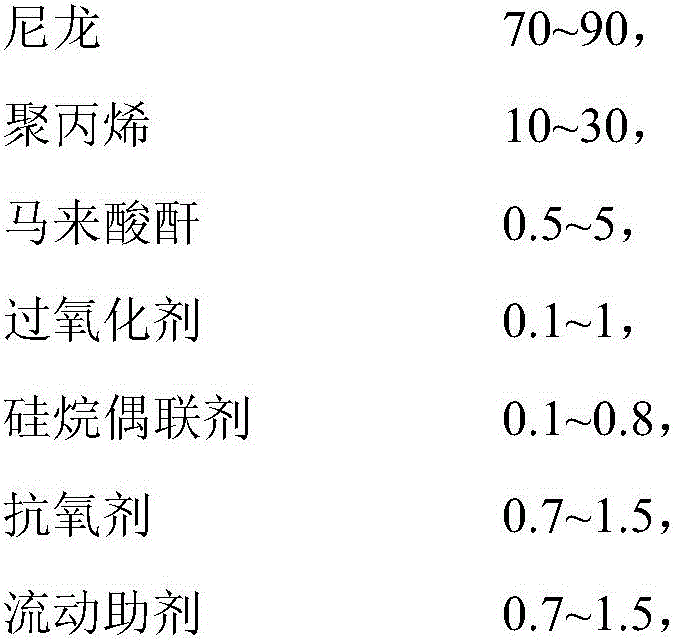

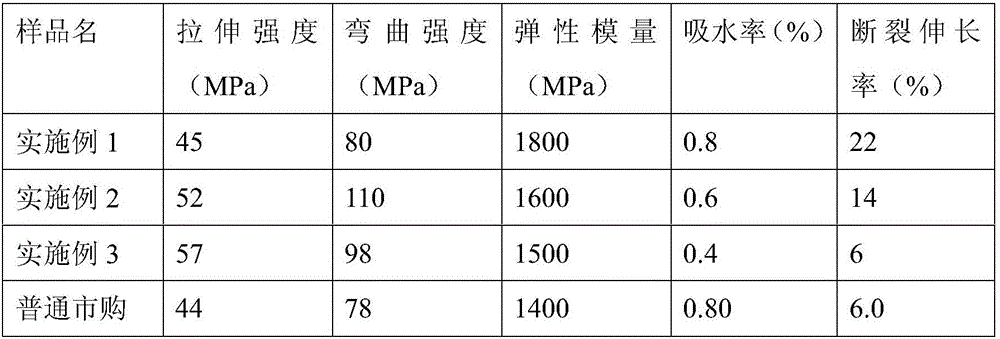

Nylon-polypropylene-filler modified composite powder, and preparation method and application thereof

InactiveCN106380832AImprove mechanical propertiesImprove bending strengthEnvironmental resistanceNylon 12

The invention relates to the field of high-molecular composite materials and provides a nylon-polypropylene-filler modified composite powder and a preparation method and application thereof to overcome the problems of high price, low application temperature and poor mechanical properties of simple nylon 12 powder materials in the prior art. The composite powder provided by the invention has the advantages of good mechanical properties, great bending strength, low shrinkage, good dimensional stability, environment friendliness, no pollution, low cost and the like, and is convenient to promote and apply.

Owner:HANGZHOU NORMAL UNIVERSITY

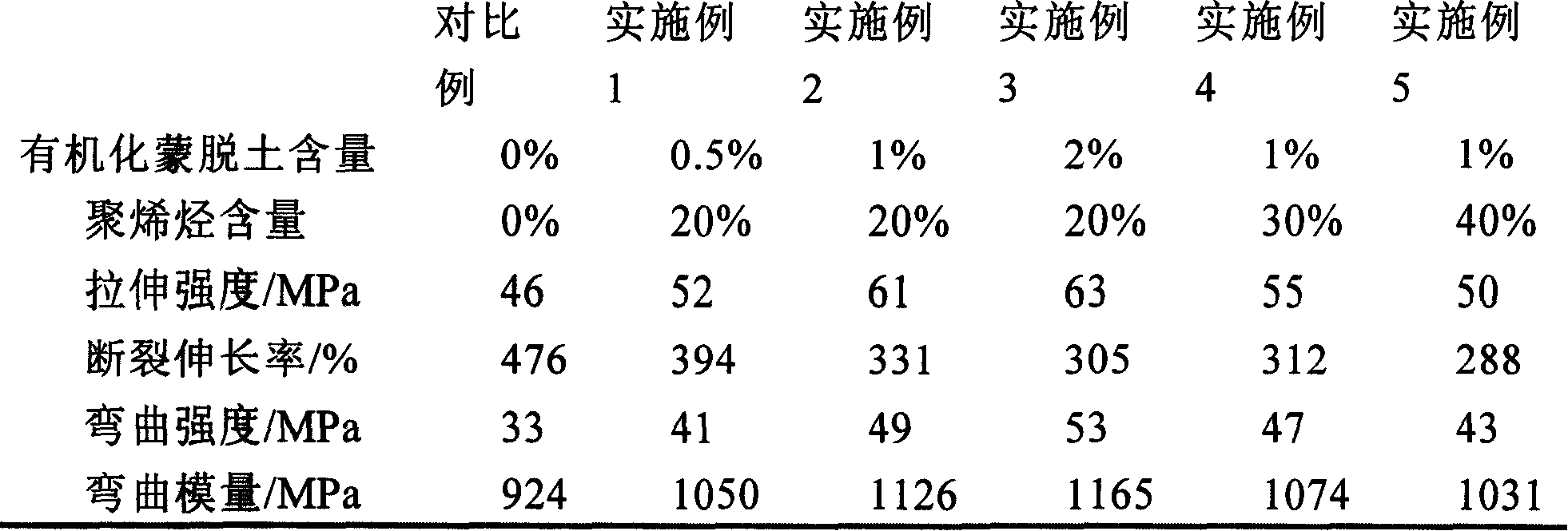

Method for preparing novel nylon 12 composite material

The present invention relates to a novel preparation method of a nylon 12 composite, which comprises technical steps as follows: (1). 20 to 40wt percent of polyolefin is added into melted nylon 12 monomer to be dispersed by stirring; (2). 0.5 to 2w percent of montmorillonite is dispersed into the melted nylon 12 monomer; (3). after the two materials are mixed, 0.5 to 2wt percent of initiator and 0.5 to 2wt percent of cocatalyst are added for the anionic ring-opening polymerization of the monomer to obtain the composite. Compared with the prior art, the present invention has the characteristics of simple technology, short flow, high efficiency, no pollution, etc.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com