Use of a polymer composite for the production of photovoltaic modules

A technology of composite materials and photovoltaic modules, which is applied in the field of plastic composite materials and can solve problems such as low adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Hereinafter reference will be made to possible embodiments of the invention (see Figure 1-4 ) and explain the invention in detail with reference to possible embodiments.

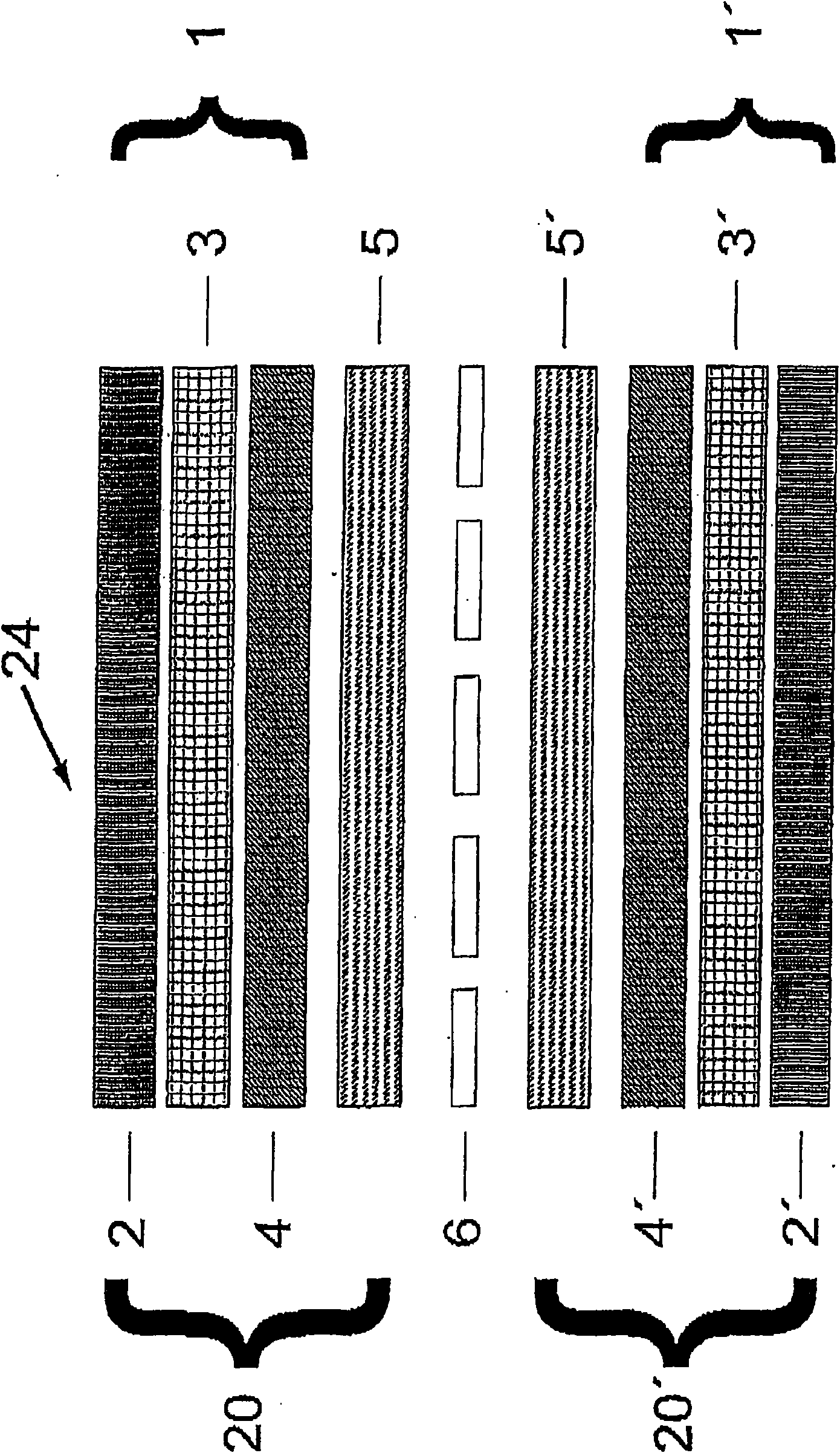

[0009] figure 1 An exemplary structure of a photovoltaic module 24 is shown in which a solar cell system is encapsulated by the material 1 , 1 ′ used according to the invention. The encapsulation material 1, 1' consists essentially of a weather-resistant film 2, 2' and a carrier material 3, 3', on which the adjoining agent acts as an adhesion promoter to the sealing layer 5, 5' The film 4, 4'. The sealing layers 5 , 5 ′ produce a non-positive connection to the solar cell system 6 .

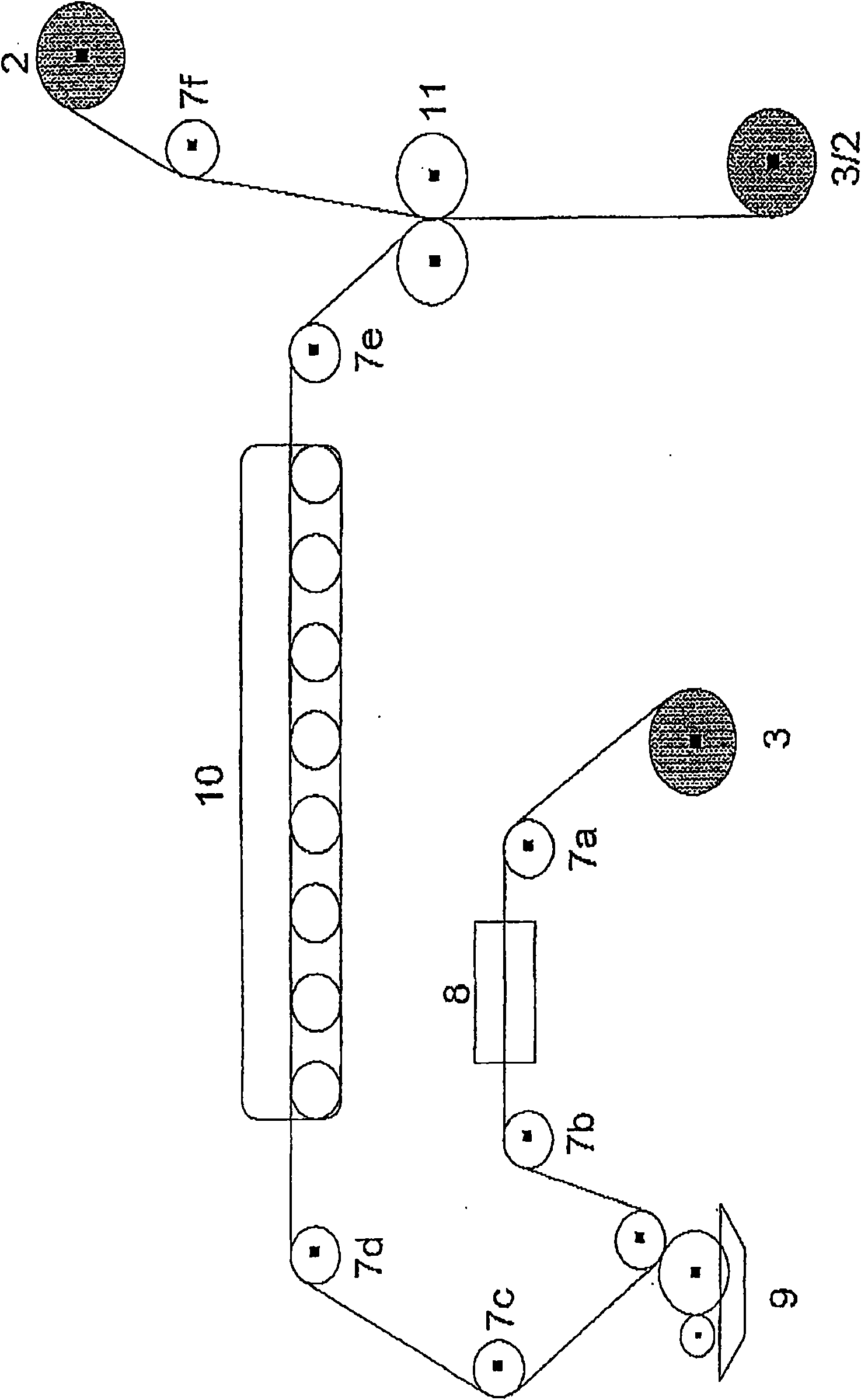

[0010] figure 2 A possible lamination device for producing the plastic composite used according to the invention is shown. A carrier material 3 selected according to the example is coated with an adhesive by means of a coating device 9 and bonded to a weather-resistant film 2 after passing through a dryer 10 . In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com