Patents

Literature

32results about How to "Improve dipping quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

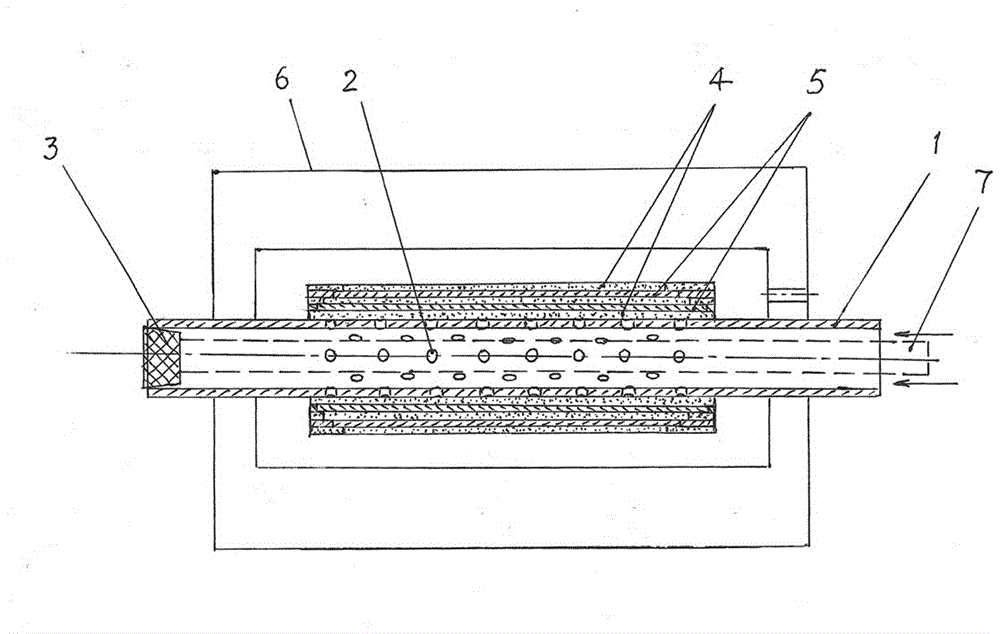

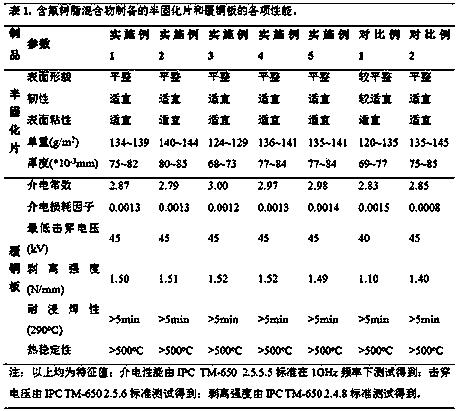

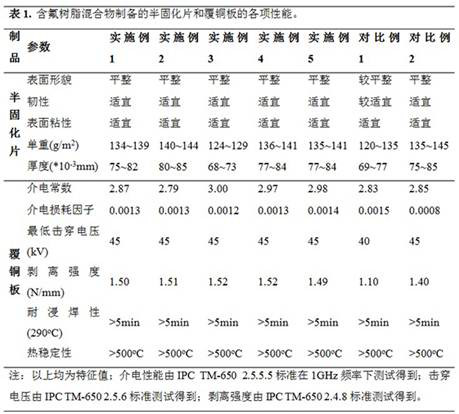

Fluororesin mixture, copper-clad plate prepared therefrom and manufacturing method thereof

ActiveCN101838431AImprove dipping qualityUniform glue contentGlass/slag layered productsMetal layered productsVinyl etherGlass fiber

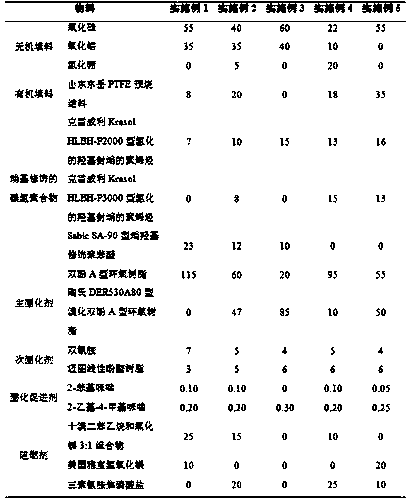

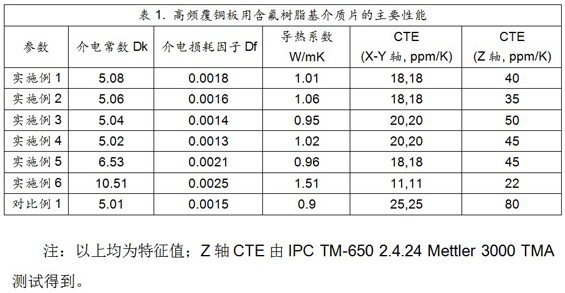

The invention relates to a fluororesin mixture, a copper-clad plate prepared therefrom and a manufacturing method thereof. The fluororesin mixture contains the following two substances as necessary components in 100 parts by weight of an organic solid substance: 90-99 parts of polytetrafluoroethylene (PTFE) emulsions and 1-10 parts of polytetrafluoroethylene perfluoroalkyl vinyl ether (PFA) emulsions. The copper-clad plate prepared from the fluororesin mixture comprises a plurality of superimposed varnished cloths and copper foil coating one or two surfaces of the varnished cloths, and each varnished cloth comprises a glass fiber cloth and the fluororesin mixture attached to the dipped and dried glass fiber cloth. The fluororesin mixture is prepared by using the PTFE emulsions as main resins and can dip the glass fiber cloths many times under the condition that the PTFE sintering temperature is330 DEG C to prepare the vanished cloths, and the vanished cloths prepared from the fluororesin mixture has the advantages of good gum dipping quality, level surface, flexibility and easy operation; and besides, the copper-clad plate made from the fluororesin mixture has excellent dielectric performance which meets the dielectric performance requirement of the high-frequency communication field for a base plate material, and has simple making method and process and is beneficial to industrial continuous production.

Owner:GUANGDONG SHENGYI SCI TECH

Fluoro-resin mixture, copper-clad plate made of same and making method thereof

ActiveCN101857708AImprove dipping qualityUniform glue contentFibre treatmentLaminationGlass fiberPolymer science

The invention relates to a fluoro-resin mixture, a copper-clad plate made of the same and a making method thereof. The fluoro-resin mixture comprises the following two substances as necessary components: 90-99 parts by weight of polytetrafluoroethylene (PTFE) emulsion and 1-10 parts by weight of fluorinated ethylene propylene (FEP) based on 100 parts by weight of an organic solid matter. The copper-clad plate made of the fluoro-resin mixture comprises a plurality of pieces of superimposed varnished cloth and copper foils covering one side or two sides of the varnished cloth, wherein each piece of varnished cloth comprises glass fiber cloth and a fluoro-resin mixture adhered thereon through dipping drying. The fluoro-resin mixture is prepared by taking the PEFE emulsion as base resins, the glass fiber cloth can be dipped for many times in the mixture under the condition of below PTFE sintering temperature (330 DEG C) to obtain the varnished cloth. The varnished cloth made from the fluoro-resin mixture has favorable gum dipping quality, uniform gum content, smooth surface, softness and easy operation. The copper-clad plate made from the fluoro-resin mixture has favorable comprehensive properties, excellent dielectric properties, simple making method and process, satisfies the dielectric property requirements on substrate materials in the field of high frequency communication and is beneficial to industrial continuous production.

Owner:GUANGDONG SHENGYI SCI TECH

Fluororesin mixture, copper-clad plate prepared therefrom and manufacturing method thereof

ActiveCN101838431BImprove dipping qualityUniform glue contentGlass/slag layered productsMetal layered productsTetrafluoroethyleneVinyl ether

Owner:GUANGDONG SHENGYI SCI TECH

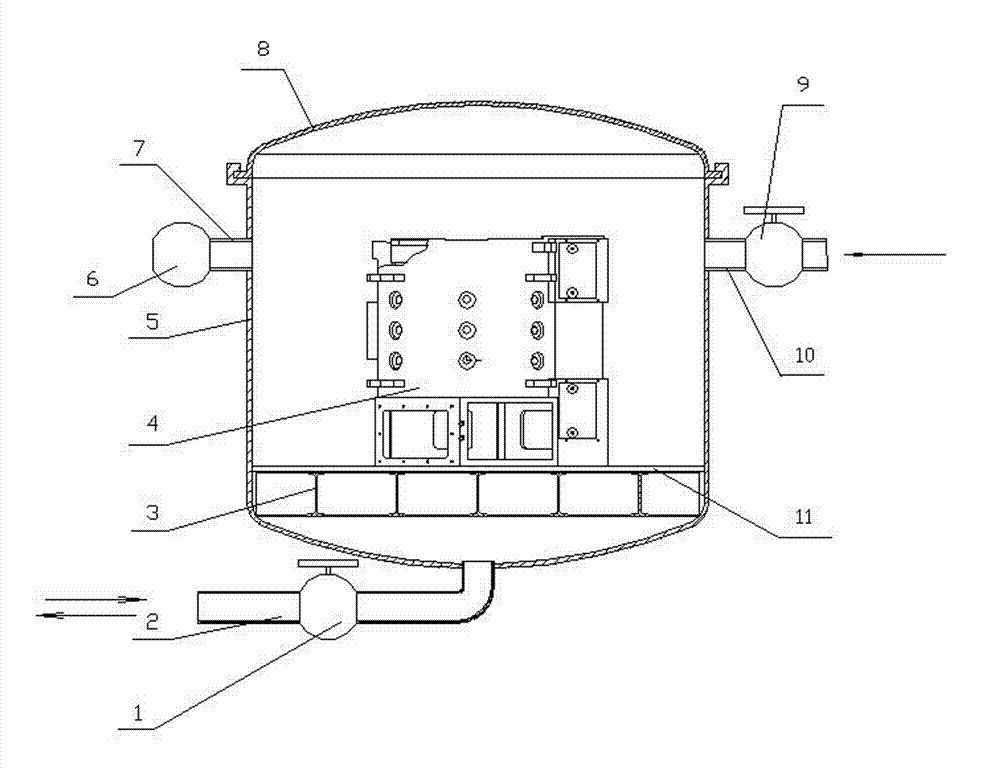

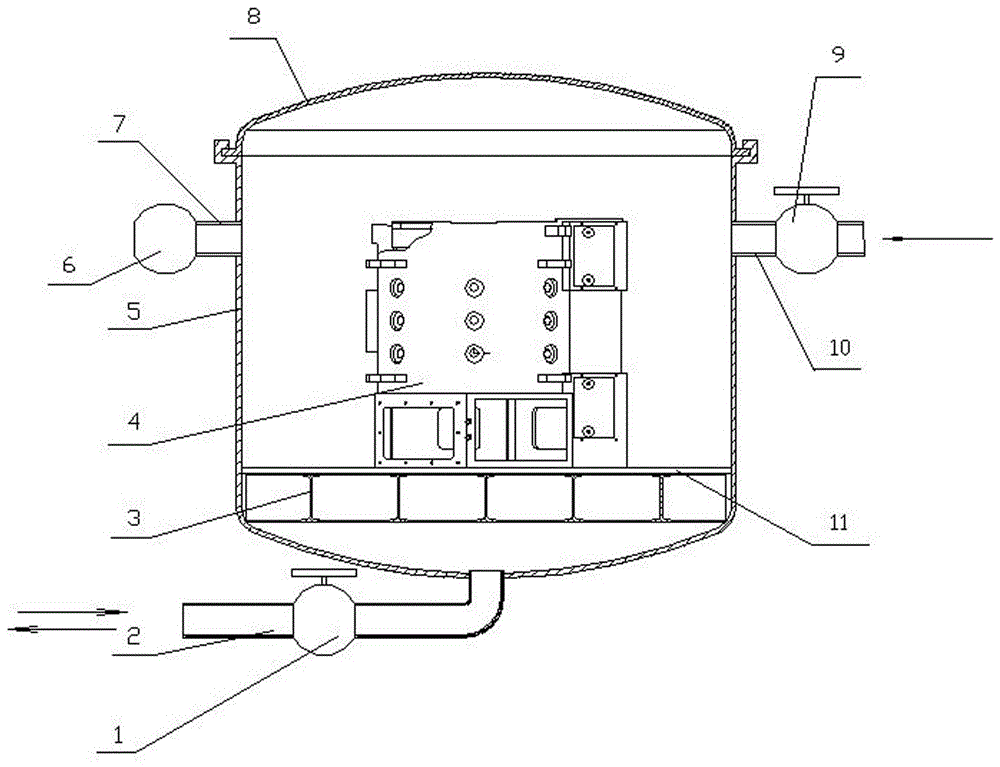

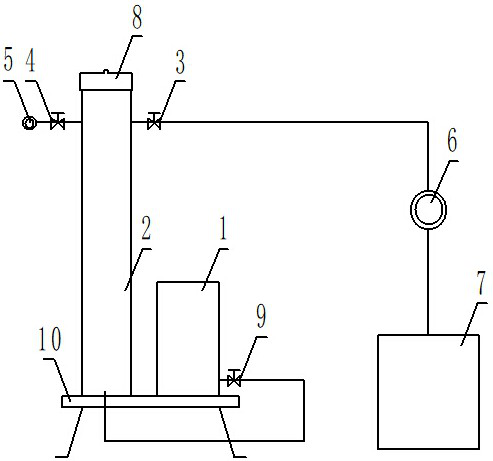

Decontamination vacuum lacquer impregnation tank and method

ActiveCN103611660AAvoid pollutionAvoid cloggingLiquid surface applicatorsCoatingsVacuum pressureLacquer

The invention relates to a vacuum pressure lacquer impregnation tank, and in particular relates to a decontamination vacuum lacquer impregnation tank and method. The decontamination vacuum lacquer impregnation tank comprises a tank body, a tank cover which is matched with the tank body, a lacquer conveying pipe, a bracket, a vacuum pump, a compressed air pipe and a filter net, wherein the bottom of the tank body is communicated with the lacquer conveying pipe; the compressed air pipe is communicated with the upper part of the tank body; the vacuum pump is connected with the upper part of the tank body; the filter net is arranged in the tank body through the bracket. The decontamination vacuum lacquer impregnation tank provided by the invention can filter insulating lacquer, and prevent metamorphic patent leather and oil contamination from entering a lacquer storage tank to pollute the insulating lacquer. By adopting the lacquer impregnation method provided by the invention, the lacquer impregnation uniformity is improved, and the motor repairing amount is increased.

Owner:CRRC LUOYANG CO LTD

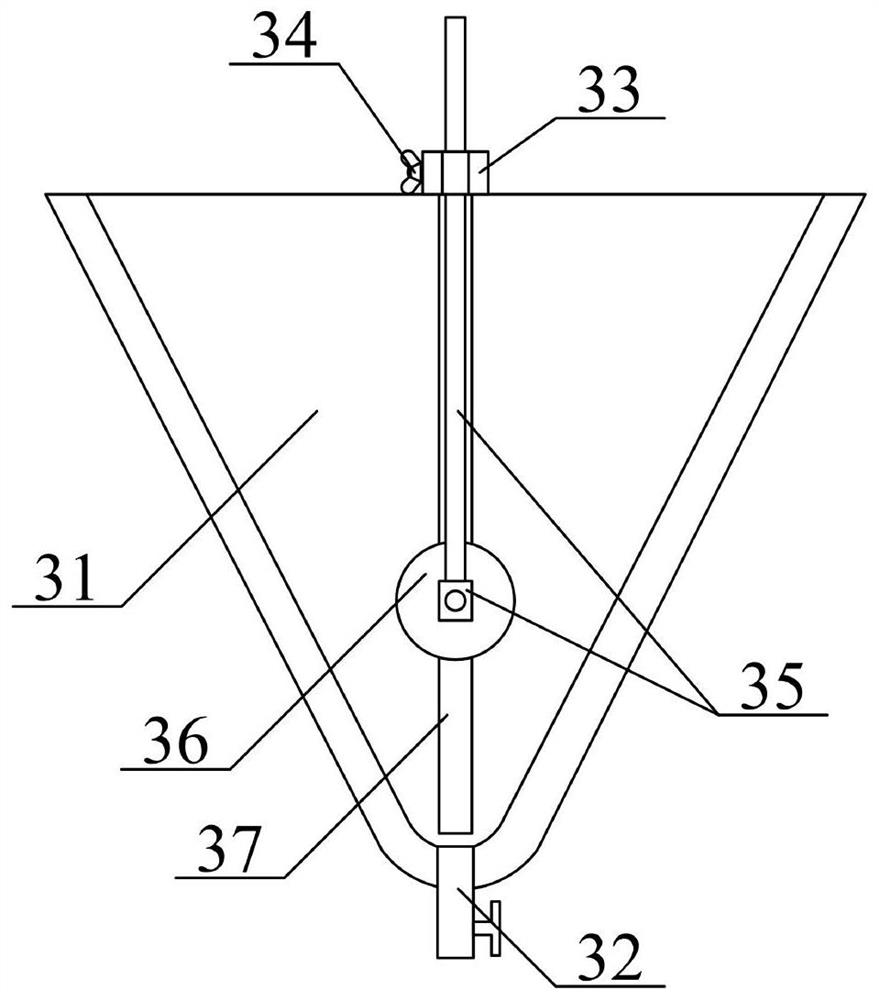

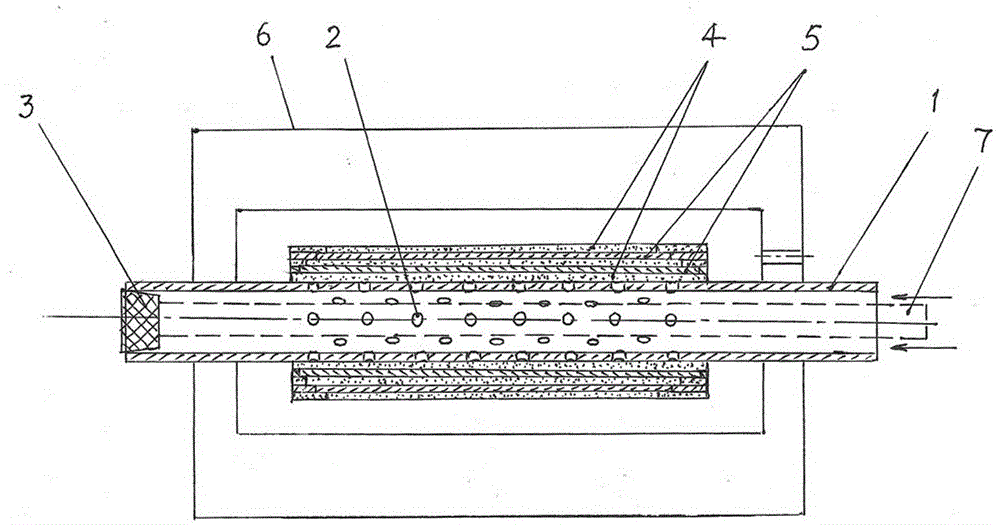

Impregnation method for dry capacitance type high-voltage bushing core

The invention relates to an impregnation method for a dry capacitance type high-voltage bushing core. The impregnation method comprises steps as follows: distributed through holes are formed in the wall of a conductive tube, one end of the conductive tube is closed, the conductive tube is wound with an insulating layer, then the insulating layer is wound with a capacitive screen, and alternate winding is performed until the specified layer number of the capacitive screens is reached; a prepared bushing core blank body is arranged in an airtight pouring die, glue with pressure is introduced through an open end of the conductive tube, is enabled to permeate layer by layer to an external wrapping layer through the through holes in the conductive tube and is gradually diffused to all insulating layers and capacitive screens, and an impregnation process of the bushing core is finished after heating and curing forming. According to the impregnation method, diffusion and permeation of the glue can be formed from inside to outside, retention of bubbles is avoided, the qualified rate of products can be increased more than 3 times after impregnation, heating and curing, the impregnation quality is also greatly improved, further, the production cost is reduced, and the economic benefit of a production enterprise can be greatly increased.

Owner:石家庄市发运电气有限公司

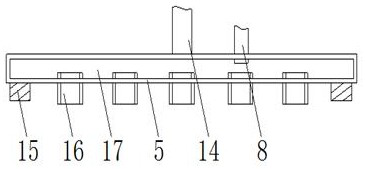

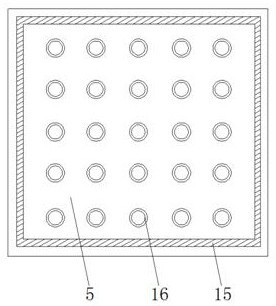

Efficient gum dipping device for raw cloth processing

InactiveCN112742673AEasy to installEasy to cleanSpraying apparatusPretreated surfacesAdhesive glueElectric machinery

The invention provides an efficient gum dipping device for raw cloth processing. The device comprises a workbench, supporting legs, a gum dipping frame structure, protective shells, an electric heating pipe, a sundry collecting frame structure, a supporting frame, a roller, a uniform gum scraping frame structure, an end cover mounting frame structure, an air drying box, a dustproof net, a fan, a driving roller and a driving motor; the supporting legs are connected to the four corners of the lower part of the workbench through bolts respectively; the gum dipping frame structure is mounted on the left side of the interior of the workbench; and the protective shells are arranged on the left side and the right side of the gum dipping frame structure correspondingly. The device has the beneficial effects that through arrangement of a mounting pipe, a mounting bolt and a supporting rod, the mounting bolt is loosened, the supporting rod is moved upwards, the supporting rod is tightly attached to the lower part of the mounting pipe, and then raw cloth winds around the lower part of the gum dipping roller, so that a worker can conveniently mount the raw cloth before gum dipping, and the worker does not need to manually enter gum to mount the raw cloth.

Owner:滨州市沾化区凯棣化工有限公司

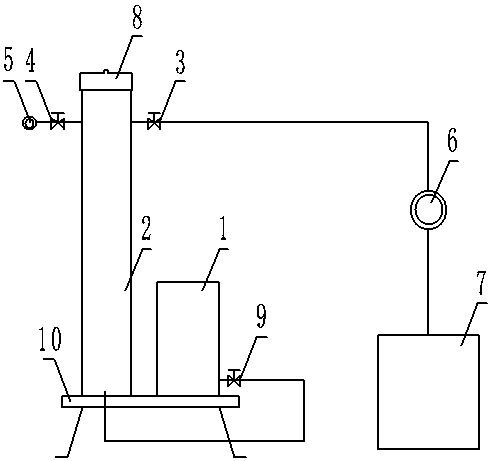

Vacuum varnish dipping method for oil tank oil measurement sensor plastic pipe

ActiveCN109530174AHigh mechanical strengthImprove fill rateLiquid surface applicatorsVacuum gaugesFuel tankInlet valve

The invention discloses a vacuum varnish dipping method for an oil tank oil measurement sensor plastic pipe, and belongs to the technical field of varnish dipping methods. The method comprises the following steps that S3, the vacuum degree is tested, a varnish dipping cylinder is sealed through a sealing cover, after a varnish inlet valve between the varnish dipping cylinder and a varnish storagetank is closed, a gas inlet valve and a vacuum gauge valve at the upper end of the varnish dipping cylinder are opened, then a vacuum pump is started for vacuumizing the varnish dipping cylinder for 1-2 minutes, thus, the vacuum degree in the varnish dipping cylinder is higher than -0.085MPa, the required time is recorded, the vacuum gauge valve is closed, and the varnish inlet valve is opened, sothat the varnish dipping cylinder communicates with the varnish storage tank so as to communicate with the outside; and S4, a part is subjected to varnish dipping, specifically, prepared and cured varnish is poured into the varnish storage tank, the varnish inlet valve is closed, and the sealing cover on the varnish dipping cylinder is taken down. The method is low in cost and insulation varnishconsumption, the penetration ability of insulation varnish can be improved, the filling rate of insulation varnish can be increased, defects such as pinholes, bubbles and pits in plastic pipe part substrates can be eliminated, and thus the overall mechanical strength, insulation strength and moisture and mildew resistance of the plastic pipe are improved.

Owner:四川泛华航空仪表电器有限公司

A kind of decontamination vacuum dipping tank and dipping method

ActiveCN103611660BAvoid pollutionAvoid cloggingLiquid surface applicatorsCoatingsVacuum pressureInsertion stent

The invention relates to a vacuum pressure immersion paint device, specifically a decontamination vacuum varnish immersion tank and a paint immersion method, comprising a tank body, a tank cover matched with the tank body, a paint delivery pipe, a bracket, a vacuum pump, compressed air Pipe and filter screen, the bottom of the tank body is connected with a paint delivery pipe, the compressed air pipe is connected with the upper part of the tank body, the vacuum pump is connected with the upper part of the tank body, and the filter screen is arranged inside the tank body through a bracket; the invention provides The decontamination vacuum varnish dipping tank can filter the insulating varnish to prevent deterioration of lacquer skin and oil stains from entering the paint storage tank to pollute the insulating varnish; the varnish dipping method provided by the invention improves the uniformity of the dipping varnish and improves the repair quality of the motor.

Owner:CRRC LUOYANG CO LTD

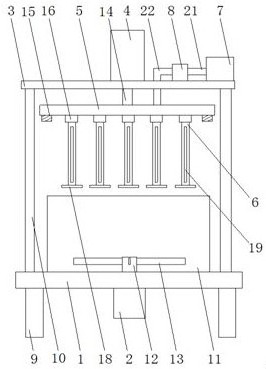

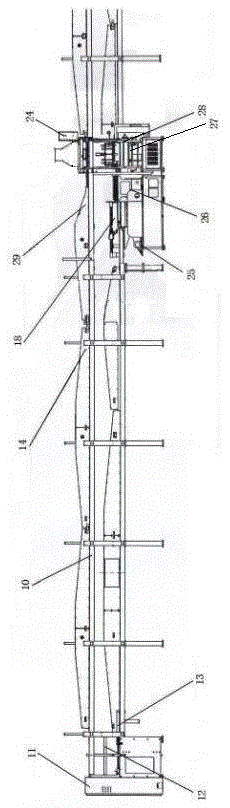

Motor rotor paint-dipping and drying equipment and operation method thereof

PendingCN111774240AImprove dipping qualityImprove drying efficiencyPretreated surfacesCoatingsHydraulic cylinderElectric machine

The invention discloses motor rotor paint-dipping and drying equipment. The equipment comprises a bottom plate, a motor, a top plate, a hydraulic cylinder, a connecting plate, bearing rods, an air blower and a heater and is characterized in that the bottom plate is arranged on a support, the motor is installed at the bottom of the bottom plate, the top plate is arranged on vertical plates, the hydraulic cylinder is arranged on the top plate, the connecting plate is connected with a piston rod, the top ends of the bearing rods are arranged in connecting screw cylinders, the air blower is arranged on the top plate, a connecting pipe is arranged on the air blower, and the heater is arranged on the top plate. According to the motor rotor paint-dipping and drying equipment, sealing blocks are arranged on the reverse side of the connecting plate, and through the sealing blocks, the airtightness between the connecting plate and a paint bucket is improved; the air blower blows airflow into aninner cavity of the connecting plate through the connecting pipe and an air conveying pipe, then the airflow in the inner cavity is discharged in the paint bucket through an air discharge groove, thuspressure inside the paint bucket is increased to make the paint sufficiently sucked on the surface of a motor rotor, and then the paint dipping quality of the motor rotor is improved.

Owner:NANLING LIANG POWER TOOLS

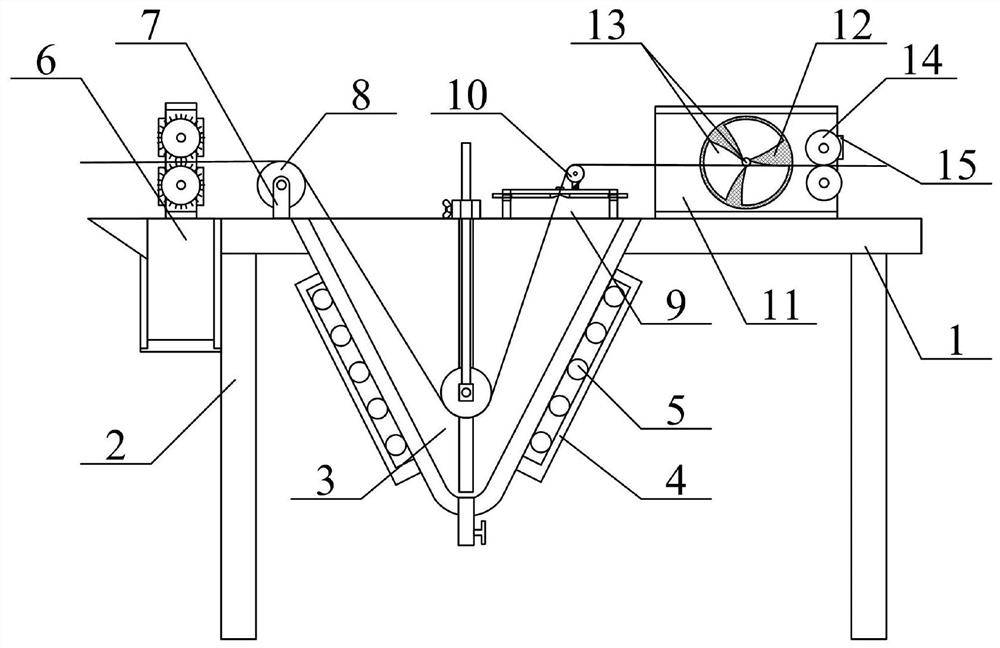

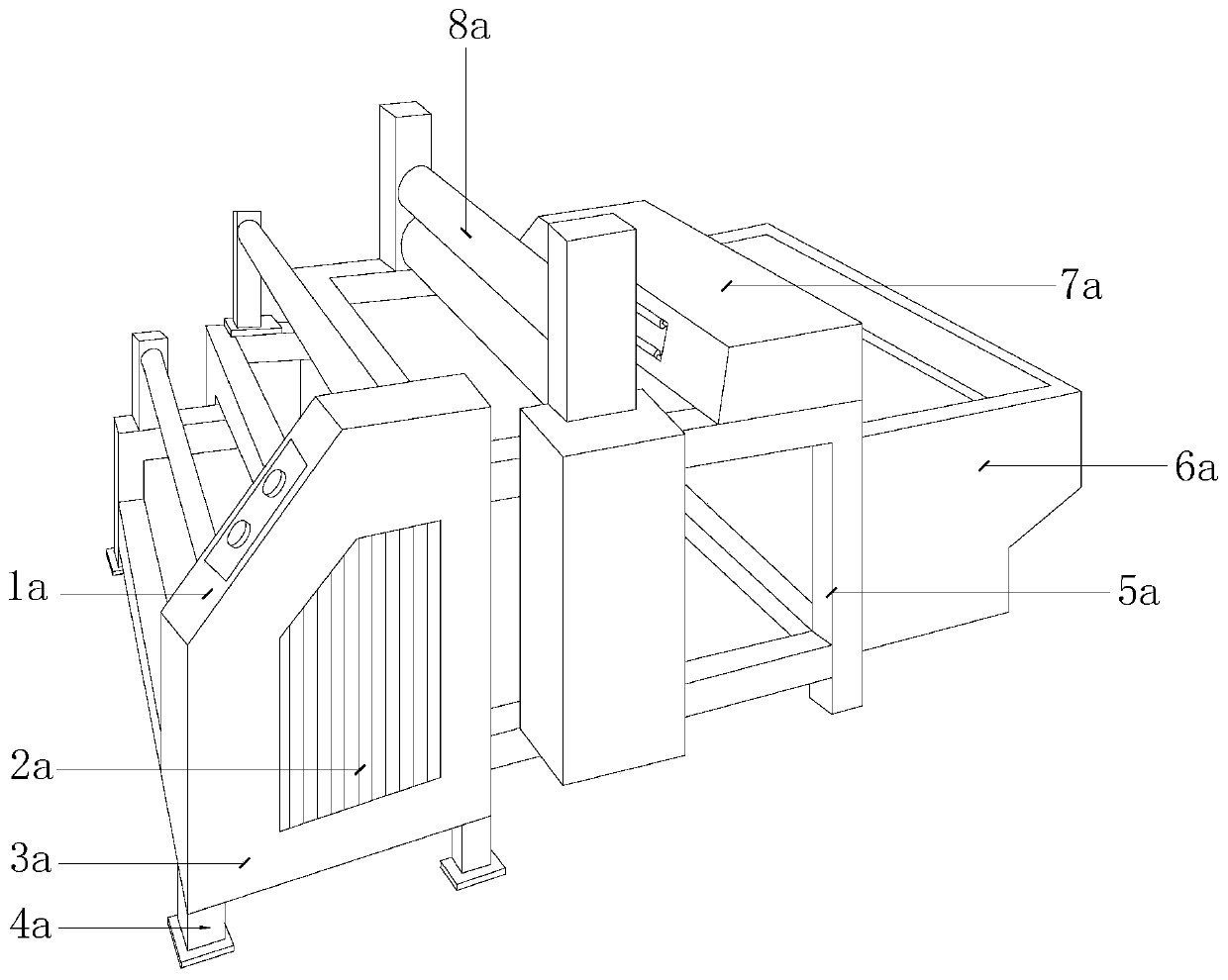

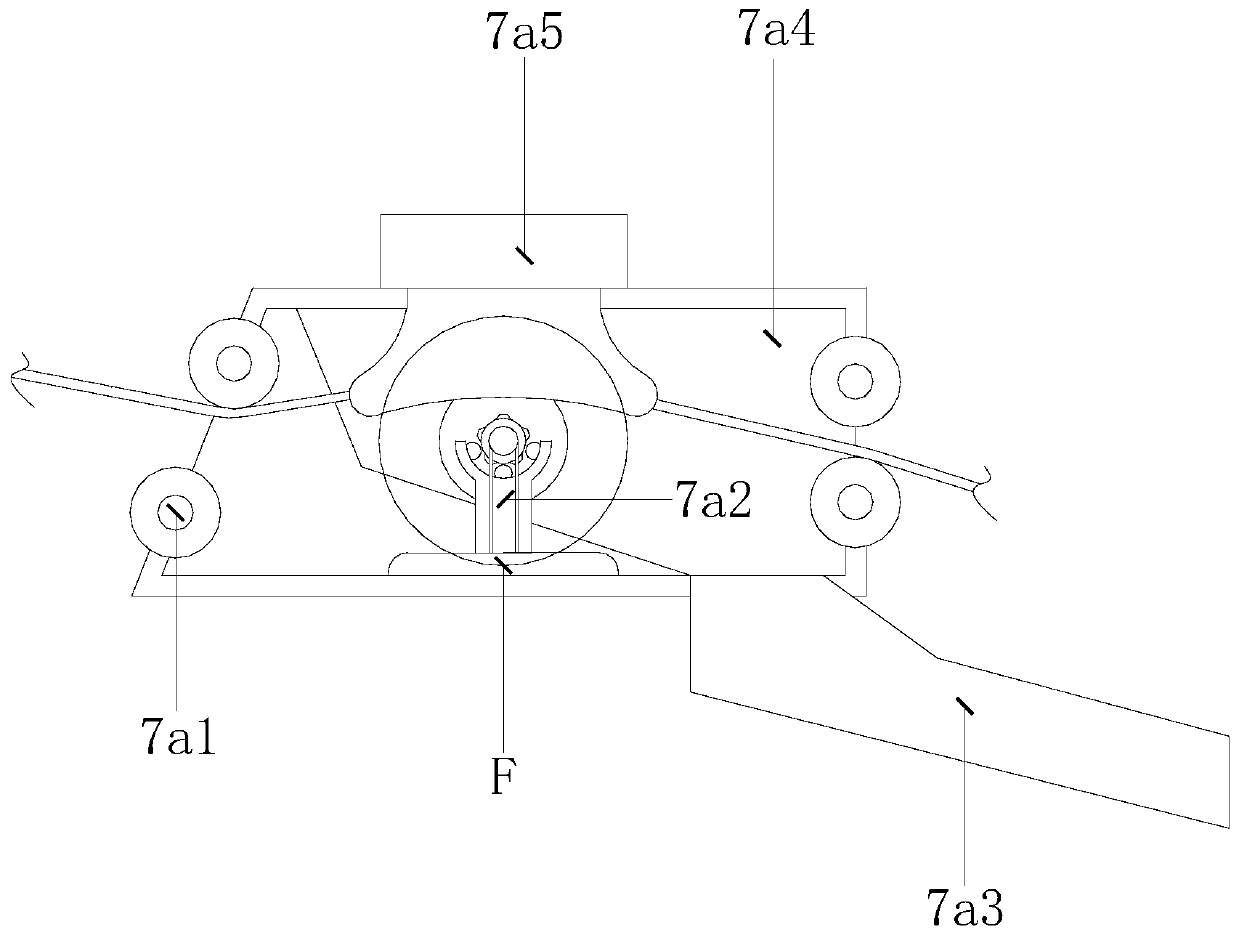

Multifunctional glue dipping machine for preparing chinlon 6 curtain cloth based on dispersing, vibrating and flat combing principle

ActiveCN110355069AImprove permeabilityReduce resistancePretreated surfacesCoatingsPulp and paper industryTextile

The invention discloses a multifunctional glue dipping machine for preparing chinlon 6 curtain cloth based on dispersing, vibrating and flat combing principle. The multifunctional glue dipping machinefor preparing chinlon 6 curtain cloth based on dispersing, vibrating and flat combing principle structurally comprises a control panel, a heat-dissipating groove, an equipment main machine, a fixed ground feet, a mounting rack, a glue dipping warehouse, a flat combing mechanism and a middle rotating shaft piece. Curtain cloth is subjected to dispersing and vibrating treatment by a dispersing andvibrating mechanism in the flat combing mechanism after glue dipping is completed, so that the superposed wire can be dispersed through vibration; and at the moment, through cooperation of a materialcovering assembly in a surface attaching mechanism and glue in the curtain cloth of a first stretching mechanism, permeating and flat combing treatment is generated, so that the glue-coated curtain cloth can guarantee certain smoothness, the surface of the dried and solidified glue layer is prevented from being rough, and the glue dipping quality is improved.

Owner:东营诺欧橡胶有限公司

High-carbon preservative bamboo wallboard and production method

ActiveCN106808550AImprove anti-corrosion performanceDoes not affect glossConstruction materialDomestic articlesHigh carbonPreservative

The invention discloses a high-carbon preservative bamboo wallboard production method, which comprises the steps of (1) removing tabasheer from a fresh bamboo and rolling the bamboo to obtain a silky bamboo splint; (2) drying the bamboo splint until the water content is lower than 6-9%; (3) carbonizing the bamboo splint that meets the water content requirement in a carbonization chamber at normal pressure, and selecting qualified and removing the unqualified bamboo splint after carbonization; (4) processing the qualified carbonized bamboo splint by impregnation, and drying the bamboo splint until the water content is between 13-17% after processing; and (5) processing the bamboo splint for health preserving and balancing in a health preserving room; (6) performing hot pressing moulding to obtain a bamboo sheet; (7) processing the bamboo sheet to obtain the bamboo wallboard. The invention also relates to a bamboo wallboard obtained by the above method. The bamboo preservative performance of the bamboo wallboard can be greatly improved by carbonization; the production period is short; the operation is simple; the appearance quality is high; and advantages like safety and environmental protection are provided.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

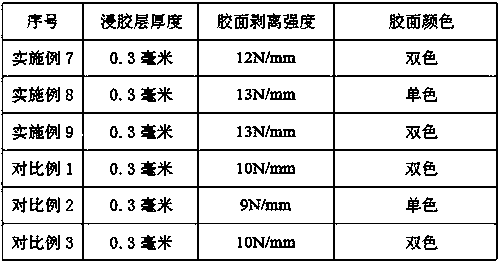

Silica gel gel dipping glove and gel dipping process thereof

InactiveCN110293645AImprove liquidityImprove adsorption capacityGlovesDomestic articlesSilica gelChemistry

The invention discloses a silica gel gel dipping glove. The silica gel gel dipping glove comprises a glove core and a gel dipping layer, wherein the gel dipping layer is a silica gel mixed gel layer,and the silica gel mixed gel material layer consists of the following components in parts by weight of 70-90% of silica gel, 5-20% of curing agent, 5-20% of a diluent and 0-10% of color paste. According to the silica gel gel dipping glove, the silica gel mixed gel material layer is composed of the silica gel, the curing agent and the diluent, and the silica gel, the curing agent and the diluent are mixed according to the above specific proportion; the gel material is good in flowing property, easy to absorb on the glove core, and firm in bonding between the gel material and the glove core after being cured, the gel surface is thin and soft, and the transparency is high; and a specific amount of the color paste is added according to color requirements, the gel surfaces with different colorscan be manufactured, the stereoscopic impression of the gel surfaces is strong, and the appearance of the glove is attractive.

Owner:HUIHONG NANTONG SAFETY PRODS

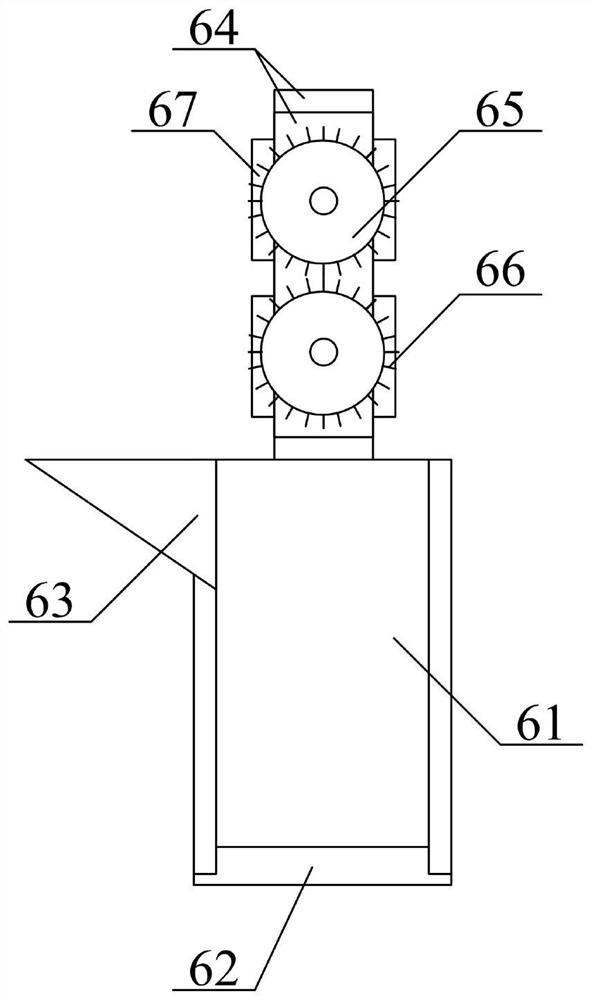

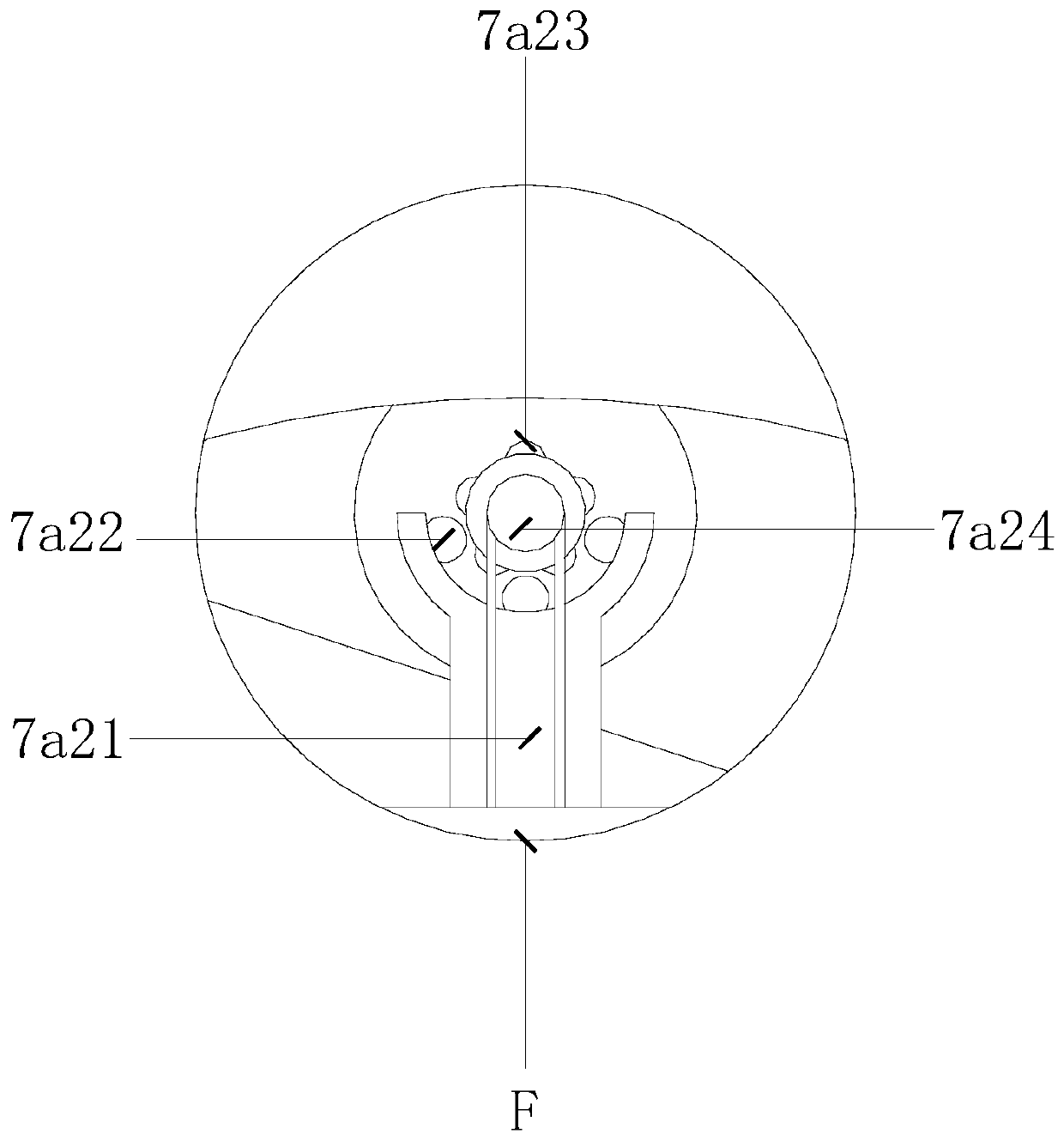

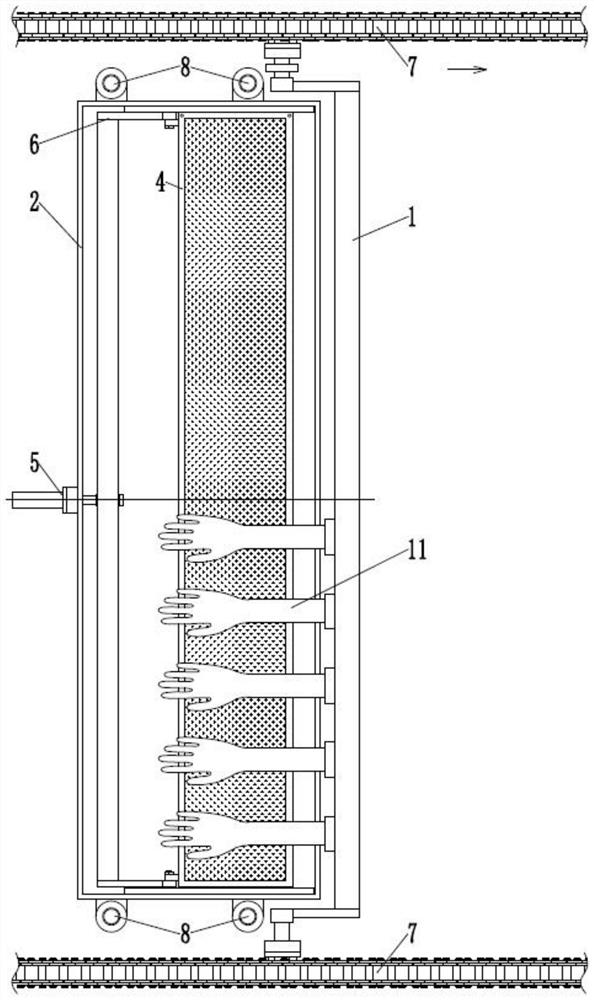

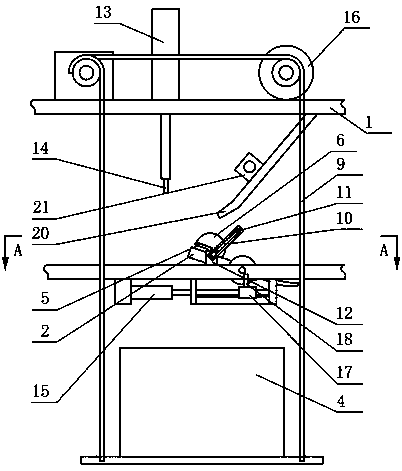

Gum dipping device in glove production process

PendingCN113927807AImprove dipping qualityAvoid crackingDomestic articlesCoatingsElastomerReciprocating motion

The invention provides a gum dipping device in a glove production process. The gum dipping device comprises a mold rod, a gum containing pool and a moving frame; a plurality of hand molds capable of mounting gloves in a sleeving mode are arranged on the mold rod at intervals, and gum dipping surfaces on the hand molds face downwards; an opening is formed in the upper end of the gum containing pool, and a gum solution is contained in the gum containing pool; the moving frame is transversely and movably arranged in the gum containing pool and is driven by a transverse reciprocating motion mechanism; upward needle-shaped elastic bodies are uniformly distributed on the upper end surface of the moving frame, and the upper ends of the needle-shaped elastic bodies are lower than the liquid level. The gum dipping device aims to impregnate the sunken parts of glove woven bodies with the gum solution through puncturing and wiping of the gum dipping surfaces of gloves so as to improve the gum dipping quality of the gloves.

Owner:会同县龙凤皮制品有限责任公司

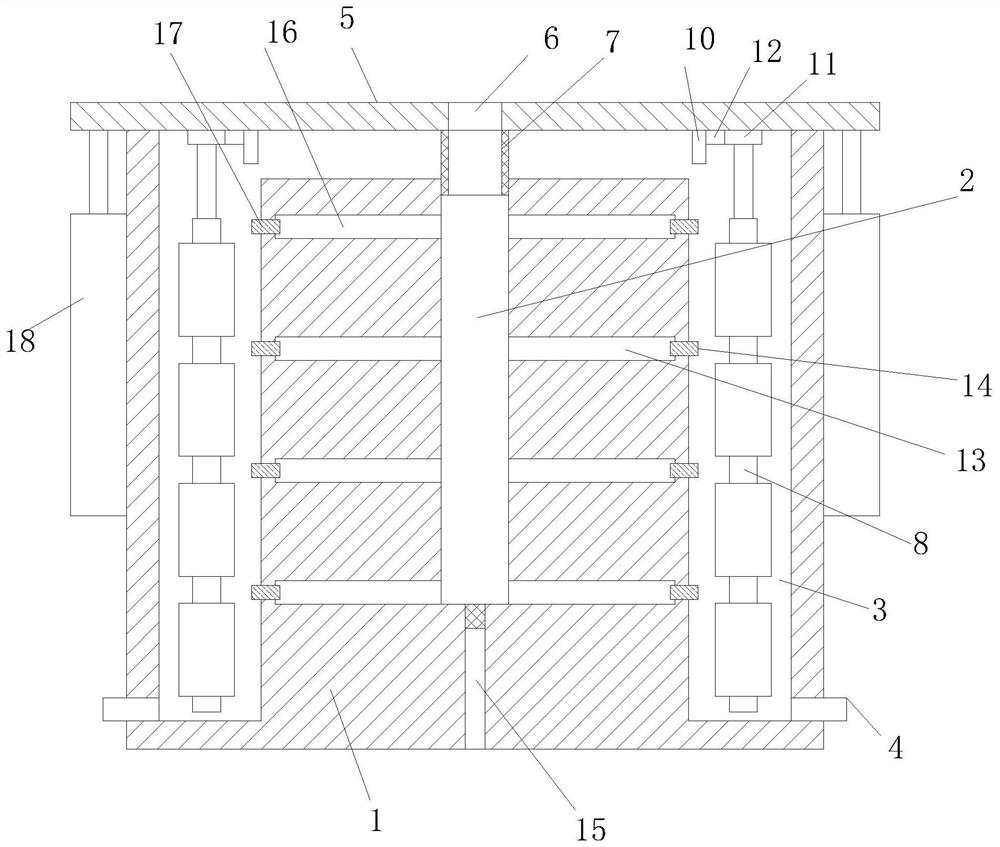

Transformer coil dipping device

InactiveCN103440979BImprove dipping qualityImprove dipping effectLiquid surface applicatorsCoatingsTransformerEngineering

The invention discloses a transformer coil paint dipping device. The transformer coil paint dipping device comprises a paint dipping groove, wherein a heating device is arranged at the bottom of the paint dipping groove, a placement notch is formed in the side wall of the paint dipping groove, and the paint dipping groove is formed in a main frame. The transformer coil paint dipping device has the advantages that the heating device is arranged at the bottom of the paint dipping groove to directly heat insulating paint so that the insulating paint can well penetrate into a transformer coil to form an insulation protection layer, a plurality of turbulent flow bars are arranged on the inner wall of the paint dipping groove so that turbulent flow can be produced through the insulating paint, therefore, the paint dipping effect is better and more even, the efficiency is improved, and meanwhile the paint dipping quality of the transformer coil is improved.

Owner:廊坊泰顺电力设备有限公司

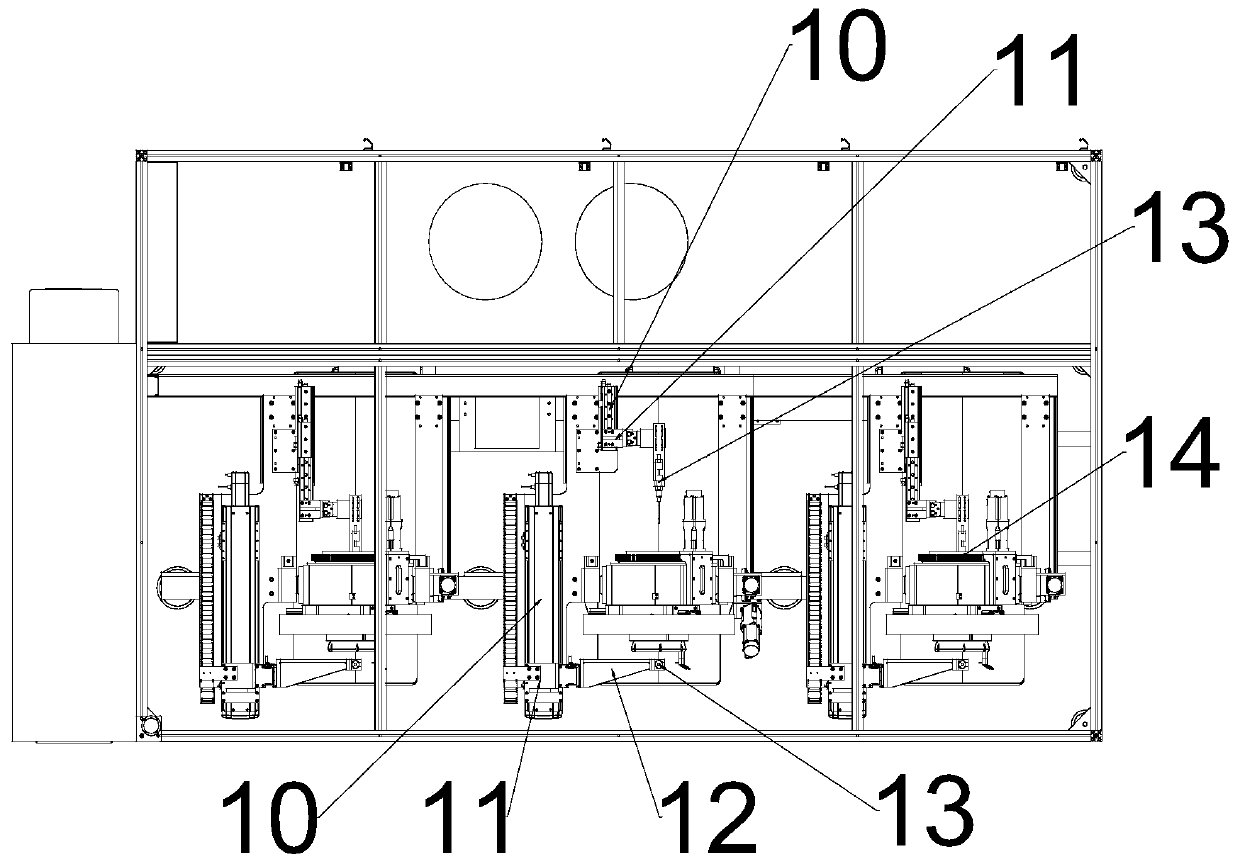

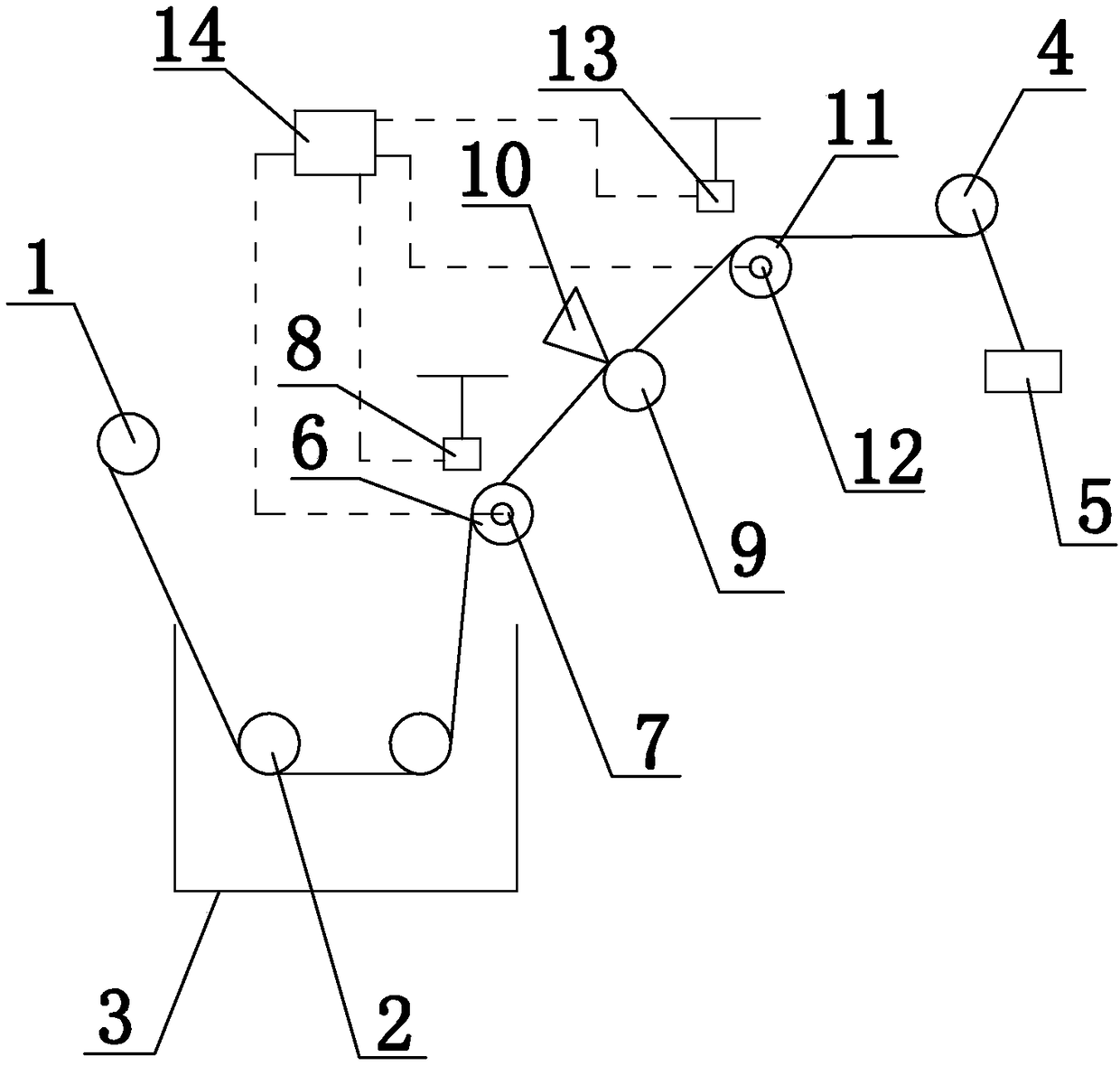

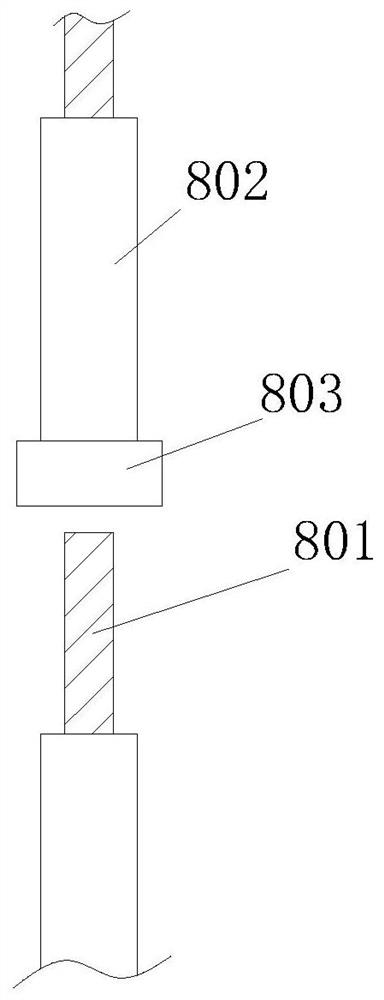

Dripping device

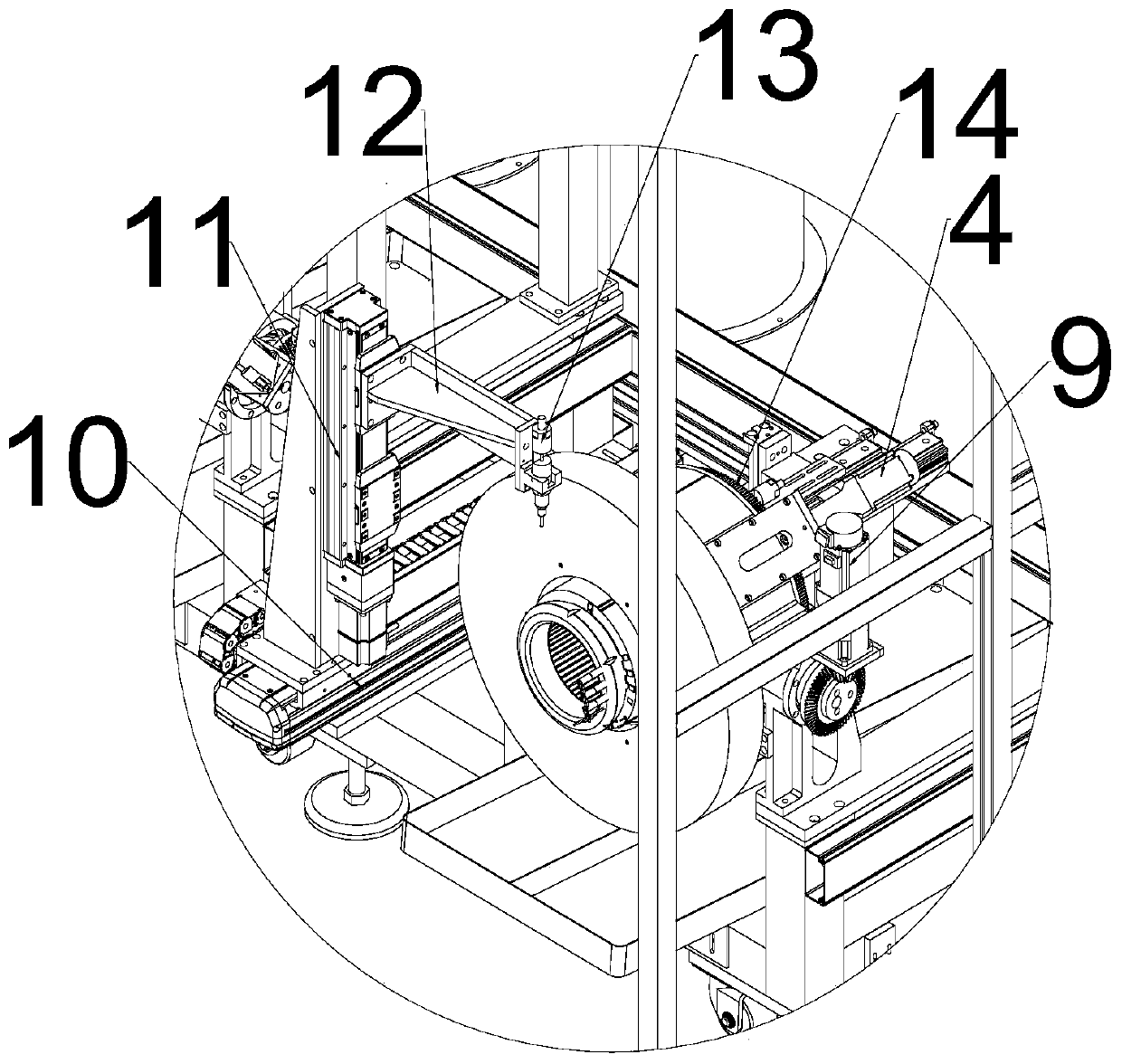

PendingCN110401318AIncrease swingImprove dipping qualityManufacturing dynamo-electric machinesLinear motorStator

The invention discloses a dripping device. The dripping device comprises a frame, the frame is internally provided with a drip paint mechanism and a rotary swing angle mechanism, the rotary swing angle mechanism comprises an outer cylinder and an inner cylinder, and the inner cylinder rotatably sleeves the internal portion of the outer cylinder, one end of the inner cylinder is extended out of theouter cylinder and is provided with a clamping device, the other end of the inner cylinder is extended out of the outer cylinder and is rotated driven by a first motor, the two sides of the outer cylinder are respectively fixedly connected with horizontally arranged rotating shafts, one of the rotating shafts is driven to rotate by a second motor, the drip paint mechanism comprises a horizontallyarranged first liner motor sliding platform and a vertically arranged second linear motor sliding platform fixed on the sliding block of the first linear motor sliding platform, and a drop paint gunis fixed on the sliding block of the second linear motor sliding platform through a support beam. The dripping device adds the swing process on a stator vertical surface based on the traditional processes such as self-rotation of the stator, paint is more easily permeated into the winding so as to effectively improve the immersion quality of the stator winding of the motor and ensure the product quality of the motor.

Owner:JULI AUTOMATION EQUIP ZHEJIANG CO LTD

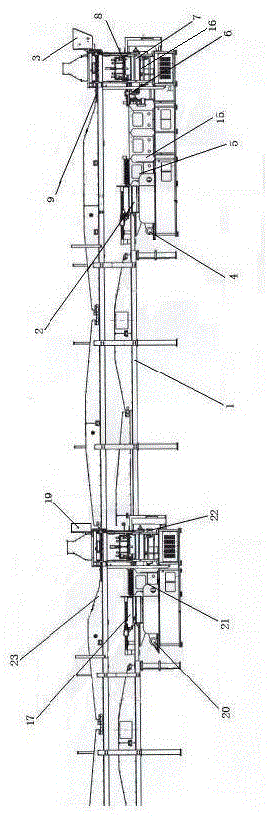

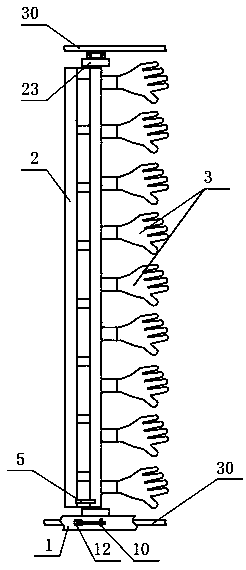

Multi-dipping-type full-automatic enteric hollow capsule forming manufacturing production line

InactiveCN105581909ADip glue evenlyAvoid uneven thickness or even microporesCapsule deliveryDomestic articlesProduction lineAdditive ingredient

The invention provides a multi-dipping-type full-automatic enteric hollow capsule forming manufacturing production line. A heating device, a secondary dipping working table and a third-time dipping working table are installed on the original basis, and rod needles are made of special capsule mold alloy steel. The multi-dipping-type full-automatic enteric hollow capsule forming manufacturing production line has the advantages that gelatin liquid can keep the necessary temperature and melting degree, uniform gelatin liquid dipping can be conveniently achieved, the condition that the capsule walls are ununiform in thickness or even micropores are formed in the capsule walls can be avoided, and the gelatin dipping quality is improved; meanwhile, gelatin dipping can be performed on a capsule mold by three times, and capsule raw materials containing different ingredients or of the different weights are supplied by gelatin melting devices arranged on the different gelatin dipping working tables, so that enteric hollow capsules are appropriately melted at the different parts such as the esophagus, the stomach and the intestines to be suitable for digestion and absorption of the different parts; in addition, by adopting the rod needles made of the material obtained through the special raw material and a formula, demolding can be better performed on hollow capsule blanks formed after gelatin dipping, and the empty shell depression rate of the capsules is decreased.

Owner:CHONGQING HENGSHENG MEDICINAL CAPSULE

Fluoro-resin mixture, copper-clad plate made of same and making method thereof

ActiveCN101857708BImprove dipping qualityUniform glue contentFibre treatmentLaminationFiberGlass fiber

The invention relates to a fluoro-resin mixture, a copper-clad plate made of the same and a making method thereof. The fluoro-resin mixture comprises the following two substances as necessary components: 90-99 parts by weight of polytetrafluoroethylene (PTFE) emulsion and 1-10 parts by weight of fluorinated ethylene propylene (FEP) based on 100 parts by weight of an organic solid matter. The copper-clad plate made of the fluoro-resin mixture comprises a plurality of pieces of superimposed varnished cloth and copper foils covering one side or two sides of the varnished cloth, wherein each piece of varnished cloth comprises glass fiber cloth and a fluoro-resin mixture adhered thereon through dipping drying. The fluoro-resin mixture is prepared by taking the PEFE emulsion as base resins, theglass fiber cloth can be dipped for many times in the mixture under the condition of below PTFE sintering temperature (330 DEG C) to obtain the varnished cloth. The varnished cloth made from the fluoro-resin mixture has favorable gum dipping quality, uniform gum content, smooth surface, softness and easy operation. The copper-clad plate made from the fluoro-resin mixture has favorable comprehensive properties, excellent dielectric properties, simple making method and process, satisfies the dielectric property requirements on substrate materials in the field of high frequency communication andis beneficial to industrial continuous production.

Owner:GUANGDONG SHENGYI SCI TECH

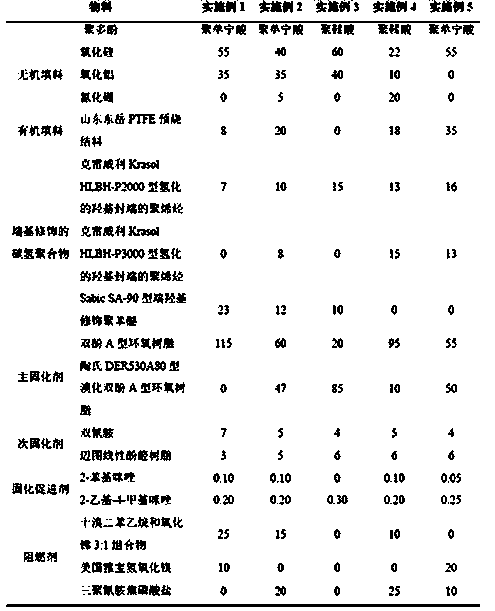

A polyphenol-modified hydrocarbon composition-based prepreg and its prepared copper-clad laminate

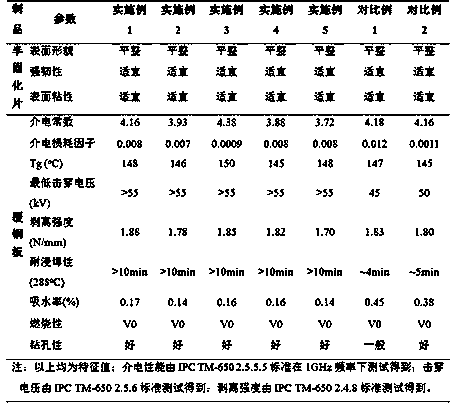

ActiveCN109796728BStrong adhesionAppropriate viscosityLaminationLamination apparatusPolymer sciencePolyolefin

The invention relates to a hydrocarbon composition-based prepreg modified by polyphenol and a copper-clad laminate prepared therefrom. The invention selects polyarylether or polyolefin resin modified by hydroxyl-terminated, amino-terminated or mercapto-terminated as matrix resin, and epoxy resin as main curing agent to construct a hydrocarbon composition with excellent dielectric properties. At the same time, the present invention also modifies polypolyphenols on the surface of reinforcing materials and fillers, because polypolyphenols are rich in hydroxyl functional groups, and can participate in the cross-linking and curing reaction of terminal-modified polyarylethers or polyolefins with epoxy resins In this way, the matrix resin is directly bonded to the surface of the reinforcement and filler, enhancing their compatibility and adhesion. Further, the high-frequency copper-clad laminate made of the prepreg and copper foil has good thermal-mechanical properties, excellent dielectric properties, good overall performance stability, good uniformity, high copper foil peel strength, and can meet high-frequency, high-speed Various comprehensive performance requirements for substrate materials in the communication field.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

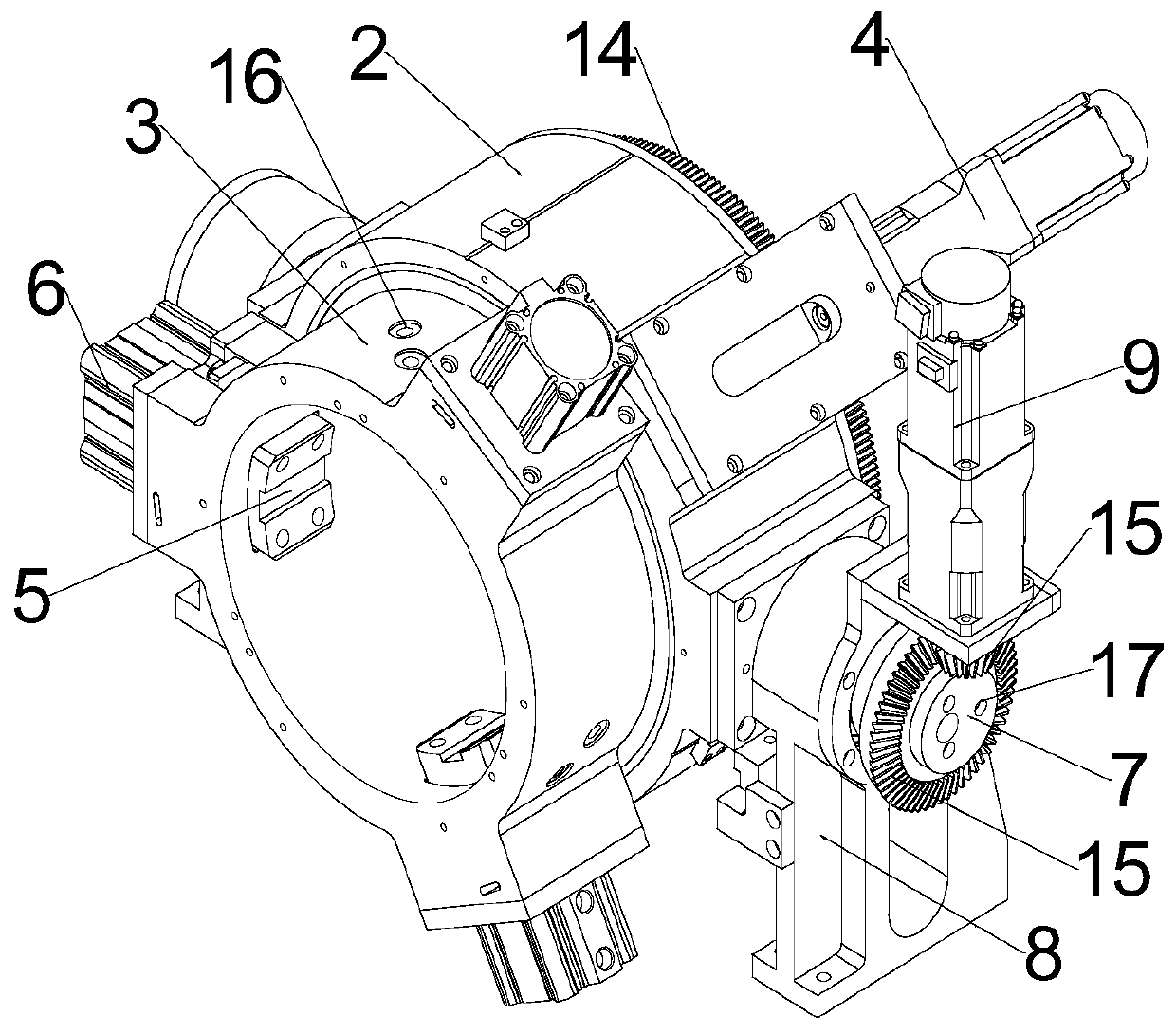

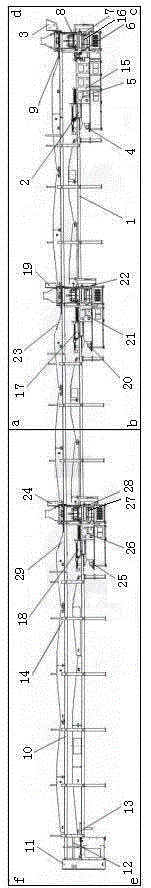

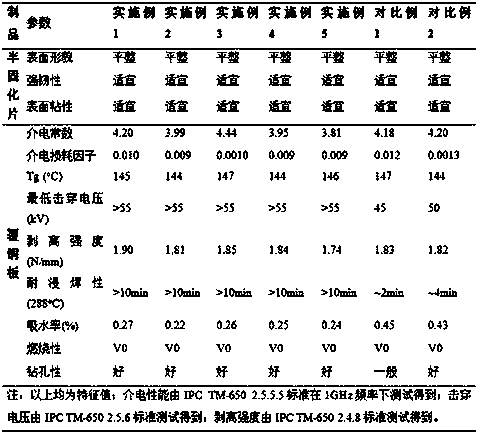

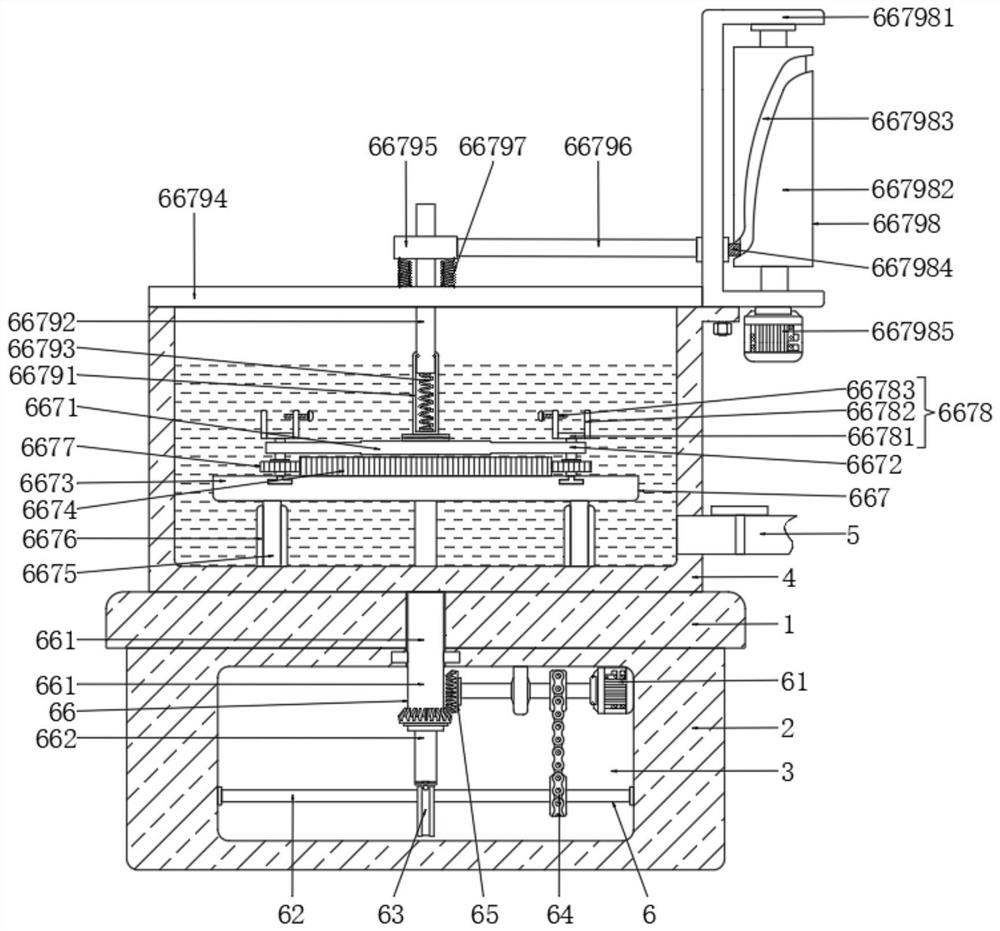

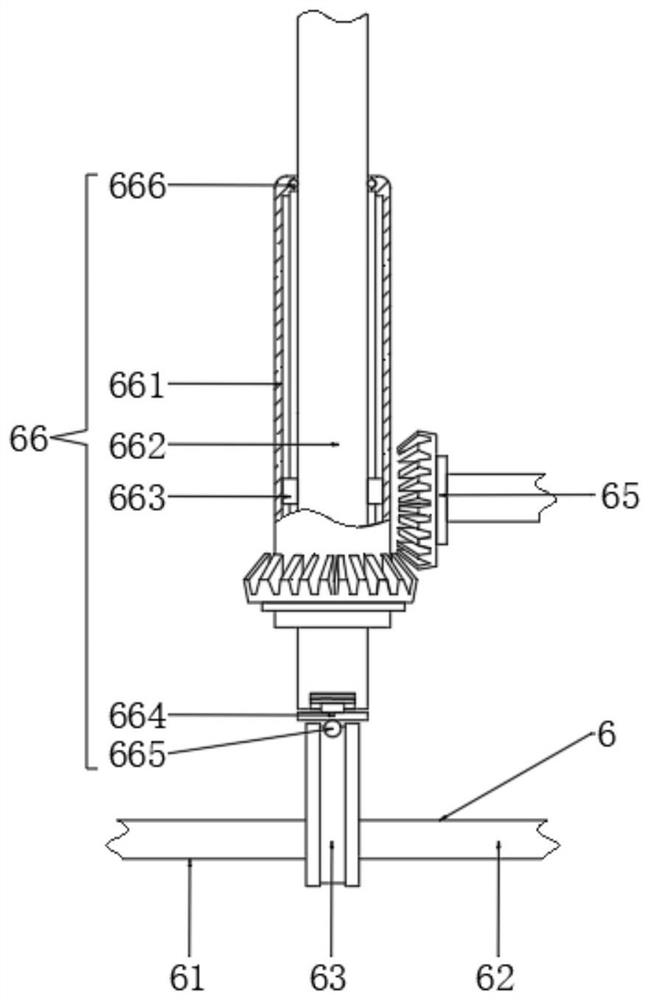

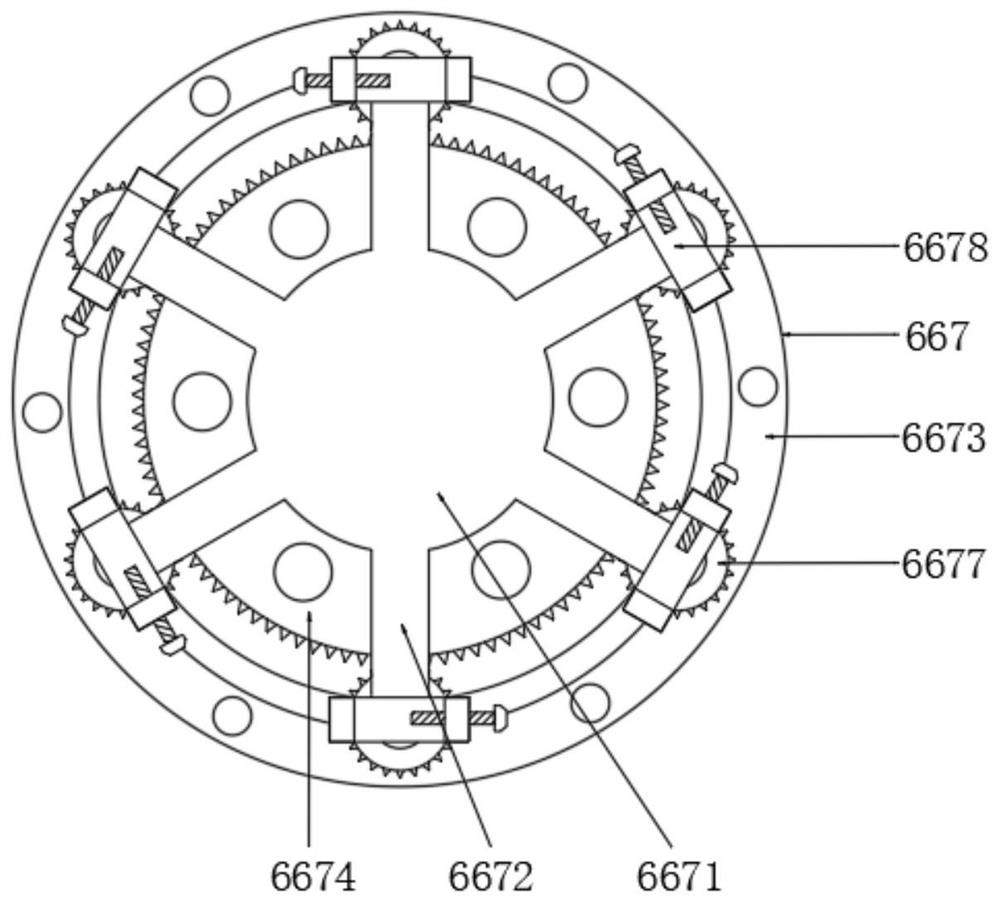

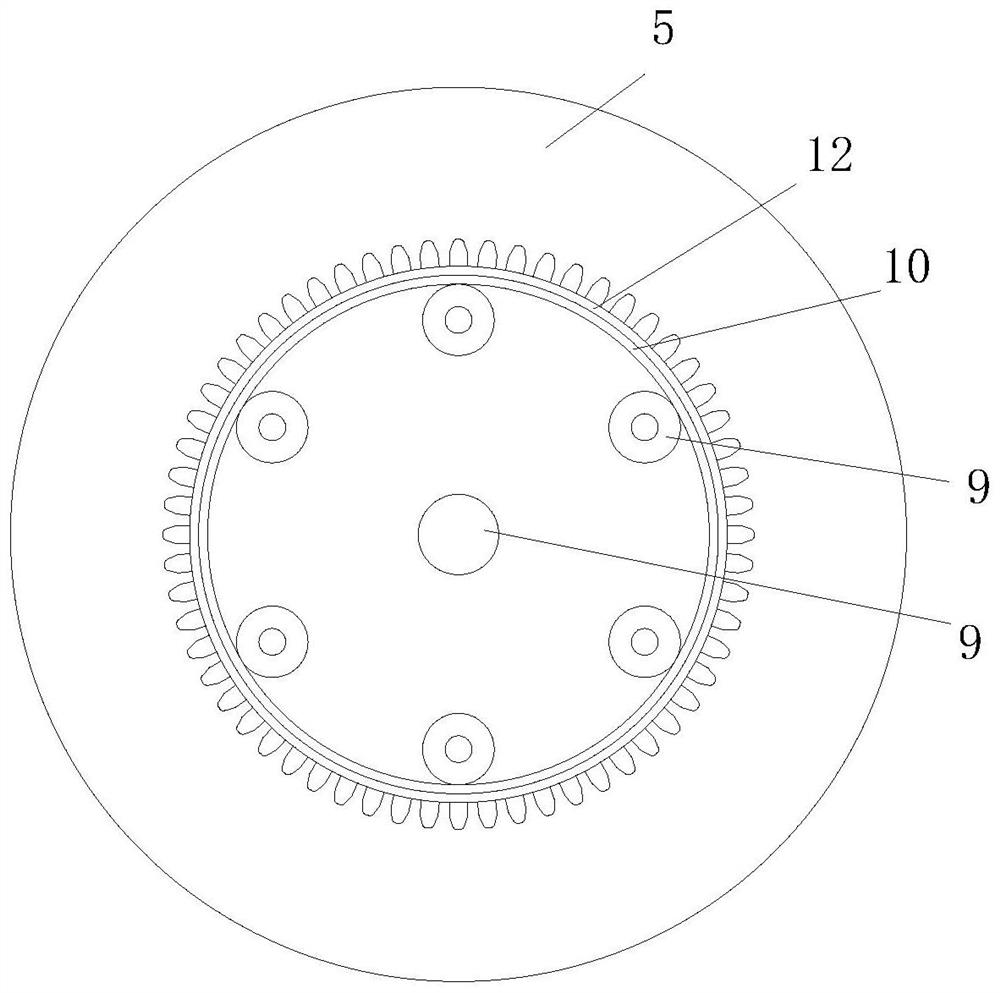

Stator assembly paint dipping device for motor production

ActiveCN112491226AImprove dipping uniformityKeep aliveManufacturing dynamo-electric machinesElectric machineGear wheel

The invention discloses a stator assembly paint dipping device for motor production in the technical field of paint dipping devices, and the stator assembly paint dipping device comprises: a base, wherein an assembly box is fixedly arranged at the bottom of the base, and a paint dipping box is fixedly arranged at the top of the base; and a paint dipping assembly which comprises a first driving motor fixed to the top of the inner wall of the right side of the assembling cavity, wherein the middle of the outer wall of the transverse rotating rod is fixedly sleeved with a cam, and a transmissionconnecting assembly matched with the driving bevel gear is arranged above the cam. According to the invention, through cooperation with a driving motor I, a transverse rotating rod, a cam, a chain, adriving bevel gear, a driven bevel gear, a transmission connection assembly, a bottom disc, a fluted disc, a driven gear and other structures, a plurality of groups of fixed motor stator assemblies tobe dipped with paint perform circular motion around a connection disc in paint and perform vertical motion in the paint while performing autorotation; and the paint dipping uniformity of the motor stator assembly is improved, meanwhile, the effect of disturbing paint is achieved, the activity of the paint is guaranteed, and the paint dipping quality is improved.

Owner:ZHEJIANG GUANGLU VIBRATOR

Deviation-prevention-type cord fabric glue dipping equipment

PendingCN109306584ANon-departure guaranteeDo not deviate do not appearTextile treatment carriersLiquid/gas/vapor textile treatmentControl signalPulp and paper industry

The invention discloses deviation-prevention-type cord fabric glue dipping equipment. The deviation-prevention-type cord fabric glue dipping equipment is structurally characterized in that a glue dipping roller is arranged in a glue dipping groove, an unwinding roller is arranged above one side of the glue dipping groove, a winding roller is arranged above the other opposite side of the glue dipping groove and connected with a winding motor, and a glue scraping roller and a scraping cutter are arranged between the glue dipping groove and the winding roller; a deviation-correction roller A is arranged between the glue dipping groove and the glue scraping roller, a deviation-correction roller B is arranged between the glue scraping roller and the winding roller, the deviation-correction roller A is connected with an adjusting motor A, and the deviation-correction roller B is connected with an adjusting motor B. The equipment has the advantages that the deviation-correction roller A can simultaneously ensure that cord fabric does not deviate when the cord fabric is in the glue dipping groove and is subjected to glue scraping, the deviation-correction roller B can further ensure that the cord fabric does not deviate during glue scraping, particularly, the adjusting motors are depended on to control the deviation-collection rollers to move left and right, it is ensured that the cordfabric cannot deviate in the whole glue feeding process, and the glue dipping quality is improved; a preferable photoelectric sensor can transmit deviation signals to a controller when receiving thedeviation signals, the controller transmits control signals to the corresponding adjusting motors, automatic deviation prevention is achieved, and the glue dipping quality is further improved.

Owner:JIANGYIN QIANGLI CHEM FIBER

Poly-polyphenyl modified fluorine-containing resin mixture and prepreg and copper-clad plate prepared therefrom

ActiveCN109825011AGood dispersionImprove adhesionSynthetic resin layered productsLaminationDispersityGlass fiber

The invention relates to a poly-polyphenyl modified fluorine-containing resin mixture and prepreg and a copper-clad plate prepared therefrom. Poly-polyphenyl is modified on the surfaces of inorganic filler and glass fiber fabric, so that dispersity of the inorganic filler in a fluorine-containing resin matrix, compatibility among the inorganic filler, the glass fiber cloth and fluorine-containingresin is improved, and interaction force among the inorganic filler, the fluorine-retaining resin, the glass fiber cloth and a copper foil is enhanced. Further, a high-frequency copper-clad plate madeby using the prepreg, a film and the copper foil is good in thermal-mechanical performance, excellent in dielectric performance, high in comprehensive performance stability, excellent in uniformity,especially high in striping strength of the copper foil and capable of meeting various comprehensive performance requirements of the high-frequency communication field on a substrate material.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

Glue dipping method for dry capacitive high voltage bushing core

Owner:石家庄市发运电气有限公司

A polyphenol-modified fluorine-containing resin mixture and prepreg and copper-clad laminate prepared therefrom

ActiveCN109825011BGood dispersionImprove adhesionSynthetic resin layered productsLaminationGlass fiberPolymer science

The invention relates to a polyphenol-modified fluorine-containing resin mixture and a prepreg and a copper-clad laminate prepared therefrom. The present invention modifies the surface of the inorganic filler and the glass fiber cloth with polyphenol, so as to promote the dispersion of the inorganic filler in the fluorine-containing resin matrix, improve the compatibility between the inorganic filler, the glass fiber cloth and the fluorine-containing resin, and further Enhance the interaction between inorganic filler, fluorine-containing resin, glass fiber cloth and copper foil. Further, the high-frequency copper-clad laminate made of the prepreg, film and copper foil has good thermal-mechanical properties, excellent dielectric properties, good overall performance stability, and good uniformity, especially the peel strength of the copper foil is very high, It can meet the comprehensive performance requirements of substrate materials in the high-frequency communication field.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

Motor coil paint dipping equipment

PendingCN112260500AEasy to paintSpeed up the flowManufacturing dynamo-electric machinesElectric machineryEngineering

The invention provides motor coil paint dipping equipment which comprises a paint dipping base. A vertically-arranged center channel with the open top end is formed in the paint dipping base, a plurality of vertically-arranged paint dipping channels with the open top ends are further formed in the paint dipping base, the multiple paint dipping channels are annularly arranged around the center channel, and the paint dipping channels communicate with the center channel. A plurality of paint outlet pipes which are respectively communicated with the plurality of paint dipping channels are arrangedon the paint dipping base, and paint outlet valves are arranged on the paint outlet pipes; a cover plate is installed at the top end of the paint dipping base in a matched mode, a paint inlet is formed in the cover plate, a paint inlet pipe which is communicated with the paint inlet and extends into the center channel is installed on the inner side of the cover plate, and a plurality of coil fixing frames which extend into the multiple paint dipping channels respectively are further installed on the inner side of the cover plate. A driving mechanism for driving the plurality of coil fixing frames to rotate in the plurality of paint dipping channels respectively is mounted on the cover plate. The paint dipping equipment is high in paint dipping efficiency and thorough in paint dipping, paint can be stirred through rotation of the coil fixing frame, flowing of the paint is accelerated, and painting of the coil is facilitated.

Owner:宣城坚腾智能传动设备有限公司

A polydopamine-modified hydrocarbon composition-based prepreg and its prepared copper-clad laminate

ActiveCN109867914BAppropriate viscosityUniform glue contentLamination ancillary operationsLaminationPolymer sciencePolyolefin

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

A kind of high-carbon anti-corrosion bamboo wallboard and production method thereof

ActiveCN106808550BImprove anti-corrosion performanceDoes not affect glossConstruction materialFlat articlesPreservativeHigh carbon

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

Fluorine-containing resin-based high-thermal-conductivity high-frequency copper-clad plate with high dielectric constant

PendingCN114536923ASmall coefficient of thermal expansionImprove bending strengthChemical industrySynthetic resin layered productsDielectricPhysical chemistry

The invention belongs to the technical field of communication materials, and particularly relates to a fluorine-containing resin-based high-thermal-conductivity high-frequency copper-clad plate with a high dielectric constant. The fluorine-containing resin-based high-thermal-conductivity high-frequency copper-clad plate is prepared in the mode that fluorine-containing resin mixture uniform dispersion liquid is prepared at first, then fluorine-containing resin-based composite paste is prepared, then a fluorine-containing resin-based dielectric sheet is prepared through blade coating, drying and sintering, and finally the fluorine-containing resin-based dielectric sheet and a copper foil are overlapped to prepare the final fluorine-containing resin-based high-thermal-conductivity high-frequency copper-clad plate.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

A method of vacuum impregnating paint for the plastic pipe of the oil quantity sensor of the fuel tank

ActiveCN109530174BHigh mechanical strengthImprove fill rateLiquid surface applicatorsSpraying apparatusLacquerFuel tank

Owner:四川泛华航空仪表电器有限公司

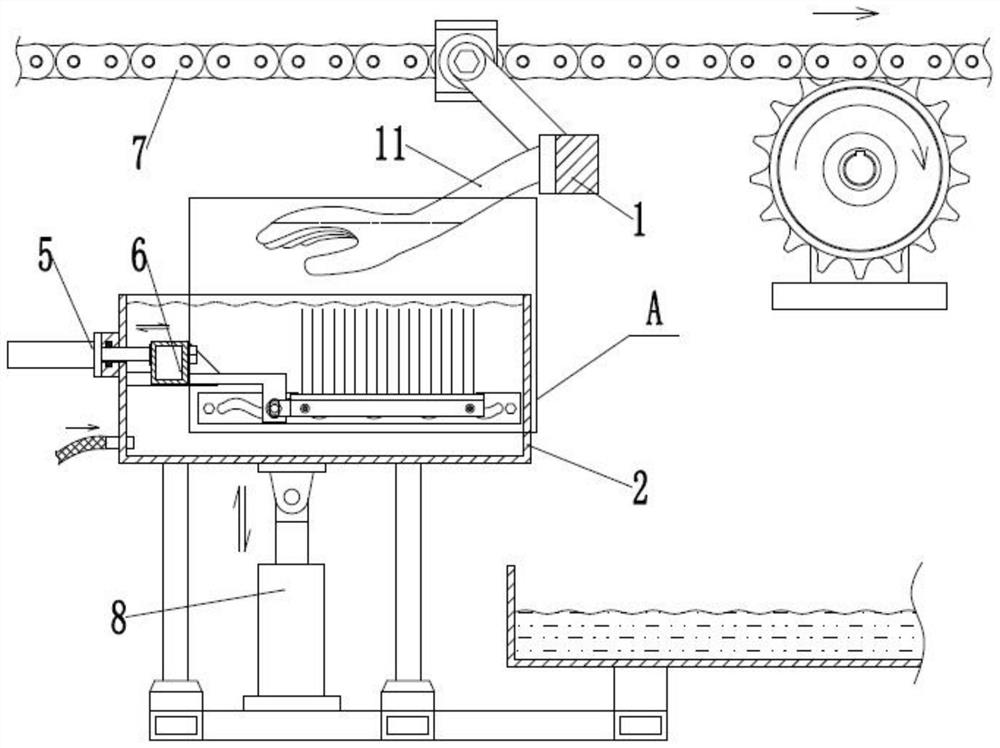

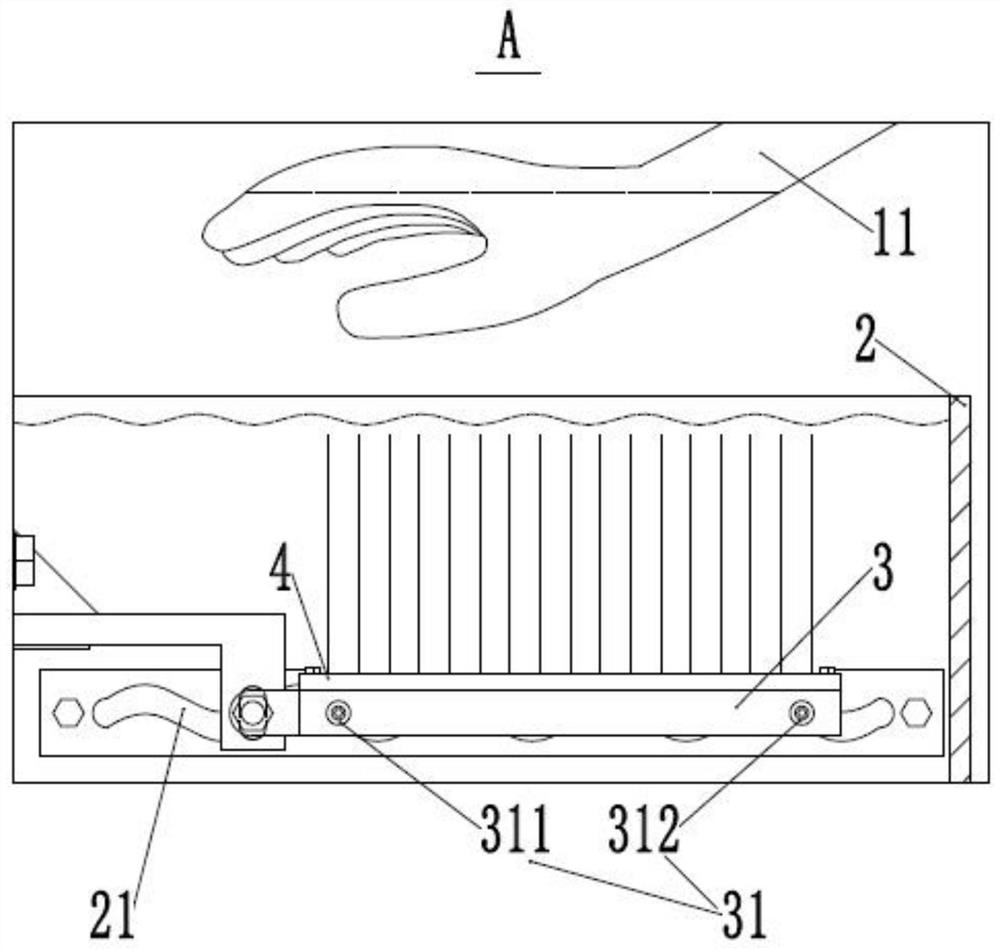

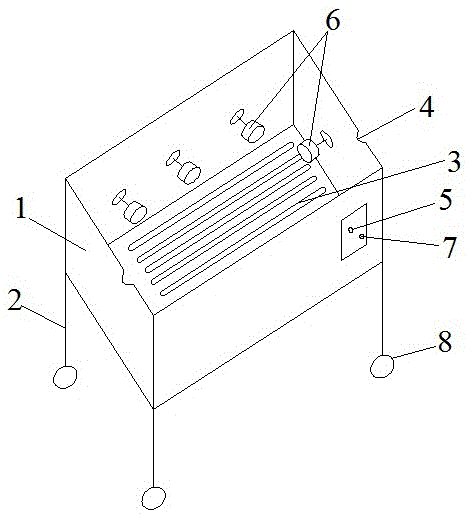

A method for dipping gloves and a dipping device for realizing the method

ActiveCN106584733BConsistent tilt angleConsistent depthDomestic articlesCoatingsEngineeringRejection rate

The invention discloses a gum dipping method for gloves. The gum dipping method comprises the following steps that 1), conveying chains drive a hand mold frame to the designated gum dipping position in a transmission manner; 2), the end of the hand mold frame is rotationally pressed; 3) the rotary shaft position of the hand mold frame is detected through a longitudinal detection switch; 4), the hand mold frame is driven to rotate; 5), the hand mold frame is driven to rotate at the set angle; 6), a gum dipping box moves upwards till hand molds are immersed into gum in the gum dipping box, and the gum dipping box falls off after gum dipping; and 7), the hand mold frame is driven to vibrate, and gum dipping of the hand molds is achieved. The invention further discloses a gum dipping device implementing the method. The gum dipping device comprises a rack. The conveying chains are connected to the rack. The hand mold frame is mounted on the conveying chain. The hand molds are mounted on the hand mold frame. The liftable gum dipping box is arranged below the rack. A rotary drive device is connected to the side of the rack. A positioning rod is mounted on the hand mold frame. A positioning rod detection device and a longitudinal detection device are mounted on the rack. By the adoption of the gum dipping method and the gum dipping device, the inclination angle of the hand molds is precise, and the gum dipping method and the gum dipping device have the beneficial effects that the gum dipping quality is high, and the rejection rate is low.

Owner:SHANDONG DENGSHENG SAFETY PROD

A kind of high-carbon anti-corrosion bamboo floor and production method thereof

ActiveCN106808547BImprove anti-corrosion performanceDoes not affect glossWood charring/burningHigh carbonCarbonization

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com