Transformer coil dipping device

A technology for transformer coils and dipping, which is applied in coil manufacturing, devices for applying liquid to surfaces, coatings, etc., can solve problems such as product quality reduction, and achieve higher efficiency, better dipping effect, and improved dipping quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

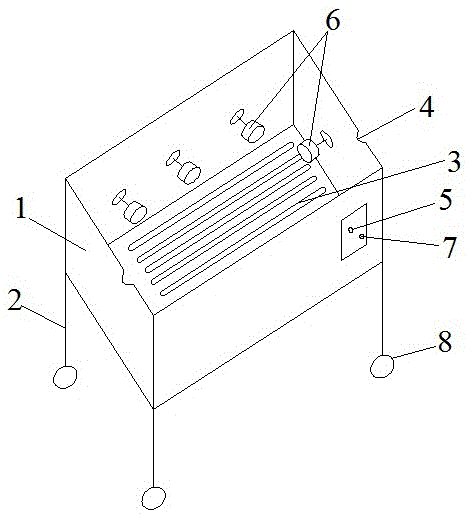

[0016] see figure 1 , The transformer coil dipping device of the present invention includes a dipping tank 1 and a main frame 2 for installing the dipping tank 1, wherein a heating device is provided at the bottom of the dipping tank 1, and a placement gap 4 is formed on the side wall. When dipping paint, first place the transformer coil on the paint dipping frame, and then clamp the two ends of the paint dipping frame in the placement gap 4, which can prevent the paint dipping frame from falling and make the paint dipping frame move to a certain extent It is convenient to manually shake the dipping frame to separate the transformer coils from each other.

[0017] As a preference, the heating device is a heating tube 3 , and the temperature of the heating tube 3 can also be adjusted freely through the temperature adjustment knob 5 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com