Silica gel gel dipping glove and gel dipping process thereof

A dipping and glove technology, applied in the field of labor insurance gloves, can solve the problems of poor firmness between the silicone layer and the glove core, affecting the wearer's comfort, and the wearer's inflexible operation, so as to achieve rich appearance colors and rich appearance of gloves. Aesthetics, the effect of improving the quality of dipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

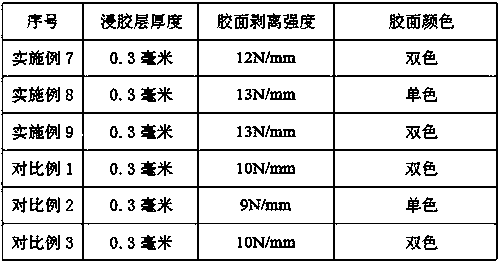

Examples

Embodiment 1

[0020] The preparation of the mixed rubber layer of silica gel: put 8Kg of silica gel in the batching kettle, add 1Kg of curing agent, 0.8Kg of 2-methyl silicone oil and 0.2Kg of color paste, and mix evenly to prepare the dipping material. The curing agent is made of positive silicon Ethyl acetate and dibutyltin dilaurate are mixed in a weight ratio of 4:1.

Embodiment 2

[0022] Preparation of silica gel mixed rubber layer: put 9Kg of silica gel in the batching kettle, add 0.5Kg of curing agent and 0.5Kg of 2-methyl silicone oil, and mix evenly to prepare the dipping material. The curing agent is composed of tetraethyl orthosilicate and Dibutyltin laurate is mixed according to the weight ratio of 5:1.

Embodiment 3

[0024] The preparation of the mixed rubber layer of silica gel: put 7Kg of silica gel in the batching kettle, add 2Kg of curing agent, 0.5Kg of 2-methyl silicone oil and 0.5Kg of color paste, and mix evenly to prepare the dipping material. The curing agent is made of positive silicon Ethyl acetate and dibutyltin dilaurate are mixed in a weight ratio of 4:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com