Multi-dipping-type full-automatic enteric hollow capsule forming manufacturing production line

A hollow capsule, fully automatic technology, applied in the direction of capsule delivery, drug delivery, household components, etc., can solve the problems of unstable sanitary conditions, high labor costs, low production efficiency, etc., achieve suitable digestion and absorption, and improve the quality of glue dipping , to avoid the effect of uneven thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

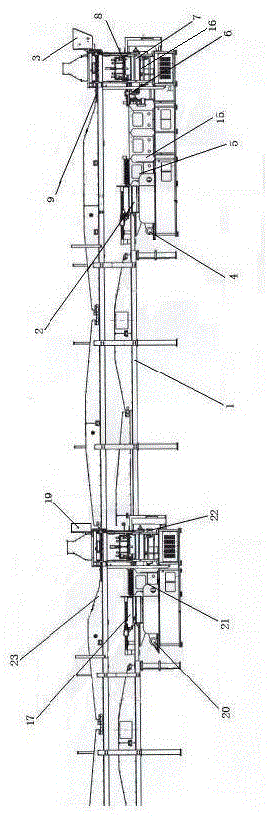

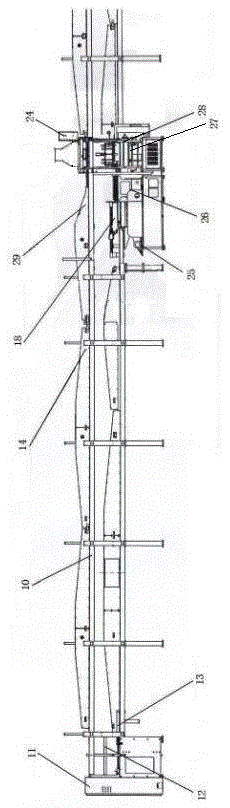

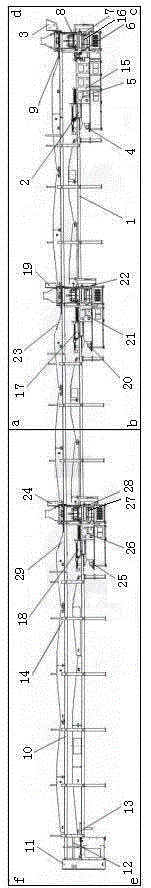

[0018] As shown in the figure, a multi-dip automatic enteric-coated hollow capsule production line is manufactured, including frame 1, main workbench 2, main electric control box 3, main drive 4, automatic machine 5, and oiling device 6 , glue dipping device 7, capsule mold 8, forward pushing device 9, conveying device 10, rear electric control box 11, lifting device 12, pushing device 13, drying device 14 and demoulding device 15; Wherein, main workbench 2 is installed At the front end of the frame 1, the rear electric control box 11, the lifting device 12, and the push-back device 13 are installed on the rear end of the frame 1 and connected to each other, the main electric control box 3, the main drive 4, the automatic machine 5, the oiling device 6, Glue dipping device 7, capsule mold 8, forward pushing device 9 and demoulding device 10 are installed on the main workbench and connected to each other, conveying device 10 and drying device 14 are installed on frame 1 and conn...

Embodiment 2

[0021] The needles (control group) made of common mold materials and the needles (experimental group) made of special capsule mold alloy steel in the present invention were used for production control test.

[0022]The composition and mass percentage of the capsule mold alloy steel used in the present invention are: C: 2.30-2.45%, Cr: 0.55%, Si: ≤0.40%, Mn: ≤0.30%, Ni: ≤0.10%, Cu: ≤0.10%, S: ≤0.030%, P: ≤0.030%, the balance is Fe.

[0023] Both the control group and the experimental group were oiled with the same release agent, and the drying temperature was kept at 30-35°C. 2), 42-45 ℃ (experiment 3), through the control experiment, the sag rate of the hollow capsule obtained is very different. The comparison list of the number of hollow capsules whose sag is greater than 0.5mm is as follows:

[0024]

[0025] It can be seen that in the present invention, the hollow capsules produced by the needles made of capsule mold alloy steel have only 2.5%, 3.1%, and 2.8% dents res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com