A servo dipping device

A technology of dipping glue and dipping glue twice, applied in the direction of coating, etc., can solve the problems of cumbersome production process, low degree of automation, and too many users, and achieve the effect of simple structure, reliable operation, and uniform dipping glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

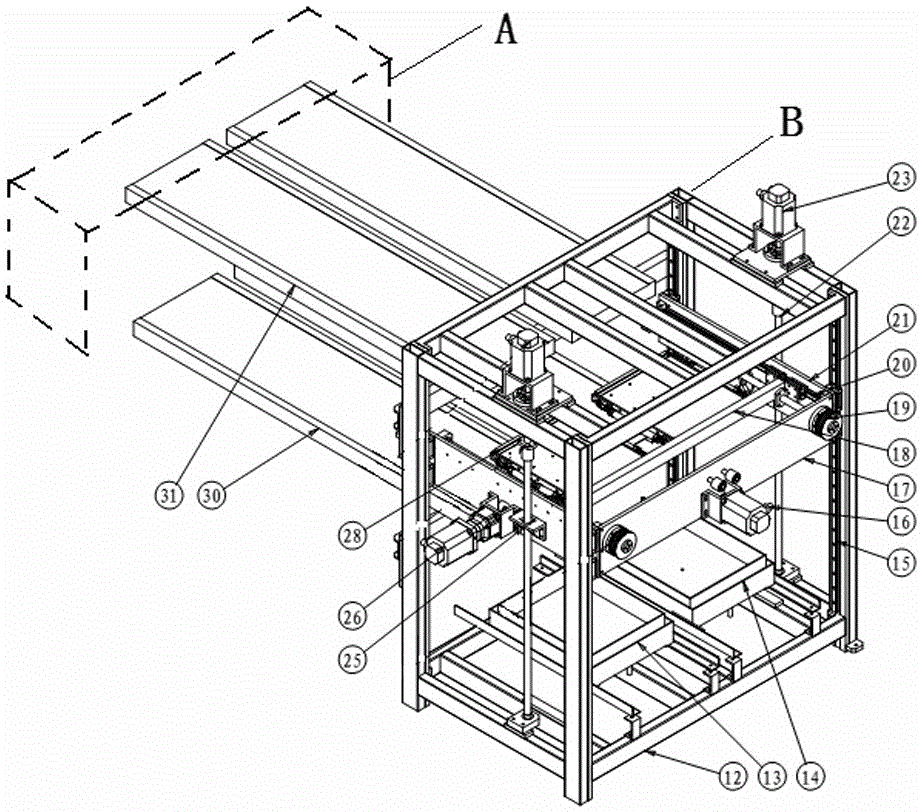

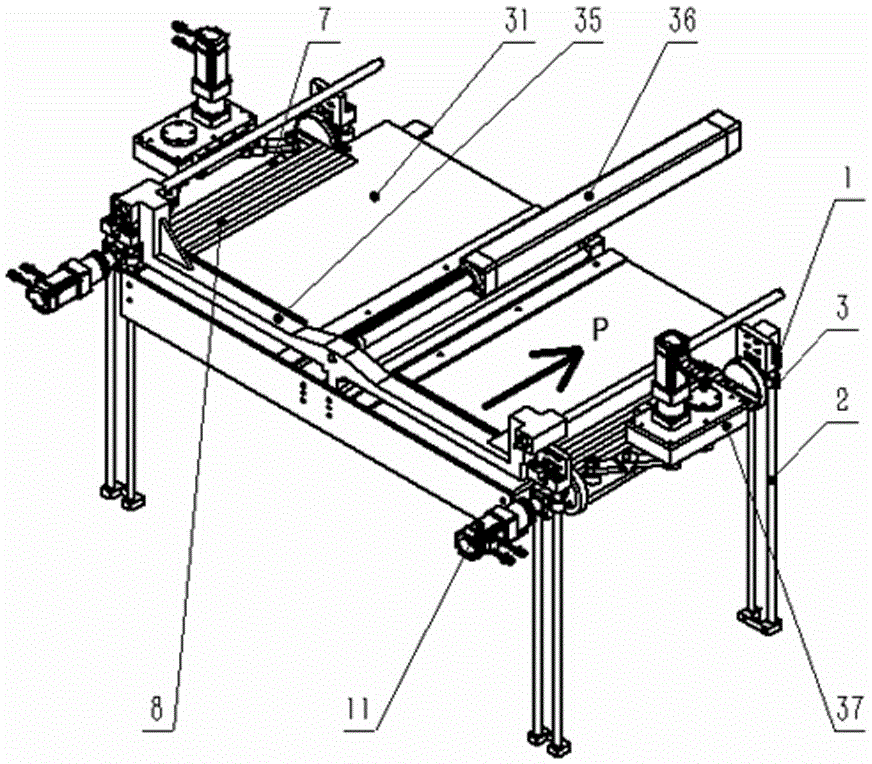

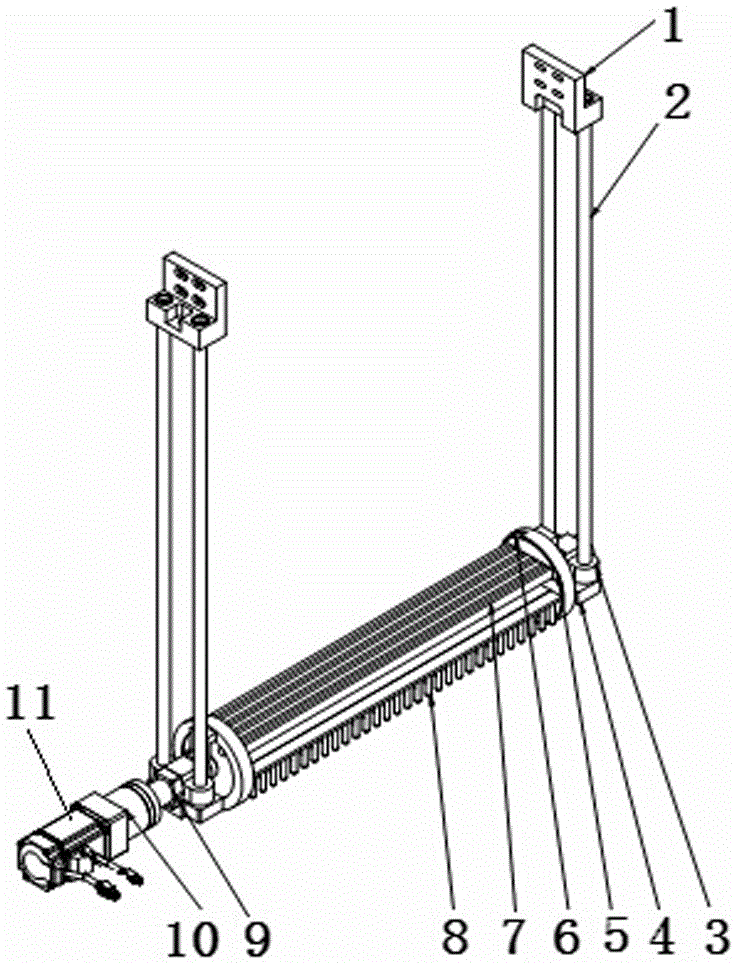

[0014] see Figure 1 to Figure 4 , a servo dipping device of the present invention, including a primary dipping assembly A, a secondary dipping assembly B, and an upper conveyor line 31 and a lower conveyor line 30 for transferring mold bars between the two, characterized in that, The secondary dipping assembly B includes a frame 12, a lifting frame, a mold strip tray 28, a tray turning motor 26, a lifting frame lifting mechanism and a lower propulsion mechanism, and the lifting frame is longitudinally slid on the frame through a guide rail. A lifting frame lifting mechanism is housed between the frame and the lifting frame; the tray turning motor 26 is installed on both sides of the lifting frame, and the output shaft of the tray turning motor 26 is connected with the bottom of the mold strip tray 28 installed in the lifting frame; A lower propulsion mechanism is provided above the pallet 28; a glue groove is provided below the lifting frame.

[0015] Described elevating fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com