Impregnation method for dry capacitance type high-voltage bushing core

A high-voltage bushing, capacitor-type technology, applied in circuits, insulators, electrical components, etc., can solve the problems of difficult to remove air bubbles, low product qualification rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

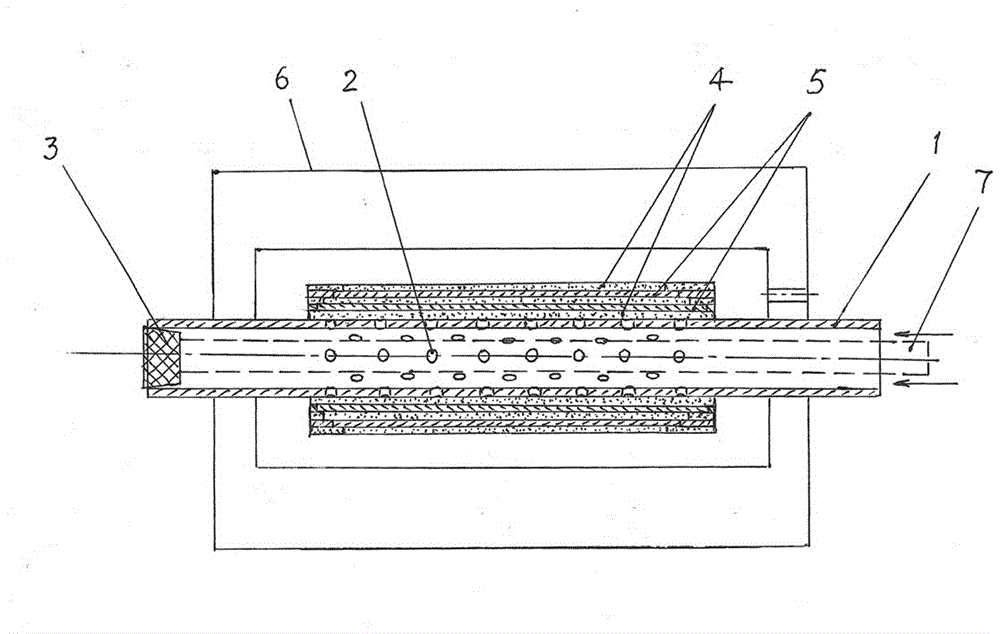

[0025] Such as figure 1 As shown, the dipping method for the core of the dry capacitor type high voltage bushing of the present invention includes the following steps:

[0026] 1. Open a number of distributed through holes 2 on the pipe wall within the range of the capacitive screen on the conductive pipe 1, so that the pipe section forms a mesh pipe section.

[0027] 2. Use the plug 3 to block one end of the conductive tube 1 to form a closed end. The closed end of the conductive tube 1 should be able to withstand more than 2 atmospheric pressures.

[0028] 3. Wrap the outer circumference of the conductive tube 1 with an insulating material to form an insulating layer 4 covering the conductive tube, and then wind the outer circumference of the insulating layer 4 with a conductive material to form a capacitive screen 5 covering the insulating layer, and then on the capacitive screen The outer circumference of 5 is wound with insulating material to form an insulating layer covering t...

Embodiment 2

[0034] Such as figure 1 As shown, the dipping method for the core of the dry capacitor type high voltage bushing of the present invention includes the following steps:

[0035] 1. Open a number of distributed through holes 2 on the pipe wall within the range of the capacitive screen on the conductive pipe 1, so that the pipe section forms a mesh pipe section.

[0036] 2. Insert an inner tube 7 into the conductive tube 1. The length of the inner tube 7 can be greater than the length of the conductive tube 1. There is a sufficient glue gap between the outer wall of the inner tube 7 and the inner wall of the conductive tube 1.

[0037] 3. Close one end (left end) of the conductive tube 1 and the inner tube 7 (the dashed line in the figure) on the same side. The closed end of the conductive tube 1 should be able to withstand more than 3 atmospheric pressures. In addition, the right end of the inner tube 7 should protrude from the open end of the conductive tube 1.

[0038] 4. Wrap the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com