A kind of decontamination vacuum dipping tank and dipping method

A vacuum immersion and varnish dipping technology, which is applied to coatings, devices for coating liquid on the surface, etc., can solve the problems of insulation performance degradation, valve and paint pipe blockage, etc., so as to reduce the incidence of accidents, prevent blockage, The effect of suitable dipping temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in combination with specific embodiments.

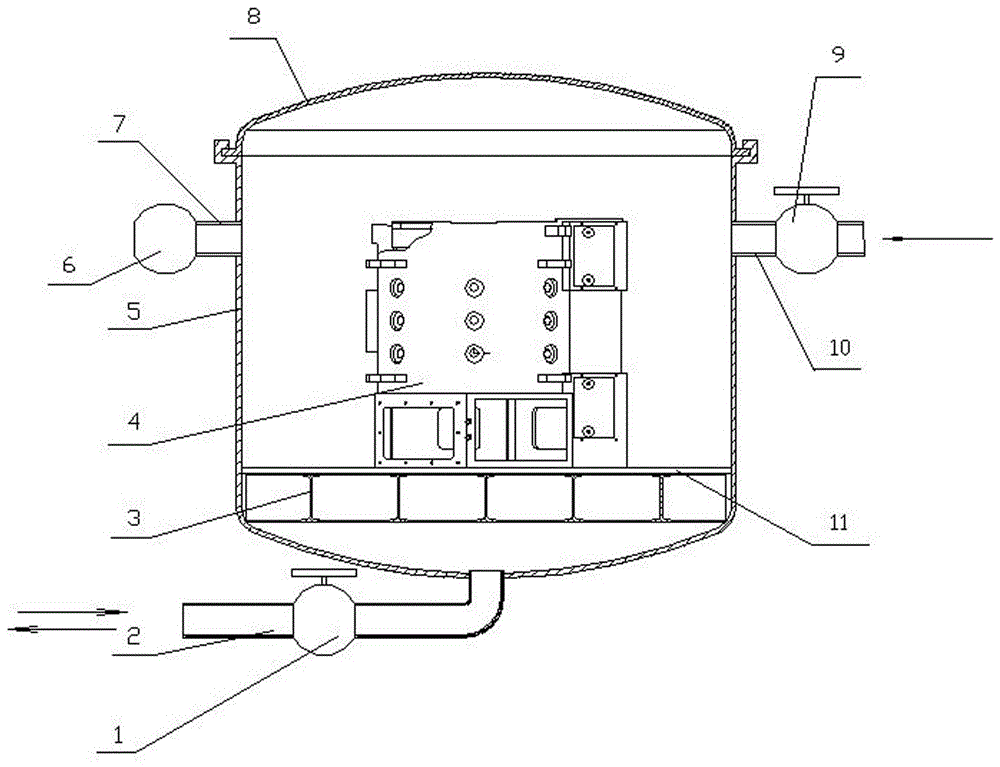

[0027] As shown in the figure: a decontamination vacuum impregnation tank, including a tank body 5, a tank cover 8 matching the tank body 5, a paint delivery pipe 2, a bracket 3, a vacuum pump 6, a compressed air pipe 10 and a filter screen 11, the The bottom of the tank body 5 is communicated with a paint delivery pipe 2, the compressed air pipe 10 communicates with the upper part of the tank body 5, the vacuum pump 6 is connected with the upper part of the tank body 5 through the vacuum tube 7, and the filter screen 11 is arranged on the tank body 5 through the bracket 3. Inside: the filter screen 11 is movably arranged on the bracket 3; the paint delivery pipe 2 is provided with a valve 1; the compressed air pipe 10 is provided with a compressed air valve 9.

[0028] A kind of method that utilizes dipping tank as above, comprises the following steps:

[0029] Step 1: P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com