Efficient gum dipping device for raw cloth processing

A dipping device and high-efficiency technology are applied in the field of high-efficiency dipping devices for original fabric processing, which can solve the problems of high cost of scraper replacement, affecting the quality of dipping, etc., so as to improve the quality of dipping, facilitate collection, and facilitate cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

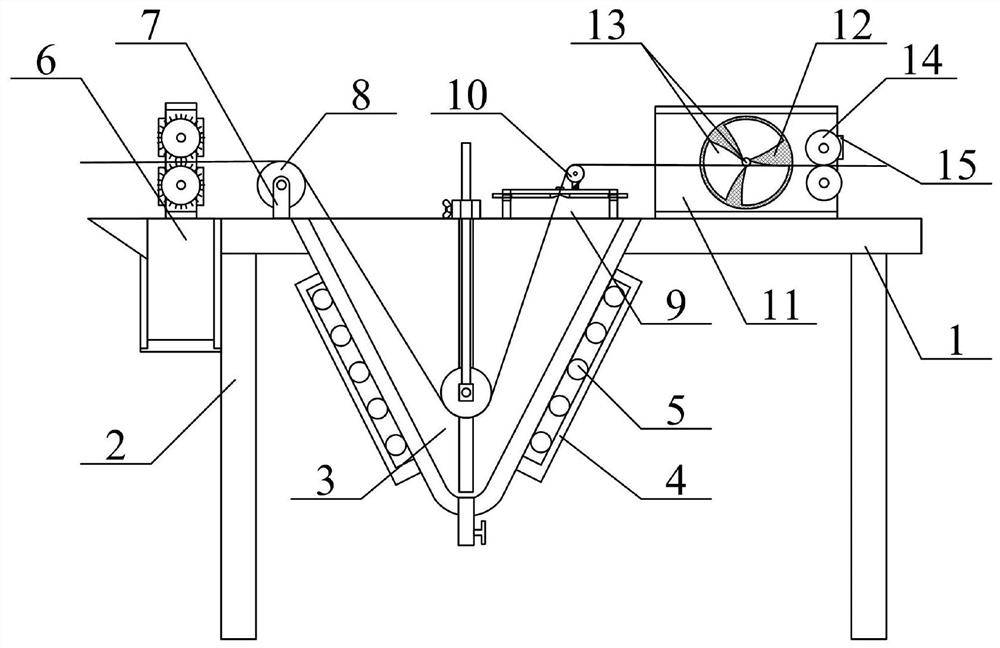

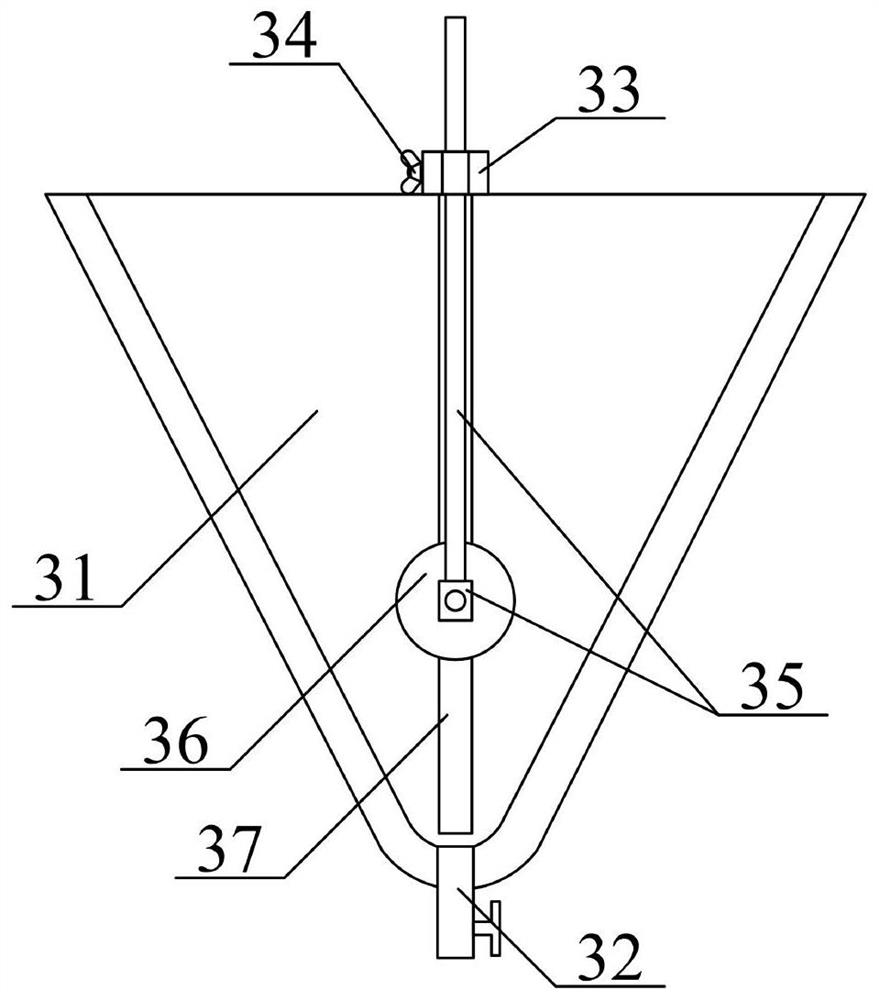

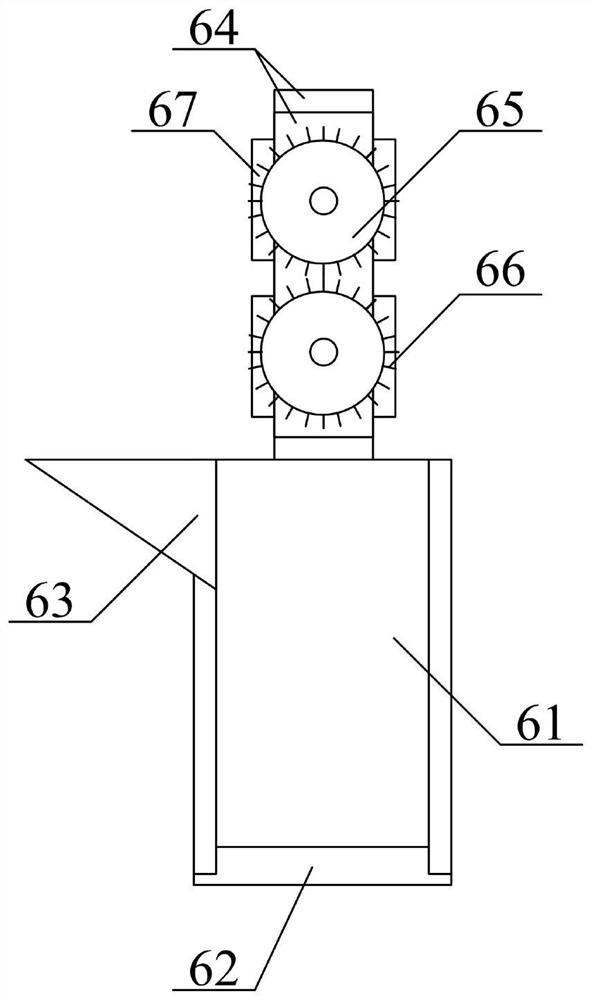

[0036] as attached figure 1 And attached figure 2As shown, a high-efficiency dipping device for raw fabric processing includes a workbench 1, support legs 2, a dipping frame structure 3, a protective shell 4, an electric heating tube 5, a debris collection frame structure 6, and a support frame 7. Roller 8, uniform scraping frame structure 9, end cover mounting frame structure 10, air-drying box 11, dust-proof net 12, fan 13, driving roller 14 and driving motor 15, and the support legs 2 are respectively bolted to the workbench The four corners of the lower part of 1; the dipping frame structure 3 is installed on the left side of the workbench 1; the protective shell 4 is respectively arranged on the left and right sides of the dipping frame structure 3; the electric heating tube 5 Screws are connected to the inner side of the protective shell 4; the sundries collection rack structure 6 is installed on the left side of the workbench 1; the support frame 7 is bolted to the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com