Glue dipping method for dry capacitive high voltage bushing core

A high-voltage bushing and capacitive technology, which is applied in the direction of circuits, insulators, electrical components, etc., can solve the problems of low product pass rate and difficult to eliminate air bubbles, and achieve high product pass rate, increase pass rate, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

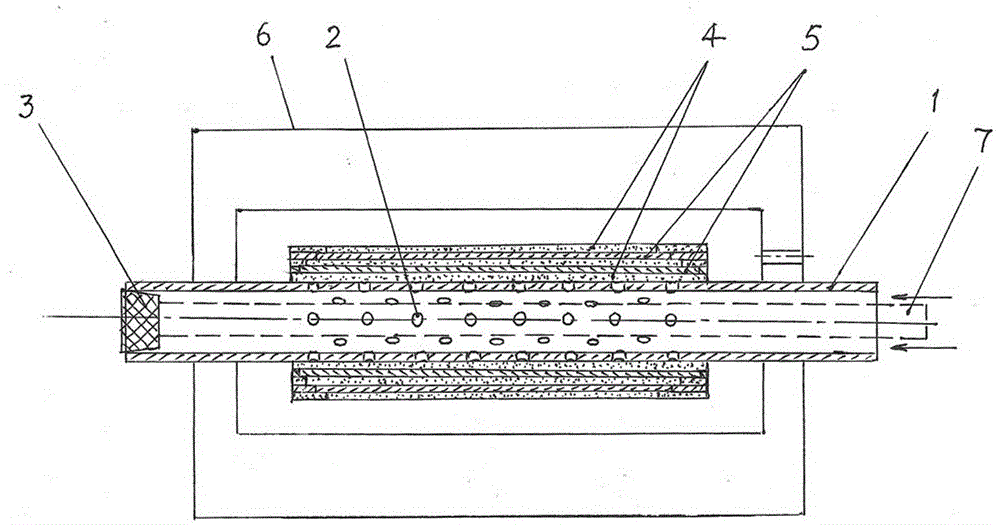

[0025] Such as figure 1 As shown, the dipping method of the dry capacitor type high voltage bushing core of the present invention comprises the following steps:

[0026] 1. A plurality of distributed through-holes 2 are opened on the tube wall within the range of the capacitive screen on the conductive tube 1, so that the tube section forms a mesh tube section.

[0027] 2. Plug one end of the conductive tube 1 with a plug 3 to form a closed end. The closed end of the conductive tube 1 should be able to withstand more than 2 atmospheric pressures.

[0028] 3. Wrap the outer circumference of the conductive tube 1 with an insulating material to form an insulating layer 4 covering the conductive tube, and then wrap the outer circumference of the insulating layer 4 with a conductive material to form a capacitive screen 5 that covers the insulating layer. The outer circumference of 5 is wound with insulating material to form an insulating layer covering the capacitive screen. Afte...

Embodiment 2

[0034] Such as figure 1 As shown, the dipping method of the dry capacitor type high voltage bushing core of the present invention comprises the following steps:

[0035] 1. A plurality of distributed through-holes 2 are opened on the tube wall within the range of the capacitive screen on the conductive tube 1, so that the tube section forms a mesh tube section.

[0036] 2. Insert an inner tube 7 into the conductive tube 1. The length of the inner tube 7 can be longer than the length of the conductive tube 1. There is a sufficient glue gap between the outer wall of the inner tube 7 and the inner wall of the conductive tube 1.

[0037]3. Close the same side (left end) of the conductive tube 1 and the inner tube 7 (the dotted line in the figure), and the closed end of the conductive tube 1 should be able to withstand more than 3 atmospheric pressures. In addition, the right end of the inner tube 7 should protrude from the open end of the conductive tube 1 .

[0038] 4. Wrap the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com