A polydopamine-modified hydrocarbon composition-based prepreg and its prepared copper-clad laminate

A technology of hydrocarbon composition and polydopamine, which is applied in the field of communication materials, can solve the problem of difficulty in satisfying functional diversification and complexity and high density, copper clad laminate dielectric properties and its uniformity are not perfect, glass fiber cloth and inorganic fillers Poor compatibility and other problems, to achieve the effect of good industrial production basis, high peel strength of copper foil, easy to batch and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

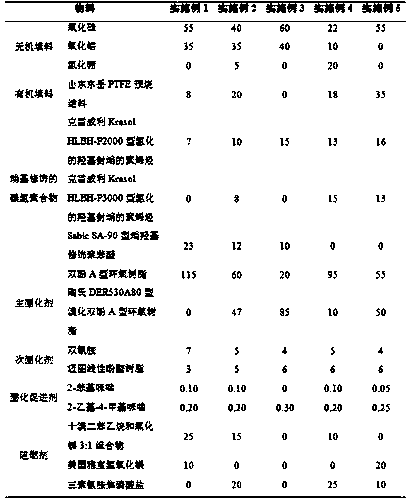

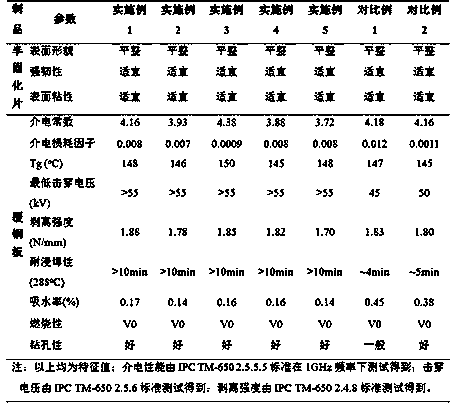

Embodiment 1~5

[0033] The 1080 glass fiber cloth was soaked in 1.5wt% dopamine Tris-HCl (pH=8.6) buffer solution for 30 minutes and then taken out to prepare the 1080 glass fiber cloth with surface modified PDA, denoted as "PDA@1080 glass fiber cloth" . The filler was stirred and soaked in a Tris-HCl (pH=8.6) buffer solution of dopamine, soaked for 30 minutes, filtered, washed, and dried to obtain a filler with surface-modified PDA, which was designated as "PDA@filler". Evenly disperse the hydroxyl-terminated hydrocarbon polymer, primary curing agent, secondary curing agent, curing accelerator, "PDA@filler" and flame retardant in toluene, control the solid content of the dispersion at 60wt%, and then "PDA@1080 glass fiber cloth" is dipped in the uniform dispersion liquid and baked to obtain a prepreg. The baking and drying temperature of the first stage is 60~100°C; the baking and drying temperature of the second stage is 120~190°C. Take 8 prepregs and stack them together, attach loz coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com