Coating method of silicon carbide ceramic membrane for high-temperature filtration

A technology of silicon carbide ceramics and filter membranes, applied in the field of porous ceramics, can solve the problems of difficulty in ensuring the uniformity and integrity of the membrane, difficulty in realizing industrial application, and high cost, and achieve easy industrial production, industrial production, and good film formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

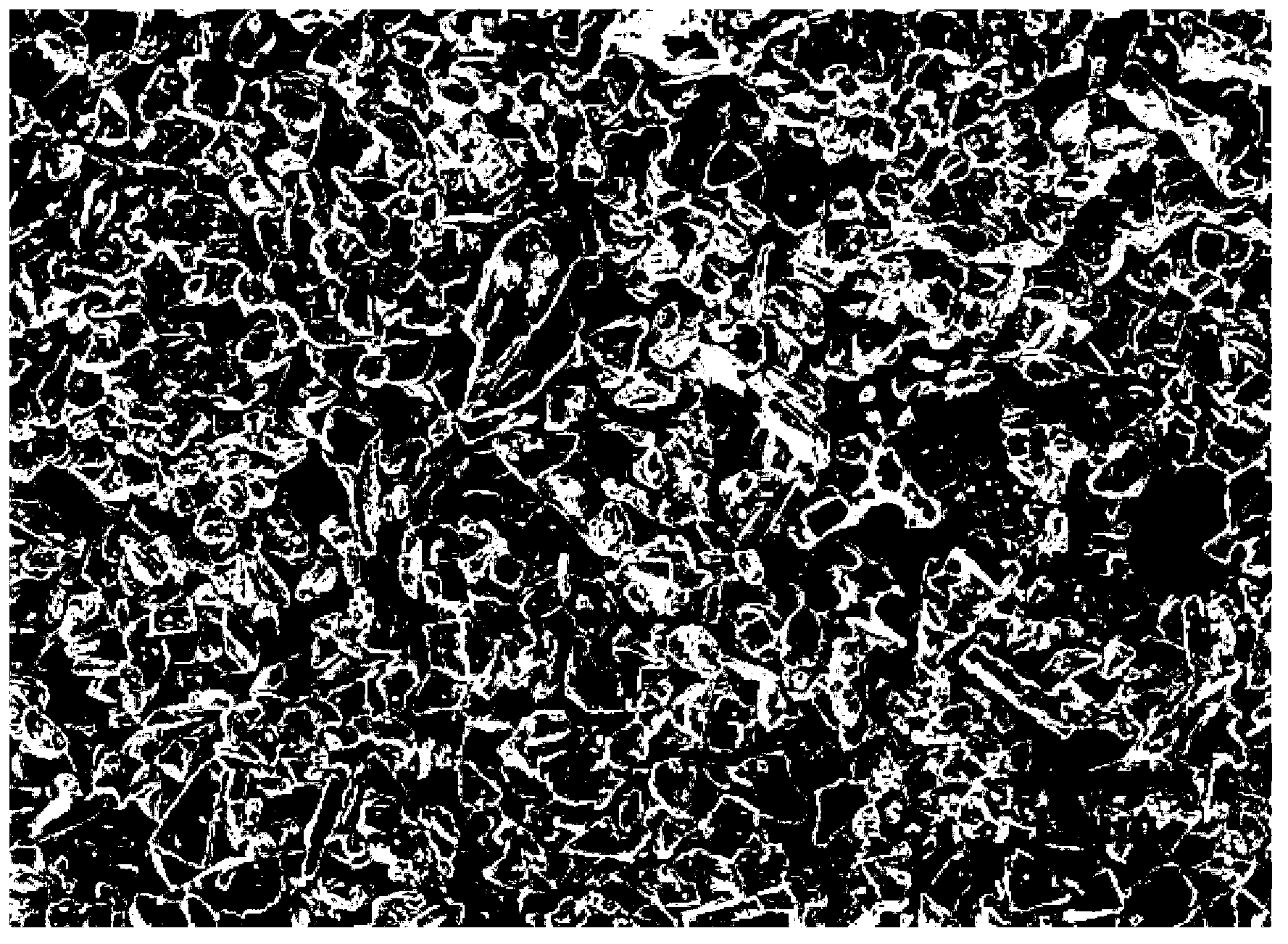

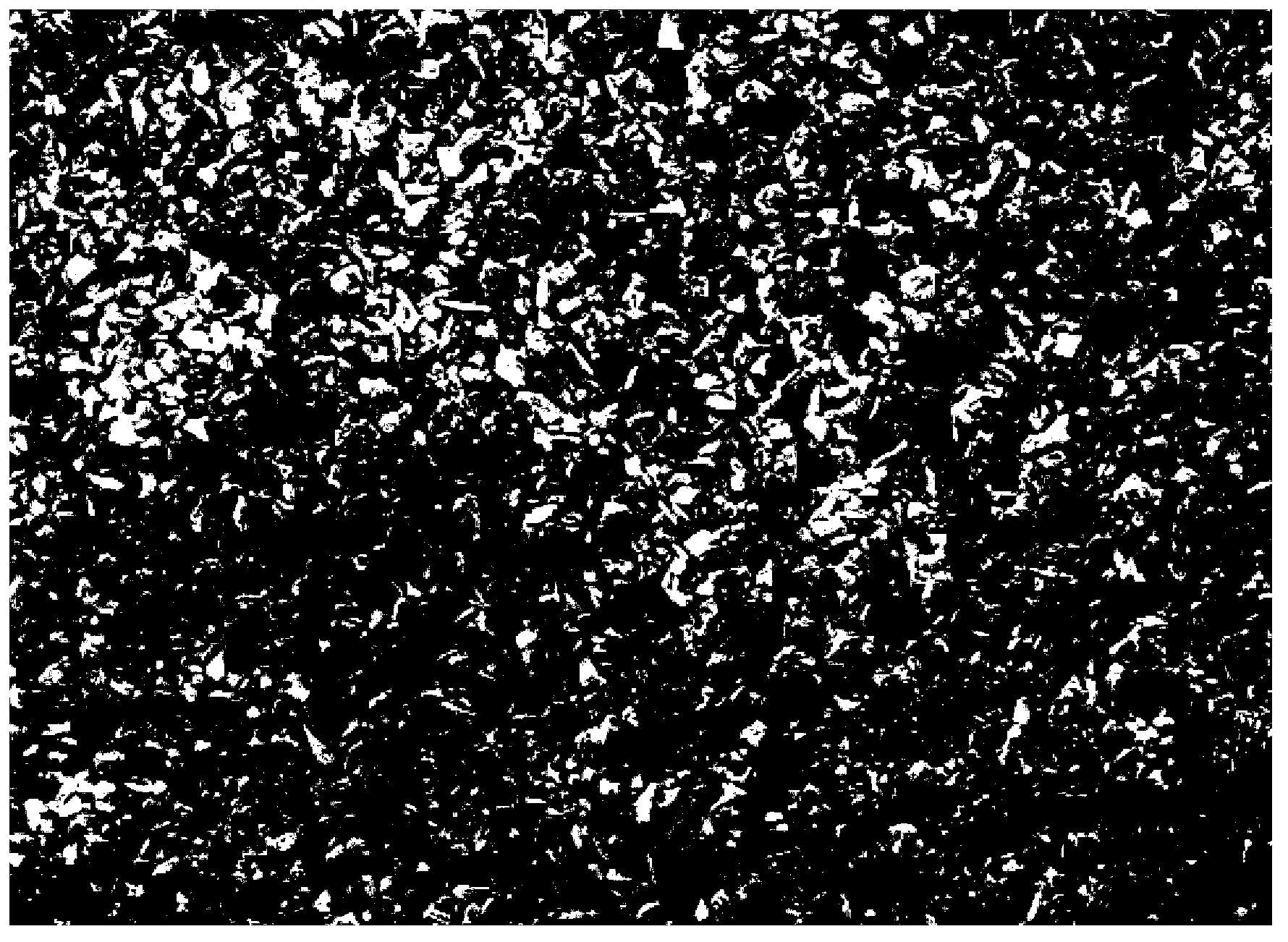

Image

Examples

Embodiment 1

[0023] (1) According to the mass ratio of silicon carbide powder, ceramic binder, pore-forming agent and sodium carboxymethylcellulose (CMC) solution as 10:1.1:0.4:1.4, the required amount of each raw material was weighed respectively, and It is mixed and stirred evenly and then dry-pressed to form a support body with a pressure of 5 MPa to prepare a green body with a diameter of 50 mm and a thickness of about 5 mm. The average particle size of silicon carbide particles is 150 μm, the mass concentration of sodium carboxymethylcellulose (CMC) solution is 1.5wt%, the pore-forming agent is graphite, and the binder is 65wt% potassium feldspar, 12wt% kaolin and 23wt% quartz sand ball mill mixture.

[0024] (2) The support was sintered, and the prepared green body was dried in an oven at 110 °C for 24 h, with a heating rate of 20 o C / min sintering to 1200°C, holding time is 1h.

[0025] (3) Weigh 2g of mullite fiber with a length of 1~2cm, 1.8g of aluminum silicate fiber, 2g of so...

Embodiment 2

[0033] (1) Same as steps (1) to (6) of Example 1

[0034] (2) The solvent of the coating solution is 15:35:50 according to the volume ratio of propylene glycol, ethanol, and ethylene glycol;

[0035] (3) Using 300 mesh chromatographic alumina as a binder;

[0036] (4) According to the mass ratio of silicon carbide powder, ceramic binder, and coating solution as 10:3:40, weigh the required amount of each raw material respectively, first add the coating solution into the beaker, and then add silicon carbide in turn The powder and the ceramic binder utilize magnetic stirring to obtain a uniform filter membrane slurry; in the preparation of the filter membrane slurry, the particle size of the silicon carbide powder is 23.1 μm, and the particle size of the chromatographic alumina binder is 0.1~19μm;

[0037] (5) with the step (8) of embodiment 1

[0038] (6) Dry the prepared filter material in an oven at 110°C for 12 hours, then dry it at 200°C for 10 hours, and calcinate the co...

Embodiment 3

[0041] (1) with the step (1)~(6) of embodiment 1;

[0042] (2) The solvent of the coating solution is 10:10:20:60 according to the volume ratio of triethylene glycol, glycerin, ethanol, and ethylene glycol;

[0043] (3) Aluminum hydroxide is used as a binder;

[0044] (4) According to the mass ratio of silicon carbide powder, ceramic binder, and coating liquid as 10:3:50, weigh the required amount of each raw material respectively, first add the coating liquid into the beaker, and then add silicon carbide in turn The powder and the ceramic binder are stirred by magnetic force to obtain a uniform filter membrane slurry; in the preparation of the filter membrane slurry, the particle size of the silicon carbide powder is 7.6 μm, and the particle size of the aluminum hydroxide binder is 0.1 μm. ~11μm;

[0045] (5) with the step (8) of embodiment 1

[0046] (6) Dry the prepared filter material in an oven at 110°C for 12 hours, then dry it at 200°C for 12 hours, and calcinate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com