Fibre membrane with porous structure and production thereof

A technology of porous structure and fiber membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as low strength, inability to meet the needs of the development of sewage treatment, and small specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

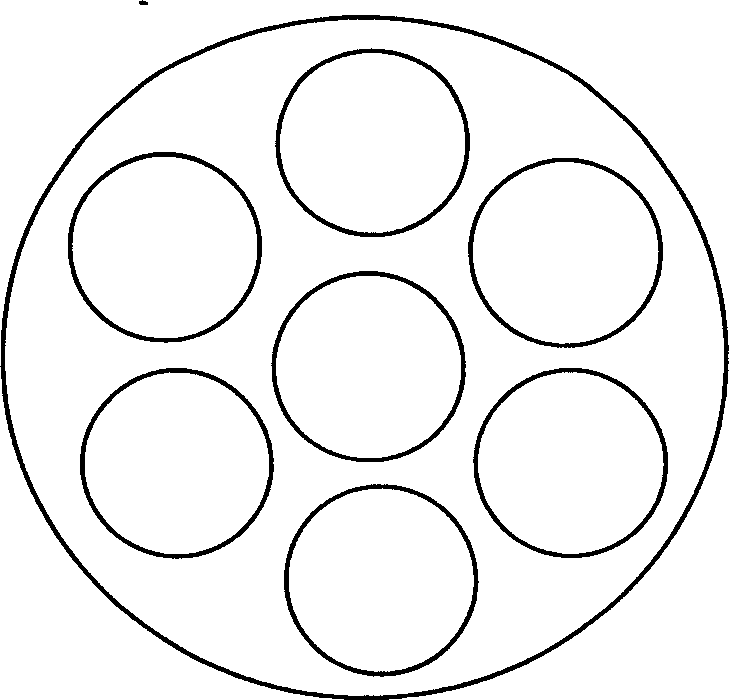

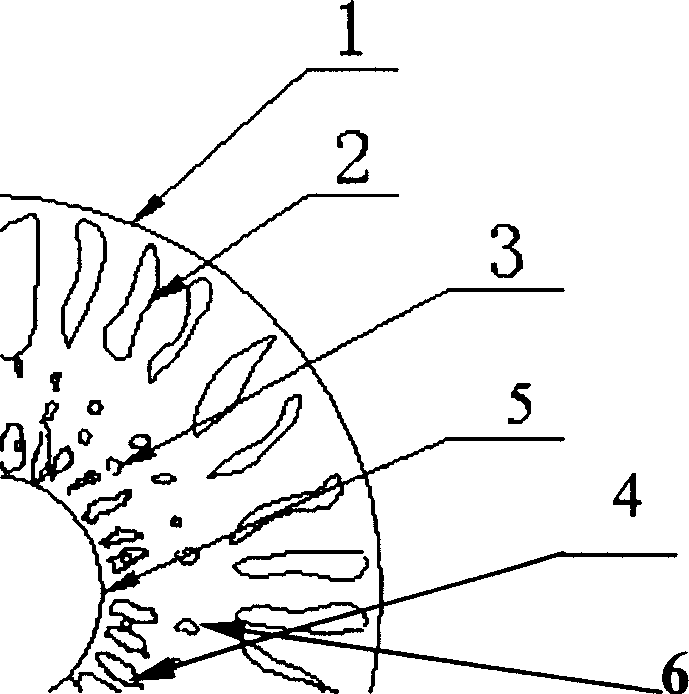

[0026] 35 grams of polyvinylidene fluoride of FR904 type and 5 grams of polyethylene glycol are dissolved in 60 grams of N, N-dimethylacetamide solvent, and then the dry-wet spinning method known in the art is used to obtain a porous structure fibrous membranes, such as figure 1 and figure 2 shown.

[0027] The dissolution temperature is 60°C, the dry spinning length is 2cm, the extrusion volume flow rate is 5ml / min, the spinning solution temperature is 20°C, and the gel bath temperature is 5°C; the gel bath is water.

[0028] The method specified in the documents "Development of Reinforced Polyvinylidene Fluoride Microporous Membrane", "Research on Hollow Fiber Polyvinylidene Fluoride Microporous Membrane", "Research on Dry-Spray Wet Spinning Polyacrylonitrile Fiber Drawing Technology" is used for detection. The water permeability of the membrane is 100L / m 2 h; the mechanical properties are as follows: breaking strength 10.23N, breaking elongation 26.4%.

Embodiment 2

[0030] Dissolve 10 grams of polyvinylidene fluoride with a molecular weight of 30,000 to 60,000 and 10 grams of polyvinylpyrrolidone in 80 grams of N-methyl-2-pyrrolidone solvent, and then adopt a dry-wet spinning process known in the art to obtain a porous structure fibrous membranes, such as figure 1 and figure 2 shown.

[0031] The dissolution temperature is 95°C, the dry spinning length is 15cm, the extrusion volume flow rate is 10ml / min, the spinning solution temperature is 90°C, and the gel bath temperature is 50°C; the gel bath is water.

[0032] The method specified in the documents "Development of Reinforced Polyvinylidene Fluoride Microporous Membrane", "Research on Hollow Fiber Polyvinylidene Fluoride Microporous Membrane", "Research on Dry-Spray Wet Spinning Polyacrylonitrile Fiber Drawing Technology" is used for detection. The water permeability of the membrane is 900L / m 2 ·h; mechanical properties are as follows: breaking strength, 8.38N; breaking elongation,...

Embodiment 3

[0034] Dissolving 20 grams of polyvinyl chloride with a molecular weight of 30000-60000 and 15 grams of additive polyethylene glycol in 65 grams of solvent, and then adopting a dry-wet spinning process known in the art to obtain a porous structure fiber membrane;

[0035] Said solvent is selected from 1-methyl-2 pyrrolidone;

[0036] The dissolution temperature is 75°C, the dry spinning length is 55cm, the extrusion volume flow rate is 12ml / min, the spinning solution temperature is 55°C, and the gel bath temperature is 27°C; the gel bath is water.

[0037] The method specified in the documents "Development of Reinforced Polyvinylidene Fluoride Microporous Membrane", "Research on Hollow Fiber Polyvinylidene Fluoride Microporous Membrane", "Research on Dry-Spray Wet Spinning Polyacrylonitrile Fiber Drawing Technology" is used for detection. The water permeability of the membrane is 200L / m 2 · h; mechanical properties are as follows: breaking strength 7.11N, breaking elongation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com