Motor rotor paint-dipping and drying equipment and operation method thereof

A technology of motor rotor and drying equipment, which is applied in the direction of pretreatment surface, coating, and surface coating liquid device, etc., which can solve the problem of inability to dry motor rotor, inconvenient recovery of paint liquid, and poor quality of motor rotor impregnated paint and other problems, to achieve the effect of improving drying efficiency and drying quality, and improving the quality of dipping paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

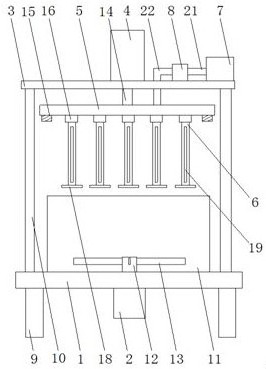

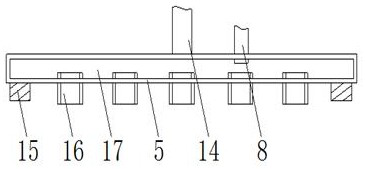

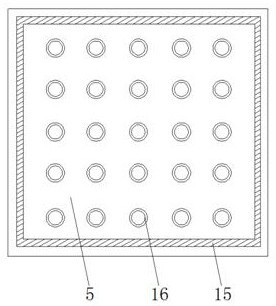

Embodiment 1

[0029] as attached Figure 1-5As shown, a motor rotor dipping and drying equipment includes a bottom plate 1, a motor 2, a top plate 3, a hydraulic cylinder 4, a connecting plate 5, a load bar 6, a blower 7 and a heater 8, and it is characterized in that the Base plate 1 is arranged on the support 9, is vertically provided with vertical plate 10 on base plate 1, and is provided with paint liquid tank 11 on the base plate 1 between vertical plate 10 and vertical plate 10, base plate 1 and support 9, vertical plate 10 is connected by welding, which improves the connection strength between the bottom plate 1 and the support 9 and the vertical plate 10, and enhances the structural strength of the dipping equipment. The motor 2 is installed at the bottom of the bottom plate 1, and a transmission shaft 12 is arranged on the motor 2 , the transmission shaft 12 is vertically extended into the paint liquid tank 11, and a stirring rod 13 is arranged on the transmission shaft 12. The mot...

Embodiment 2

[0044] as attached Image 6 As shown, a motor rotor dipping and drying equipment includes a bottom plate 1, a motor 2, a top plate 3, a hydraulic cylinder 4, a connecting plate 5, a load bar 6, a blower 7 and a heater 8, and it is characterized in that the Base plate 1 is arranged on the support 9, is vertically provided with vertical plate 10 on base plate 1, and is provided with paint liquid tank 11 on the base plate 1 between vertical plate 10 and vertical plate 10, base plate 1 and support 9, vertical plate 10 is connected by welding, which improves the connection strength between the bottom plate 1 and the support 9 and the vertical plate 10, and enhances the structural strength of the dipping equipment. The motor 2 is installed at the bottom of the bottom plate 1, and a transmission shaft 12 is arranged on the motor 2 , the transmission shaft 12 is vertically extended into the paint liquid tank 11, and a stirring rod 13 is arranged on the transmission shaft 12. The motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com