A polyphenol-modified hydrocarbon composition-based prepreg and its prepared copper-clad laminate

A technology of hydrocarbon composition and polyphenol, which is applied in the field of communication materials, can solve the problems of multifunctional and complex high density, imperfect dielectric properties and uniformity of copper clad laminates, glass fiber cloth and inorganic materials. Poor compatibility of fillers and other problems, to achieve the effect of good industrial production basis, high copper foil peel strength, easy batch and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

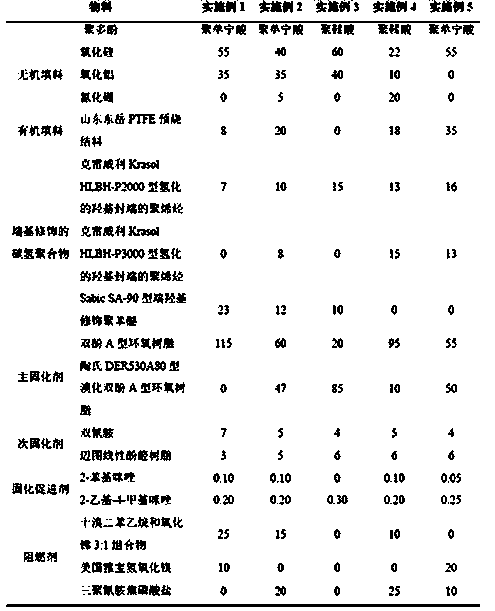

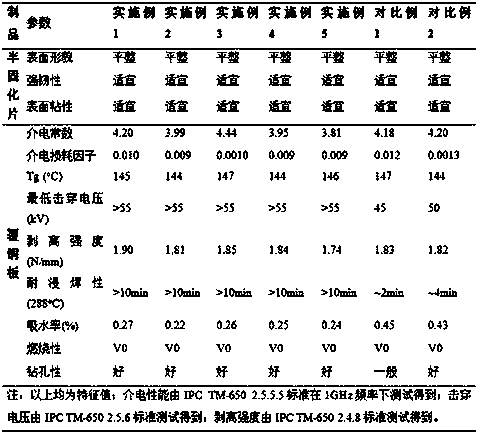

Embodiment 1~5

[0028] Soak 1080 glass fiber cloth in 40mg / mL polyphenol aqueous solution for 30min and irradiate with ultraviolet light at the same time. The wavelength of ultraviolet light is 260nm, and the light intensity of ultraviolet light is 10mW / cm 2 , the ambient temperature was 30°C, and the distance between the ultraviolet light source and the irradiated object was 30cm, and then the 1080 glass fiber cloth with polyphenol surface modified was taken out, which was recorded as "polyphenol@1080 glass fiber cloth". Stir and soak the filler in an aqueous solution of 40mg / mL polyphenol for 30min while irradiating with ultraviolet light, the wavelength of ultraviolet light is 260nm, and the light intensity of ultraviolet light is 10mW / cm 2 , the ambient temperature is 30°C, and the distance between the ultraviolet light source and the irradiated object is 10cm. After filtering, washing, and drying, the filler with polyphenol modified on the surface is obtained, which is recorded as "polyph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com