A polyphenol-modified fluorine-containing resin mixture and prepreg and copper-clad laminate prepared therefrom

A polyphenol modified, fluorine-containing resin technology, applied in the field of communication materials, can solve the problems of chemical bond formation and weak interaction of ordinary alkane chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

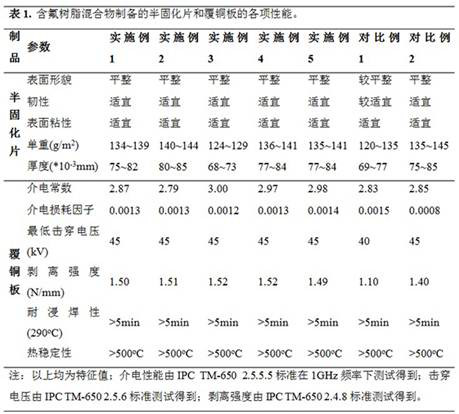

Examples

Embodiment 1

[0031] Under the air atmosphere, 60 parts of silicon oxide (Xinyi Hongrun) and 20 parts of aluminum oxide (Zibo Hengbang) were evenly dispersed in 600 parts of 20mg / mL tannic acid aqueous solution, stirred and soaked for 30min, then taken out, and then After washing with isopropanol, washing with water, and drying, the SiO surface-modified polytannic acid was prepared. 2 / Al 2 o 3 Composite inorganic filler, denoted as "polytannic acid@SiO 2 / Al 2 o 3 "; Soak the 1080 glass fiber cloth in 20mg / mL tannic acid aqueous solution for 30 minutes, take it out, then soak it in isopropanol for 20 minutes to remove the weakly adhered polytannic acid, and finally soak it in water to remove isopropyl alcohol. Alcohol, prepared the surface modified glass fiber cloth of polytannic acid, recorded as "polytannic acid@1080 glass fiber cloth"; take 50 parts of polytetrafluoroethylene emulsion (DuPont Teflon ® PTFEDISP30, solid content 60%), 120 parts tetrafluoroethylene-perfluoroalkoxy vi...

Embodiment 2

[0033] Under the air atmosphere, 70 parts of silicon oxide (Xinyi Hongrun) and 30 parts of aluminum oxide (Zibo Hengbang) were evenly dispersed in 700 parts of 30mg / mL tannic acid aqueous solution, stirred and soaked for 45min, then taken out, and then subjected to isotropic After washing with propanol, washing with water, and drying, the SiO surface-modified polytannic acid was prepared. 2 / Al 2 o 3 Composite inorganic filler, denoted as "polytannic acid@SiO 2 / Al 2 o 3 "; Soak 1080 glass fiber cloth in 25mg / mL tannic acid aqueous solution for 30 minutes, take it out, then soak it in isopropanol for 20 minutes to remove the weakly adhered polytannic acid, and finally soak it in water to remove isopropanol, A glass fiber cloth with polytannic acid modified on the surface has been prepared, which is denoted as "polytannic acid@1080 glass fiber cloth"; 60 parts of polytetrafluoroethylene emulsion (DuPont Teflon ® PTFE DISP30, solid content 60%), 110 parts perfluoroethylene...

Embodiment 3

[0035] In an air atmosphere, 70 parts of titanium oxide (Tianjin Zhongzheng Huamei Technology) and 20 parts of aluminum oxide (Zibo Hengbang) were evenly dispersed in 650 parts of 30mg / mL tannic acid aqueous solution, stirred and soaked for 40min, then taken out, and then Washed with isopropanol, washed with water, and dried, the TiO surface-modified polytannic acid was prepared. 2 / Al 2 o 3 Composite inorganic filler, denoted as "polytannic acid@TiO 2 / Al 2 o 3 "; Soak the 1080 glass fiber cloth in 25mg / mL tannic acid aqueous solution for 30 minutes, take it out, then soak it in isopropanol for 20 minutes to remove the weakly adhered polytannic acid, and finally soak it in water to remove isopropyl alcohol Alcohol, prepared the surface modified glass fiber cloth of polytannic acid, recorded as "polytannic acid@1080 glass fiber cloth"; take 50 parts of polytetrafluoroethylene emulsion (DuPont Teflon ® PTFE DISP30, solid content 60%), 60 parts tetrafluoroethylene-perfluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com