Low-temperature nylon powder material for selective laser sintering and preparation method thereof

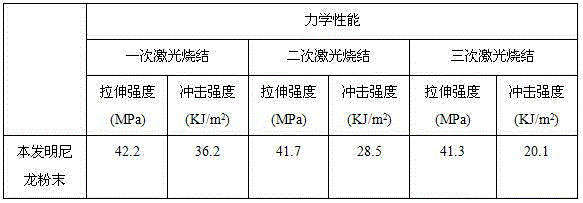

A technology of laser sintering and nylon powder, which is applied in the direction of solid material additive processing, processing and manufacturing, additive processing, etc., can solve the problems of complex operation, powder can not be reused and waste, long forming cycle, etc., to achieve tensile strength and low temperature High impact strength, increased recycling rate, and high Vicat softening temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A method for preparing a low-temperature nylon powder material for selective laser sintering: comprising the following preparation steps:

[0068] Step 1. Mix dodecanedibasic acid and nylon 12 particles evenly into the reactor, add double-ended amino polyethylene glycol and deuterated trifluoroacetic acid into the reactor, seal it, vacuumize it, and fill it with carbon dioxide. And the initial pressure of the reactor is 0.2MPa.

[0069] Step 2: Heat the reactor to gradually heat up to 180°C, start stirring, continue to heat up to 200°C, open the exhaust valve, reduce the pressure in the kettle to 1.4MPa, and keep the pressure down slowly and uniformly for 0.5 hours, so that the inside of the reactor The pressure was reduced to normal pressure within 2 hours, kept at normal pressure for 0.5 hours, the stirring was stopped, the product was taken out and placed in a cold water tank, and finally dried to obtain the product.

[0070] Step 3: The above-mentioned product, ant...

Embodiment 2

[0083] A method for preparing a low-temperature nylon powder material for selective laser sintering: comprising the following preparation steps:

[0084] Step 1. Mix dodecanedibasic acid and nylon 12 particles evenly into the reactor, add double-ended amino polyethylene glycol and deuterated trifluoroacetic acid into the reactor, seal it, vacuumize it, and fill it with carbon dioxide. And the initial pressure of the reactor is 0.3MPa.

[0085] Step 2: Heating, so that the temperature of the reactor is gradually raised to 190°C, the stirring is started, and the temperature is continued to be raised to 210°C, the exhaust valve is opened, the pressure in the kettle is reduced to 1.3MPa, and the pressure is reduced slowly and uniformly for 0.4 hours, so that the inside of the reactor The pressure was reduced to normal pressure within 1.8 hours, kept at normal pressure for 0.7 hours, the stirring was stopped, the product was taken out and placed in a cold water tank, and finally ...

Embodiment 3

[0099] A method for preparing a low-temperature nylon powder material for selective laser sintering: comprising the following preparation steps:

[0100] Step 1. Mix dodecanedibasic acid and nylon 12 particles evenly into the reactor, add double-ended amino polyethylene glycol and deuterated trifluoroacetic acid into the reactor, seal it, vacuumize it, and fill it with carbon dioxide. And the initial pressure of the reactor is 0.1MPa.

[0101] Step 2: Heat to make the reaction kettle gradually heat up to 170°C, start stirring, continue to heat up to 190°C, open the exhaust valve, reduce the pressure in the kettle to 1.5MPa, and keep the pressure down slowly and uniformly for 0.6 hours, so that the inside of the reaction kettle The pressure was reduced to normal pressure within 2.2 hours, kept at normal pressure for 0.4 hours, the stirring was stopped, the product was taken out and placed in a cold water tank, and finally dried to obtain the product.

[0102] Step 3: The abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com