Injecting ferrite permanent magnet material formula

A ferrite permanent magnet and ferrite magnet technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of low product stability, unsatisfactory magnetic performance, short service life, etc. The processing and production process is simple, the water absorption is small, and the service life is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

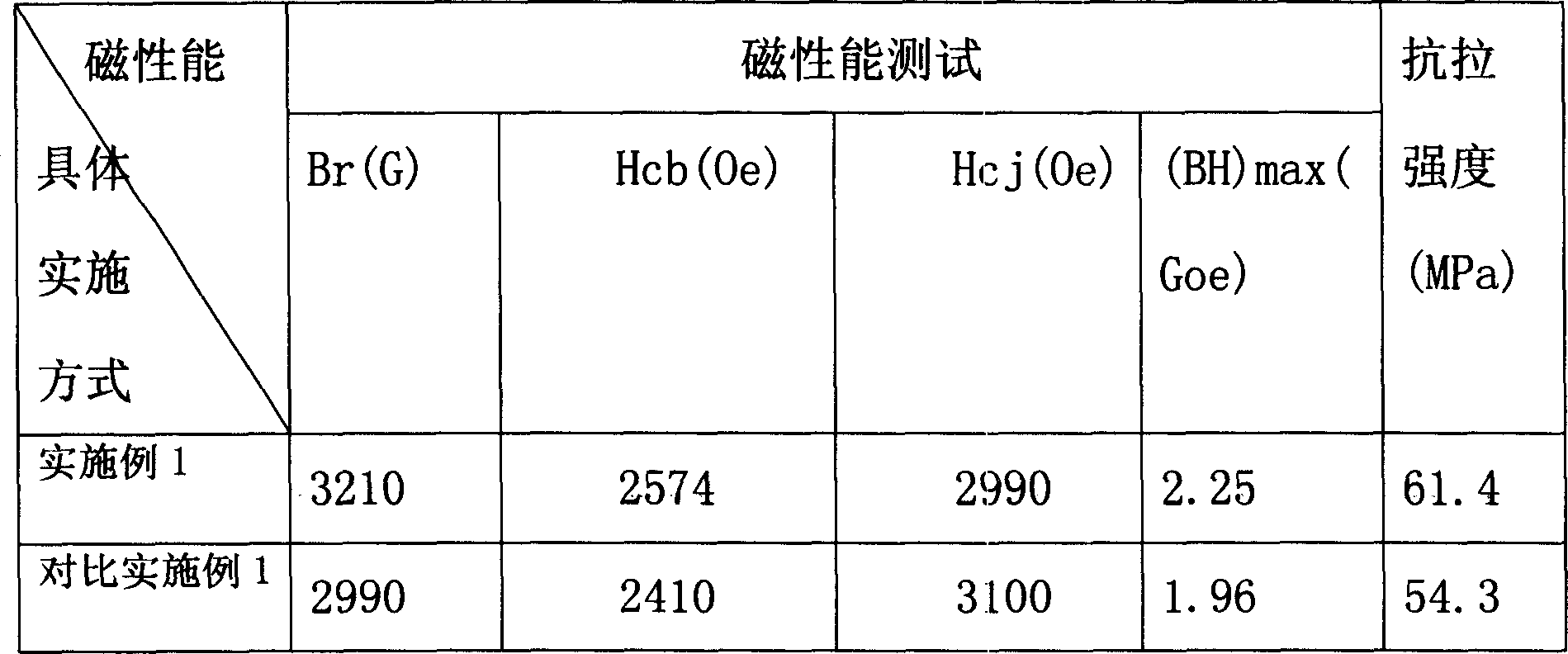

Embodiment 1

[0024] Example 1: After the ferrite is surface treated with a coupling agent, the content of the binder nylon 12 resin is weighed and mixed evenly in a mixer, and then mixed with a twin-screw mixer. After granulation, the nylon 12 high-performance injection molding permanent magnet ferrite in the designed shape is obtained by injection molding. Whether to carry out magnetic field orientation can be determined according to the properties of the magnetic powder used during molding.

[0025] Anisotropic strontium ferrite powder, silane coupling agent, binder nylon 12, organic external lubricant calcium stearate, inorganic internal lubricant aluminum oxide. Mix it well with a high-speed mixer.

[0026] Then, using a twin-screw kneader at 232° C., the formulation mixtures of the compositions shown in Table 1 were fully kneaded to obtain nylon 12 high-performance injection molded permanent magnet ferrite. Next, pelletizing is performed to obtain pellets with an average particle di...

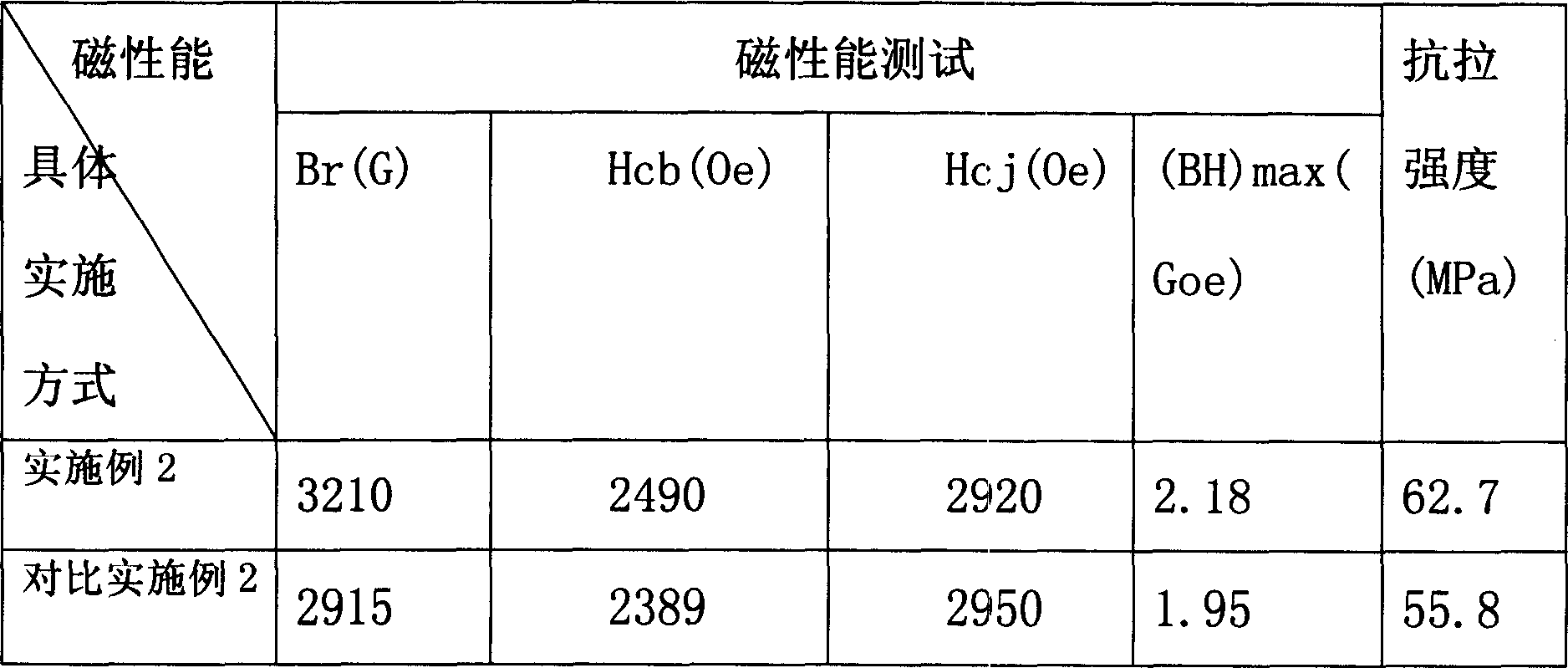

Embodiment 2

[0033] Example 2: After the ferrite is surface treated with a coupling agent, the content of the binder nylon 12 resin is weighed and mixed evenly in a mixer, and then mixed with a twin-screw mixer. After granulation, the nylon 12 high-performance injection molding permanent magnet ferrite in the designed shape is obtained by injection molding. Whether to carry out magnetic field orientation can be determined according to the properties of the magnetic powder used during molding.

[0034] Mix anisotropic strontium ferrite powder, titanate coupling agent, binder nylon 12, organic external lubricant 12-hydroxystearic acid magnesium salt, and inorganic internal lubricant molybdenum disulfide with a high-speed mixer well mixed. Then, using a twin-screw kneader at 230° C., the formulation mixtures of the compositions shown in Table 1 were fully kneaded to obtain nylon 12 high-performance injection molded permanent magnet ferrite. Next, pelletizing is performed to obtain pellets w...

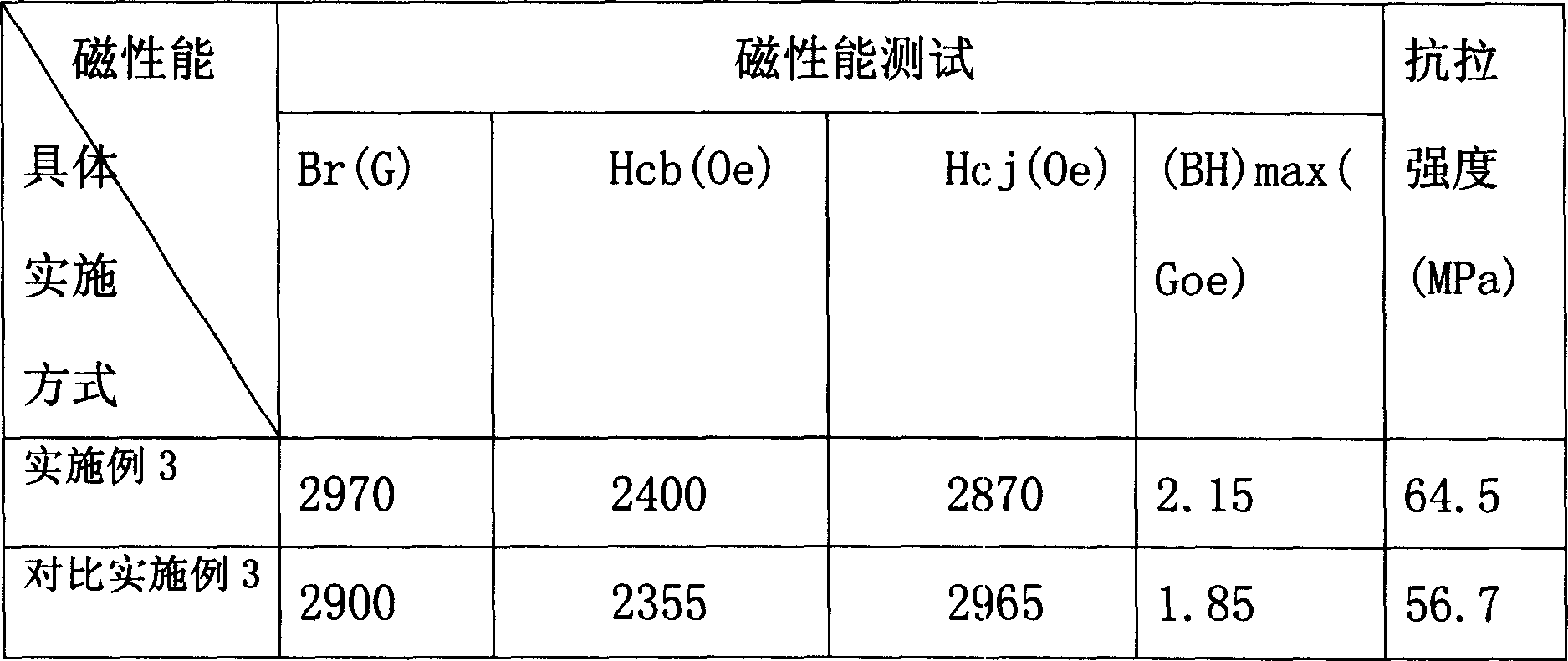

Embodiment 3

[0041] Embodiment 3: After the ferrite is surface treated with a coupling agent, the content of the binder nylon 12 resin is weighed and mixed evenly in a mixer, and then mixed with a twin-screw mixer. After granulation, the nylon 12 high-performance injection molding permanent magnet ferrite in the designed shape is obtained by injection molding. Whether to carry out magnetic field orientation can be determined according to the properties of the magnetic powder used during molding.

[0042] Mix anisotropic strontium ferrite powder, silane coupling agent, binder nylon 12, antioxidant, organic lubricant amide compound, and inorganic lubricant molybdenum disulfide with a high-speed mixer. Then, using a twin-screw kneader at 228° C., the formulation mixtures of the compositions shown in Table 1 were fully kneaded to obtain nylon 12 high-performance injection molded permanent magnet ferrite. Next, pelletizing is performed to obtain pellets with an average particle diameter of 2 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com