Nylon-polypropylene-filler modified composite powder, and preparation method and application thereof

A technology of composite powder and polypropylene, which is applied in the field of preparation of nylon-polypropylene-filled modified composite powder, can solve the problems of high price, low service temperature and poor mechanical properties, and achieve low cost, high bending strength and large size good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

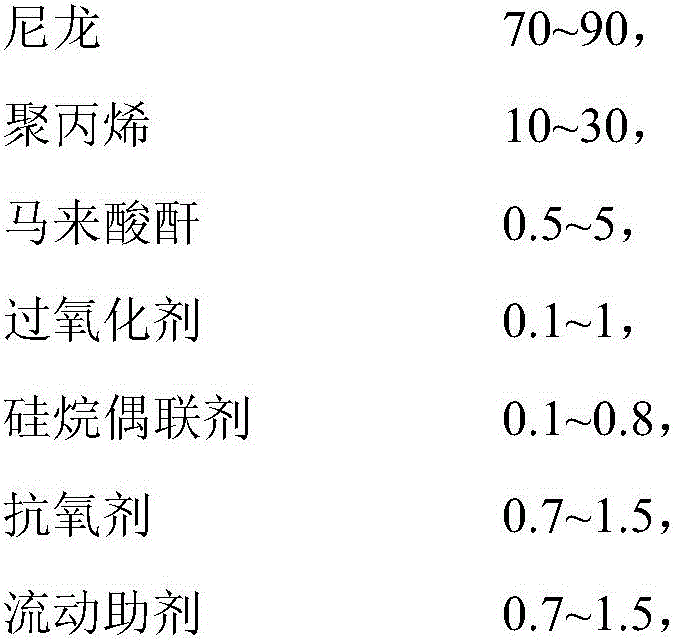

Method used

Image

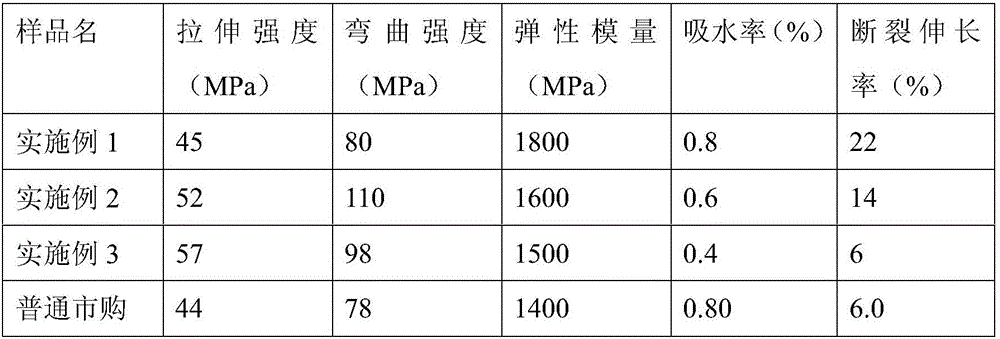

Examples

Embodiment 1

[0028] (1) Mix 10 parts of polypropylene (PP, melt index 15), 0.5 parts of maleic anhydride (MAH) and 0.1 part of dicumyl peroxide (DCP) and then melt and extrude them in a twin-screw extruder After pelletizing, the temperature of each zone of the twin-screw extruder is 210°C, 235°C, 235°C, 235°C, 235°C, 232°C, and the extrusion temperature is 225°C. After drying, repeat extrusion and granulation once 10 parts of polypropylene grafted maleic anhydride compatibilizer (PP-g-MAH) were obtained;

[0029] (2) Add 10 parts of PP-G-MAH and 90 parts of nylon 6 particles, and then add 0.75 parts of 1,3,5-trimethyl-2,4,6-tri(3,5-di-tert-butyl-4 -Hydroxybenzyl)benzene, 0.75 parts of 2,2'-ethylenebis(4,6-di-tert-butylphenyl)fluorophosphite 2000rpm mixed, then melted and extruded to pelletize by twin-screw extruder , where the temperatures in each zone of the twin-screw extruder are 210°C, 235°C, 235°C, 235°C, 235°C, and 232°C, respectively, and the extrusion temperature is 225°C. After v...

Embodiment 2

[0032] (1) After mixing 20 parts of polypropylene (PP, with a melt index of 15), 2 parts of maleic anhydride (MAH) and 0.4 parts of benzoyl peroxide (BPO), they are melted and reacted in a twin-screw extruder and extruded For pelletizing, the temperatures in each zone of the twin-screw extruder are 212°C, 237°C, 237°C, 237°C, 237°C, and 234°C respectively, and the extrusion temperature is 228°C. After drying, repeatedly extrude and granulate for 2 times to obtain 20 parts of polypropylene grafted maleic anhydride compatibilizer;

[0033] (2) 20 parts of polypropylene grafted maleic anhydride compatibilizers prepared in step (1) are mixed with 80 parts of nylon 66 particles, 0.6 parts of 2,6-di-tert-butyl-4-methyl-phenol, 0.6 parts of four (2,4-di-tert-butylphenyl)-4,4'-biphenyl bisphosphite is mixed at a high speed of 500rpm, and melted and extruded to pelletize by a twin-screw extruder, wherein each zone of the twin-screw extruder The temperatures are 212°C, 237°C, 237°C, 23...

Embodiment 3

[0036] (1) After mixing 30 parts of polypropylene (PP, with a melt index of 30), 5 parts of maleic anhydride (MAH) and 1 part of benzoyl peroxide (BPO), they are melted and reacted in a twin-screw extruder and extruded For pelletizing, the temperatures in each zone of the twin-screw extruder are 216°C, 240°C, 240°C, 240°C, 240°C, and 238°C respectively, and the extrusion temperature is 232°C. After drying, repeatedly extrude and granulate 3 times to obtain 30 parts of polypropylene grafted maleic anhydride compatibilizer;

[0037] (2) 30 parts of polypropylene grafted maleic anhydride with 70 parts of nylon 1212 particles, 035 parts of 2,2'-bis(4-methyl-6-tert-butyl-phenol)methane, 0.35 parts of 2,2' - Ethylene bis(4,6-di-tert-butylphenyl) fluorophosphite is mixed at a high speed of 1500rpm, then melted and extruded into granules by a twin-screw extruder, wherein the temperatures in each zone of the twin-screw extruder are respectively They were 216°C, 240°C, 240°C, 240°C, 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com