125 DEG C irradiation crosslinking oil-resistant low-smoke halogen-free flame retardant cable material and preparation method thereof

A flame-retardant cable material and irradiation technology, which is applied in the direction of cable/conductor manufacturing, cable insulation, conductor/cable insulation, etc., can solve the problems of high scrap rate, little practical application value, complicated production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1: A radiation-crosslinked, oil-resistant, low-smoke, halogen-free, flame-retardant cable material with a temperature resistance rating of 125°C

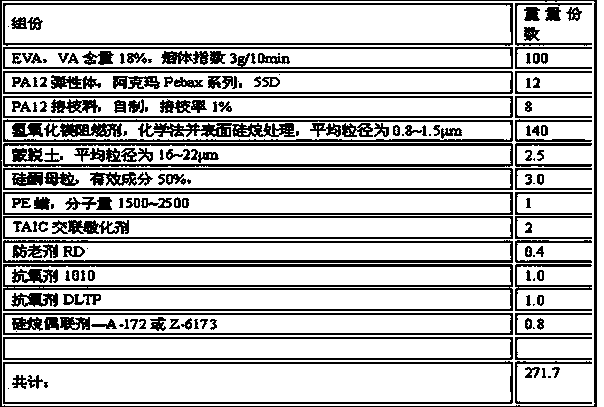

[0075] 1. Material formula

[0076]

[0077] 2. Preparation process

[0078] The first step: mix the copolymer of ethylene vinyl acetate copolymer EVA, nylon 12 elastomer and nylon 12 grafted maleic anhydride in a high-speed mixer for 30 seconds at a high speed according to the formula weight, and then pass through a twin-screw granulator Mixing and plasticizing granulation, the processing temperature is: conveying section 130-140°C, melting section 150-165°C, mixing section 170-180°C, exhaust section 165-175°C, homogenizing section 165-175°C, machine head 170~180℃;

[0079] Step 2: Add the above materials into magnesium hydroxide flame retardant, montmorillonite synergistic flame retardant, silicone masterbatch, lubricant, cross-linking sensitizer triallyl isotrimer Cyanate ester TAIC, silane coupling agent, an...

Embodiment 2

[0083] Example 2: A radiation-crosslinked, oil-resistant, low-smoke, halogen-free, flame-retardant cable material with a temperature resistance rating of 125°C

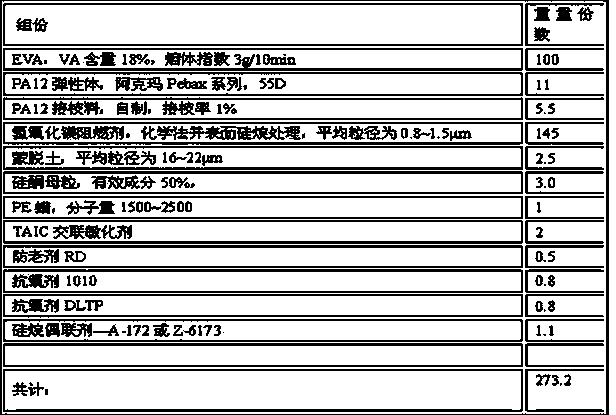

[0084] 1. Material formula

[0085]

[0086] 2. Preparation process

[0087] Same as embodiment one.

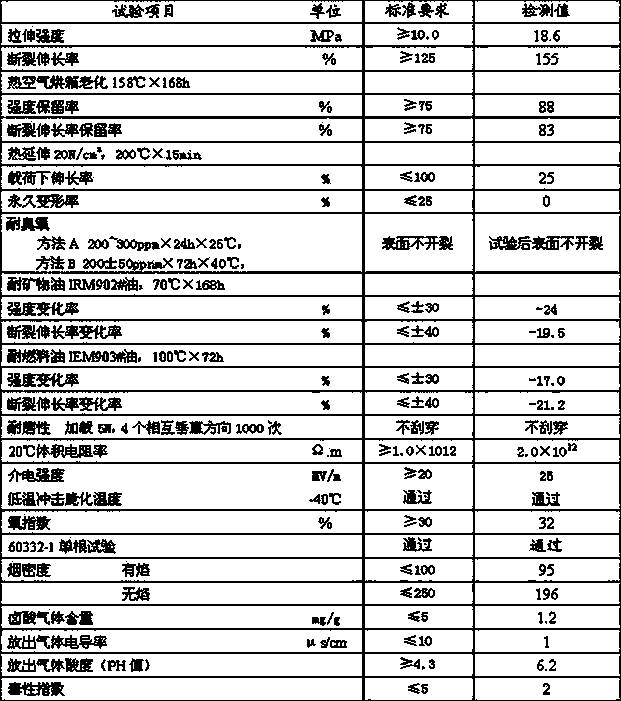

[0088] 3. Technical indicators

[0089]

Embodiment 3

[0090] Example 3: A radiation-crosslinked, oil-resistant, low-smoke, halogen-free, flame-retardant cable material with a temperature resistance rating of 125°C

[0091] 1. Material formula

[0092]

[0093] 2. Preparation process

[0094] Same as embodiment one.

[0095] 3. Technical indicators

[0096]

[0097] As can be seen from the foregoing examples, the present invention is modified by adding nylon PA12 elastomer and nylon PA12 grafting material in the material formula, so that the insulating compound and the sheath compound base material for locomotives are modified, and the product quality is improved. Oil resistance performance, meeting the standard requirements of EN50264 for halogen-free insulating compound and halogen-free sheath compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com