Method for Improving Oxidation Resistance of Graphite Electrodes by Chemical Vapor Deposition SIC/C Gradient Surface Coating

A technology of chemical vapor deposition and graphite electrodes, which is applied in the direction of coating, gaseous chemical plating, metal material coating technology, etc., can solve the problems of decreased protection effect, improve oxidation resistance, enhance bonding degree, and reduce steel consumption per ton volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Choose an ultra-high power graphite electrode with a diameter of 450mm and a length of 1500mm as the substrate, and process the graphite electrode according to the following process:

[0025] Step 1, surface cleaning, polishing, cleaning and drying of the graphite electrode.

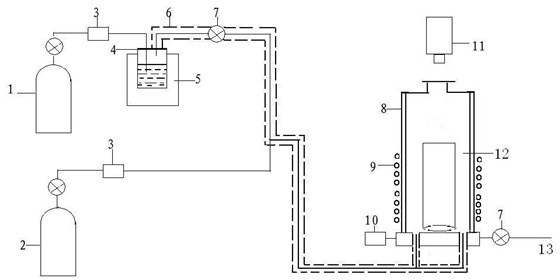

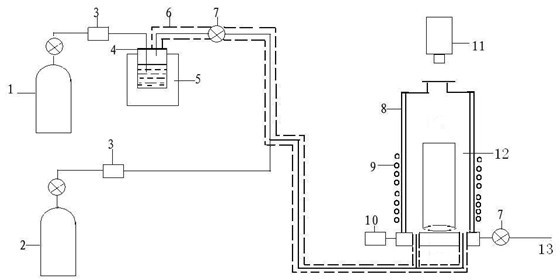

[0026]Step 2: Fix the graphite electrode after the surface pretreatment on the bracket in the water-cooled reaction furnace of the chemical vapor deposition equipment, and vacuumize the furnace to 0.2Pa.

[0027] Step 3, heat the graphite electrode in the reaction furnace, when the temperature reaches 1400°C, feed CH 4 Gas, so that the pressure in the reaction furnace is maintained at 1kPa, and maintained under this condition for 2h, so that a layer of pyrolytic carbon is formed on the surface of the graphite electrode.

[0028] Step 4, feed carrier gas H 2 , H 2 Via boiling SiCl 4 Liquid, SiCl 4 brought out, and with ch 4 The gas reacts and deposits on the surface of the graphite electrode,...

Embodiment 2

[0032] Choose an ultra-high power graphite electrode with a diameter of 450mm and a length of 1500mm as the substrate, and process the graphite electrode according to the following process:

[0033] Step 1, surface cleaning, polishing, cleaning and drying of the graphite electrode.

[0034] Step 2: Fix the graphite electrode after the surface pretreatment on the bracket in the water-cooled reaction furnace of the chemical vapor deposition equipment, and vacuumize the furnace to 0.5Pa.

[0035] Step 3, heat the graphite electrode in the reaction furnace, when the temperature reaches 1450°C, pass CH 4 Gas, so that the pressure in the reaction furnace is maintained at 1.5kPa, and maintained under this condition for 3h, so that a layer of pyrolytic carbon is formed on the surface of the graphite electrode.

[0036] Step 4, feed carrier gas H 2 , H 2 Via boiling SiCl 4 Liquid, SiCl 4 brought out, and with ch 4 The gas is reactively deposited on the surface of the graphite ele...

Embodiment 3

[0040] Choose an ultra-high power graphite electrode with a diameter of 450mm and a length of 1500mm as the substrate, and process the graphite electrode according to the following process:

[0041] Step 1, surface cleaning, polishing, cleaning and drying of the graphite electrode.

[0042] Step 2: Fix the graphite electrode after surface pretreatment on the bracket in the water-cooled reaction furnace of the chemical vapor deposition equipment, and vacuumize the furnace to 0.8Pa.

[0043] Step 3, heat the graphite electrode in the reaction furnace, when the temperature reaches 1500°C, pass CH 4 Gas, so that the pressure in the reaction furnace is maintained at 2kPa, and maintained under this condition for 1h, so that a layer of pyrolytic carbon is formed on the surface of the graphite electrode.

[0044] Step 4, feed carrier gas H 2 , H 2 Via boiling SiCl 4 Liquid, SiCl 4 brought out, and with ch 4 The gas is reactively deposited on the surface of the graphite electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com