Cooling liquid for lens glass processing and preparation method of cooling liquid

A coolant and glass technology, applied in chemical instruments and methods, heat exchange materials, lubricating compositions, etc., can solve the problems of poor cutting effect of grinding wheel rods, alkaline coolant, prone to hand allergies, etc., and achieve improvement smoothness, reduce edge chipping, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

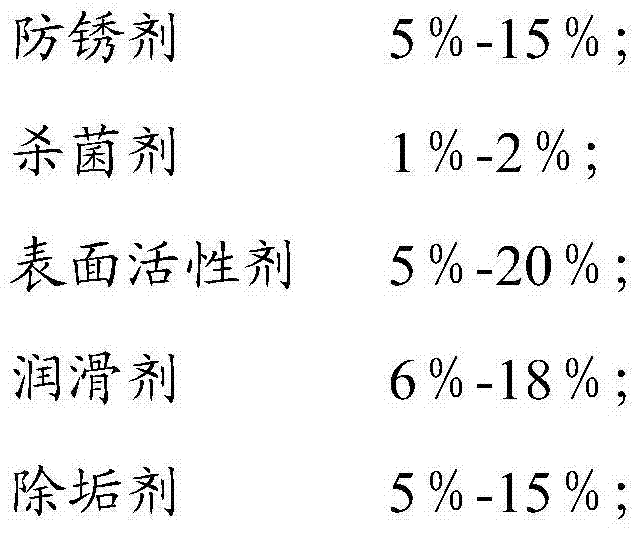

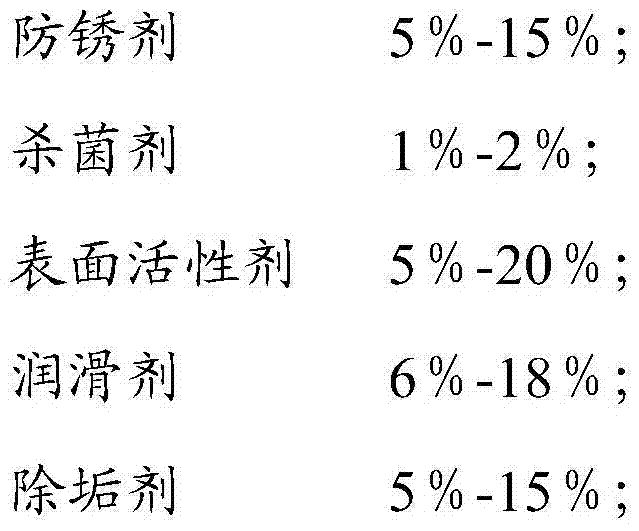

Method used

Image

Examples

Embodiment 1

[0021] Weigh triethanolamine borate 10%; hydroxyethylhexahydro-s-triazine 1%; diethanolamine 15%; glycerol 6%; oxalic acid 5%; purified water 63%; Hexahydro-s-triazine, diethanolamine, glycerol, and oxalic acid are added to pure water in turn, and stirred until uniform and transparent to obtain the cooling liquid for lens glass processing of the present invention; its pH value is measured to be 7.2.

Embodiment 2

[0023] Weigh triethanolamine borate 15%; boric acid 2%; diethanolamine 8%; glycerol 10%; oxalic acid 10%; purified water 55%; add triethanolamine borate, boric acid, diethanolamine, glycerin, and oxalic acid in turn into pure water, and stirring until uniform and transparent, the cooling liquid for lens glass processing of the present invention is obtained; the pH value thereof is measured to be 7.0.

Embodiment 3

[0025] Weigh triethanolamine borate 12%; boric acid 1%; diethanolamine 5%; glycerol 15%; oxalic acid 15%; purified water 52%; add triethanolamine borate, boric acid, diethanolamine, glycerol, and oxalic acid in sequence into pure water, and stir until it is uniform and transparent, namely, the cooling liquid for lens glass processing of the present invention is obtained; the pH value thereof is measured to be 6.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com