Patents

Literature

228results about How to "Stable hoisting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

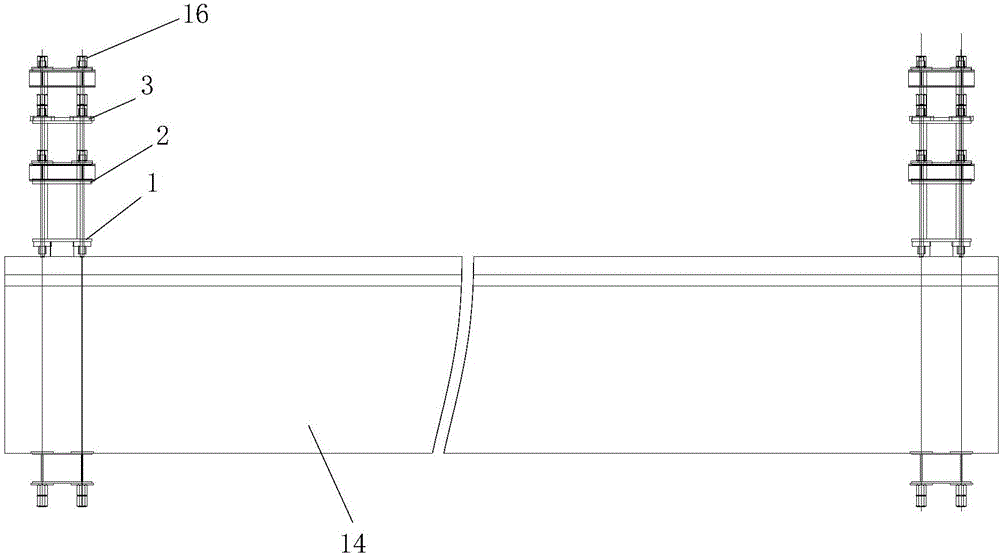

Hoisting method of thin-wall long and thin large-size equipment

InactiveCN101830393AStable hoistingHoisting safetyLoad-engaging elementsMarine engineeringLarge size

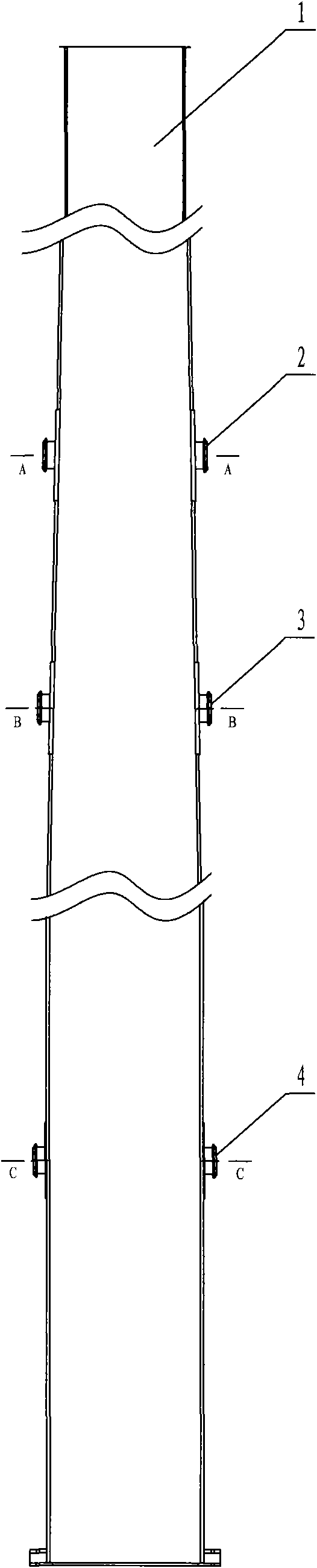

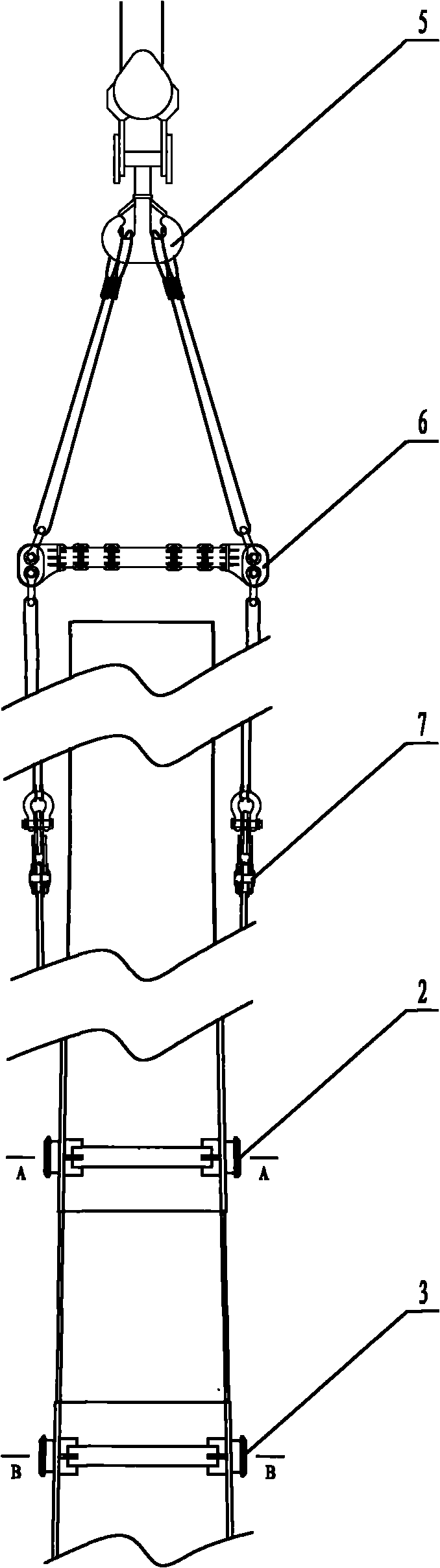

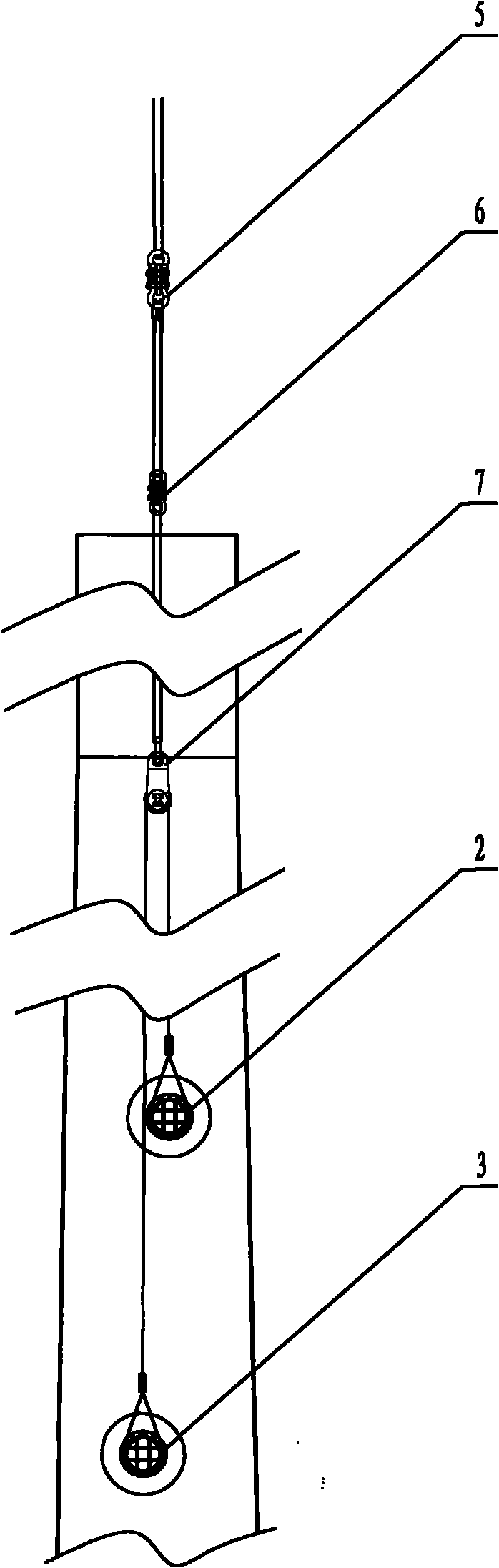

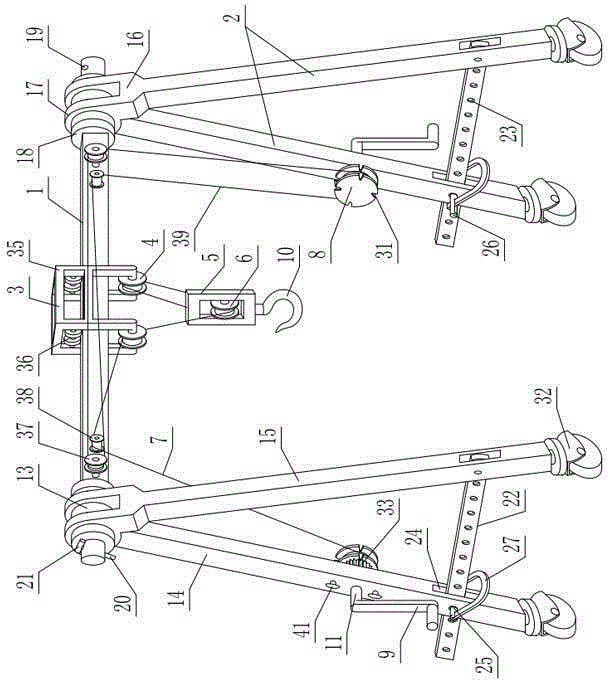

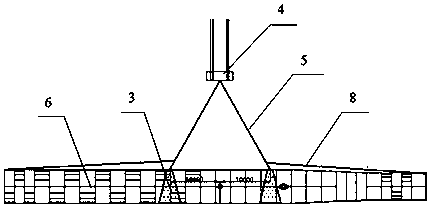

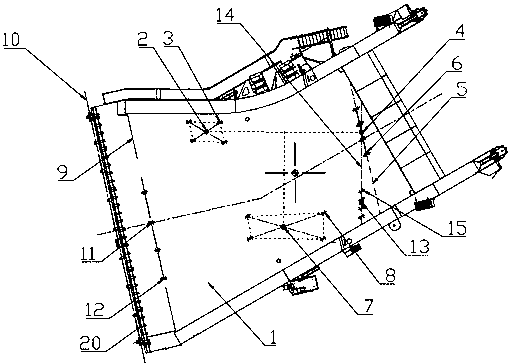

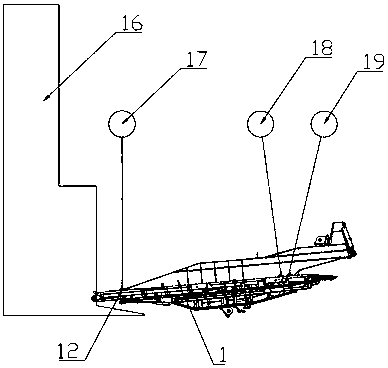

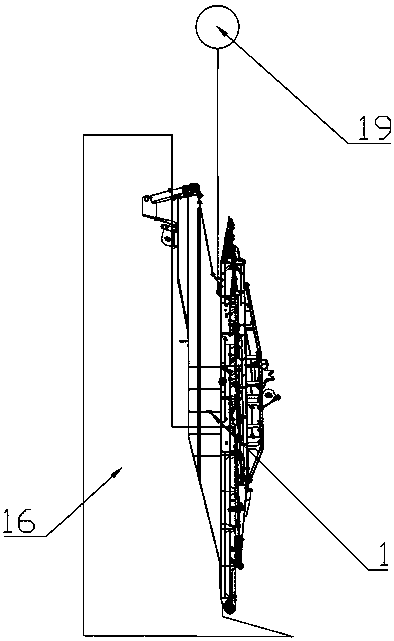

A hoisting method of thin-wall long and thin large-size equipment comprises the following steps of: arranging two upper groups of main lifting lugs I and two lower groups of main lifting lugs II on the thin-wall long and thin large-size equipment; arranging two sliding tail lifting lugs at the tail of the thin-wall long and thin large-size equipment, wherein the distance from the sliding tail lifting lugs to the bottom end is 0.14 time of total length; by using a formed integral steel wire rope hoisting system, lifting off a saddle by using a main hoist and an auxiliary hoist; after the saddle is removed, crowing, advancing and rotating by using the main hoist; crowing and rotating by a sliding tail hoist along with the main hoist; and when the elevation of the equipment reaches 70-75 degrees, gradually loosening a lifting hook by using the auxiliary hoist , rotating by using the main hoist after the equipment erects and hoists the equipment to the in-place orientation to be in place. The invention has the advantages of stable and safe hoisting process, 100 percent of quality integrity of the equipment and inner parts, less than 0.2 thousands of ratio of the deflection to the span length during the hoisting, stability, smoothness and safe operation in the whole hoisting process.

Owner:中国石化集团第五建设公司

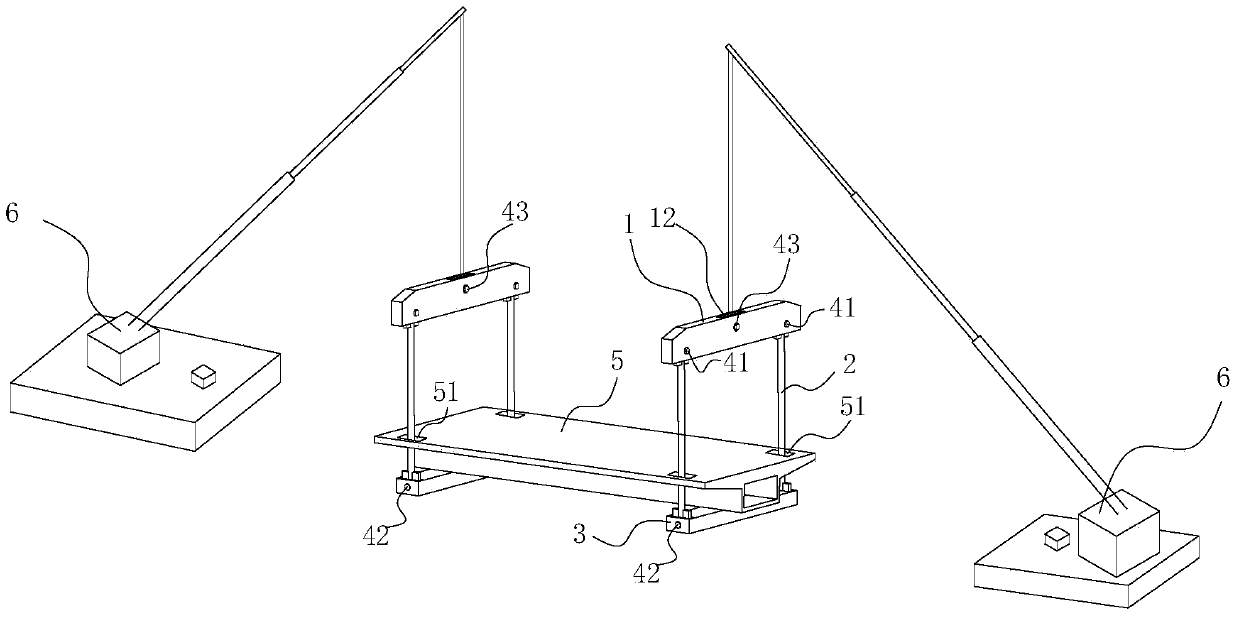

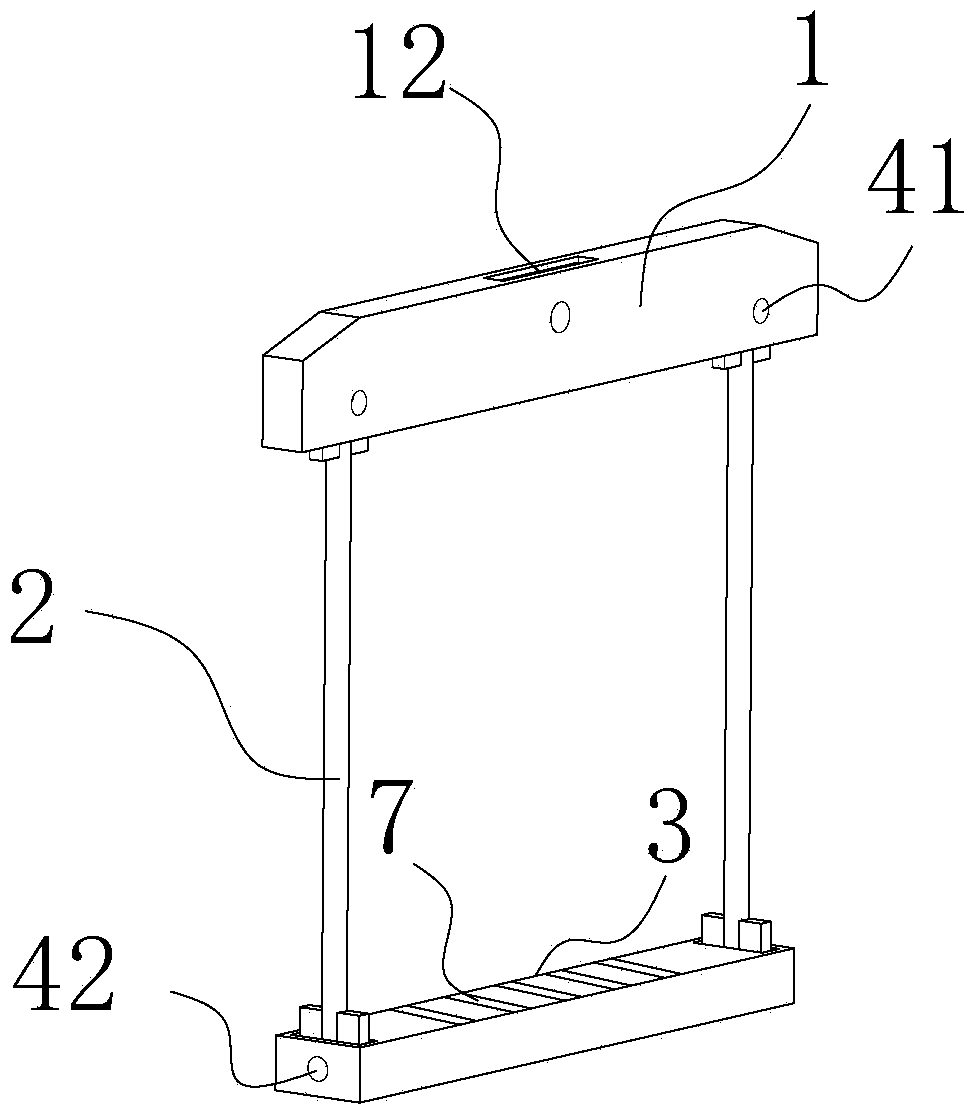

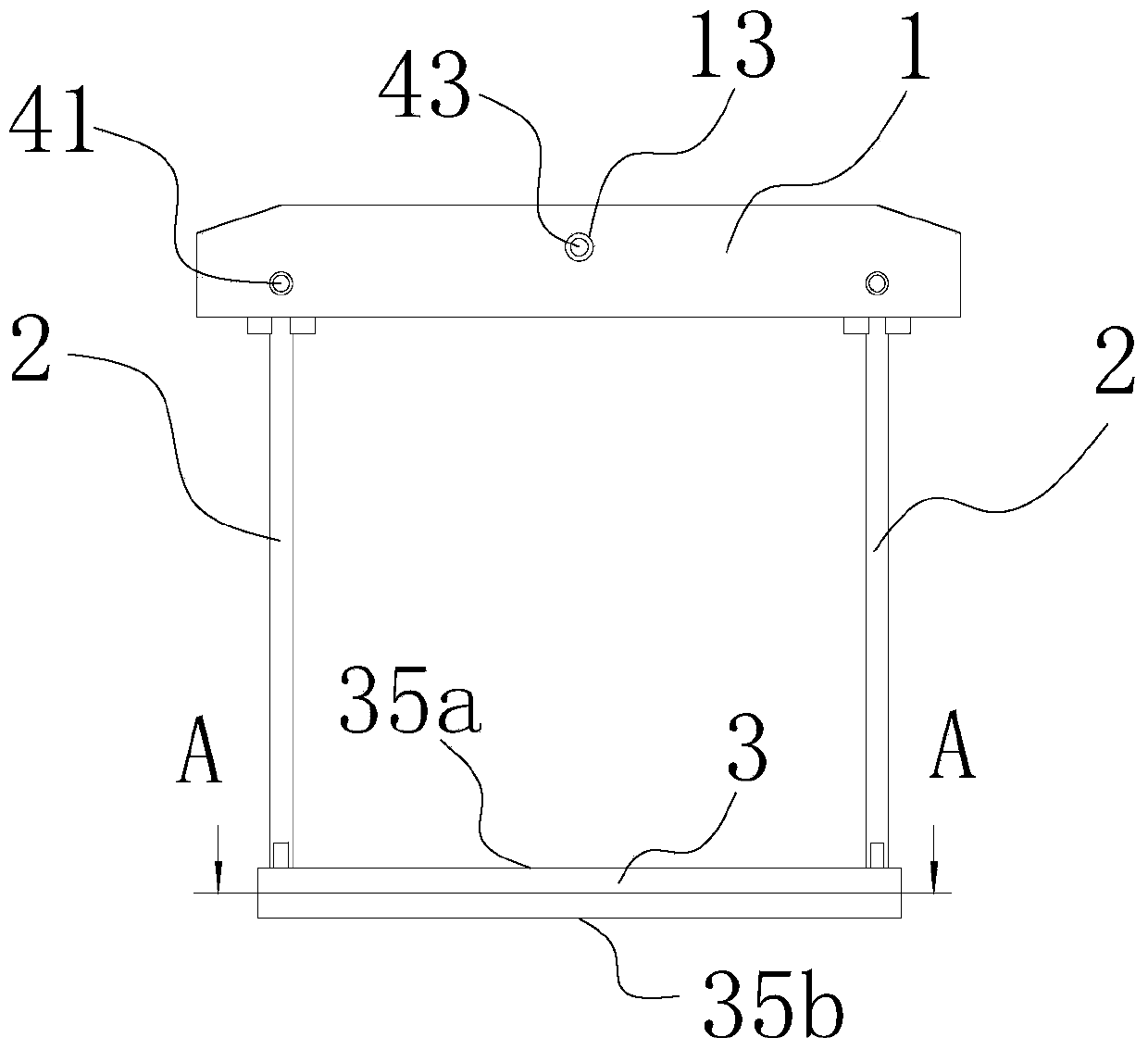

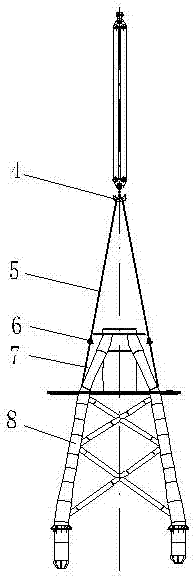

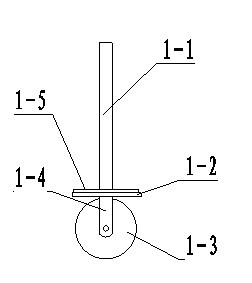

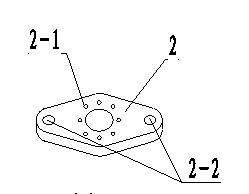

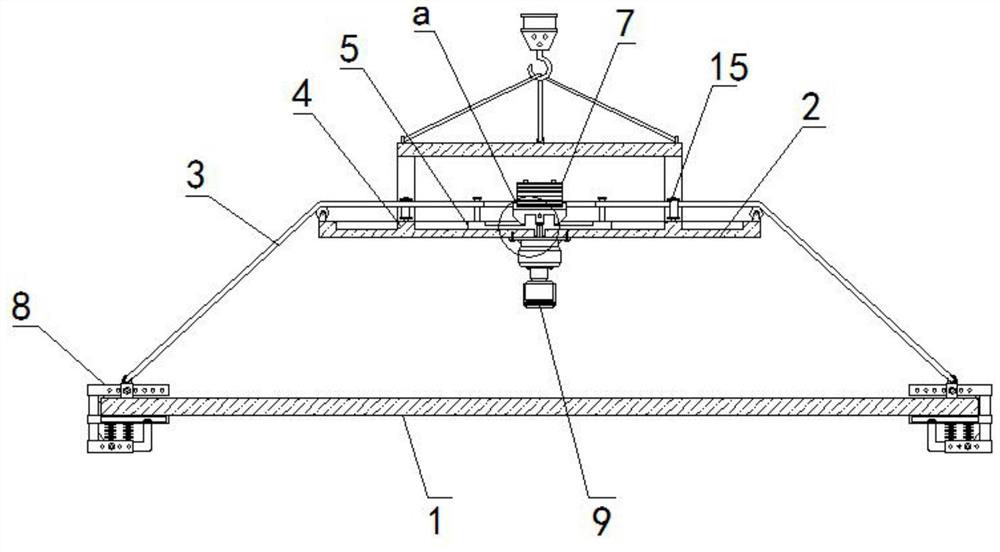

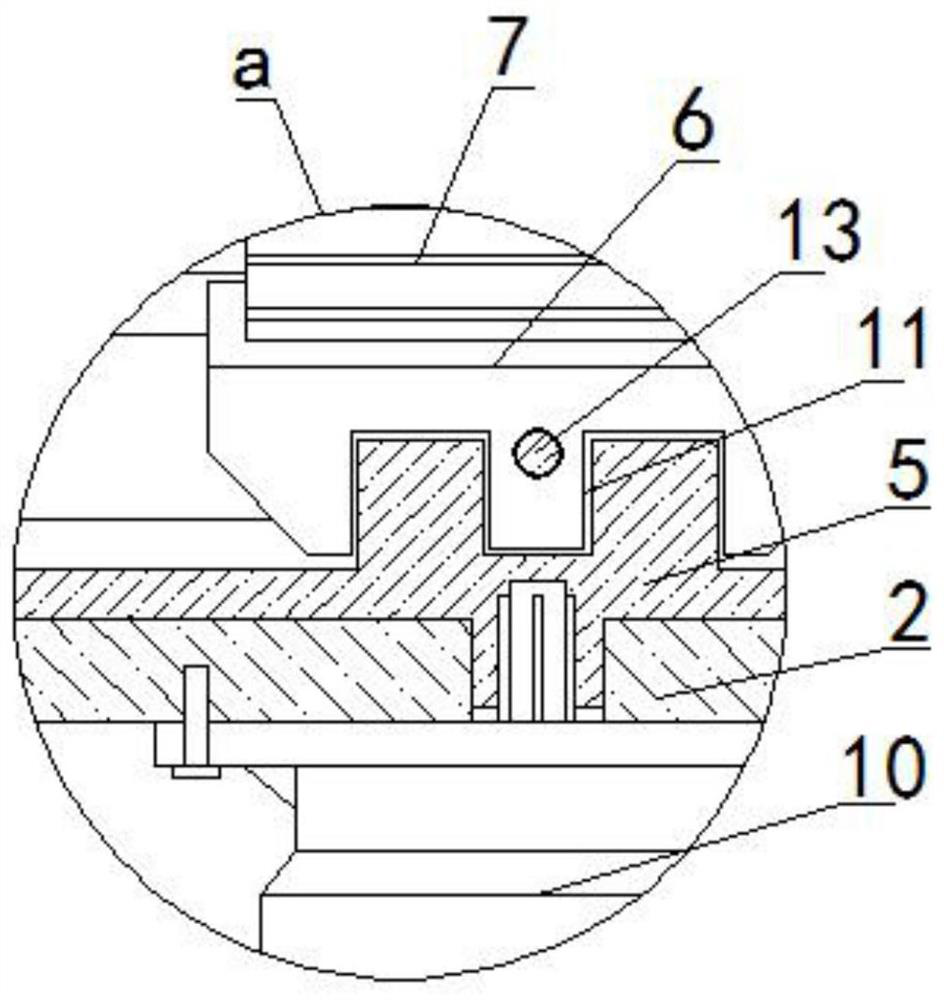

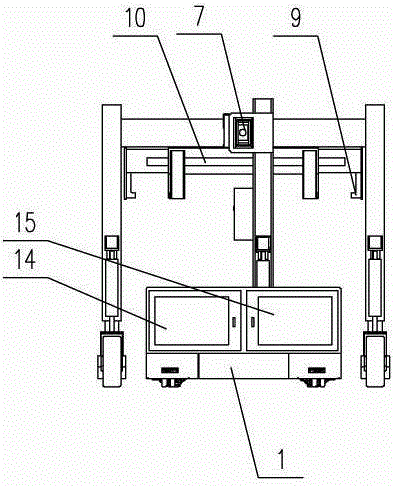

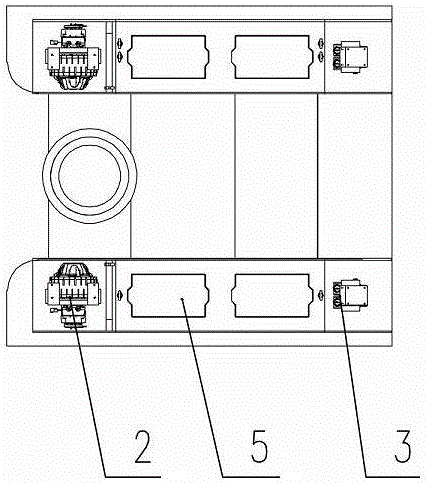

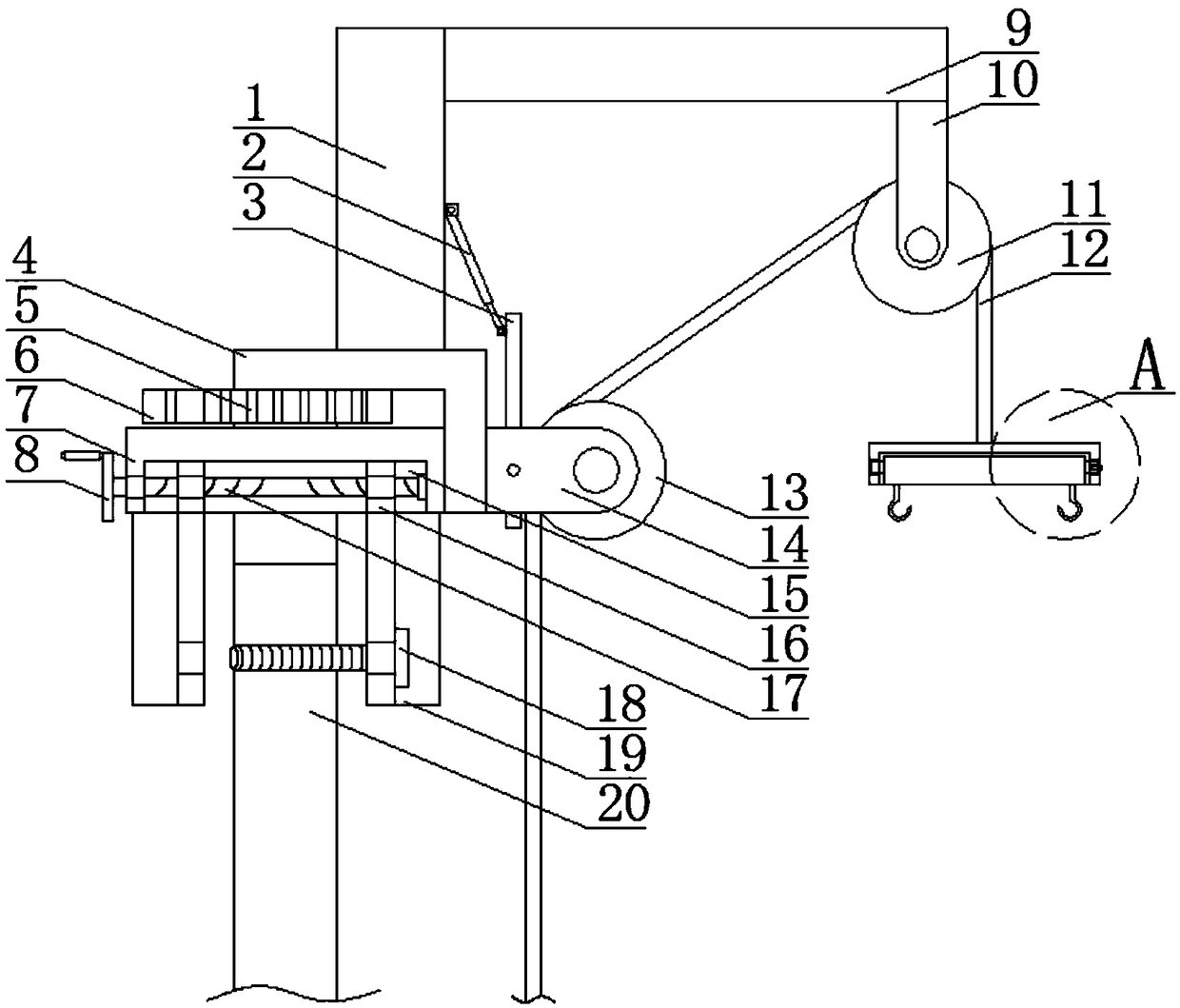

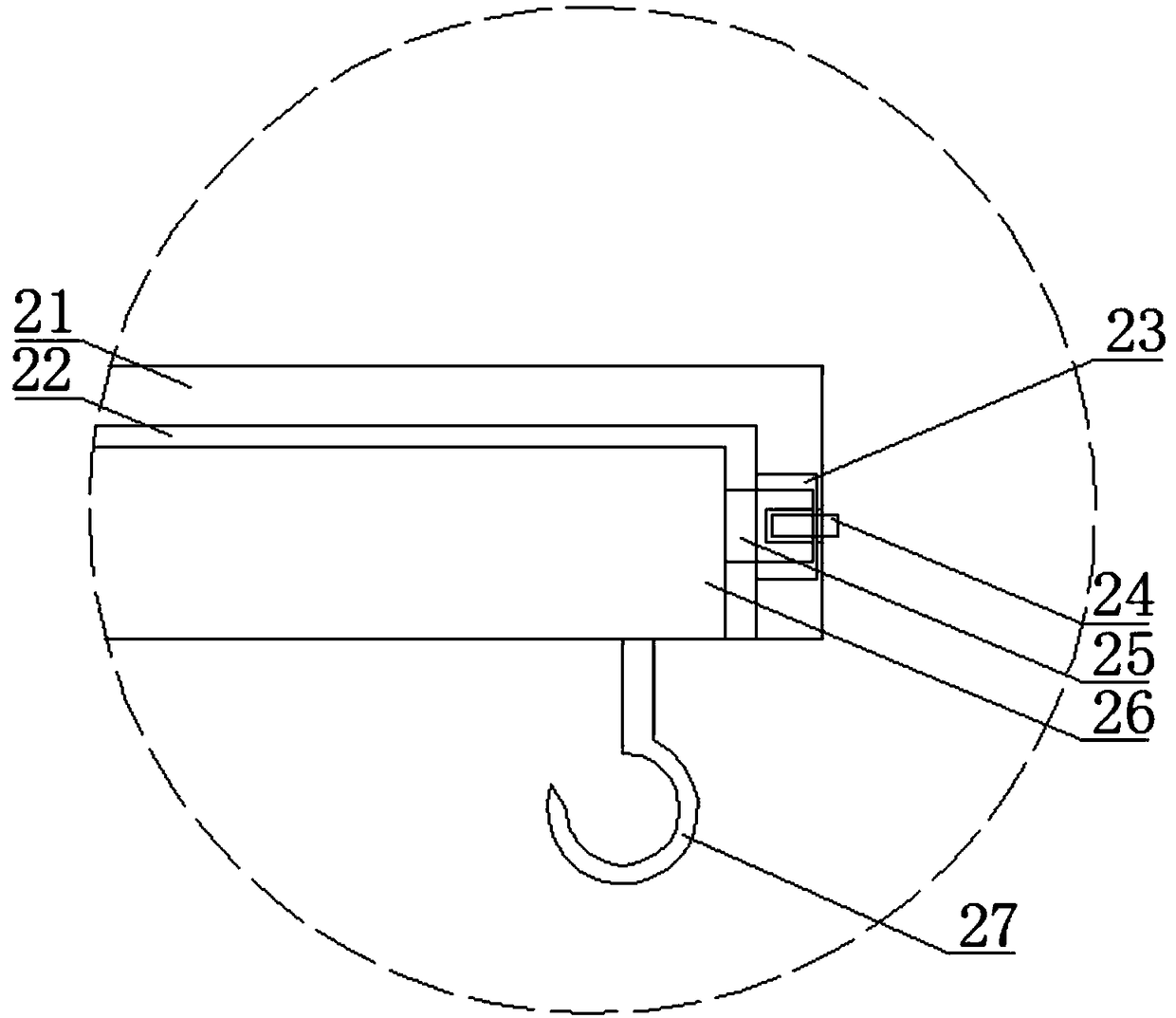

Simple and detachable electric power hoisting tool

The invention discloses a simple and detachable electric power hoisting tool. The simple and detachable electric power hoisting tool comprises a cross arm. Supporting frames are arranged at the two ends of the cross arm. Two fixed pulleys are installed on the cross arm through an installation frame. The simple and detachable electric power hoisting tool further comprises a hoisting frame. A hoisting hook is fixedly arranged at the lower end of the hoisting frame. A movable pulley is installed on the hoisting frame. A steel wire rope wound on the movable pulley and the fixed pulleys is connected to the upper end of the hoisting frame. The supporting frames comprise sliding sleeves which are arranged at the two ends of the cross arm in a sleeving mode. Main supporting arms are perpendicularly and fixedly arranged in the middle portions of the sliding sleeves. Auxiliary supporting arms are coaxially hinged to the sliding sleeves. An adjustment mechanism which can be used for adjusting and fixing the included angle between each main supporting arm and the auxiliary supporting arm is arranged between the main supporting arm and the auxiliary supporting arm. Wire winding mechanisms which are connected with the tail ends of the steel wire rope are installed on the supporting frames. Universal wheels with self-locking functions are installed at the bottoms of the main supporting arms and the auxiliary supporting arms. The simple and detachable electric power hoisting tool has the beneficial effects that assembly is convenient and rapid, hoisting is effortless and stable, movement is convenient, the occupied space is small after the hoisting tool is detached, transportation is convenient, and the simple and detachable electric power hoisting tool is particularly suitable for field working of an electric power system.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

Full-set dismantling and installing construction method of bridge overpassing existing line

ActiveCN106149576ASimple stepsReasonable designBuilding repairsBridge erection/assemblyBuilding constructionEngineering

Owner:中铁二十局集团第三工程有限公司

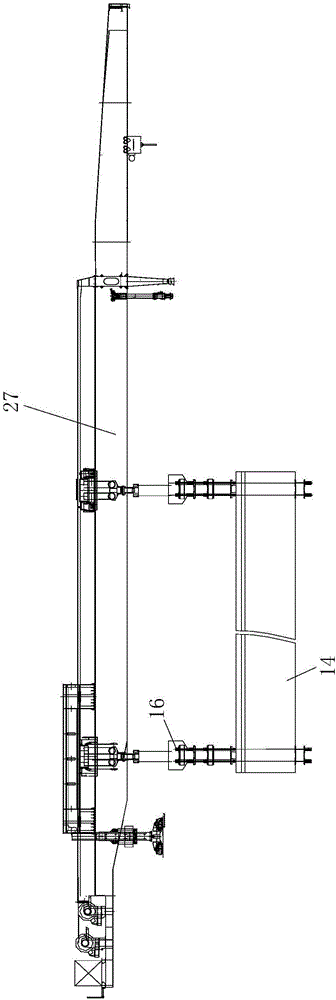

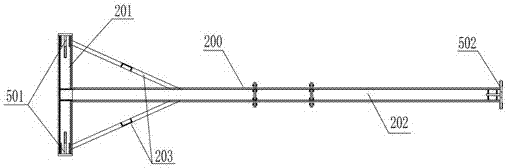

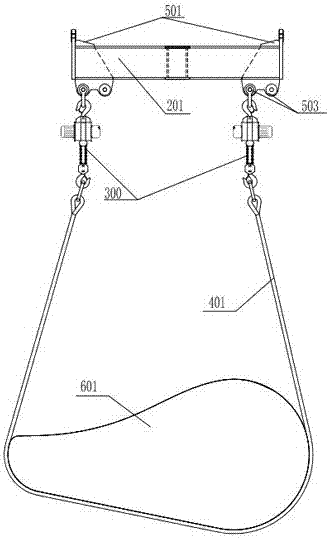

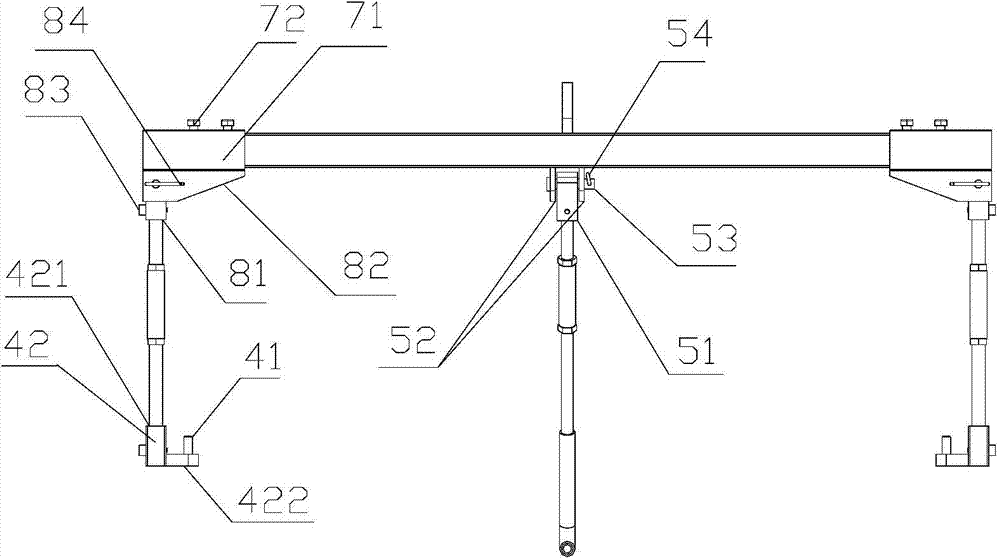

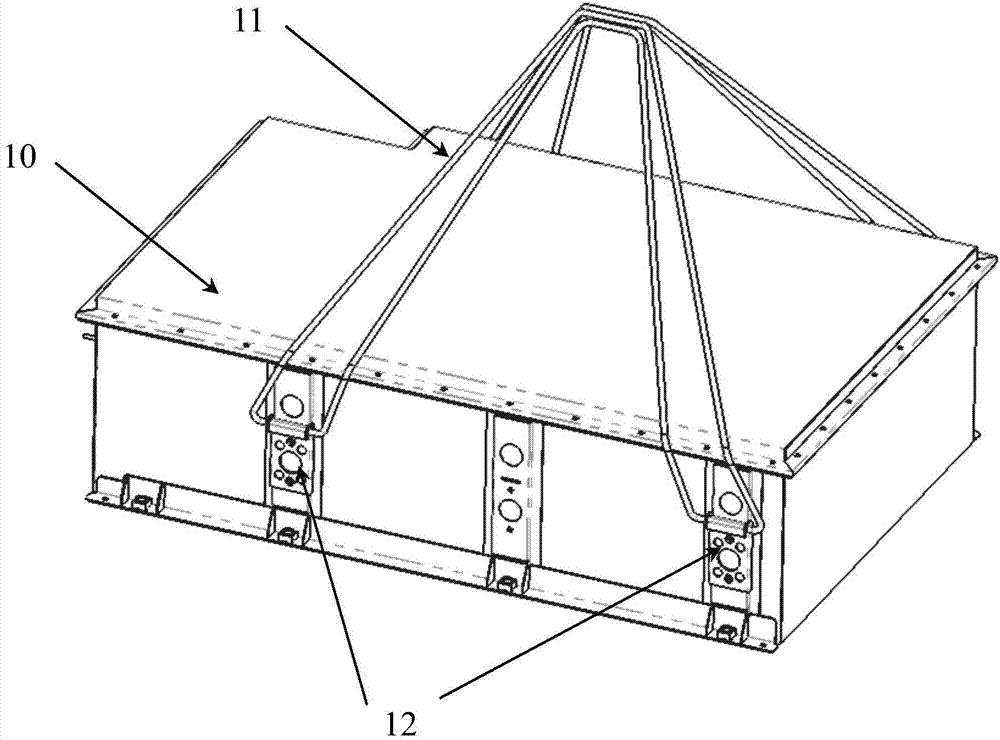

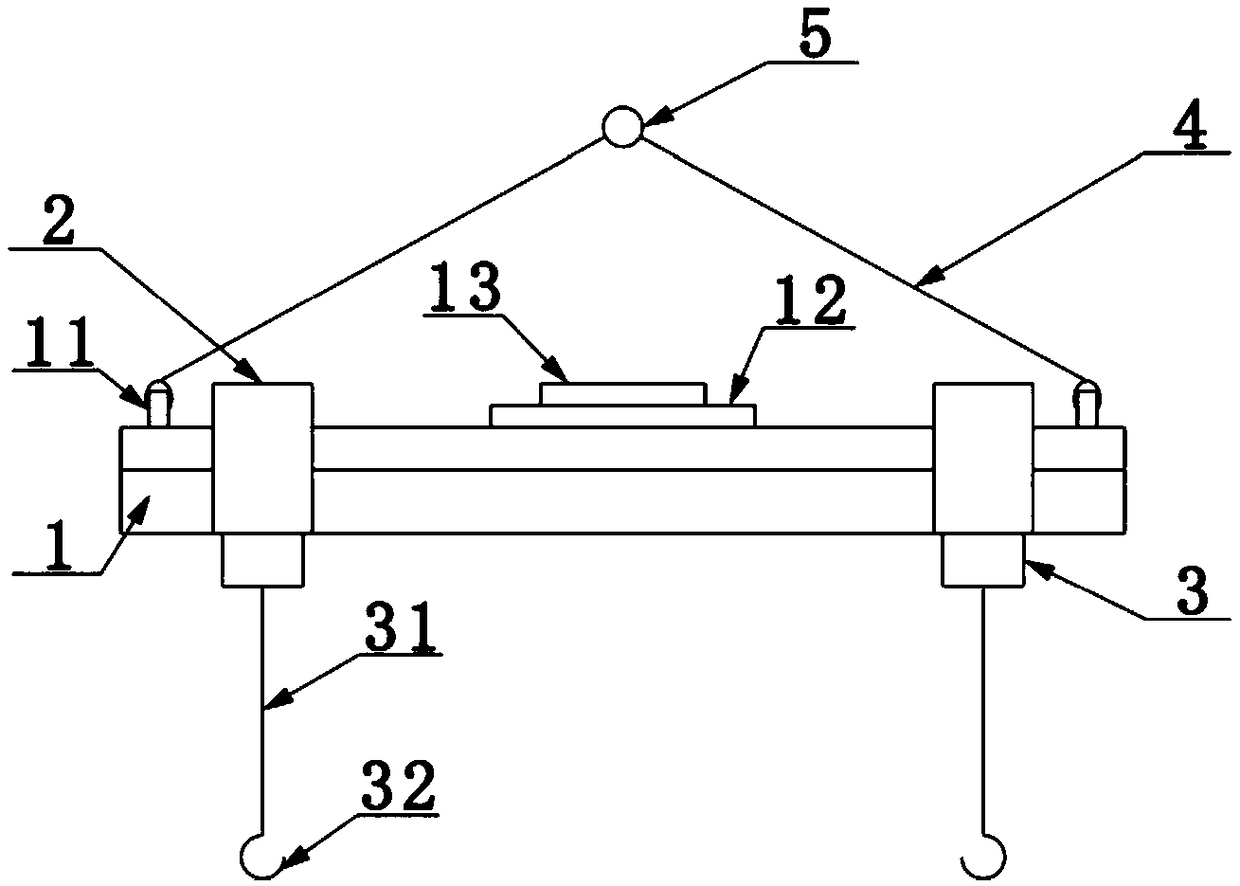

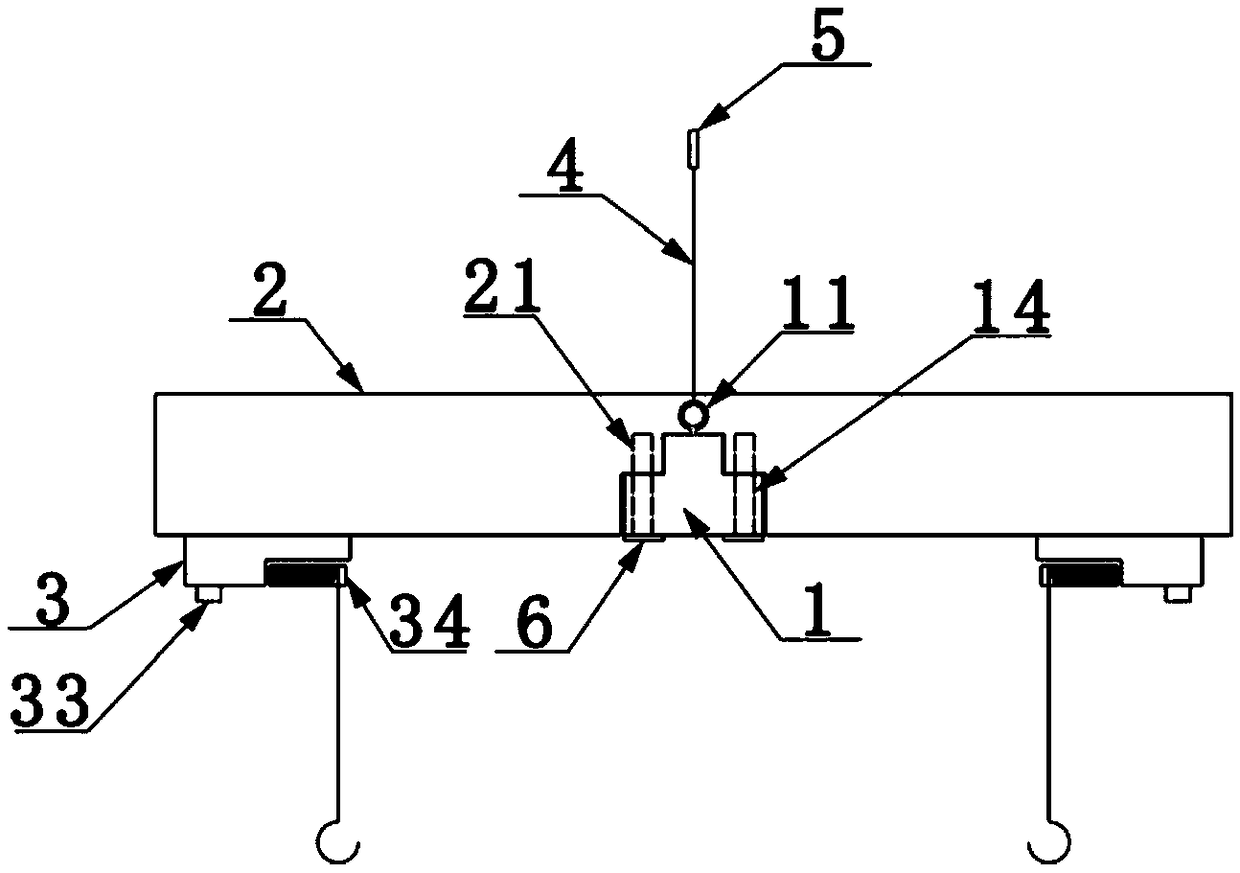

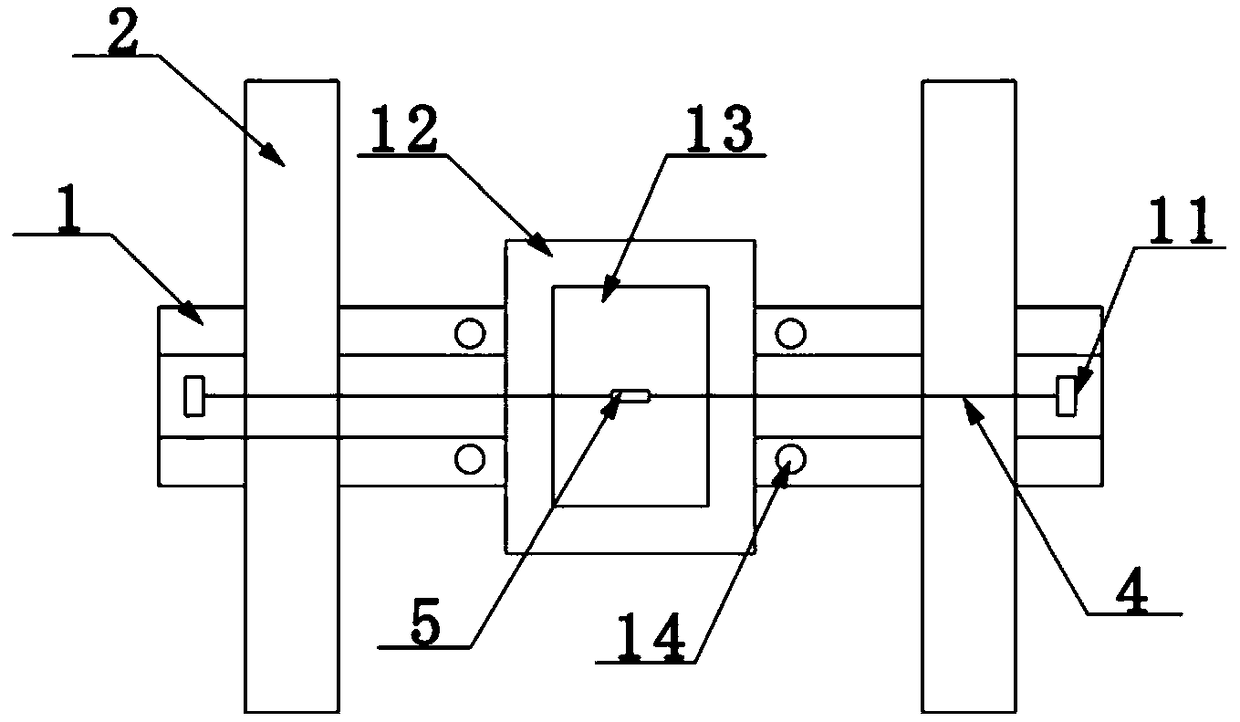

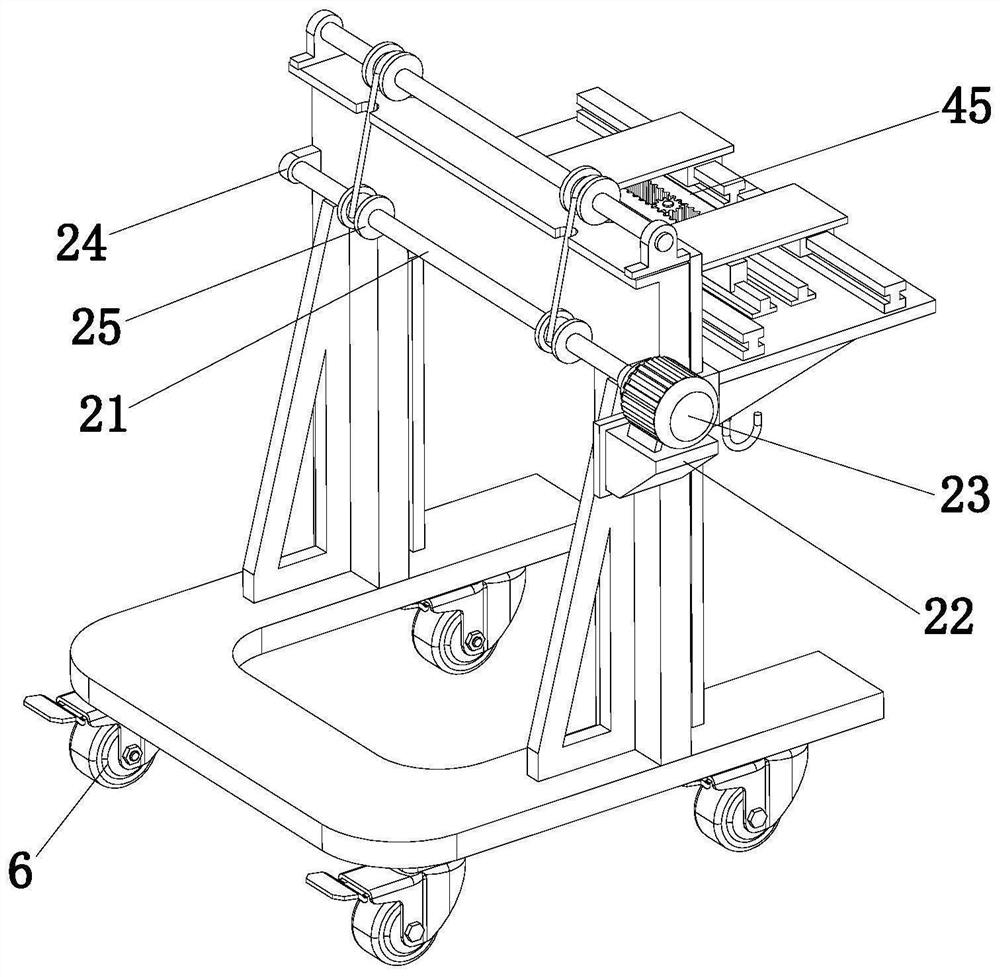

Fan blade flat sling and exchangeable sling

InactiveCN107399665AReduce damageEasy to disassemble and dockMachines/enginesWind energy generationChain deviceEngineering

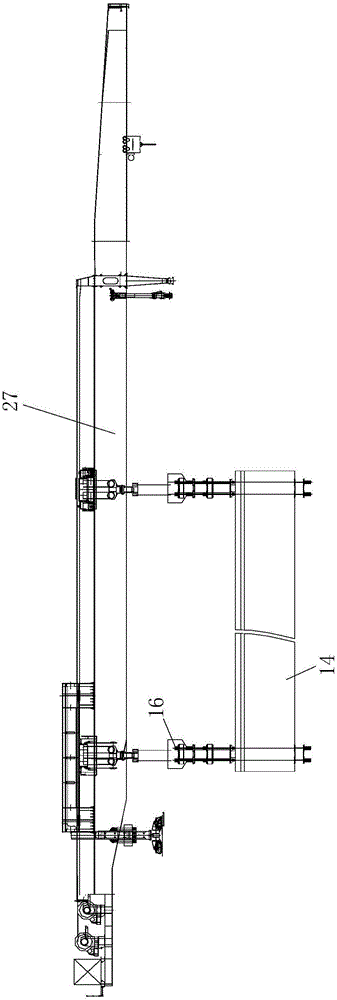

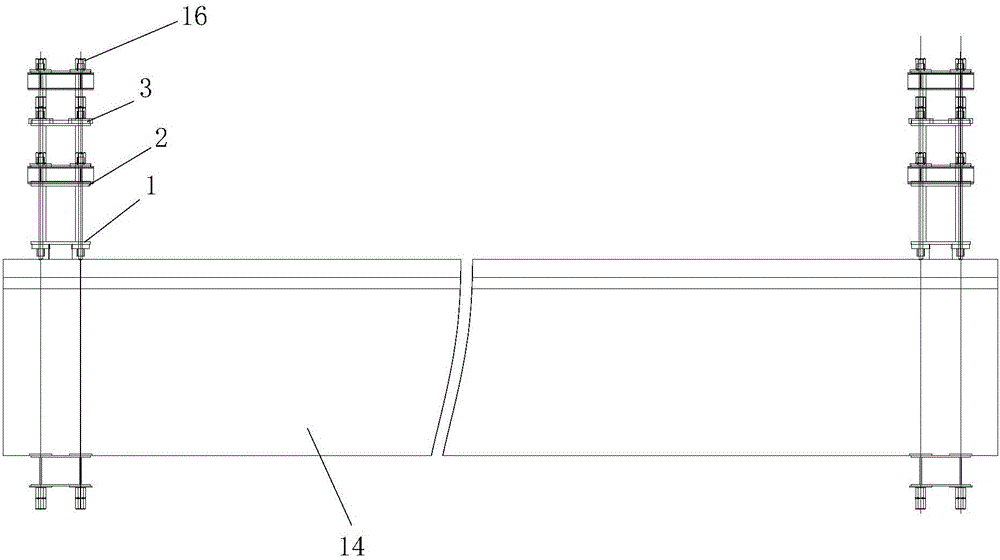

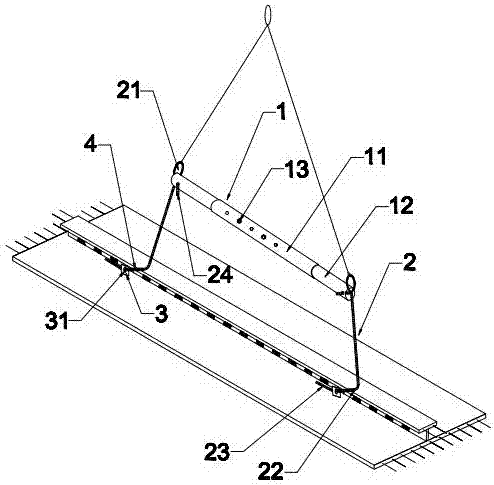

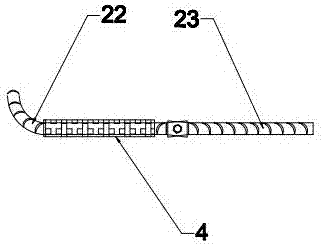

The invention relates to a fan blade flat sling and an exchangeable sling. The fan blade flat sling comprises a sling chain device, a T-shaped beam lifted at the lower end of the sling chain device, and a suspender arranged on the lower part of the T-shaped beam, wherein the sling chain device is composed of a lifting ring, a sling chain hung on the lifting ring and a lifting hook; the T-shaped beam comprises a longitudinal beam and a transverse beam one end of which is connected to the middle of the longitudinal beam; a group of winding and unwinding devices are respectively arranged at two ends of the longitudinal beam; the suspender is divided into a blade tip suspender and a blade root suspender; two ends of the blade tip suspender are respectively lifted on suspension centers at the lower ends of the two groups of winding and unwinding devices; and the blade root suspender is hung on the suspension centers at the lower end of the transverse beam through a rotary pulley. The fan blade flat sling disclosed by the invention is applicable to aerial lifting, replacement, detachment and other operations of fan blades and has the advantages of low lifting cost, high efficiency, easiness and convenience in operation, wide application range and the like.

Owner:DATANG GUIGUANPAN SIGE WIND POWER +2

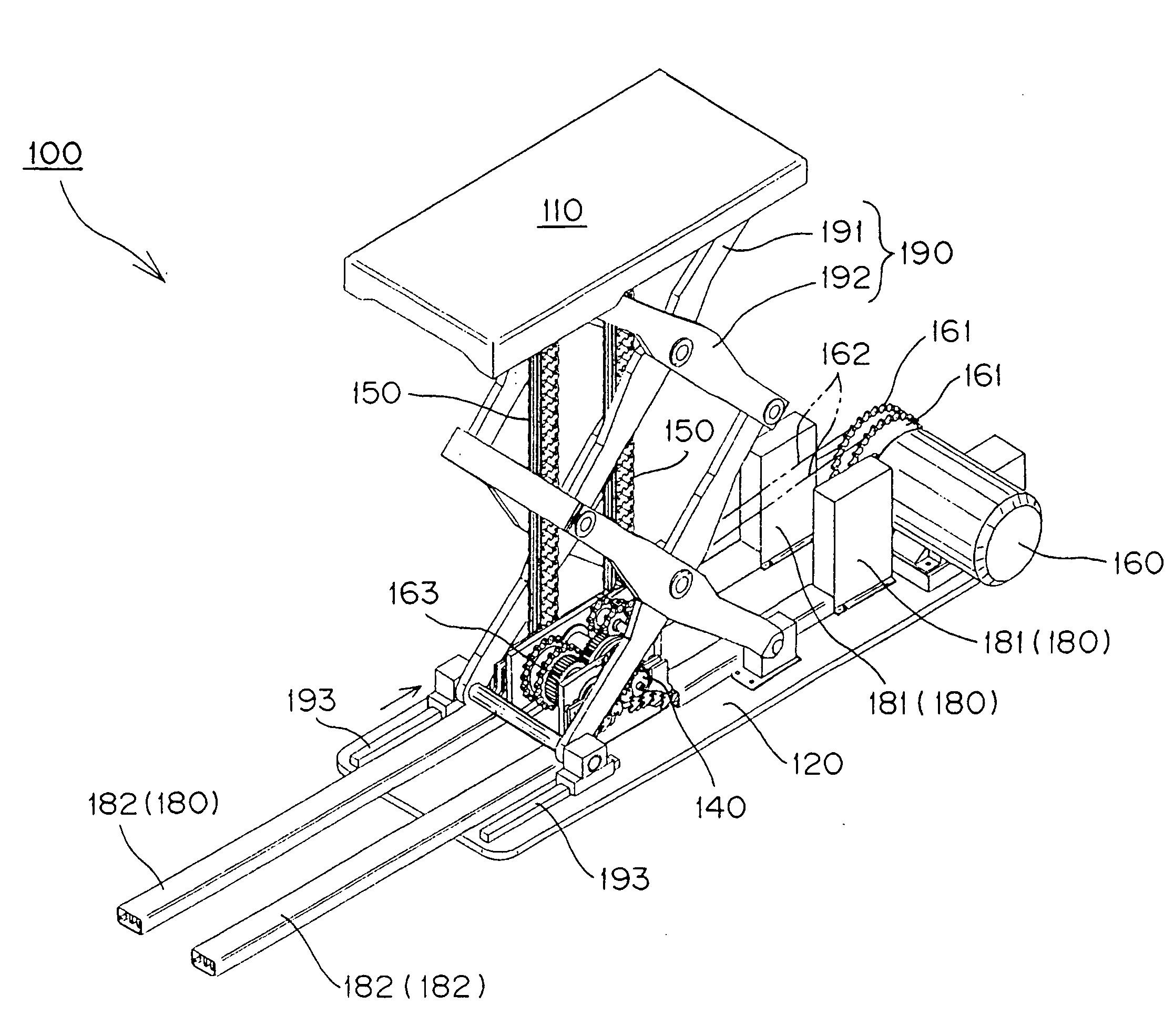

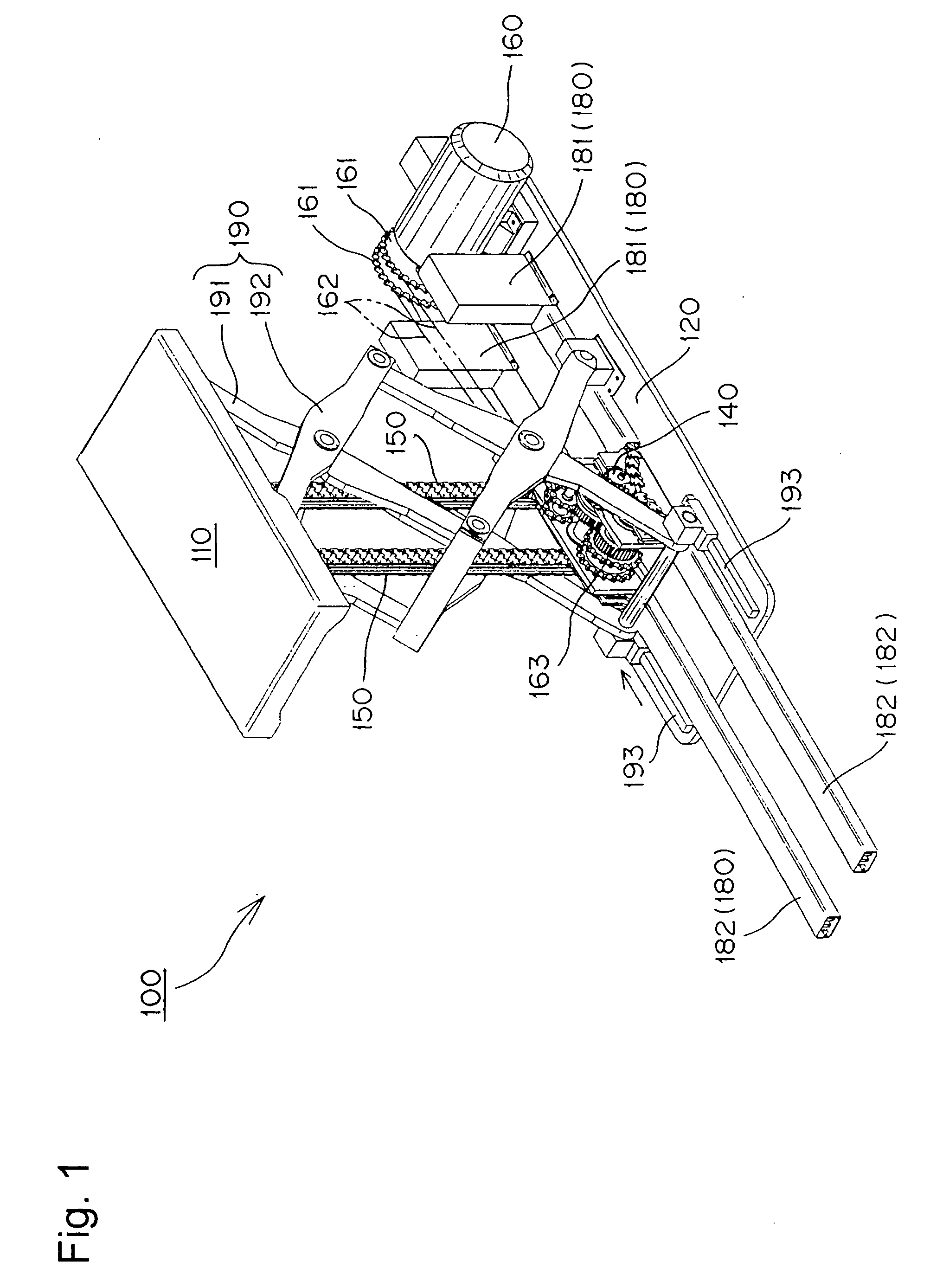

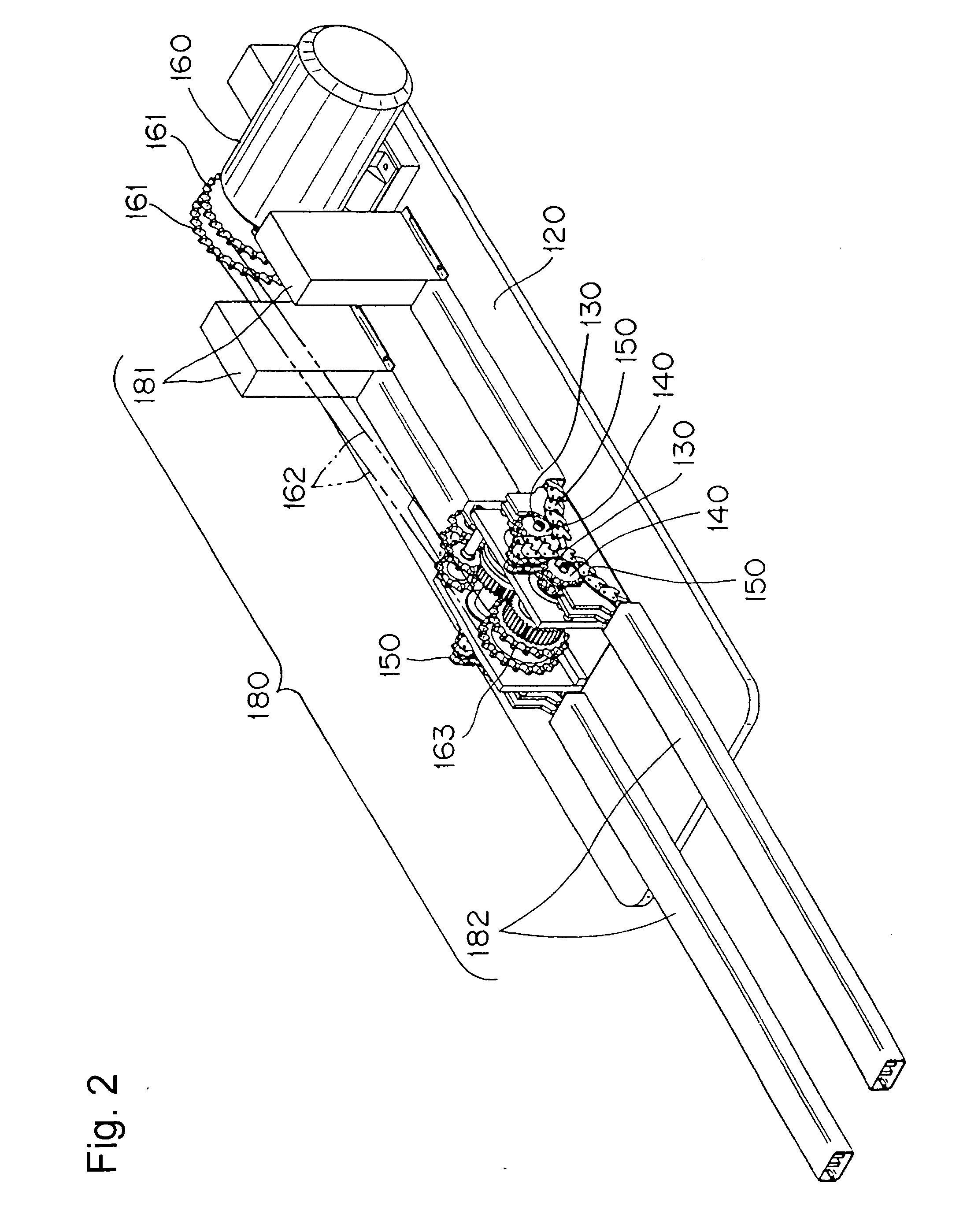

Engagement chain type hoisting and lowering device

InactiveUS20080315168A1Improve design flexibilitySignificant comprehensive benefitsPortable liftingLifting framesChain typeSprocket

An engagement chain type hoisting and lowering device is disclosed, having a hoisting and lowering table attached to the upper end of two or more pairs of hoisting and lowering driving engagement chains. A driving motor drives two pairs of hoisting and lowering sprockets which, in turn, raise or lower two pairs of hoisting and lowering driving engagement chains. By arranging two pairs of hoisting and lowering driving engagement chains on two opposed sides of the hoisting and lowering table, buckling of the hoisting and lowering driving engagement chains is suppressed, resulting in stable hoisting and lowering operations without slippage of articles on the hoisting and lowering table, and chain endurance is improved. The device is designed so that the lowest position of the hoisting and lowering table can be lower than the height of the peripherally located driving motor, for ease and safety of operation and maintenance.

Owner:TSUBAKIMOTO CHAIN CO

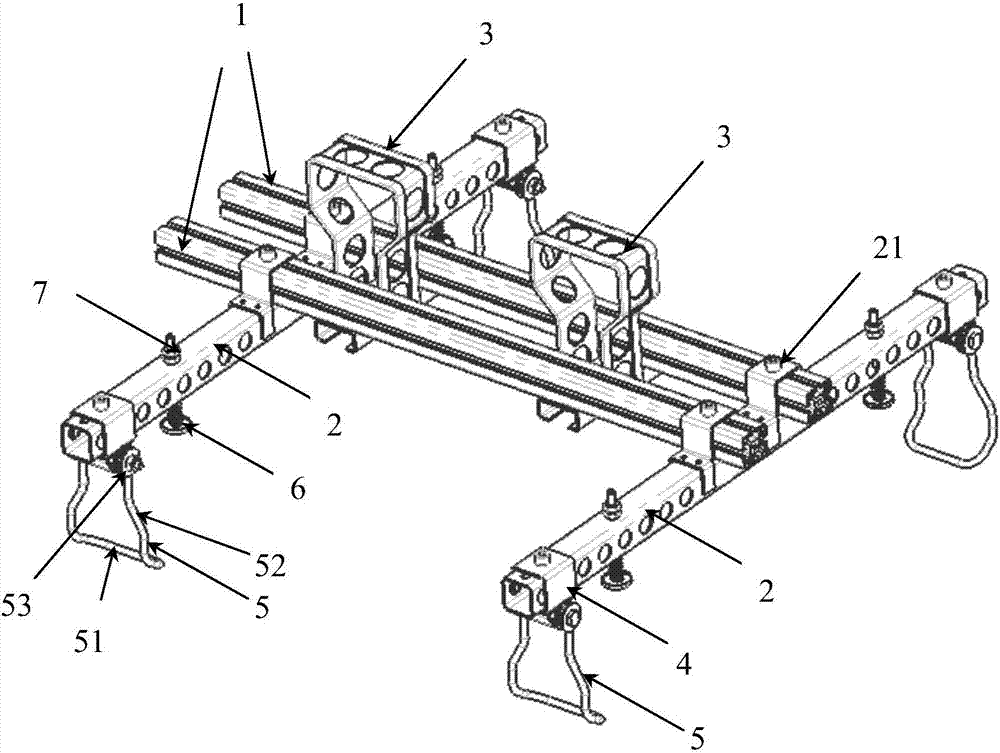

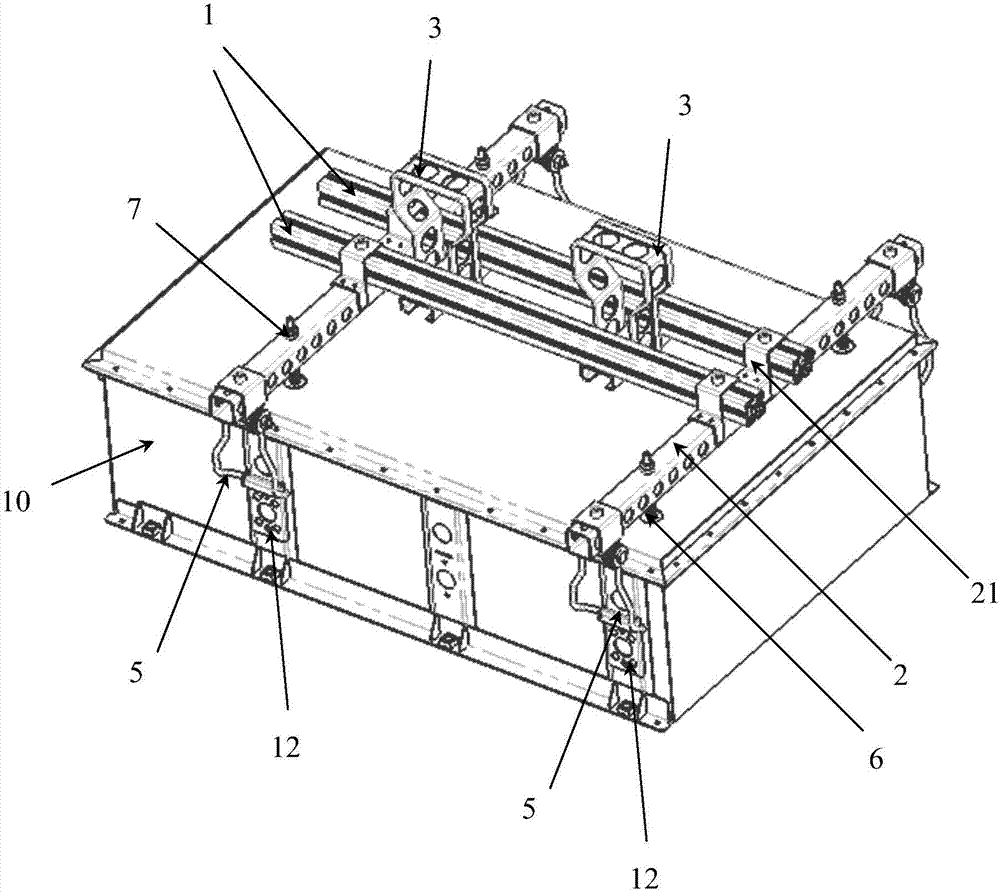

Lifting appliance of automobile auxiliary frame

ActiveCN103523650ANot easy to shakeGuaranteed stabilityLoad-engaging elementsVehicle frameIndustrial engineering

Owner:CHERY AUTOMOBILE CO LTD

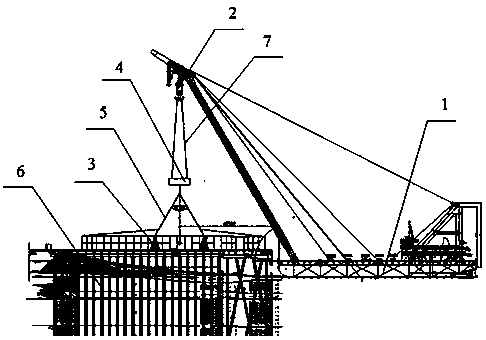

Lifting transportation process of wind power steel pipe piles

InactiveCN107685835AReduce tensionAvoid breakingPreventing unwanted cargo movementCargo handling apparatusElectricityWind power

The invention discloses a lifting transportation process of wind power steel pipe piles, comprising: selecting a floating crane, calculating lifting parameters of the floating crane, selecting liftingpoints for steel pipe piles, selecting a transport vessel, selecting transport supports, installing the transport supports, lifting the steel pipe piles, loading the steel pipe piles, tying the steelpipe piles, and installing auxiliary parts. The lifting transportation process of wind power steel pipe piles has the advantages that the process steps are stable and ordered, lifting is table, tyingfirmness is good, two lifting points selected, the position of a hook combiner is determined, the included angle between two lifting wire ropes is not greater than 45 degrees, tension between the lifting wire ropes is decreased, breakage of the lifting wire ropes is avoided, slight increase of one end in weight due to the sliding of the lifting wire ropes to the middle of a steel pipe pile is also prevented, and lifting safety is ensured; by calculating the number of the transport supports and bearing capacity of each transport support, no damage can be caused to the transport vessel during transport of the wind power steel pipe piles; the steel pipe piles are tied firmly and stably, shaking of the transport vessel during transporting is avoided, and transport safety is ensured.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

Battery box hoisting device

Owner:WUHAN LISHEN POWER CELL SYST TECH CO LTD

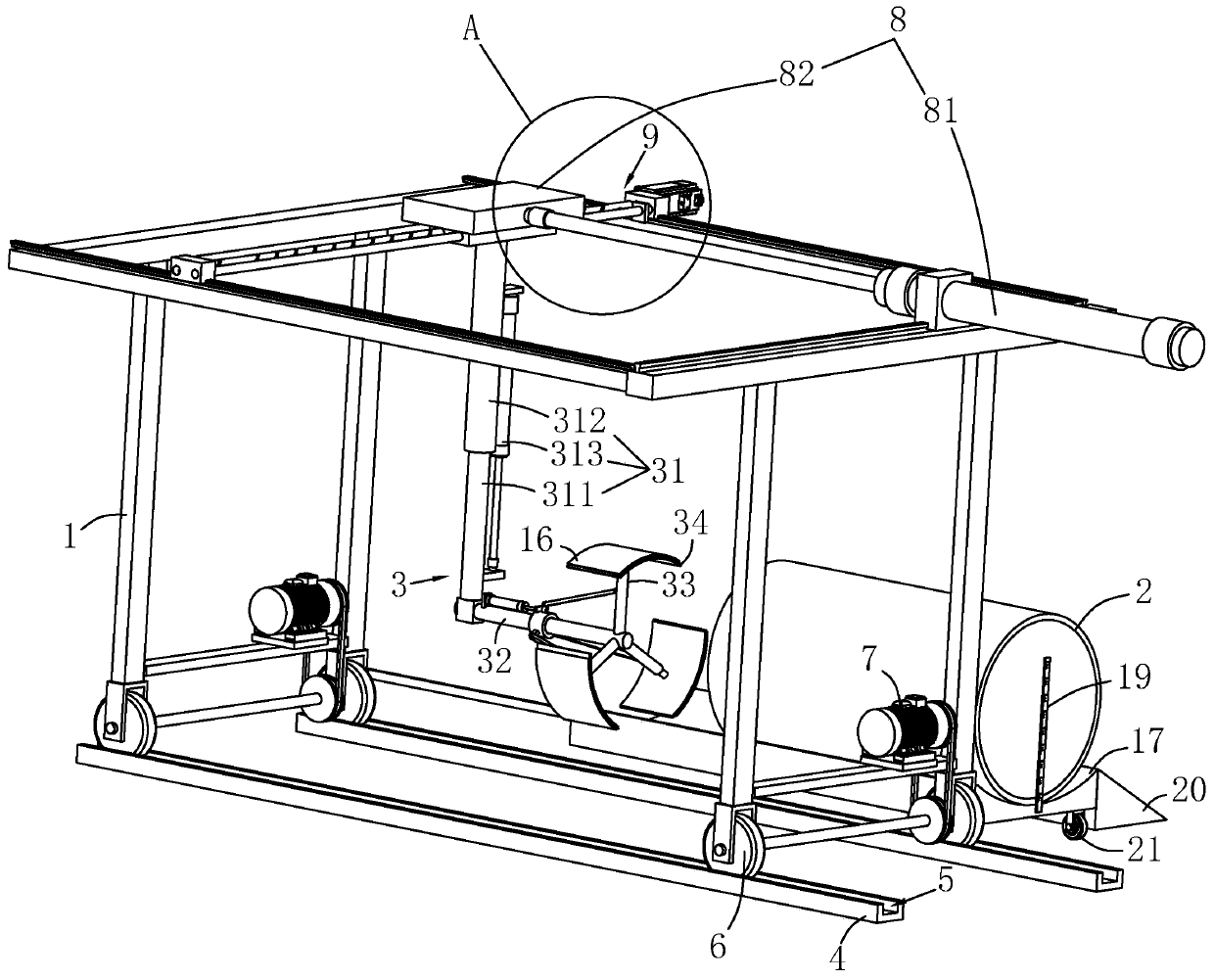

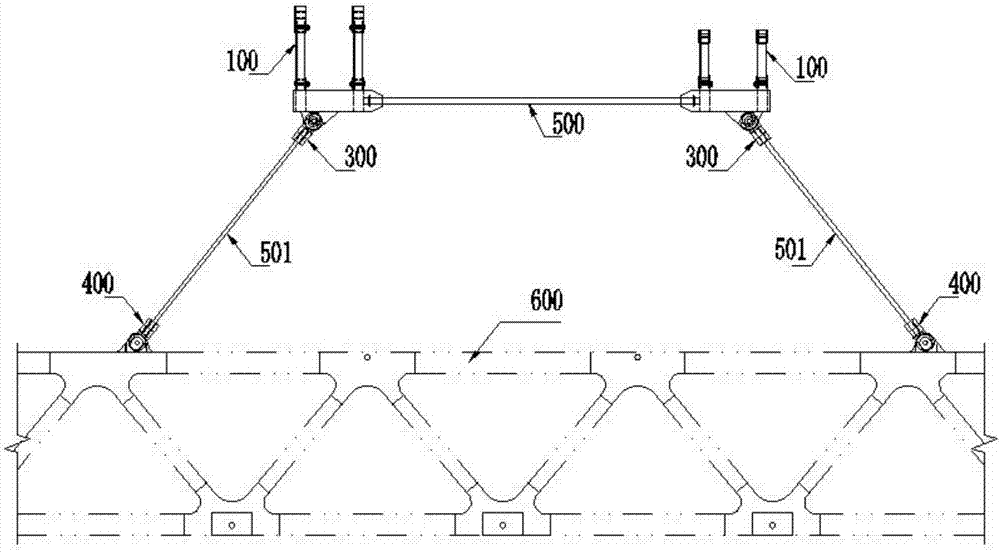

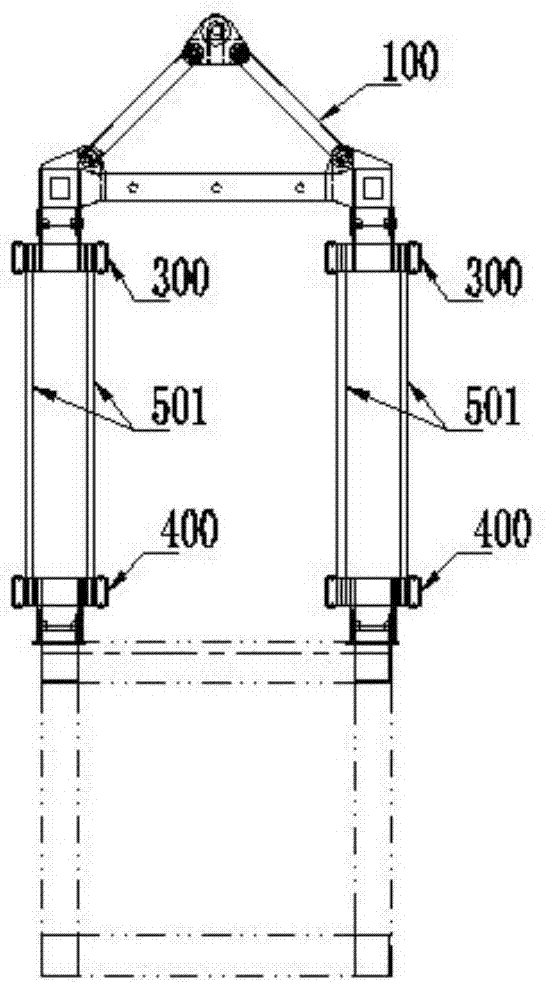

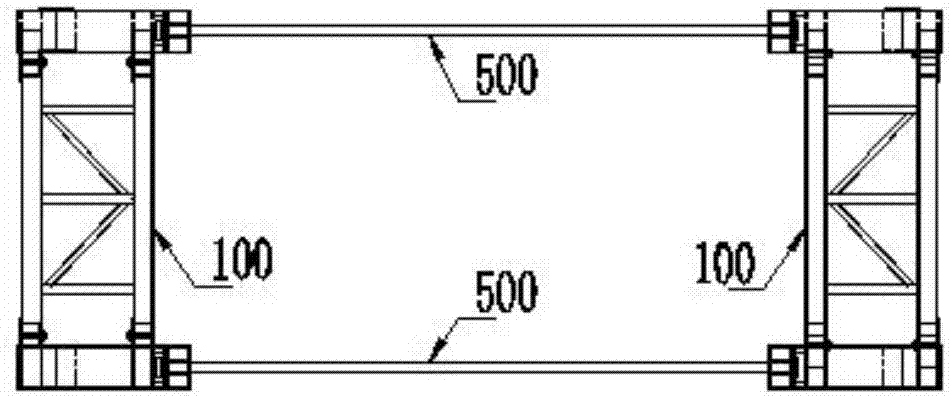

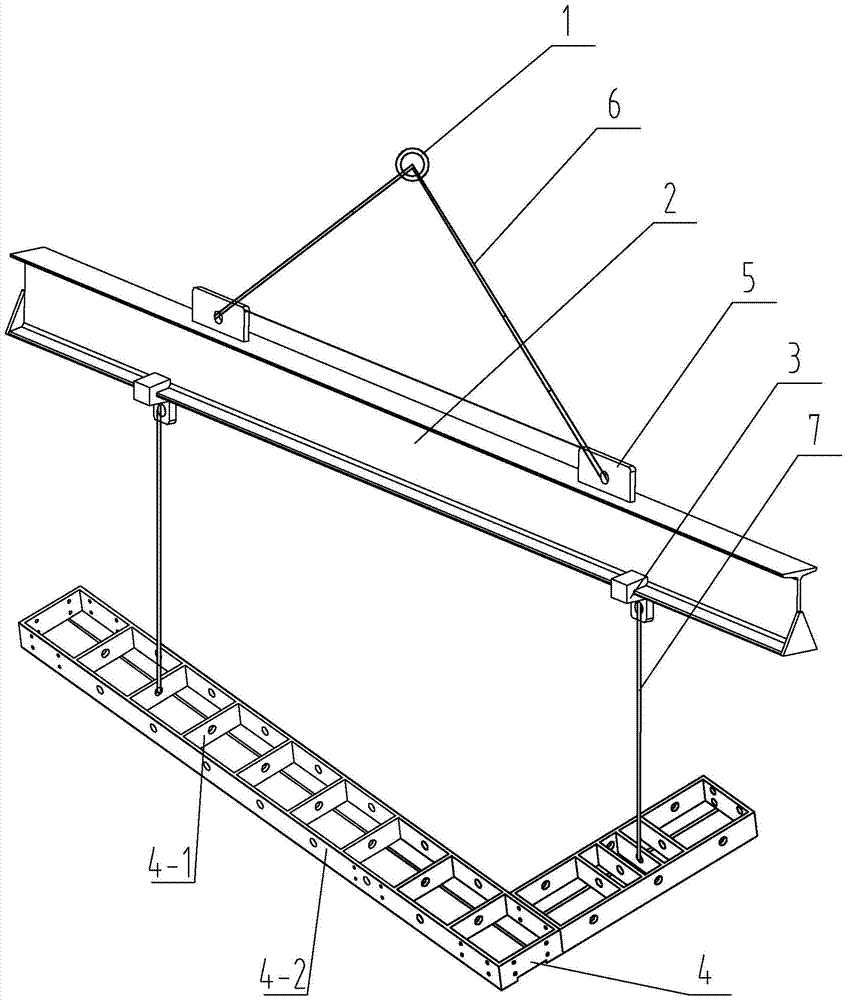

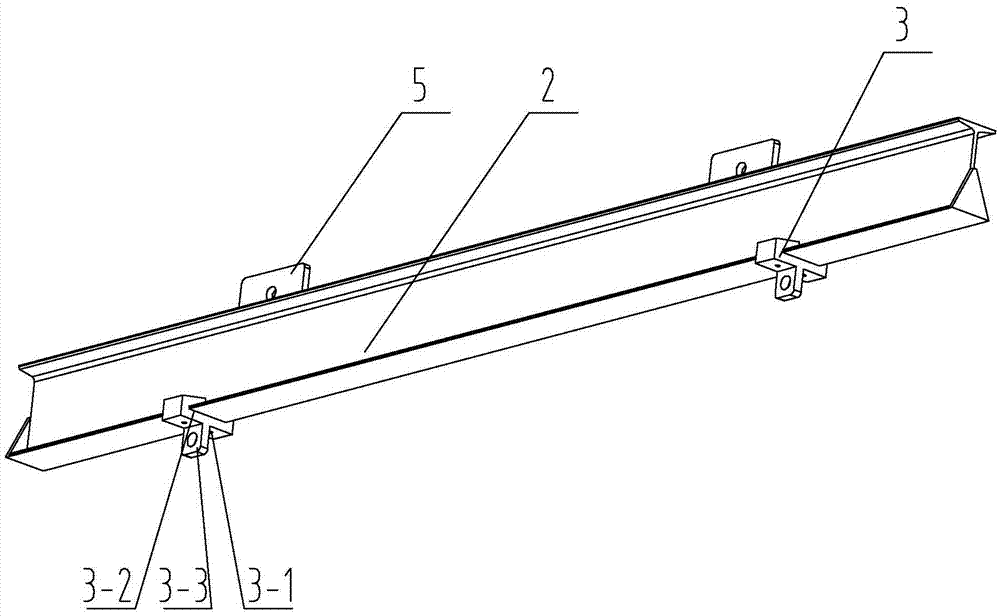

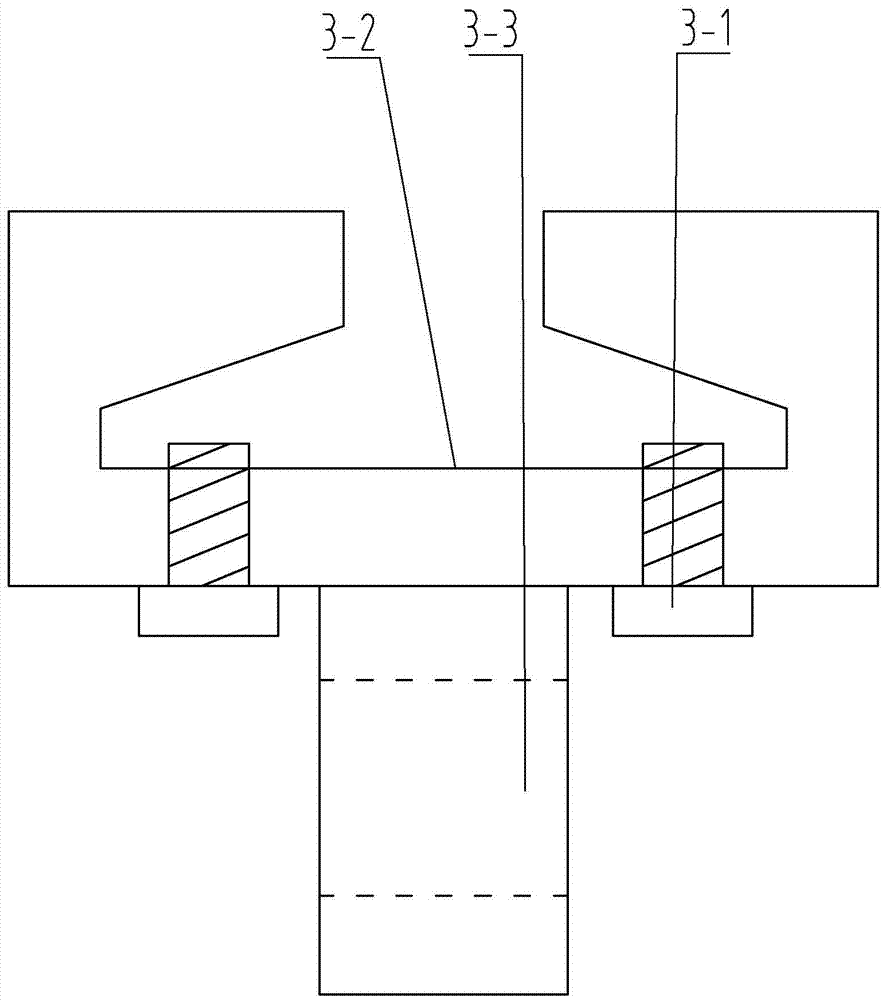

Hoisting method and hoisting device for concrete prefabricated box beam

ActiveCN103437298AStable hoistingImprove stabilityBridge erection/assemblyLoad-engaging elementsStructural engineering

The invention discloses a hoisting method and a hoisting device for a concrete prefabricated box beam. The hoisting method and the hoisting device can be used for reducing damage of the concrete prefabricated box beam in a hoisting process while ensuring that the prefabricated box beam is horizontal in the hoisting process. The concrete prefabricated box beam hoisting device comprises a balance beam, a connecting rod and a cross beam. The hoisting method comprises the following steps of: mounting hoisting devices at the two ends of the concrete prefabricated box beam; starting the hoisting equipment to hoist the balance beam; adjusting the position of the concrete prefabricated box beam to be horizontal; driving the concrete prefabricated box beam by the cross beam to rise above a bridge pier; positioning and mounting. The hoisting device has compact structure and good stability and can be used for reducing damage of the concrete prefabricated box beam in the hoisting process; the hoisting device can be repeatedly used and has long service life; the hoisting method is simple to operate, and can ensure that the concrete prefabricated box beam is always at a horizontal position in the hoisting process so as to facilitate the positioning and obtain higher safety of the hoisting process.

Owner:CHINA 19TH METALLURGICAL CORP

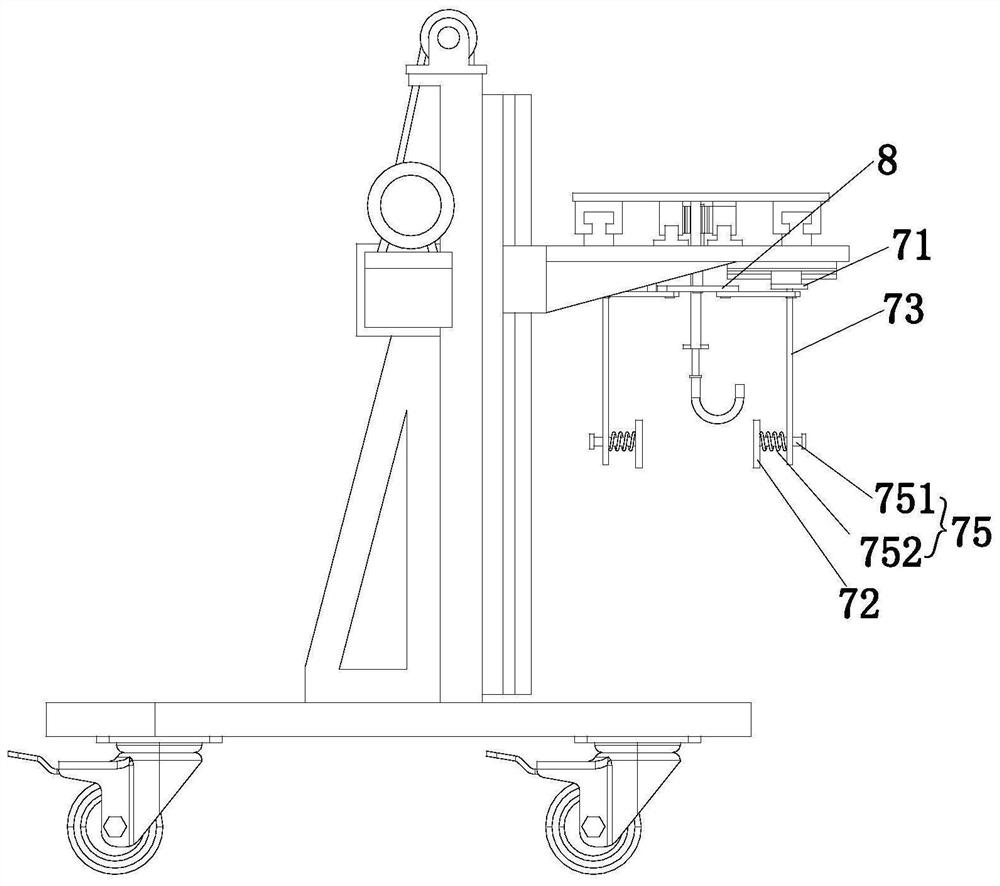

Municipal road sewer construction device and method thereof

ActiveCN110295662AStable hoistingStable layingSewer pipelinesReciprocating motionArchitectural engineering

The invention relates to a municipal road sewer construction device. The municipal road sewer construction device comprises a machine frame and a hanging mechanism used for hanging a pipeline, whereina first drive mechanism used for driving the hanging mechanism to preform reciprocating motion along the moving direction of the machine frame is arranged on the machine frame, a second drive mechanism used for driving the hanging mechanism to perform reciprocating motion along the direction vertical to the moving direction of the machine frame is arranged on the machine frame, the hanging mechanism comprises an elastic telescopic bar, a cross bar, loop bars and an arc plate, the loop bars are vertically arranged at one end of the cross bar along the circumferential direction, a slide rod penetrates through each loop bar and is connected with each loop bar in a sliding mode, an open groove is formed in each loop bar, a sleeve sleeves the cross bar and is connected with the cross bar in asliding mode, the sleeve passes through the open grooves through a connection rod and is connected with one end, close to the cross bar, of each slide rod, the other end, far away from the cross bar,of each slide rod, is fixedly connected with the arc plate used for abutting against the interior of a pipeline, and a first air cylinder used for driving the sleeve to perform reciprocating motion isarranged on the cross bar and along the length direction of the cross bar. The municipal road sewer construction device has the effect of facilitating stable paving of the pipeline.

Owner:华虹建筑安装工程集团有限公司

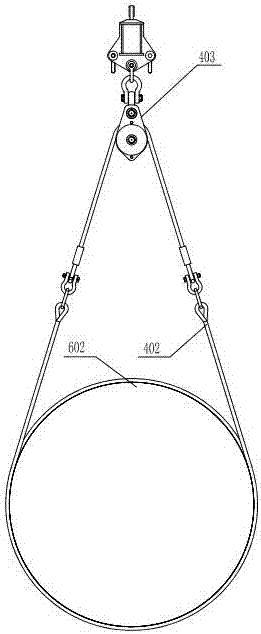

Jacket lifting and binding process

ActiveCN107089584AGuaranteed stabilitySimple materialLoad-engaging elementsMarine engineeringMechanical equipment

The invention relates to a jacket lifting and binding process. The jacket lifting and binding process comprises the following steps in sequence: a crane ship is positioned in the field; a barge leans against a wharf on the left side of the crane ship; mechanical equipment of each part is checked to determine good conditions; two main hooks are loosened, and steel wire ropes are respectively hung to corresponding lifting hooks; O-shaped lifting belts are manually mounted; constructors connect the steel wire ropes on the main lifting hooks with shackles for the lifting belts in sequence; hook hanging persons use iron rods for knocking on conduction parts of the lifting belts, so that the lifting belts are firmly bound with steel pipes at lifting point parts; after the hanging persons check each lifting point normally, the main hooks are continuously lifted up to reach a preset height; an anchor system of the crane ship is twisted to shift the ship; and a jacket is shifted above the barge, and is loosened to fall on the barge. The jacket lifting and binding process has the following advantages: lifting equipment adopts a floating crane; connecting devices adopt the O-shaped lifting belts, the steel wire ropes and the shackles; the materials are simple; the lifting is stable; and the jacket is vertically lifted, and is vertically mounted on the barge without needing such operations as turning, so that the operation is simple and easy.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

Hoisting tool of laminated plate and hoisting method of laminated plate

ActiveCN109319652AStable hoistingEnsure midline symmetryLoad-engaging elementsEngineeringThree-phase

The invention discloses a hoisting tool of a laminated plate and a hoisting method of the laminated plate, The tool comprises a hanging bracket, the hanging bracket comprises a longitudinal rod and ahorizontal rod, lifting lugs are arranged at the two ends of the longitudinal rod, and the lifting lugs are fixedly connected with a lifting ring through a steel wire rope; winching mechanisms are arranged at the end parts of the transverse rod, and internally comprise outer shells of three-phase motors and laser distance measuring sensors; winding drums are fixedly connected to rotating shafts ofthe three-phase motors, the steel wire rope is wound around the winding drums, the tail ends of the steel wire rope are fixedly connected with hooks, and the laser distance measuring sensors are fixed perpendicular to the lower sides of the outer shells; a mounting table is arranged in the middle of the longitudinal rod, and a power supply for supplying power to the winching mechanisms is arranged on the mounting table; when the laminated plate is hoisted, the position of the horizontal rod is adjusted according to the size of the laminated plate in advance, then a truss is hooked by the hooks, and finally a lifting device is used for hooking the lifting ring and hoisting the laminated plate to a preset position. The tool and the hoisting method are adopted, so that the technical problemof difficulty in leveling in a hoisting process of the laminated plate can be effectively solved.

Owner:CHINA MCC5 GROUP CORP +1

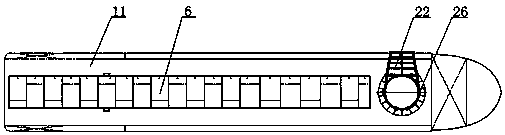

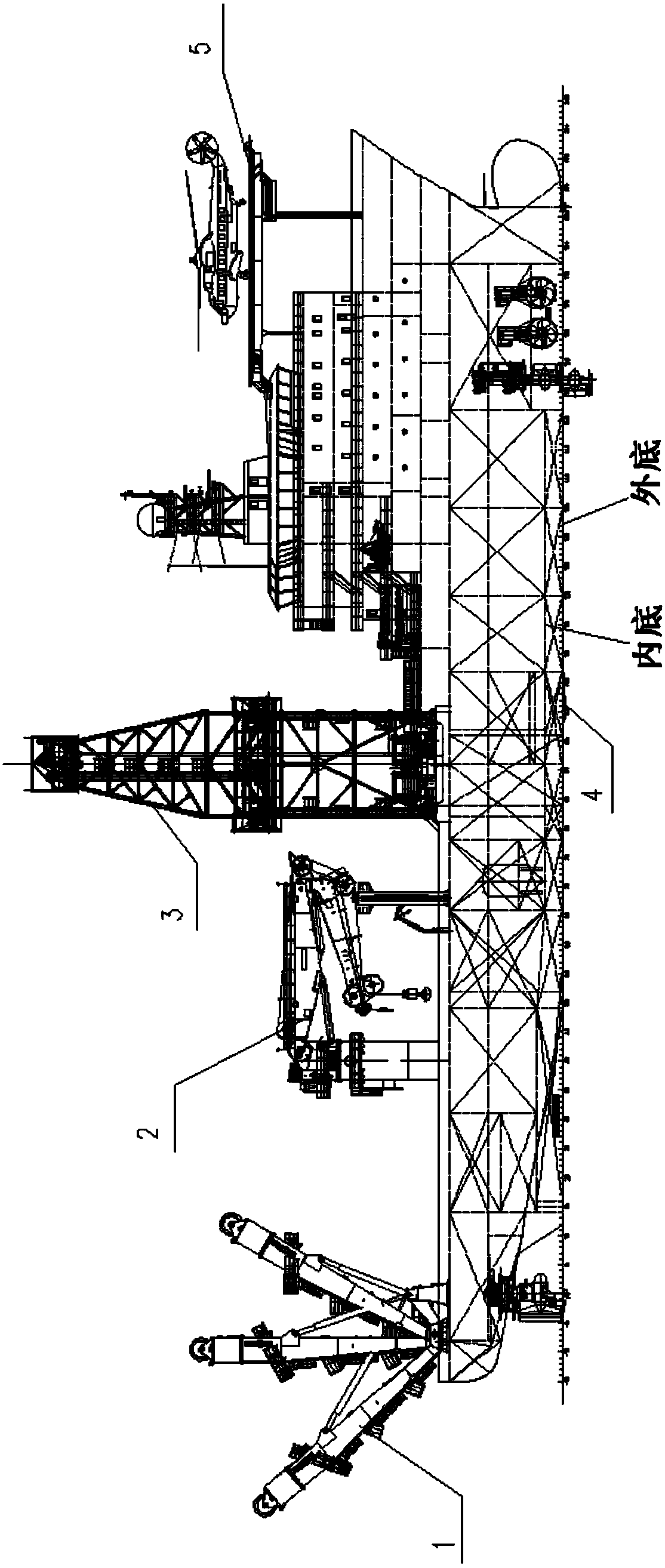

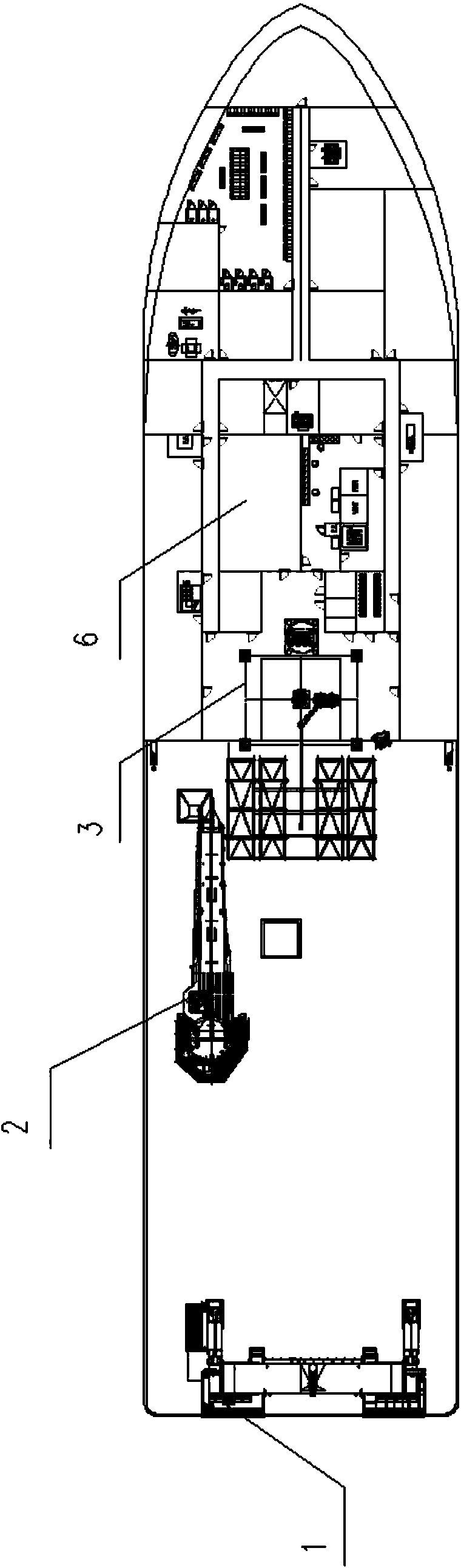

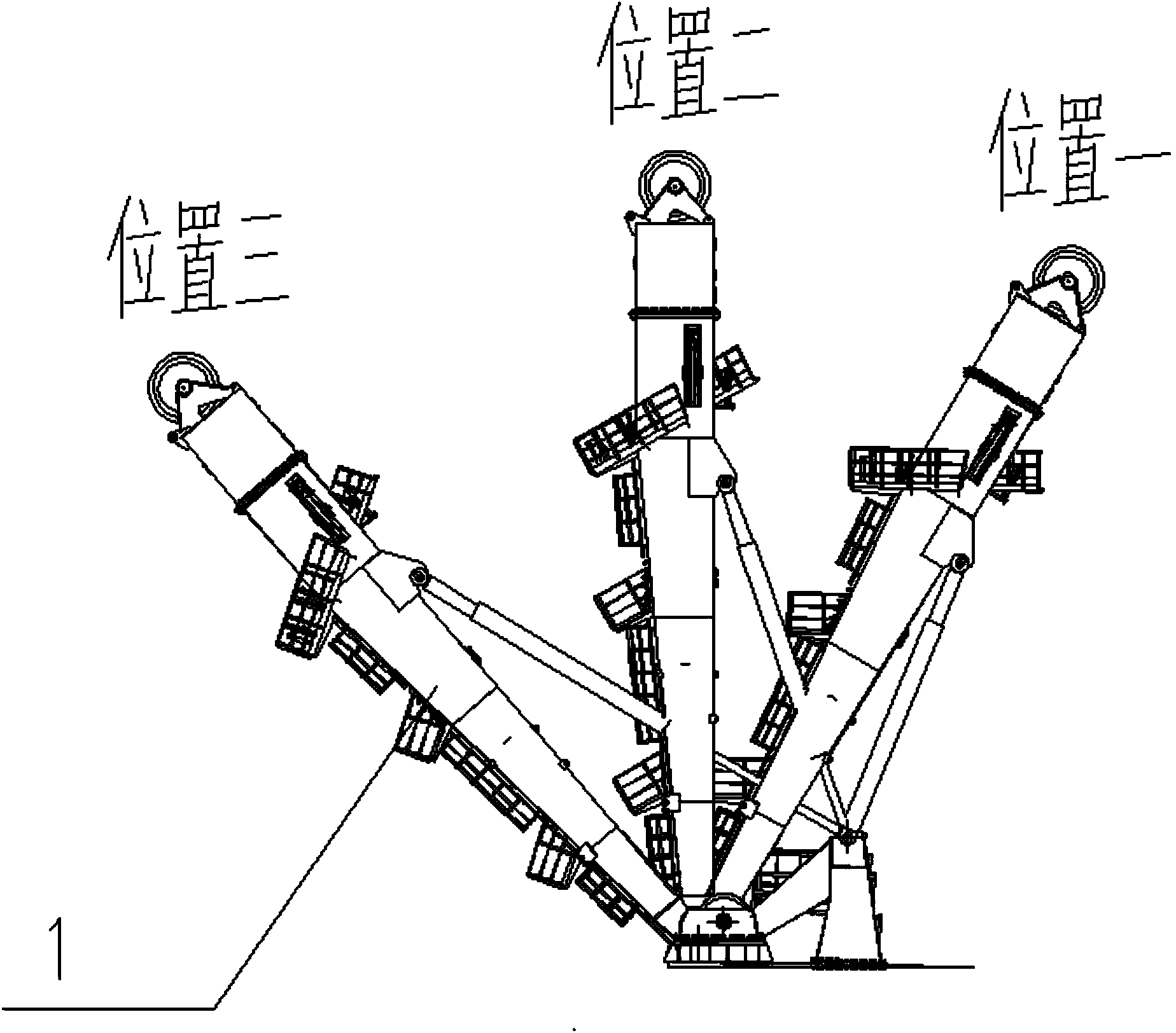

Multifunctional installation and investigation vessel

ActiveCN103395479AAchieve streamliningImprove efficiencyWaterborne vesselsSpecial purpose vesselsWinchEnergy converter

The invention relates to a multifunctional installation and investigation vessel, which comprises a vessel body and is characterized in that an A-type lifting frame, an oceanographic engineering crane and a derrick are sequentially arranged in the X direction on a main deck of the vessel body; a crane winch is arranged below the main deck, and a steel wire rope passes through the main deck; the crane and the crane winch are respectively arranged in positions on two sides of the vessel body; multiple empty tanks are arranged between the inner bottom and the outer bottom of the vessel body and in positions on two sides of the vessel body, and multiple lower water ballast tanks are arranged on the inner sides of the two sides of the vessel body; opposite tanks on the two sides of the vessel body are communicated via communication passages; an energy converter tank is also arranged at the bottom of the vessel body. When the tanks are damaged, water can enter the empty tanks uniformly, so that the stability is improved; when water in the empty tanks on one side of the vessel body is excessive, water can flow from one side to the other side of the vessel body via the communication passages, so that the transverse inclination after damage of the vessel can be reduced and the damaged stability is improved.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

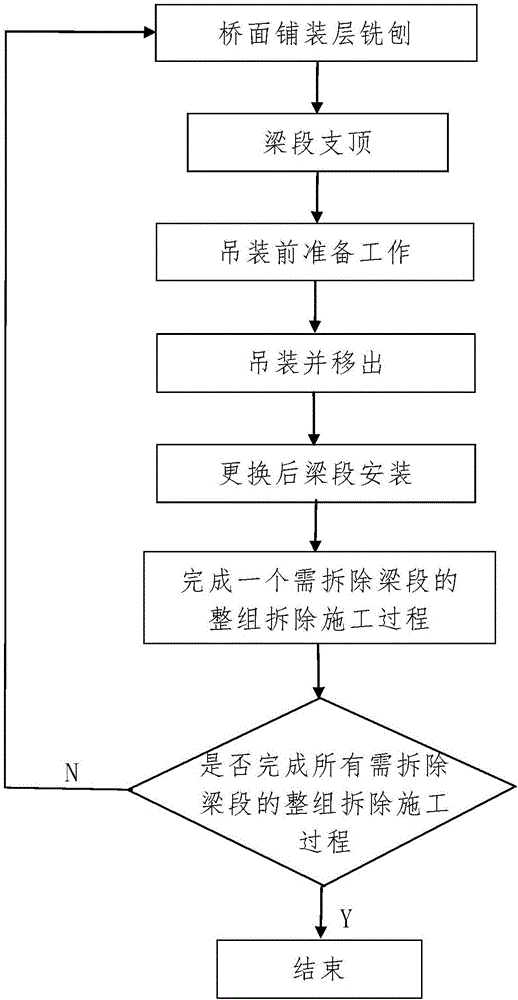

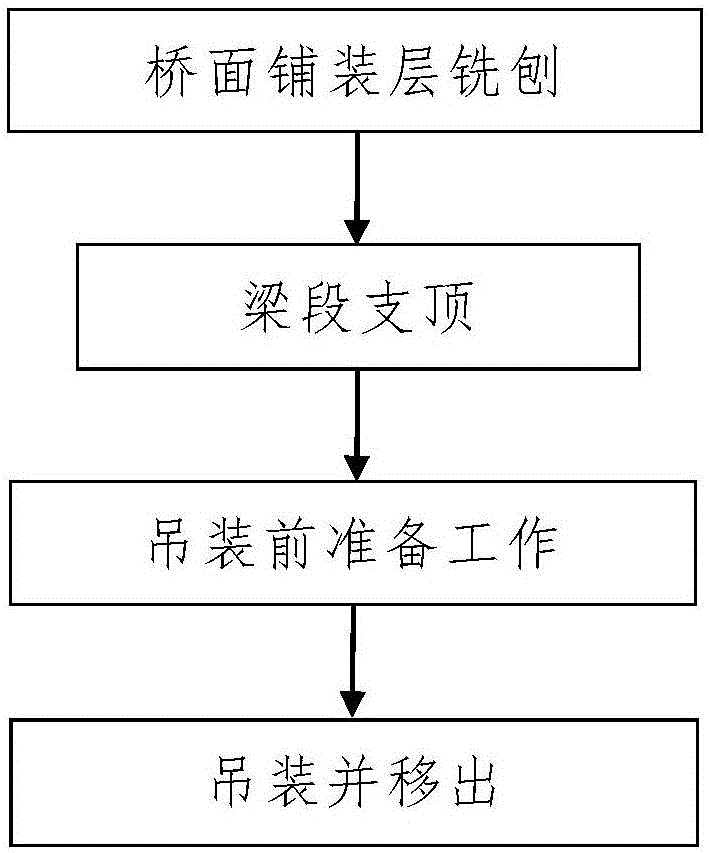

Crossing existing line bridge girder dismounting method

ActiveCN106284109ASimple stepsReasonable designBuilding repairsBridge strengtheningBridge deckRailway line

The invention discloses a crossing existing line bridge girder dismounting method. A dismounted bridge girder is a girder crossing an existing railway line and is formed by splicing a plurality of girder segments to be dismounted from front to back. During complete set dismounting construction of any segment to be dismounted, the process comprises the following steps that firstly, a bridge deck pavement is milled, specifically, the bridge deck pavement of the girder segment constructed currently is milled; secondly, the girder segment is jacked up, specifically, the girder segment constructed currently is horizontally jacked upwards through a vertical jacking device, so that the girder segment constructed currently is separated from two supporting piers; thirdly, preparation operation before hoisting is conducted; and fourthly, the girder segment constructed currently is horizontally hoisted upwards through a bridge girder erection machine and moved to the outer sides of the two supporting piers. The method is simple in step, reasonable in design, easy and convenient to construct and good in application effect, the complete set dismounting construction process of the crossing existing line bridge girder can be completed easily, conveniently and rapidly, and the construction process is safe and reliable, the construction period is short, and the method is economic and practical.

Owner:中铁二十局集团第三工程有限公司

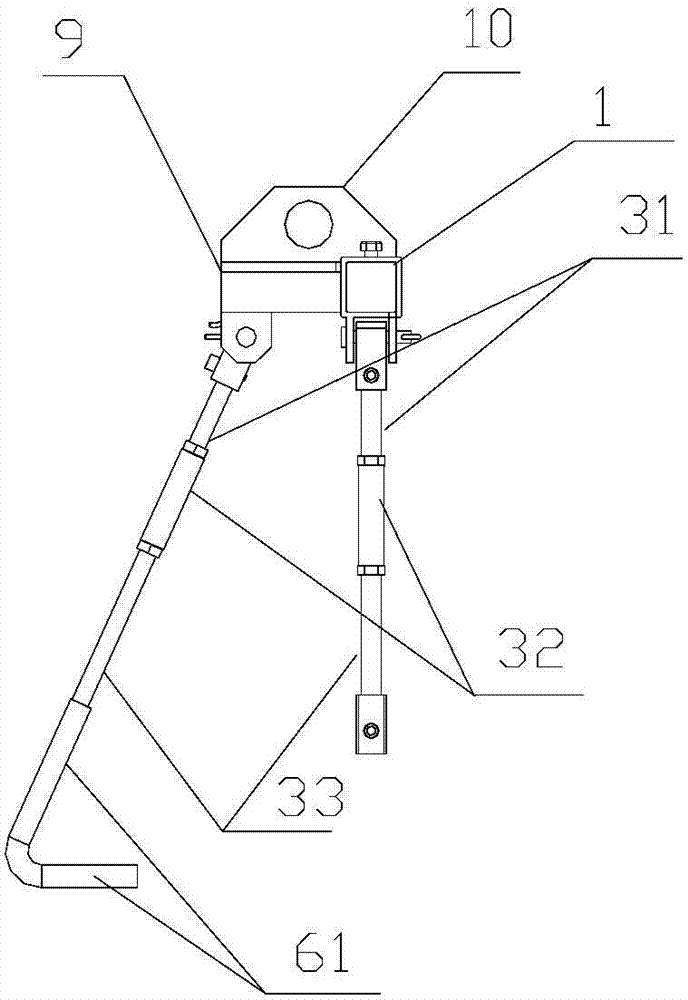

PK prestressed concrete composite slab lifting appliance and lifting method adopting same

ActiveCN107055309ASimple and fast operationStable hoistingLoad-engaging elementsComposite slabPrestressed concrete

The invention discloses a PK prestressed concrete composite slab lifting appliance and a lifting method adopting the same. The lifting appliance comprises a telescopic support tube and two lifting hooks mounted at the left end and the right end of the support tube respectively; a lifting ring is arranged at one end of each of the lifting hooks, the other ends of the lifting hooks bend outwards to form lifting hook bending parts; the upper ends of the lifting hooks are detachably connected with the telescopic support tube; the lifting method comprises the following lifting steps: S1, mounting and fixing the upper ends of the lifting hooks at the two ends of the telescopic support tube; S2, enabling the lifting hook bending parts to be aligned with corresponding PK slab rib holes, inserting the lifting hook bending parts into the corresponding slab rib holes and further using fixing clamping pieces to fix the tail ends of the lifting hook bending parts on a PK base plate; S3, adopting a steel wire rope for connecting the lifting appliance with the lifting hooks of a lifting machine; S4, inspecting whether the connection at the connecting points of the lifting hooks is firm or not, and starting the lifting machine for lifting. According to the PK prestressed concrete composite slab lifting appliance and lifting method adopting the same, the self-made lifting appliance is adopted for lifting PK slabs, so that not only is the manufacturing cost of the lifting appliance reduced, but also the lifting time is shortened.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

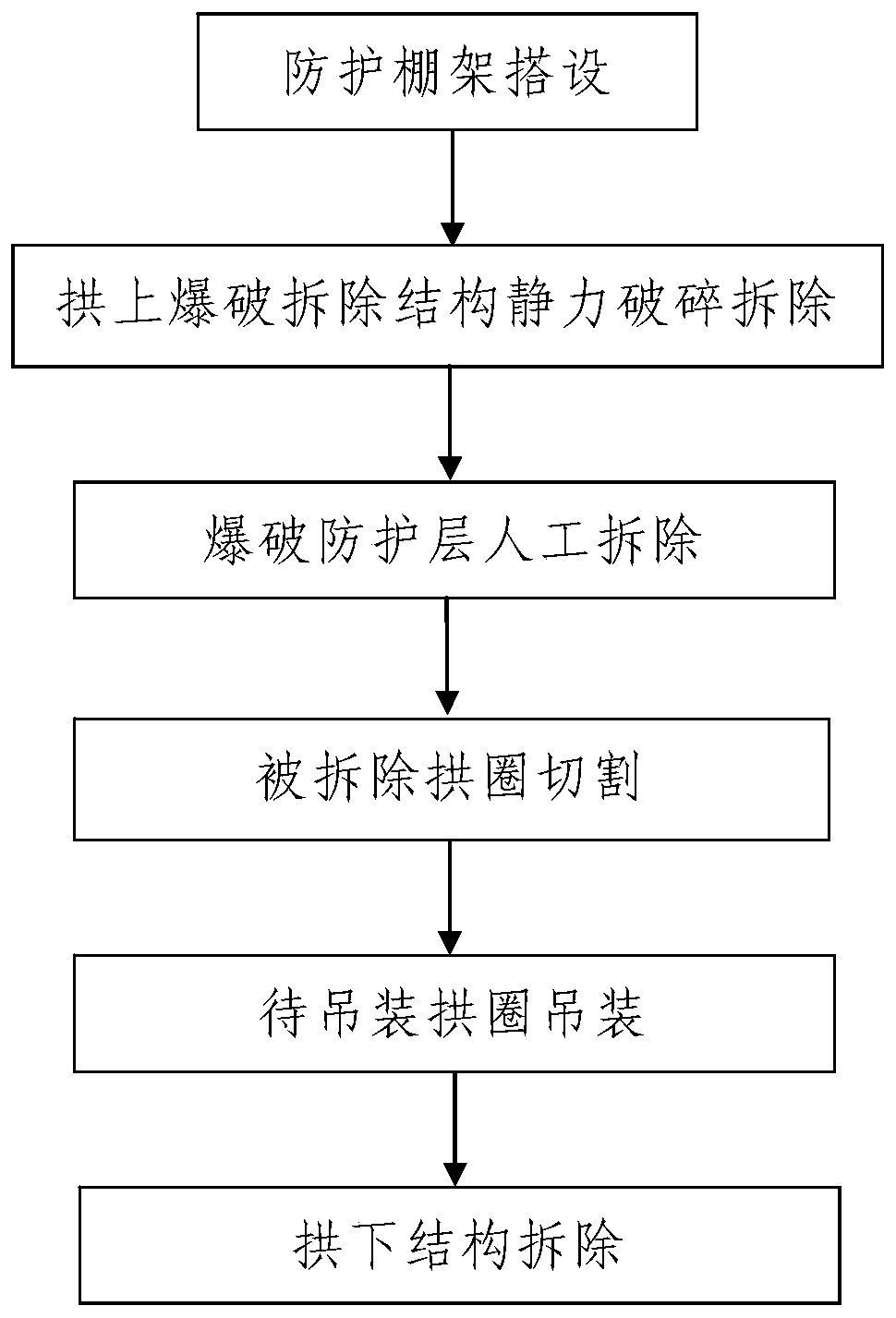

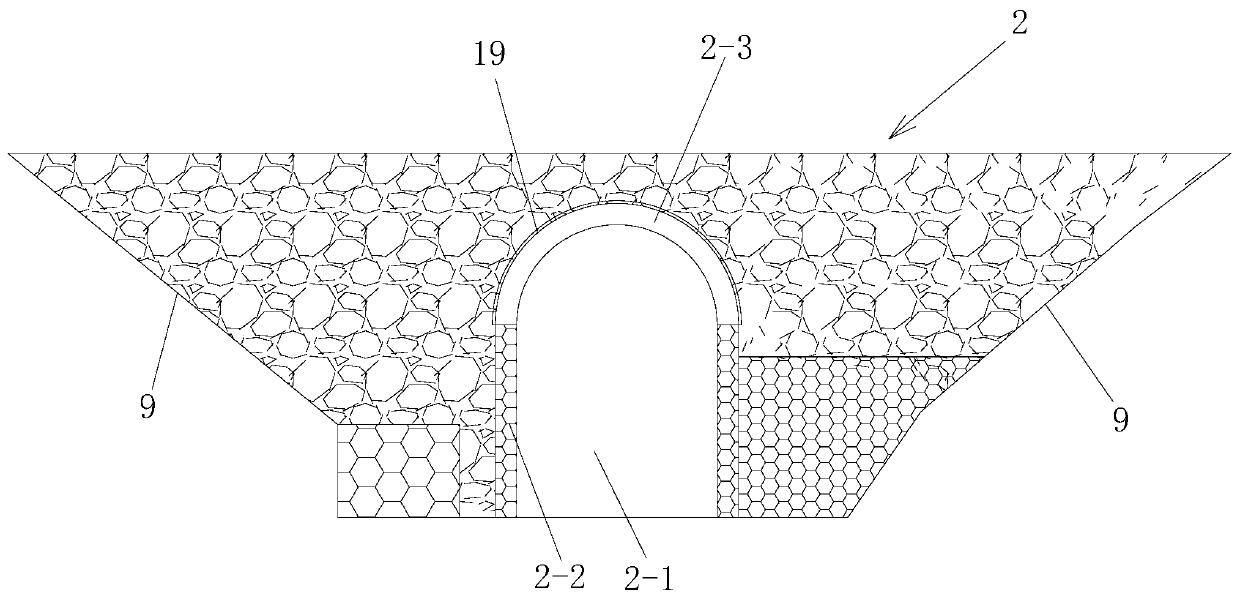

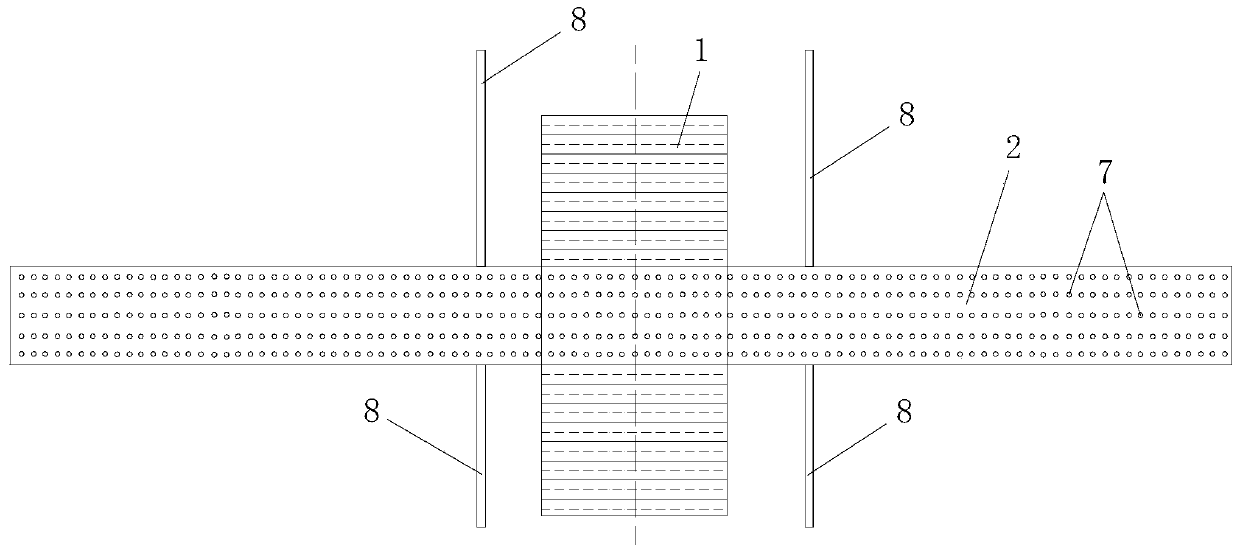

Demolition construction method for overpass existing line arch bridge

ActiveCN110904867AThe method steps are simpleReasonable designBuilding repairsBridge strengtheningArchitectural engineeringStructural engineering

The invention discloses a demolition construction method for an overpass existing line arch bridge. The demolition construction method comprises the steps: 1, erecting a protective shed frame; 2, carrying out static crushing demolition on the arch blasting demolition structure; 3, manually removing the blasting protection layer; 4, cutting the removed arch ring; 5, hoisting the arch ring to be hoisted; and 6, dismantling the under-arch structure. The method is simple, reasonable in design, easy and convenient to construct and good in using effect; the protection shed frames fixed to the frontside and the rear side of the removed arch bridge are adopted for effective protection, meanwhile, the structure on the arch of the removed arch bridge is removed in the mode that static crushing andmanual chiseling are combined, it is guaranteed that a plain concrete arch ring cannot be damaged in the static crushing process, and an existing spanned railway line cannot be disturbed. After the arch ring is exposed, the removed arch ring is cut and decomposed through a rope saw and then hoisted and removed, then the under-arch structures on the left side and the right side are rapidly removed,the construction period can be effectively shortened, the arch bridge removing efficiency is improved, and the removing process is safe and reliable.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

Special tool for lifting bushing

InactiveCN102602794AStable forceNo collisionLoad-engaging elementsTraveling blockIndustrial engineering

The invention relates to a special tool for lifting a bushing, which is used for realizing stable lifting of a transformer bushing or a CT (Current Transformer). The special tool comprises a tackle and a fixed plate, wherein the tackle is assembled at the bottom part of the bushing; the fixed plate is arranged at the top part of the bushing; and a lifting rope of the bushing penetrates through the fixed plate and then is connected with a flange lifting ring of the bushing. The special tool has the advantages that the structure is simple, the operation is convenient, not only can the bushing or CT be prevented from being collided and impacted in the lifting process, but also the operation time is shortened, the number of operators is reduced, and the working efficiency is improved.

Owner:STATE GRID CORP OF CHINA +2

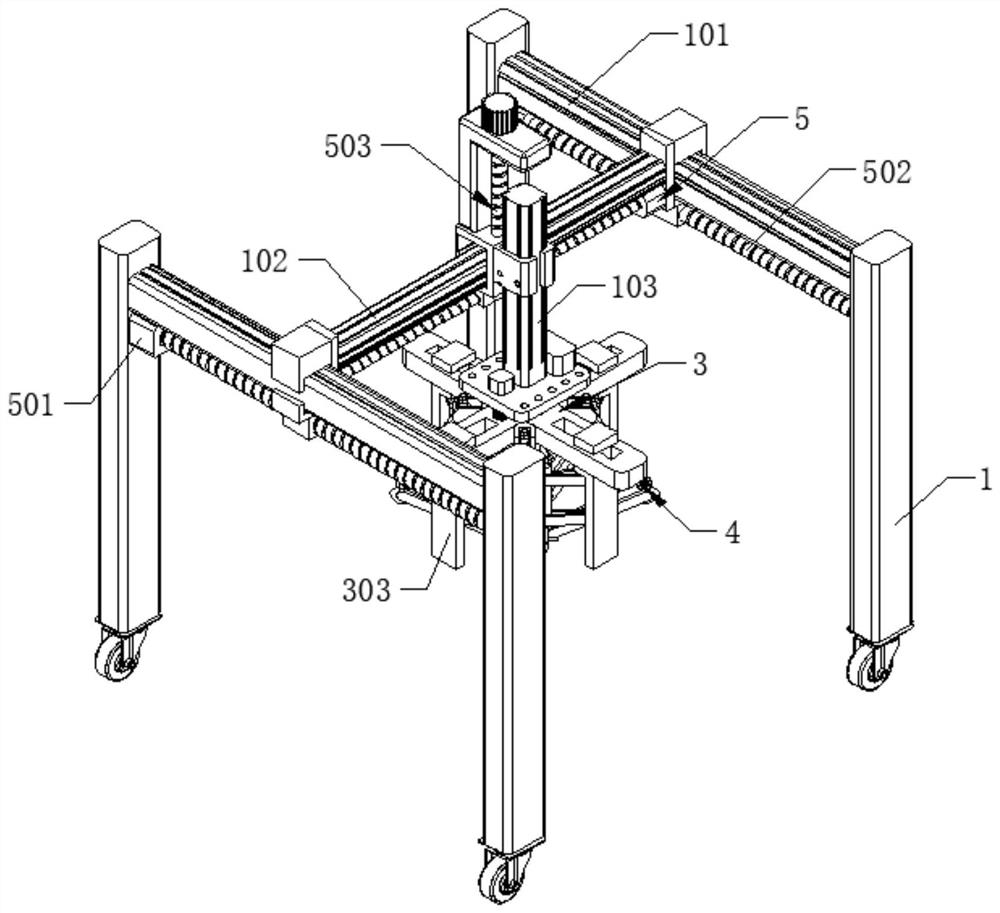

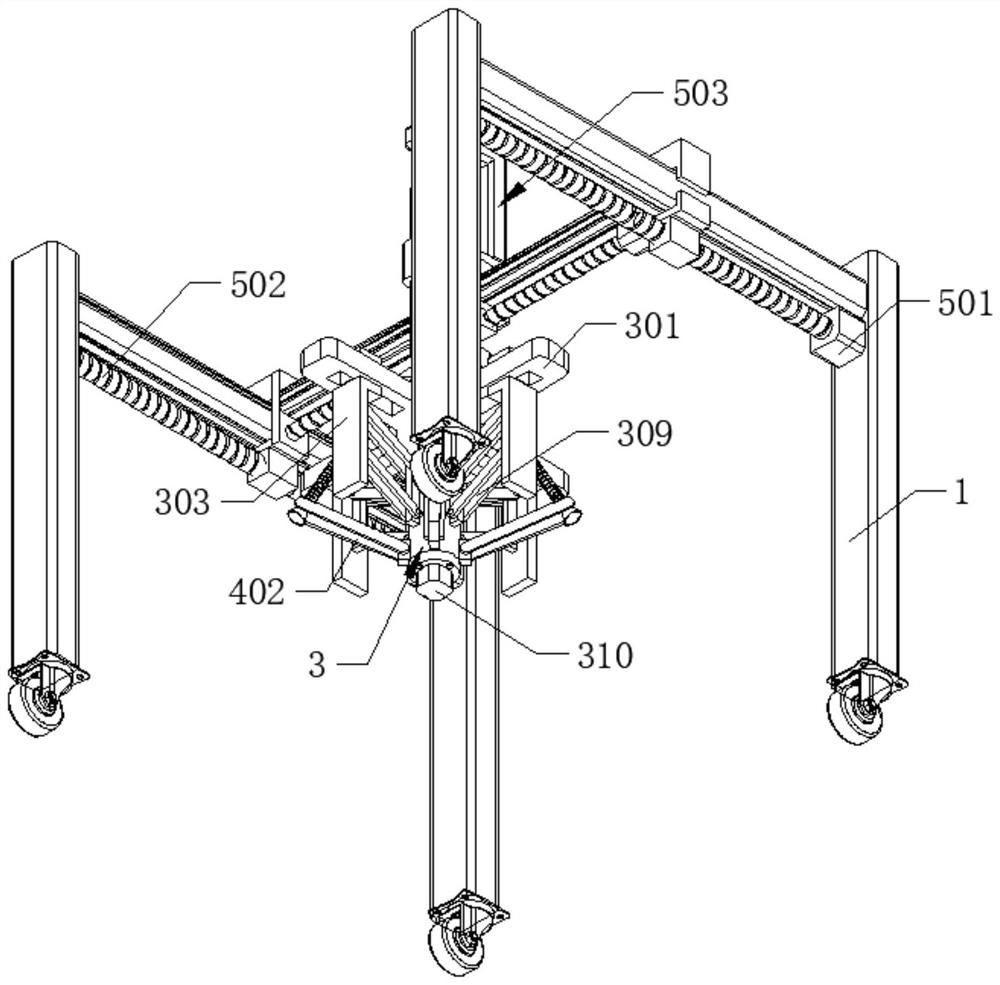

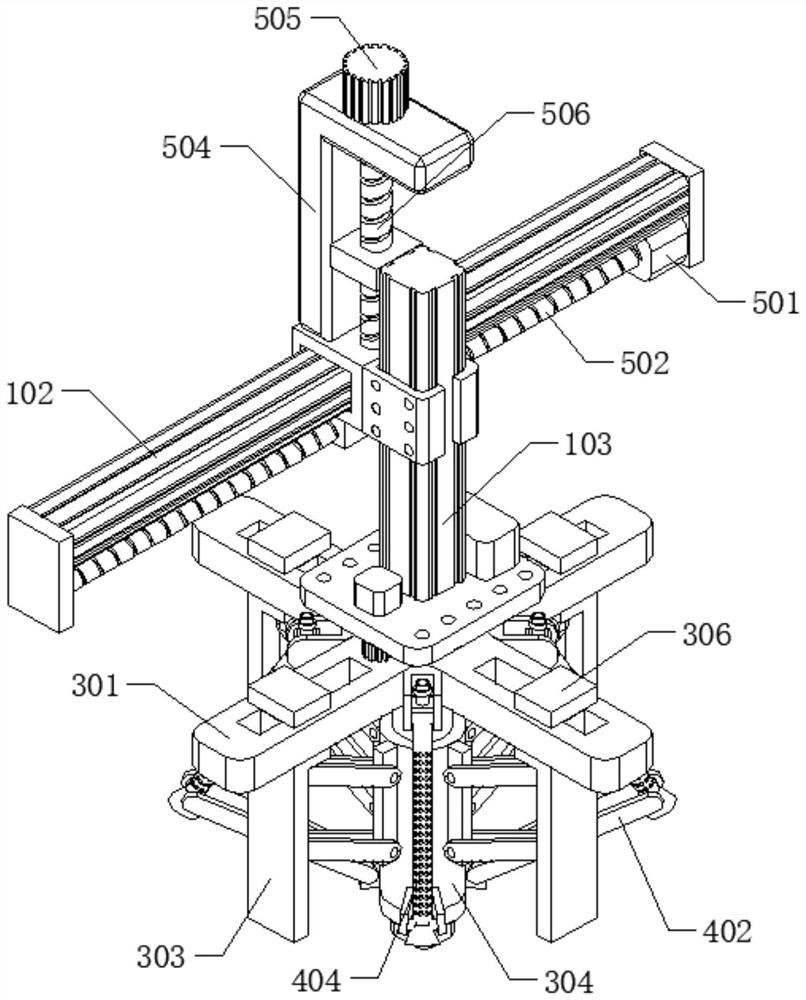

Adaptive adjustment hoisting equipment for fabricated building composition board body

ActiveCN113184687AMaintain hanging stabilityFlexible adjustmentLoad-engaging elementsControl engineeringControl theory

Owner:南通永楠建设工程有限公司

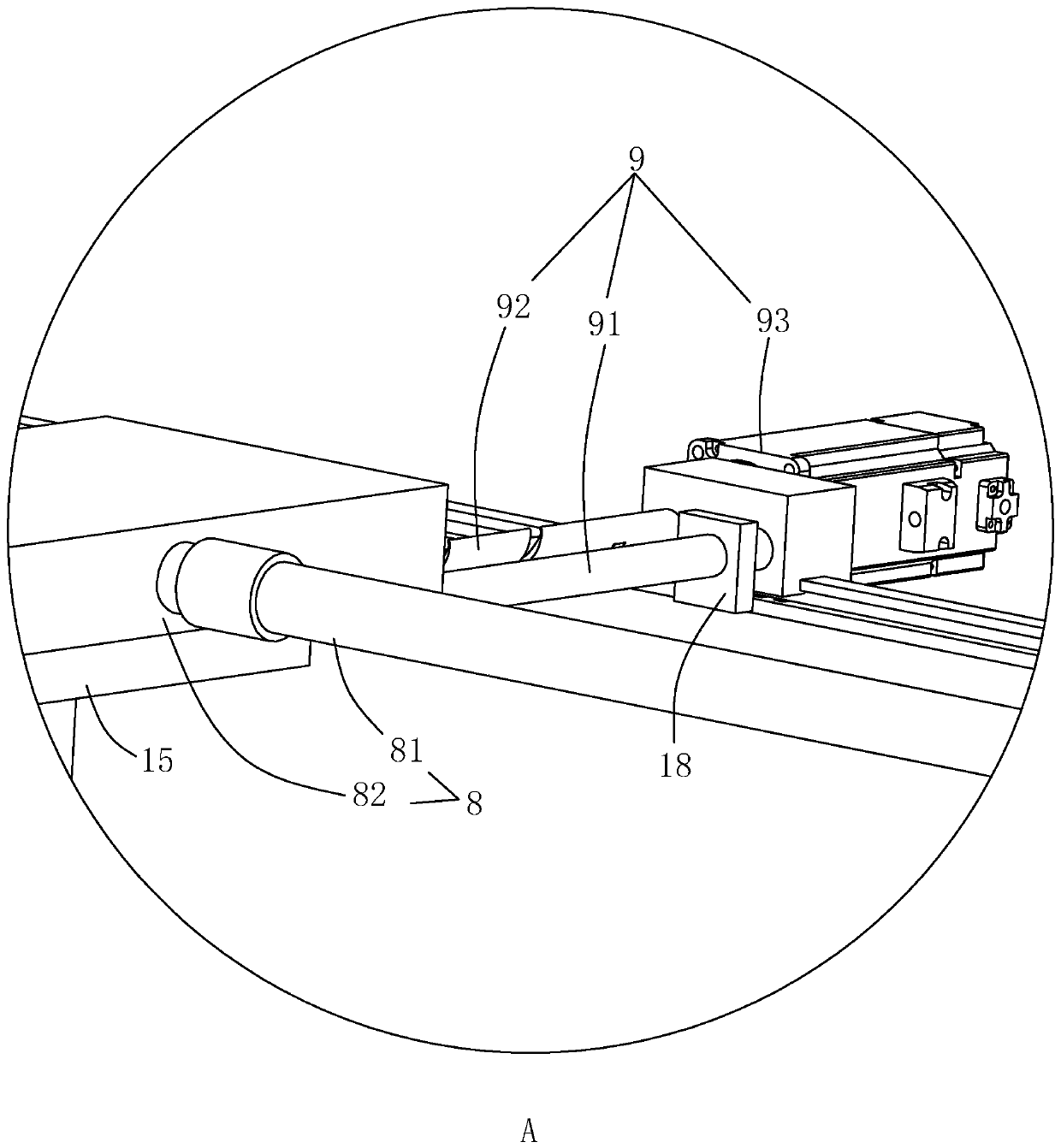

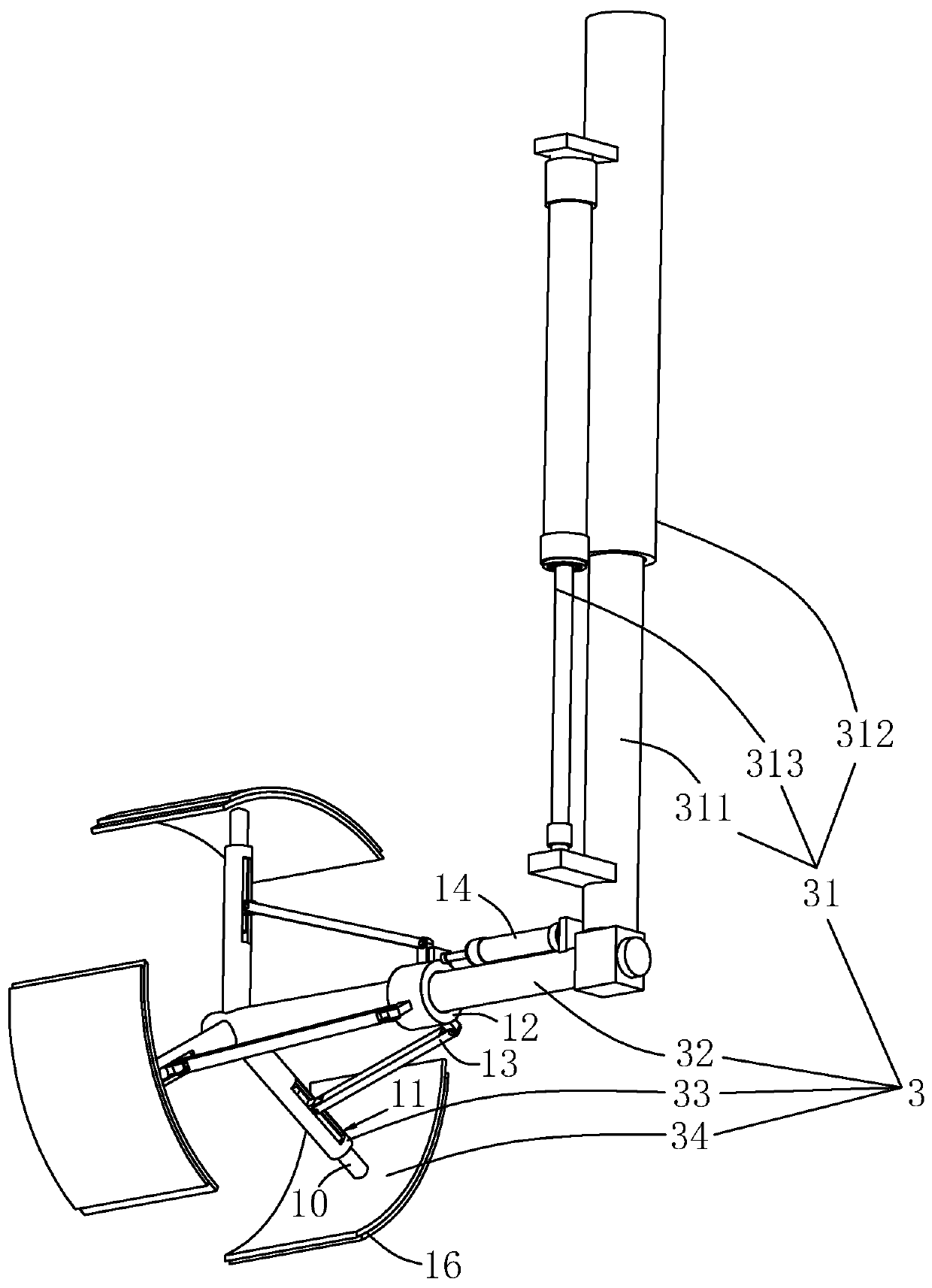

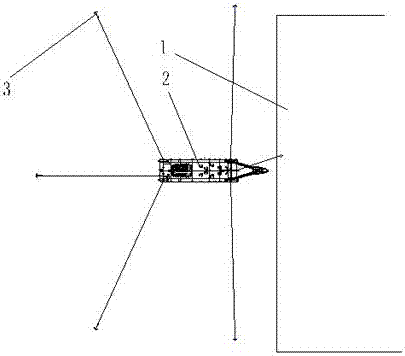

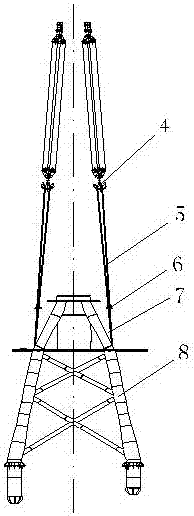

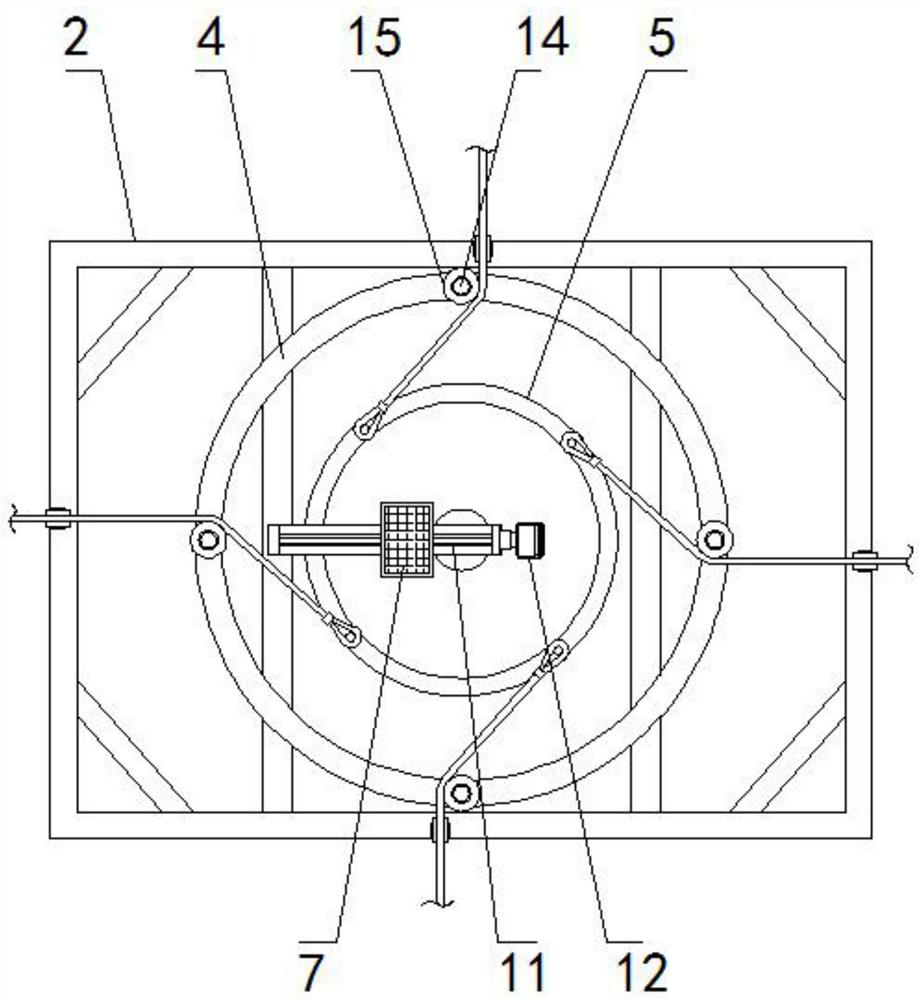

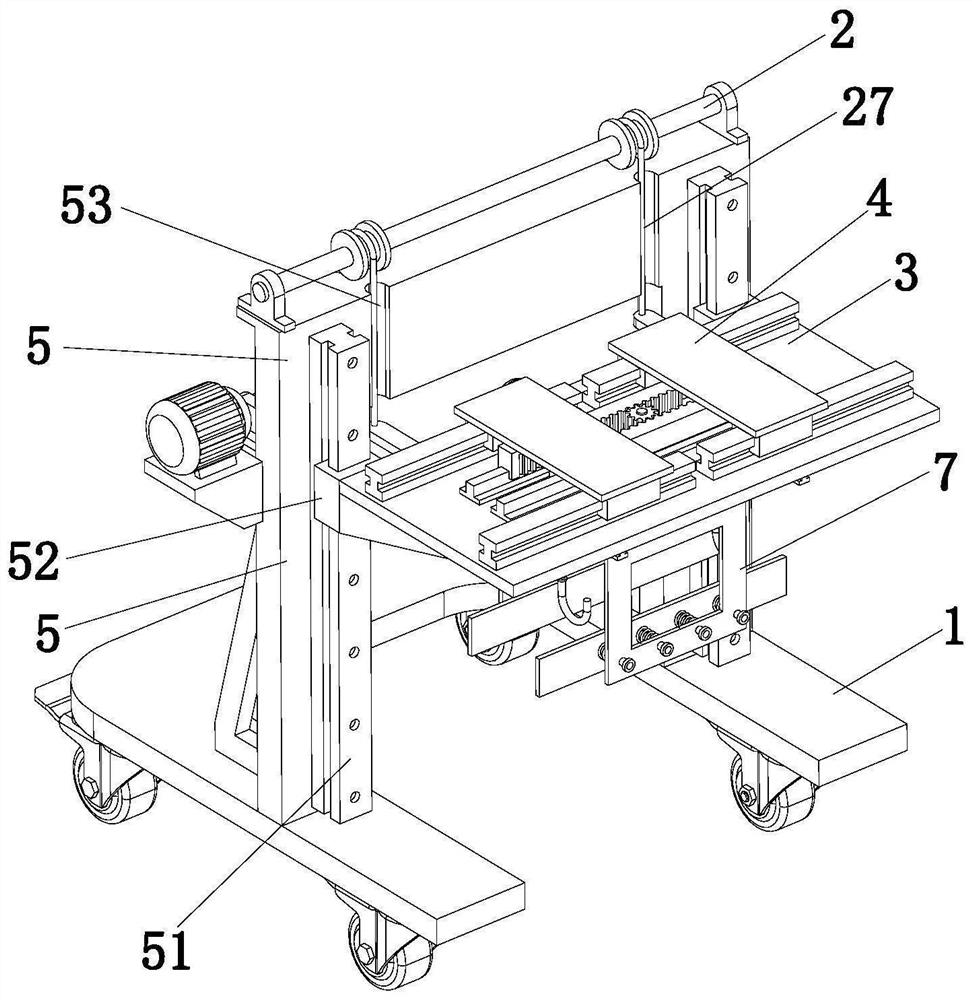

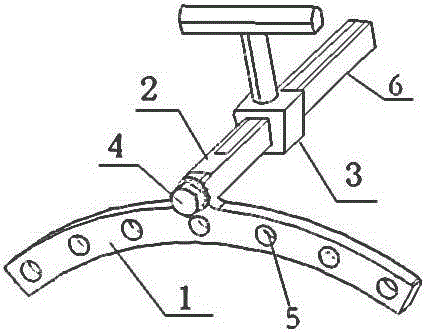

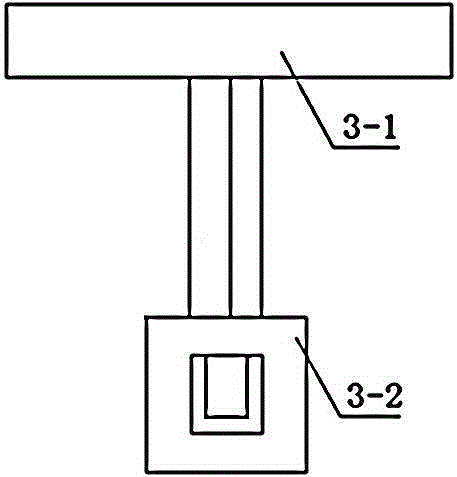

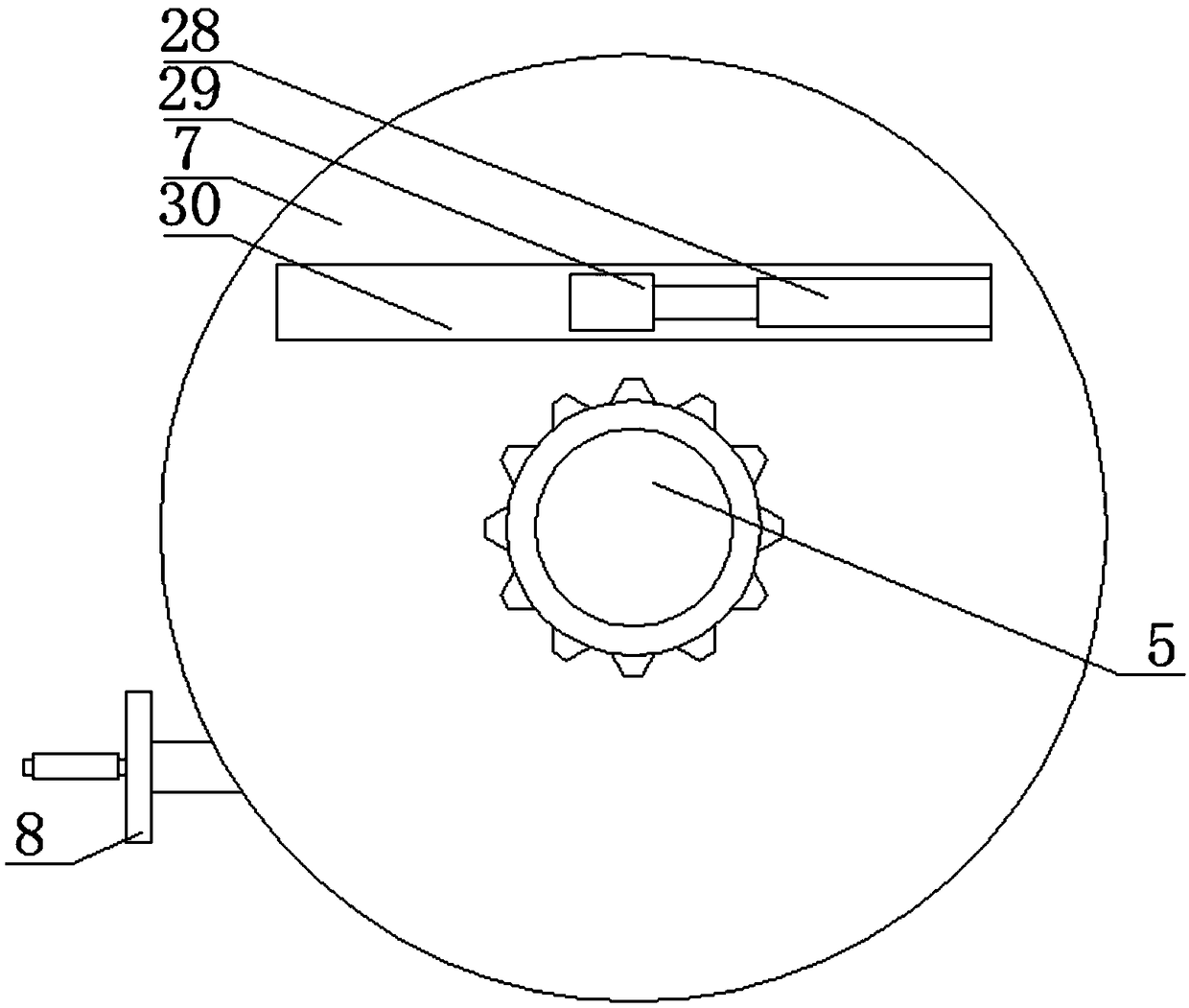

Circular knitting machine needle cylinder installation and adjustment auxiliary equipment and using method thereof

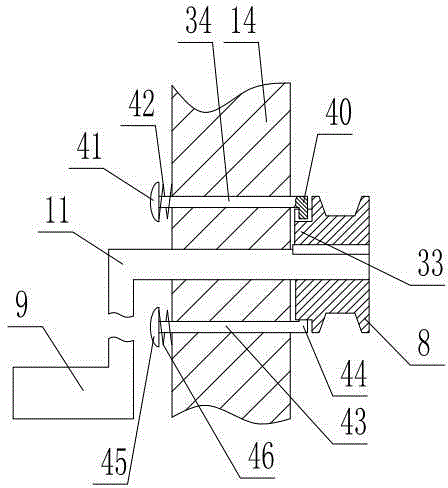

InactiveCN111977517AEasy to grab and fixAvoid damageBase supporting structuresBraking devices for hoisting equipmentsGear wheelDust control

The invention discloses circular knitting machine needle cylinder installation and adjustment auxiliary equipment. The equipment comprises a supporting frame and a fixing assembly, a first supportingplate is connected with the supporting frame, a rotating disc is further connected with the bottom wall of the first supporting plate, a second supporting plate is connected with the bottom wall of the rotating disc, the fixing assembly is connected with the bottom wall of the rotating disc, a dust removing assembly is connected with the outer wall of the second supporting plate, the end, away from a connecting base, of the dust removing assembly is rotationally connected with the fixing assembly through a second connecting rod, a fourth motor is arranged on the top wall of the first supporting plate, the output end of the fourth motor penetrates through the first supporting plate and is connected with a first gear, a second gear is engaged with the first gear, and the second gear is connected with the outer wall of the rotating disc. According to the circular knitting machine needle cylinder installation and adjustment auxiliary equipment, the needle cylinder can be stably hoisted, itis avoided that the needle cylinder shakes in the installation process so that the needle cylinder can not rub with a circular knitting machine or a supporting frame to cause damage, then the stability and safety of the needle cylinder in the hoisting process are improved, the needle cylinder and the circular knitting machine can be effectively dedusted, and the butt joint quality is improved.

Owner:绍兴市华获智能装备有限公司

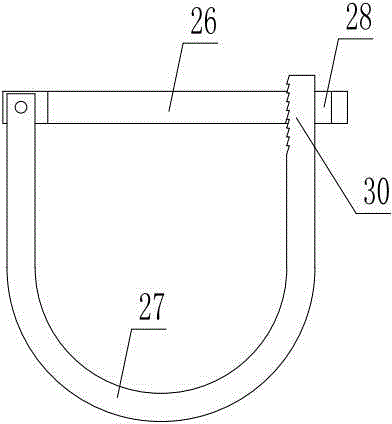

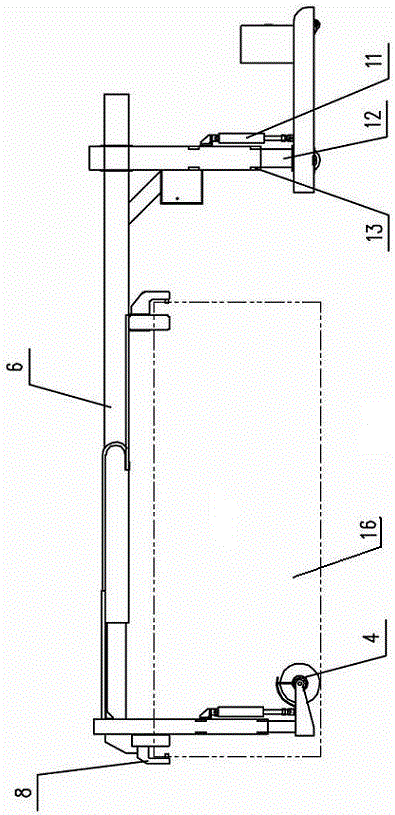

Intelligent hoisting equipment used for motor shells

PendingCN111606190AAvoid shakingTroubleshoot flat technical issuesWinding mechanismsCranesControl engineeringElectric machinery

The invention discloses intelligent hoisting equipment used for motor shells, and belongs to the technical field of auxiliary lifting equipment. The intelligent hoisting equipment comprises a U-shapedbase, an automatic lifting assembly, a lifting platform, a spacing adjusting assembly, a centralizing and shake-prevention assembly and a portal frame arranged at the top of the U-shaped base. Vertical slide rails are arranged at the two sides of the front end of the portal frame, each slide rail is provided with a lifting block which is in sliding fit with the slide rail, the spacing adjusting assembly comprises a moving part and two moving platforms arranged at an interval, the portion, corresponding to each moving platform, of the lifting platform is provided with two guide rails, a hoisting rope is arranged at the bottom of each moving platform, and a hook is arranged at the bottom end of each hoisting rope. The intelligent hoisting equipment has the advantages that under the effect of the spacing adjusting assembly, the spacing of the two hoisting ropes can be adjusted to hoist the motor shells with different specifications, and by adoption of the centralizing and shake-prevention assembly, the motor shells can be centralized, so that the motor shells are unlikely to deviate in the hoisting process.

Owner:安徽杰特电气有限公司

Intelligent conveying device of containers in warehouse

The invention provides an intelligent conveying device of containers in a warehouse. The intelligent conveying device comprises a car body chassis device, a driving power system, a length adjusting mechanism, a clamping mechanism, a hydraulic jacking mechanism, a hydraulic control system and an electrical control system. Compared with traditional universal container conveying technologies and devices, the intelligent conveying device has the advantages of being small in structure and capable of flexibly conveying the containers in the limited space of the warehouse with the space fully utilized through cooperation among a driving wheel set, a front universal set and a rear orientation set; through automatic control, the manual work is reduced to the maximum degree, and the conveying operation does not depend on the professional levels of professional drivers; the containers of different specifications can be conveyed through the length adjusting mechanism; the safety and the reliability are higher through the clamping mechanism composed of fixed clamping jaws, stretchable clamping jaws and a driving control unit; and the efficiency and the safety of conveying the containers are greatly improved, the utilization rate of the storage space is increased to the maximum degree, the manual work is reduced, the conveying period is shortened, and the conveying cost is greatly lowered.

Owner:大连四达高技术发展有限公司

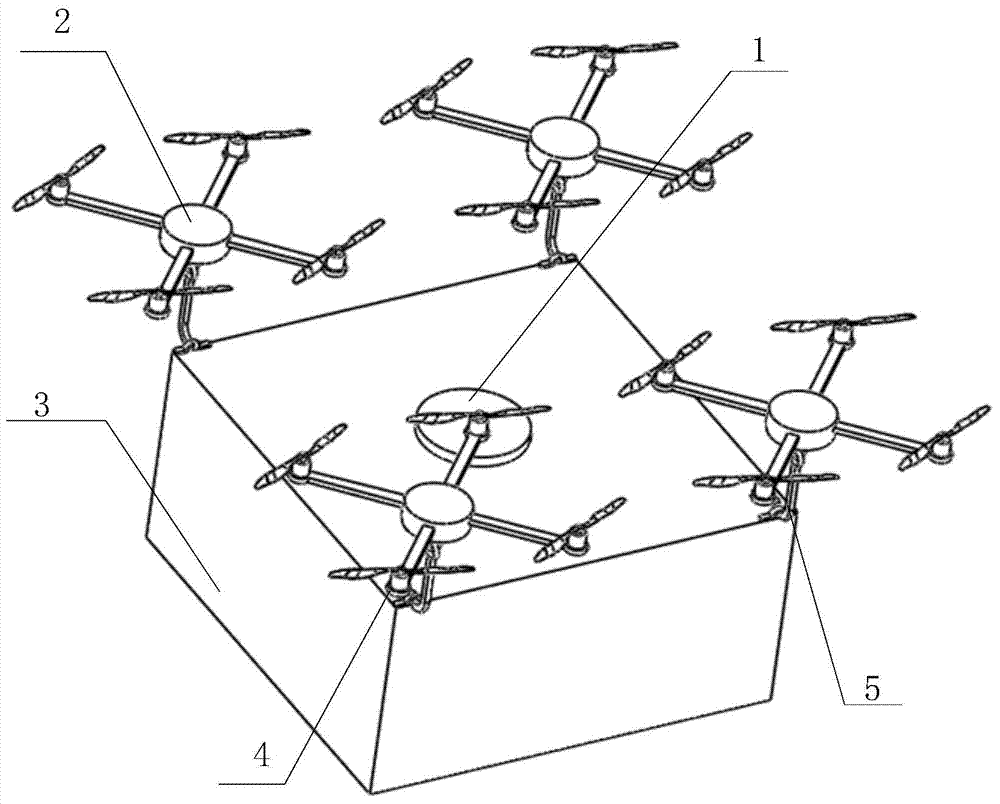

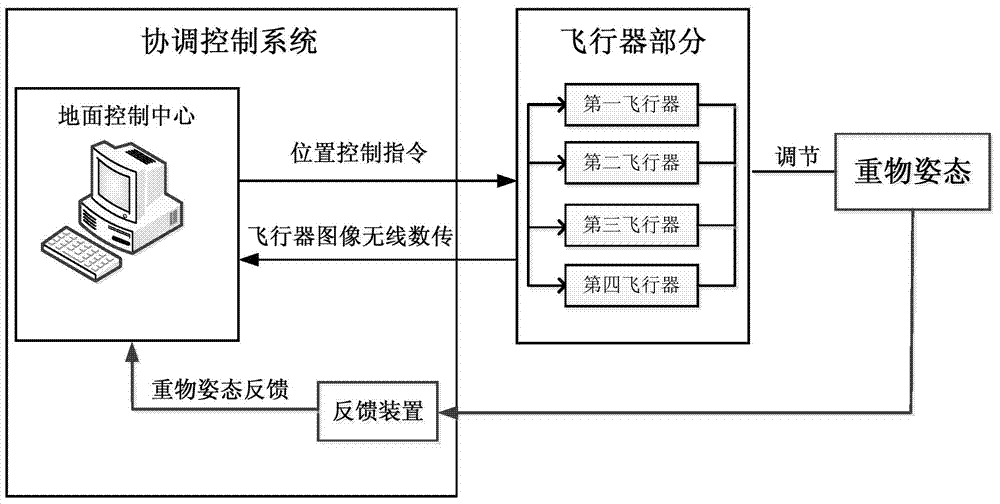

Multi-aircraft hoisting coordinated control system

ActiveCN103699133AEasy to operateStable hoistingPosition/course control in three dimensionsFlight heightControl system

The invention discloses a multi-aircraft hoisting coordinated control system, which comprises a ground control center and a feedback device, wherein the ground control enter is used for controlling a plurality of aircrafts; the feedback device is used for measuring the current attitude information, the current acceleration and the current flight height information of a weight; each aircraft is provided with an on-board controller; the feedback device is arranged on the weight hoisted by the aircrafts; an inertial attitude measuring unit and a height sensor are integrated in the feedback device; measured information is sent to the ground control center by the feedback device; real-time control signals are sent to all the aircrafts by the ground control center after being optimized and distributed; attitude adjustment is performed on the aircrafts according to the received control signals, so that the weight is kept stable all along. The coordinated control system disclosed by the invention does not stick to the species of the aircrafts; as long as the control port protocol of the ground control center is met, a user can freely select the types of the aircrafts. The multi-aircraft hoisting coordinated control system disclosed by the invention has the advantages that the application range is broad; the operation is simple; the stability during a hoisting process is realized.

Owner:XI AN JIAOTONG UNIV

Method for lifting top ring in dome structure installation

ActiveCN103510711AGuaranteed accuracyStable hoistingBuilding material handlingButt jointMaximum diameter

The invention provides a method for lifting a top ring in dome structure installation. The method includes the steps that an appropriate crane and an appropriate lifting appliance are correctly selected to ensure that mechanical performance of the crane meets the lifting requirement, and a temporary steel support of the top ring is lifted and arranged; before the top ring is in place, steel wire ropes are arranged on the temporary steel support as mooring ropes for stabilizing the temporary steel support; a 2t chain block is configured on each mooring rope as a tightening device; the category and the model of the crane are determined according to the weight, the maximum diameter, the body height and the installation height of the top ring; steel tubes on the upper chord and the bottom chord of a main steel frame of components are connected in a butt joint mode through the top ring; the lifting and the locating of the top ring must be simultaneously achieved, wherein the locating of the top ring include direction locating of a culmination top ring, center locating of the top ring, horizontal locating of the top ring and elevation locating of the top ring.

Owner:CHINA SIXTH METALLURGICAL CONSTR

Lifting appliance

InactiveCN105347176AStable hoistingReduce processing costsLoad-engaging elementsMechanical engineeringEngineering

Owner:PINGGAO GRP +2

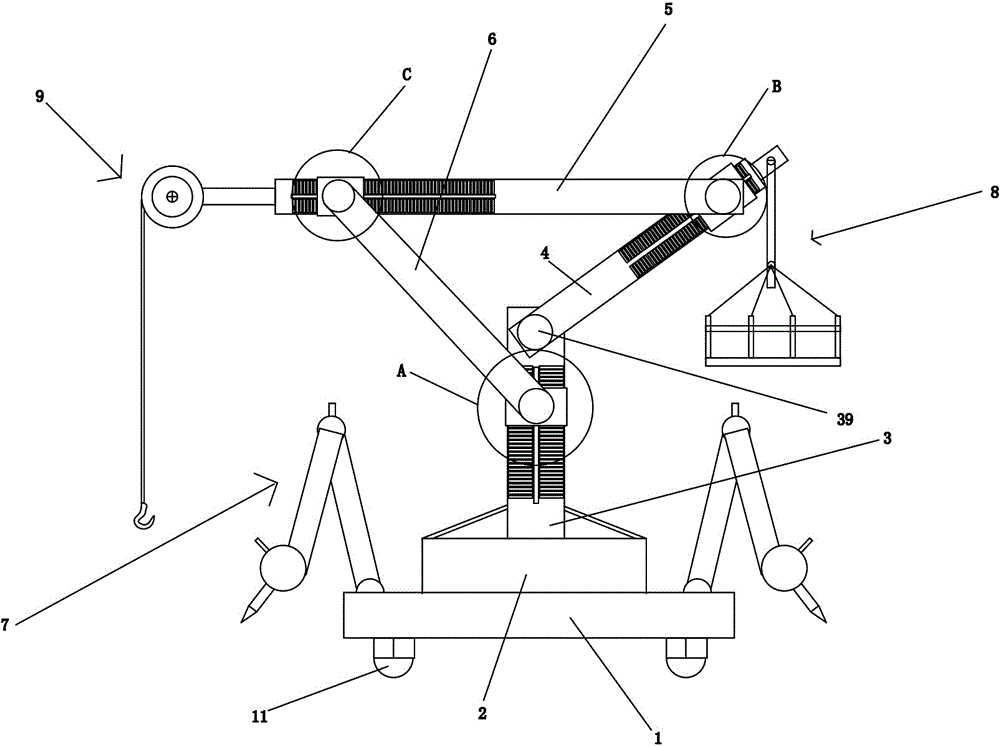

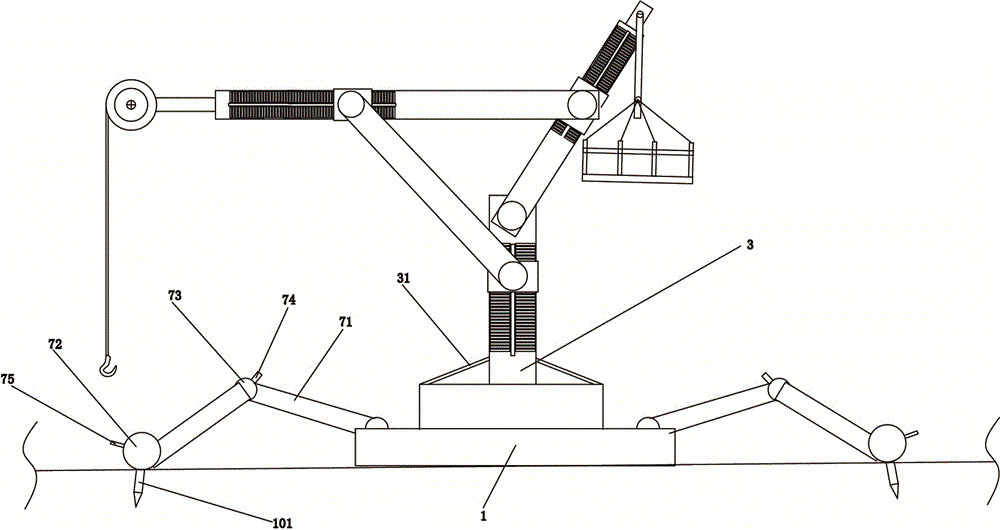

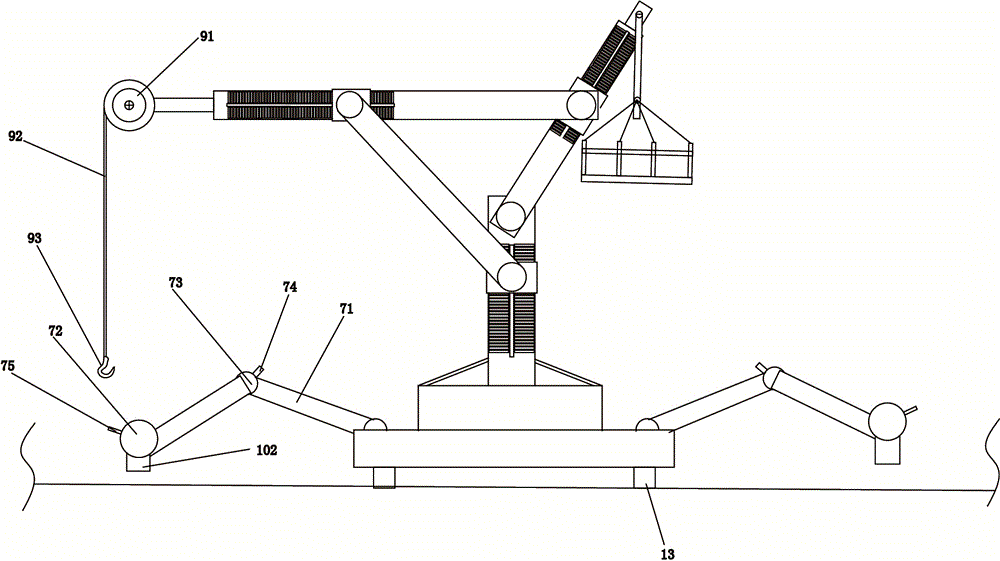

Movable type crane

The invention discloses a movable type crane and relates to a crane. The movable type crane comprises a base. A crane rod is arranged on the base. A first rotating shaft is arranged on the crane rod. A balance arm is arranged on the first rotating shaft in a rotary manner. A sliding sleeve is arranged on the balance arm in a movable manner. A second rotating shaft is arranged on the sliding sleeve. A hoisting arm is arranged on the second rotating shaft in a rotary manner. A support sleeve is further arranged on the crane rod in a sliding manner. A third rotating shaft is arranged on the support sleeve and provided with a support arm. A fixed sleeve is arranged on the hoisting arm in a sliding manner and provided with a fourth rotating shaft. The fourth rotating shaft is connected with the support arm. A detachable counterweight support is arranged at the bottom end of the balance arm. A jack is arranged at the top end of the hoisting arm. Compared with the prior art, by means of the movable type crane, a cargo boom can be adjusted; the load moment can be adjusted according to the weight of cargo, the height to which the cargo needs to be hoisted and the position where the cargo is located; stability of the crane is maintained; and basic hoisting performance and multi-environment applicability of the crane are greatly improved.

Owner:宁波建工建乐工程有限公司 +1

Long-span steel beam lifting appliance and steel beam lifting method thereof

PendingCN107419665ADirect forceLight structureBridge erection/assemblyLong spanIndustrial engineering

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

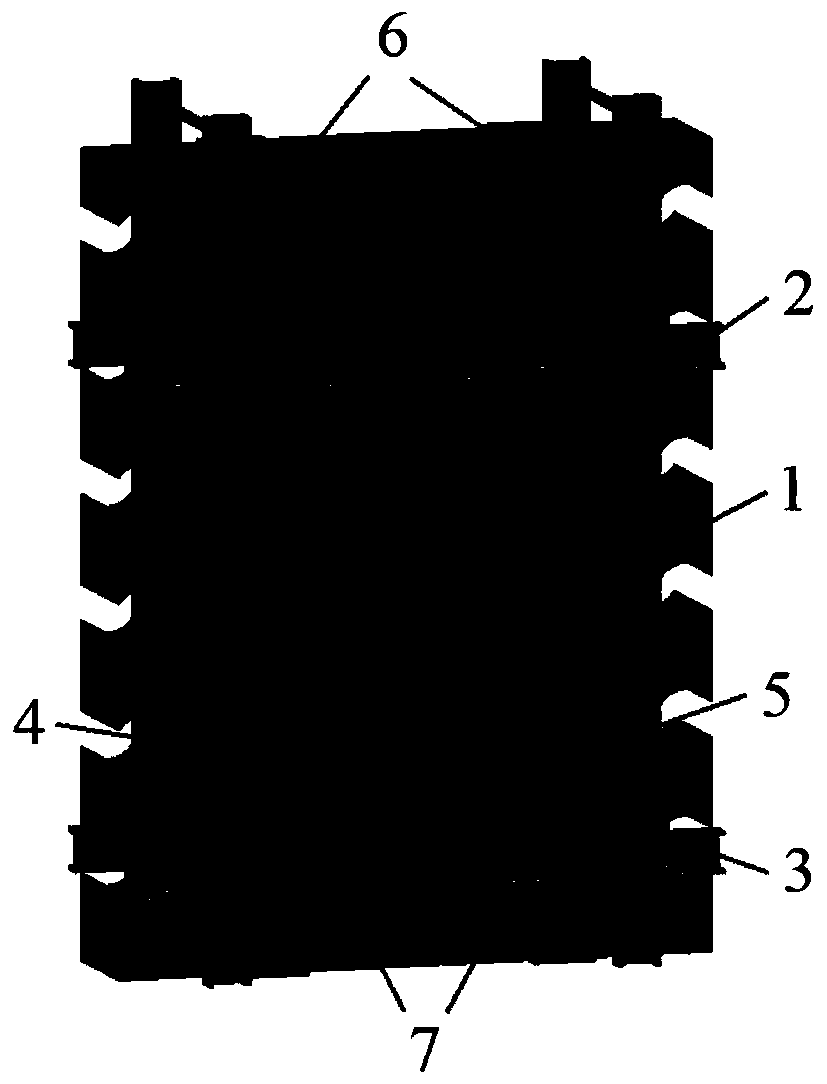

Prestress anchor clamping method for dismantling brick masonry wall piece

InactiveCN109779290AImprove performanceStable hoistingBuilding repairsReinforced concreteBrick masonry

The invention relates to the technical field of civil engineering construction, in particular to a prestress anchor clamping method for dismantling a brick masonry wall piece. The invention aims to solve the problems that a wall piece is easy to incline in a transportation and hoisting process of dismantled brick masonry wall pieces, is damaged and cannot be safely and stably transported and hoisted to a construction part. The method comprises the steps that the front face and the rear face of the dismantled brick masonry wall piece are each provided with a prestress clamping frame, and the prestress clamping frames are connected with the wall piece through bolts. The prestress clamping frame is composed of an upper frame, a lower frame, a left frame and a right frame and lead screws. According to the invention, the overall performance of the demolition of the brick masonry wall piece is enhanced. Compared with the prior art, the anti-bending capacity outside the plane of the wall piece is improved, the wall piece can be simply transported and hoisted through an embedded part like a reinforced concrete component, overturning damage of the wall piece in the transporting and hoistingprocess is avoided, the construction process is simplified, and stable hoisting for dismantling the masonry wall piece is achieved.

Owner:HARBIN INST OF TECH

Base station equipment lifting auxiliary device

InactiveCN108706488ASolve the problem of inconvenient adjustment of directionEasy to automatically adjust the orientationPortable liftingGearing elementsEngineeringRotating disc

The invention discloses a base station equipment lifting auxiliary device. The base station equipment lifting auxiliary device comprises a rotating disc, a gear is rotatably connected to the upper endof the rotating disc, a bearing groove is formed in one side of the upper end of the rotating disc, a second electric telescopic rod is fixed to the side wall of one end in the bearing groove, a bearing block is fixed to one end of the second electric telescopic rod, a straight rack is fixed to the upper end of the bearing block, the straight rack and the gear are engaged, an L-shaped plate is fixed to the upper end of the gear, a fixed rod is fixed to the upper end of the L-shaped plate, and a connecting rod is fixed to one end of the fixed rod. According to actual conditions, the angle is adjusted, rapid lifting is achieved, mounting and dismounting are facilitated, the position is adjusted rapidly according to the site condition, connection is stable, forceful supporting is provided, mounting is better achieved, the distance is adjusted conveniently according to equipment conditions, lifting is more stable, and construction safety is improved.

Owner:苏州傲达通信设备有限公司

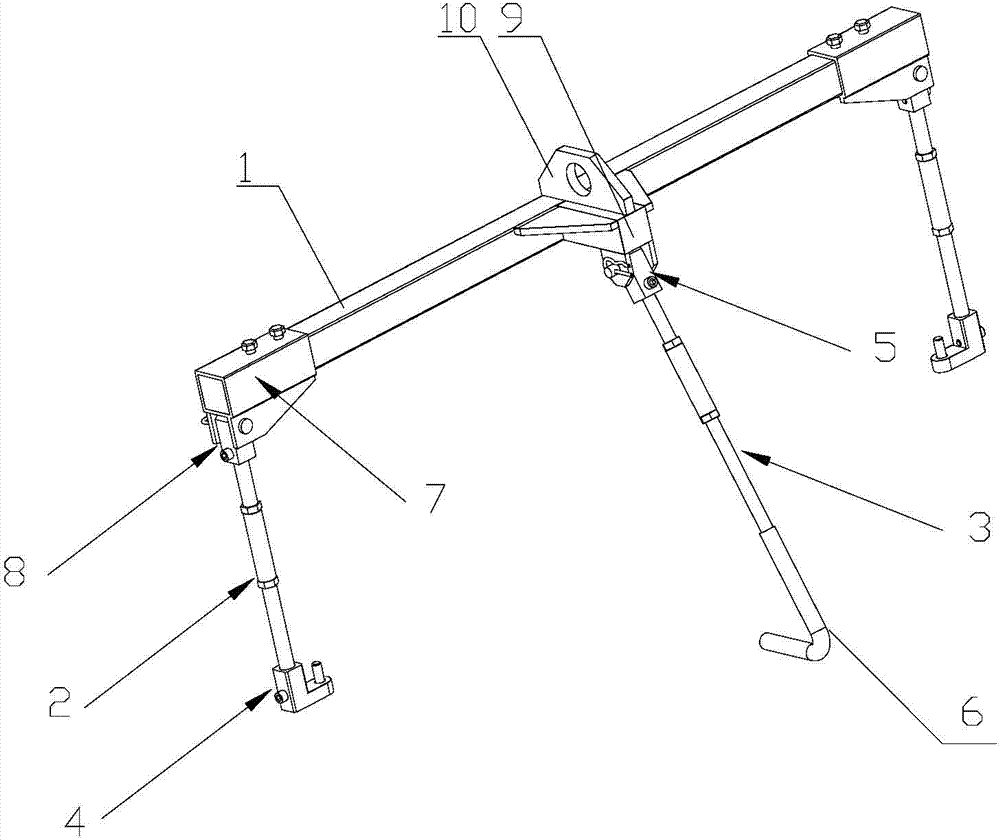

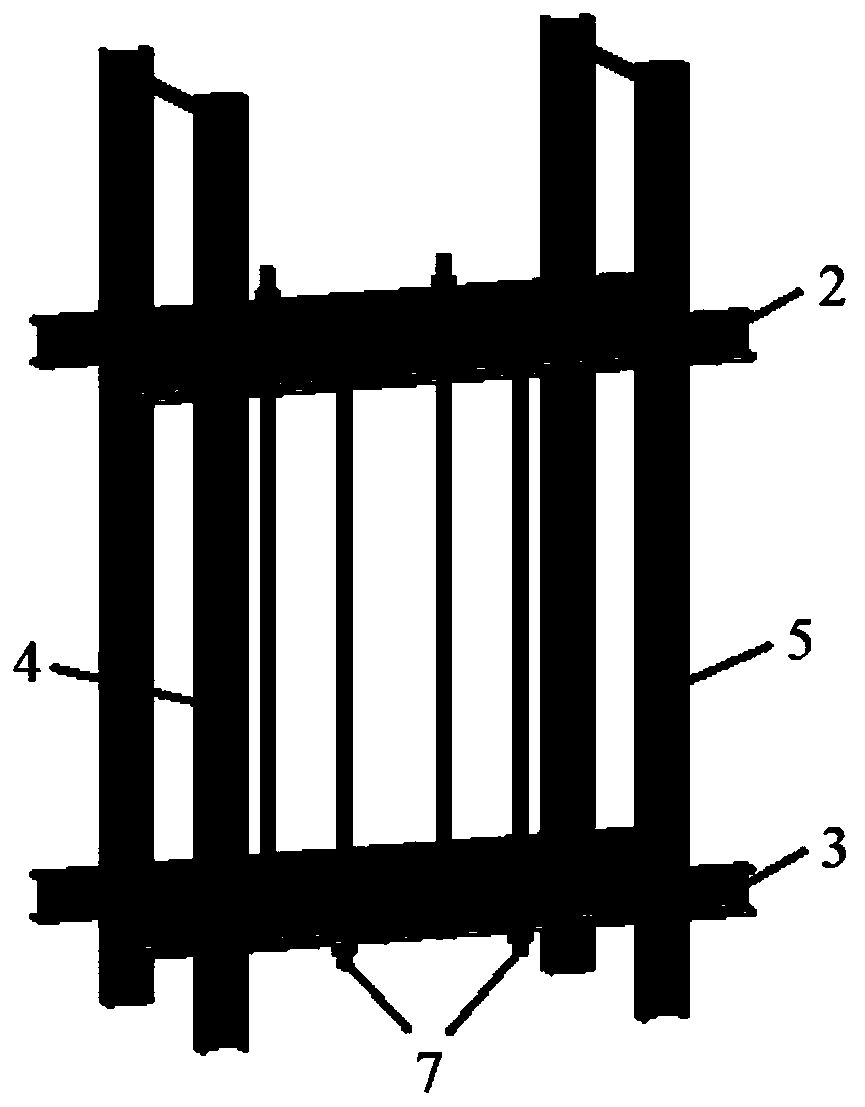

Two-point centering hoisting device and method of integrated mode brickwork wall piece

The invention discloses a two-point centering hoisting device and method of an integrated mode brickwork wall piece, and relates to the hoisting device and method. The problems that an existing brickwork wall piece is prone to tilt and damage in the hoisting process and can not be safely and stably hoisted to a construction part are solved. The hoisting device comprises a hoisting hook, a balance beam, a binding beam and two rope penetrating devices, wherein the hoisting hook is arranged in the middle over the balance beam, the two rope penetrating devices are arranged at the lower end of the balance beam and slide in the length direction of the balance beam, the binding beam is arranged below the balance beam, and the binding beam is connected with the two rope penetrating devices through lower hoisting ropes respectively. The hoisting method includes the steps of binding the wall piece, determining the horizontal position of the hoisting hook, determining the positions of the rope penetrating devices, determining the height of the hoisting hook, connecting the binding beam, and starting hoisting. The device and method are used for hoisting the brickwork wall piece.

Owner:HARBIN DACHENG GREEN BUILDING TECH DEV

Hoisting method for stern ramp

The invention discloses a hoisting method for a stern ramp and belongs to the technical field of ship building. The hoisting method comprises the following steps that 1, a first set of lifting rings is arranged on a ramp panel of the stern ramp; 2, a second set of lifting rings is arranged on the ramp panel of the stern ramp; 3, a third set of lifting rings is arranged on the ramp panel of the stern ramp; 4, a fourth set of lifting rings is arranged on the ramp panel of the stern ramp; 5, a fifth set of lifting rings is arranged on the ramp panel of the stern ramp; 6, the stern ramp is hoistedto a transporting vehicle from a supporting pier; and 7, the stern ramp is mounted on a ship body structure at a dock. The stern ramp is hoisted through the hoisting method, hoisting is stable, the hoisting efficiency is high, and the hoisting safety is high.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com