Two-point centering hoisting device and method of integrated mode brickwork wall piece

An integrated mode and hoisting device technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of unsafe and stable hoisting, easy tilting and damage of block wall pieces, etc., to simplify construction and avoid overturning damage , The effect of stability in the hoisting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

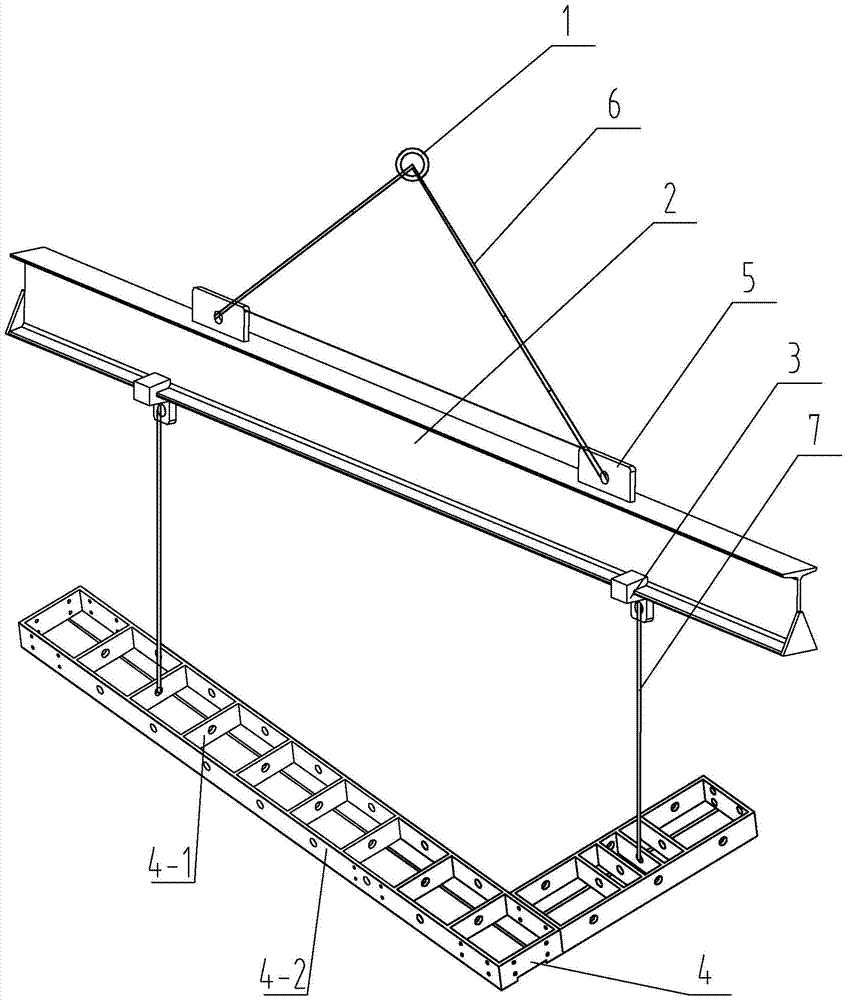

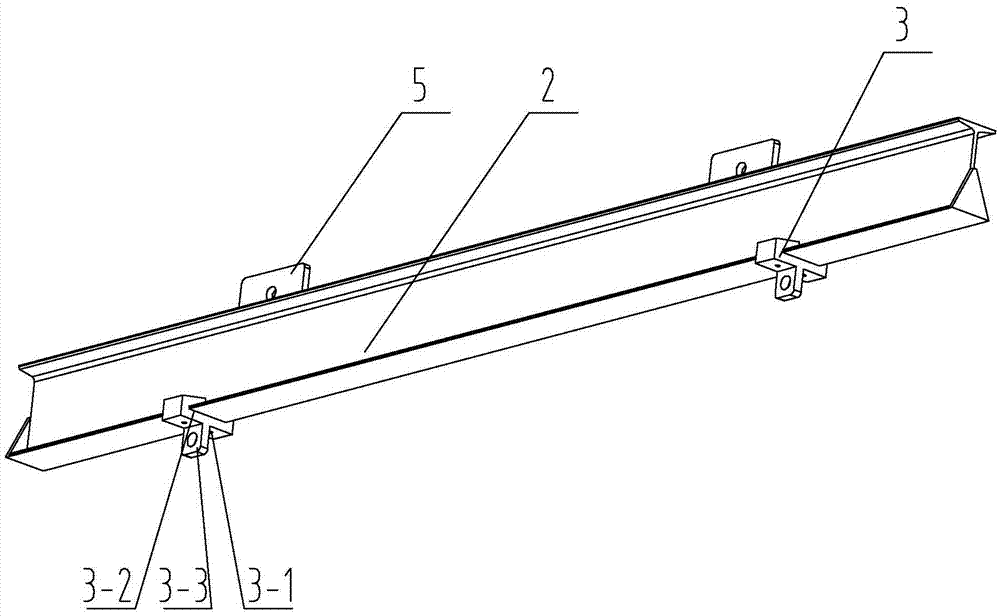

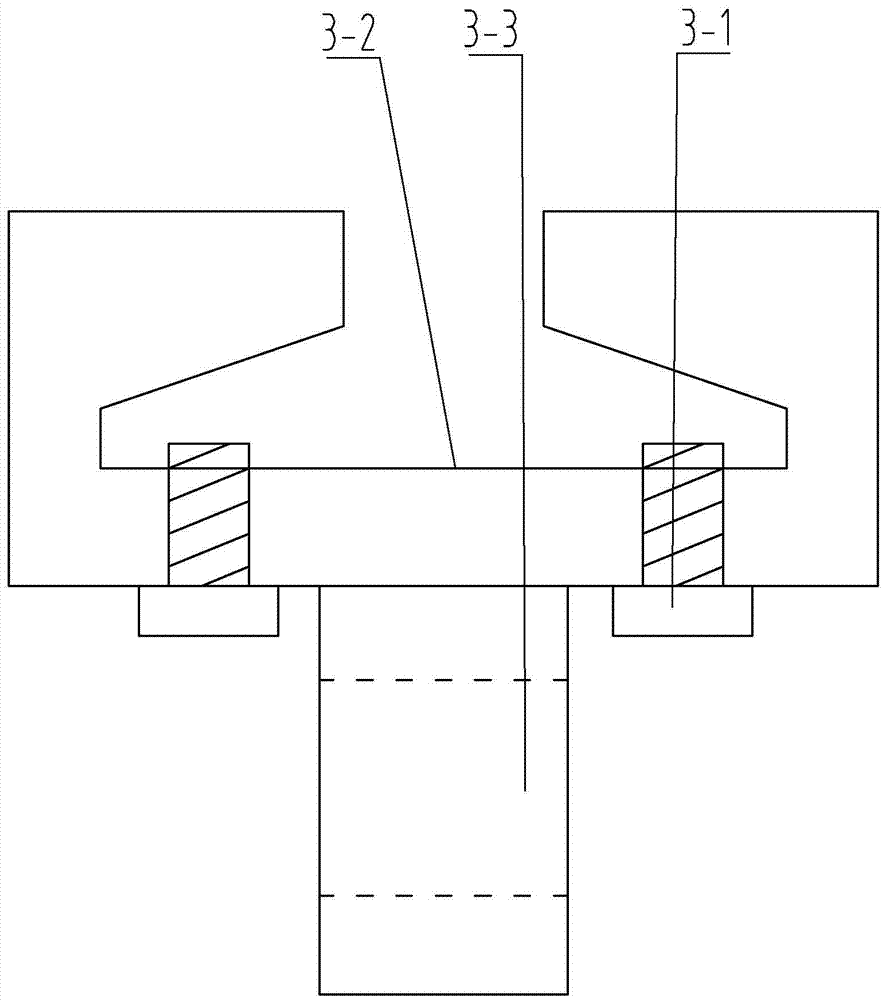

[0026] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment. The two-point centering hoisting device for the integrated pattern masonry wall sheet in this embodiment includes a hook 1, a balance beam 2, a binding beam 4 and two rope threaders 3. The upper end of the balance beam 2 is along the length direction There are two upper lifting lugs 5 symmetrically fixed, and the hook 1 is set in the middle of the balance beam 2. A rope threader 3, the rope threader 3 slides along the length direction of the balance beam 2, and the lower end surface of the rope threader 3 is vertically symmetrically provided with two fastening bolts 3-1, the fastening bolts 3-1 The end of the end is against the balance beam 2, the binding beam 4 is arranged below the balance beam 2, and the binding beam 4 and the two rope threaders 3 are respectively connected by the lower hoisting rope 7.

[0027] The block model is a new industrialization model that integrates s...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 and Figure 4 To describe this embodiment, the cross-sectional shape of the balance beam 2 in this embodiment is an I-shape. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 1 and Figure 4 The present embodiment will be described. The shape of the binding beam 4 in this embodiment is the same as the shape of the upper end surface of the wall piece. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0030] The binding beam 4 is a beam arranged on the top of the wall sheet and used for hoisting the wall sheet. The wall piece is bound to the binding beam 4 through the binding rope, so that the load of the wall piece is transmitted to the binding beam 4 through the binding rope. In this way, during hoisting, the force at the hook 1 can be distributed to each binding point by the binding beam 4 . The wall piece is bound on the binding beam 4, which improves the overall rigidity and avoids the influence of the sudden uneven force on the binding beam 4 at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com