Patents

Literature

50results about How to "Operational impact is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

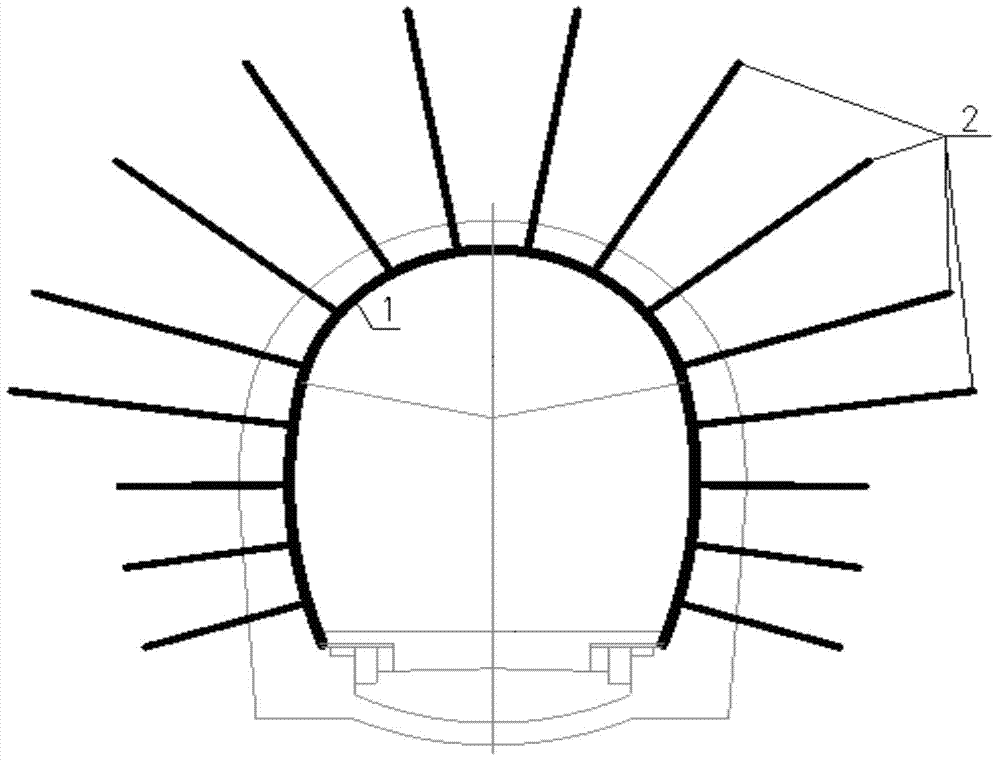

Method for reinforcing cracked and damaged lining of operation tunnel

ActiveCN104121027AEconomic savingsImprove stabilityUnderground chambersTunnel liningSteel barRepair time

The invention discloses a method for reinforcing a cracked and damaged lining of an operation tunnel. An annular reinforcing structure is mainly formed by ribbing steel bars, anchor rods, a steel bar mesh and jetting concrete, and therefore the cracked and damaged lining is reinforced. The method is easy to implement, the lining of the tunnel can be prevented from being detached and changed on a large scale, the influence on tunnel operation is reduced to the maximum, the repairing construction method and technology are fast and rapid to conduct, the repairing time can be greatly shortened, and the construction process and structure safety can be ensured. Thus, by means of the structure, great economic benefits can be brought, and the method is particularly suitable for reinforcing of the lining of the operation tunnel.

Owner:CENT SOUTH UNIV

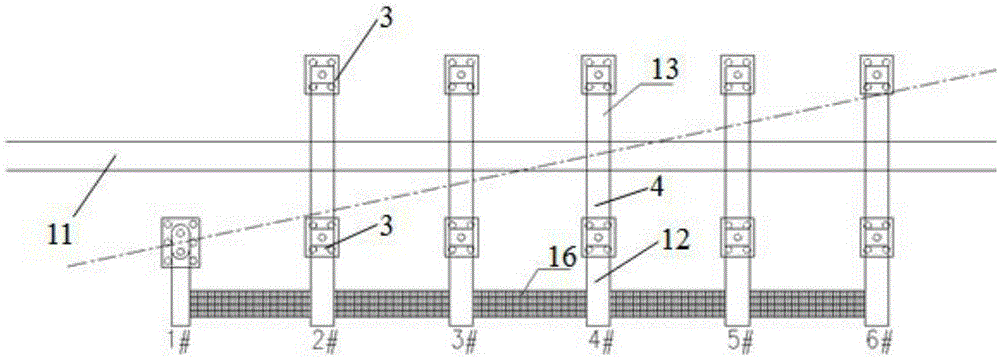

Full-set dismantling and installing construction method of bridge overpassing existing line

ActiveCN106149576ASimple stepsReasonable designBuilding repairsBridge erection/assemblyBuilding constructionEngineering

Owner:中铁二十局集团第三工程有限公司

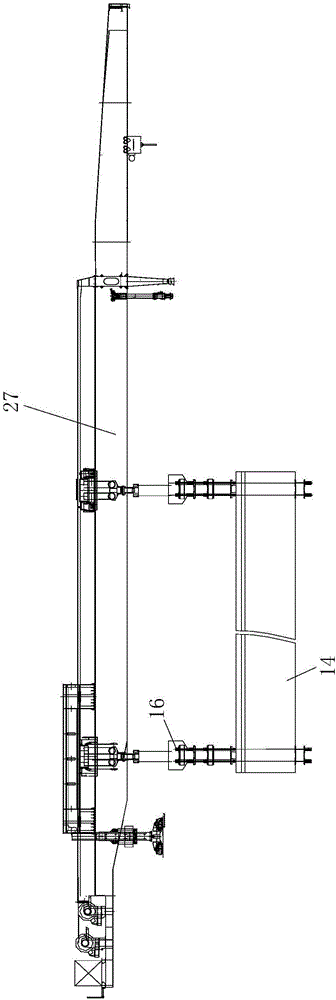

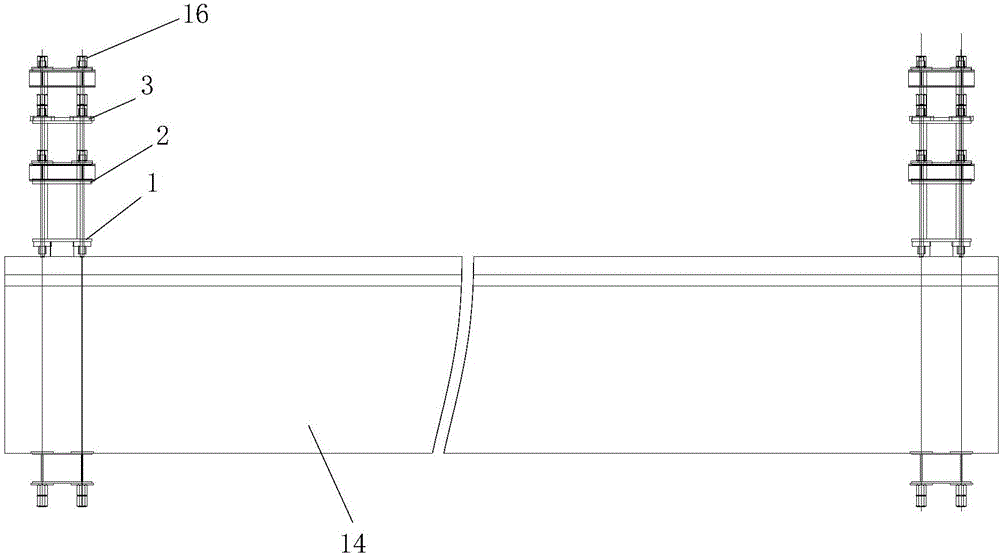

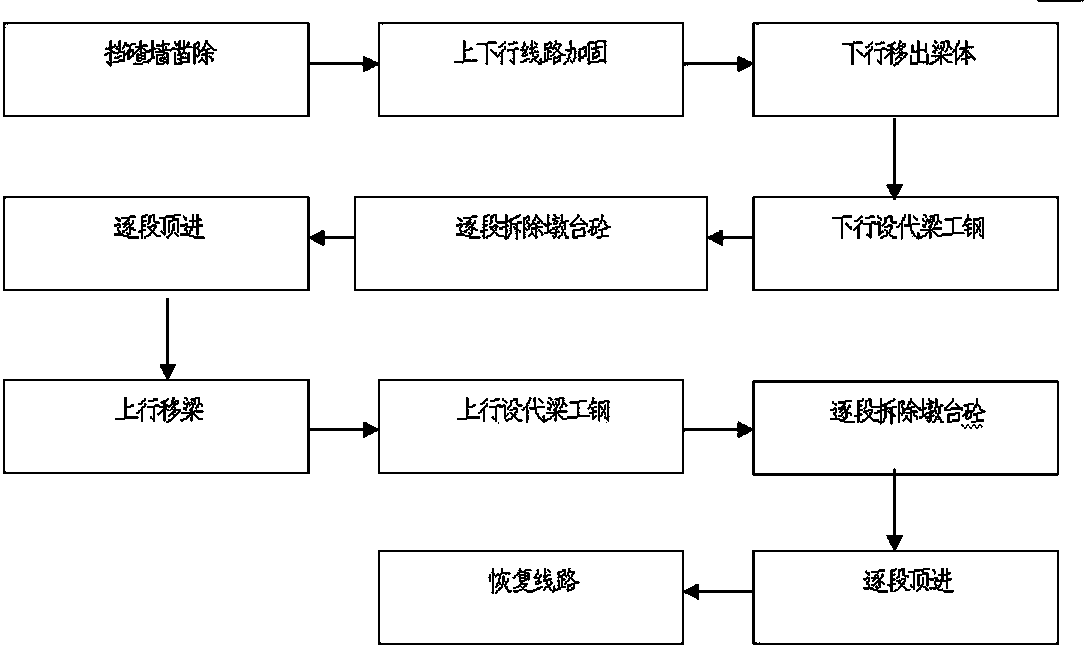

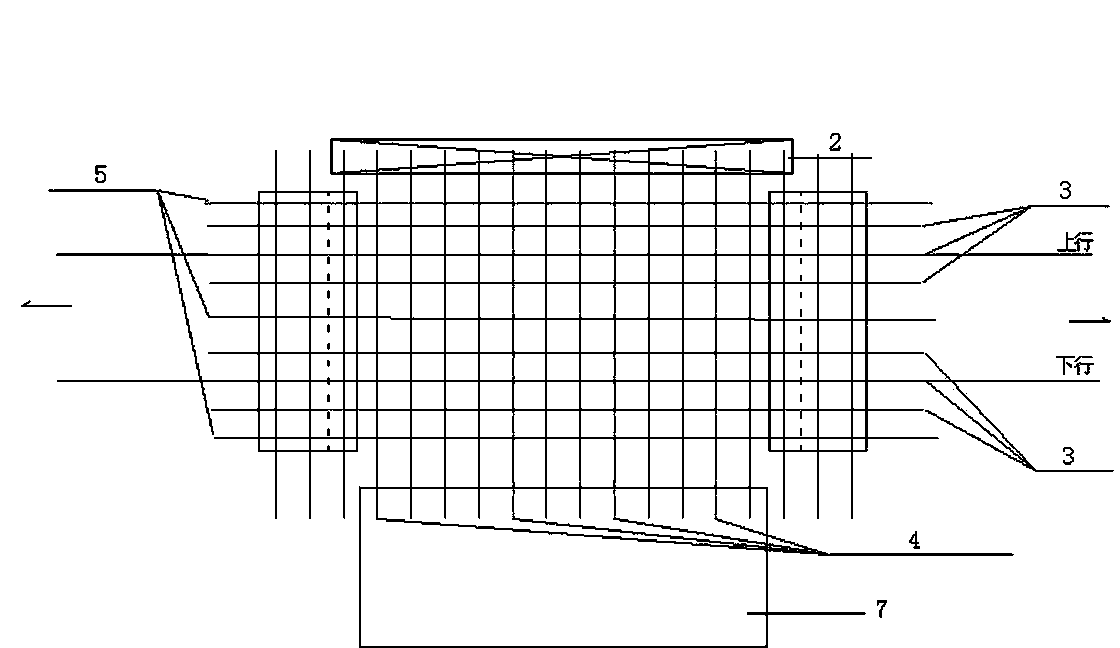

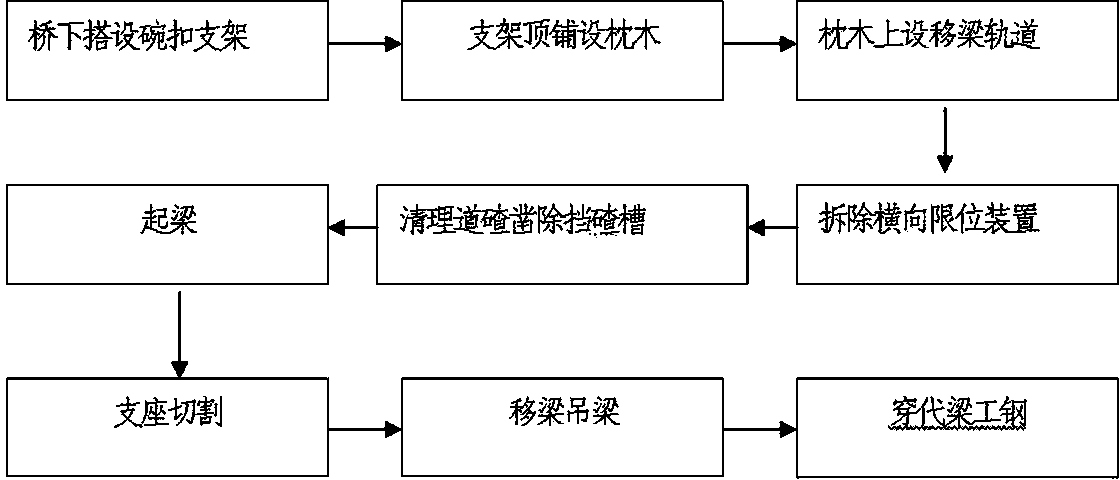

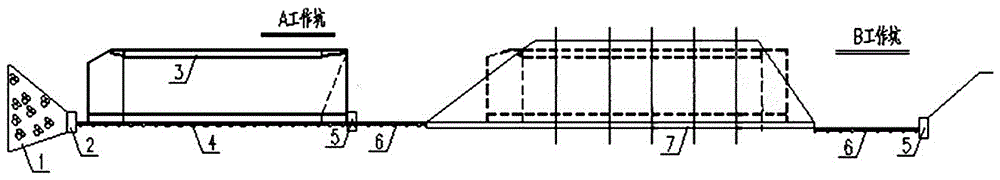

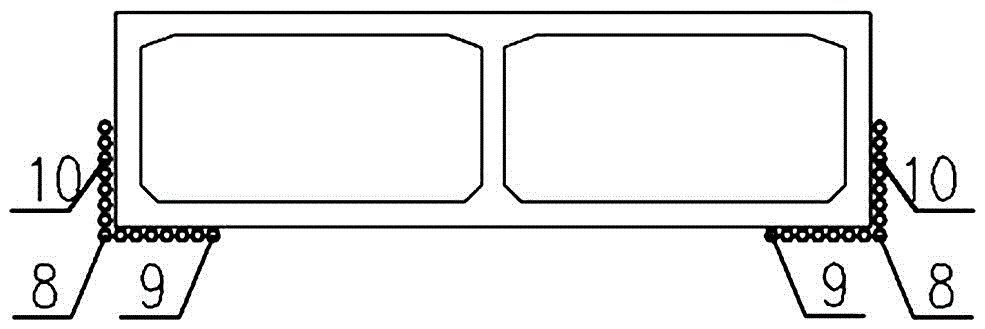

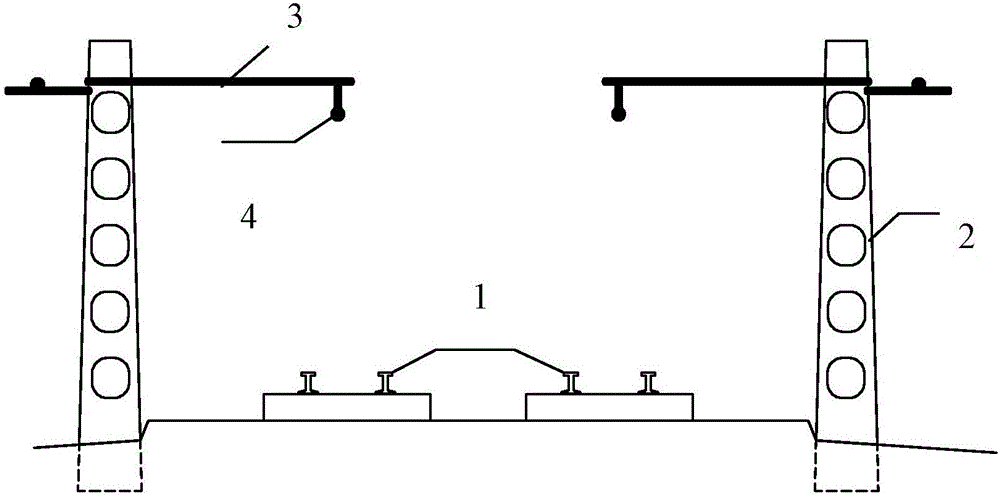

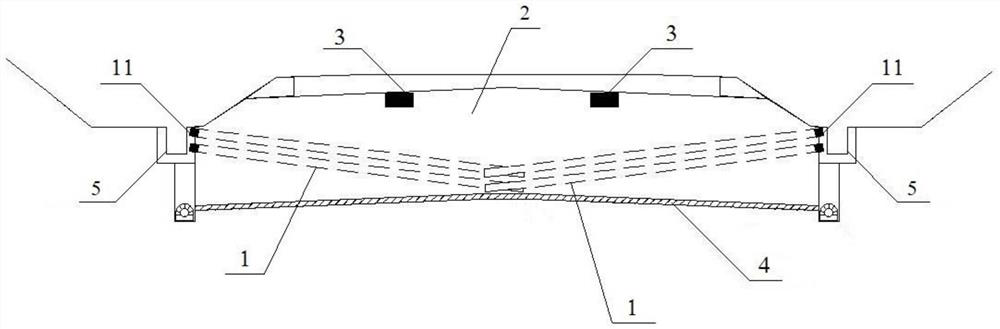

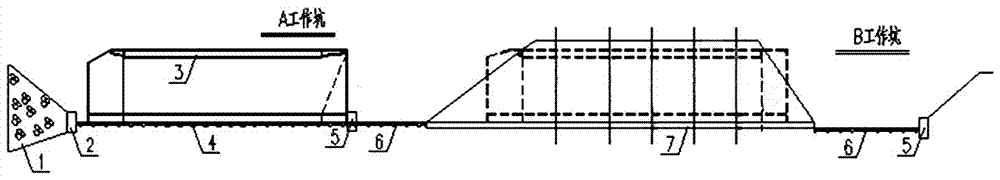

Railway construction method of dismantling existing girder bridge and pushing frame structure in situ

InactiveCN103726451AOperational impact is smallSolve the problem that the small spacing cannot be appliedBridge erection/assemblyBridge strengtheningSunroofRailway line

The invention relates to a railway construction method of dismantling an existing girder bridge and pushing a frame structure in situ. The method of conducting pushing after removing beams is adopted for construction, the position for a beam containing platform is reserved when the frame structure is prefabricated, the upper line and the lower line of a railway line are simultaneously reinforced, beam moving is conducted on the upper line and the lower line independently in the beam moving process, substitute I-beams are used for supporting the railway line after beam bodies are removed, the substitute I-beams are dismantled one by one while pushing is conducted, beam removing is conducted through night skylight closing points, the beams on the lower line are removed at a time from the lower line side, the beams on the upper line are removed at a time from the upper line side, the skylight closing points are occupied once when the beams on the upper line are removed and once when the beams on the lower line are removed, and the skylight closing points are closed for three hours each time. When the construction method is used, the railway operation of each railway line only needs to be interrupted for a short period of time, the operation is convenient, the construction cost is low, and it can be ensured that the influences on the railway operation are reduced to the maximum degree.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

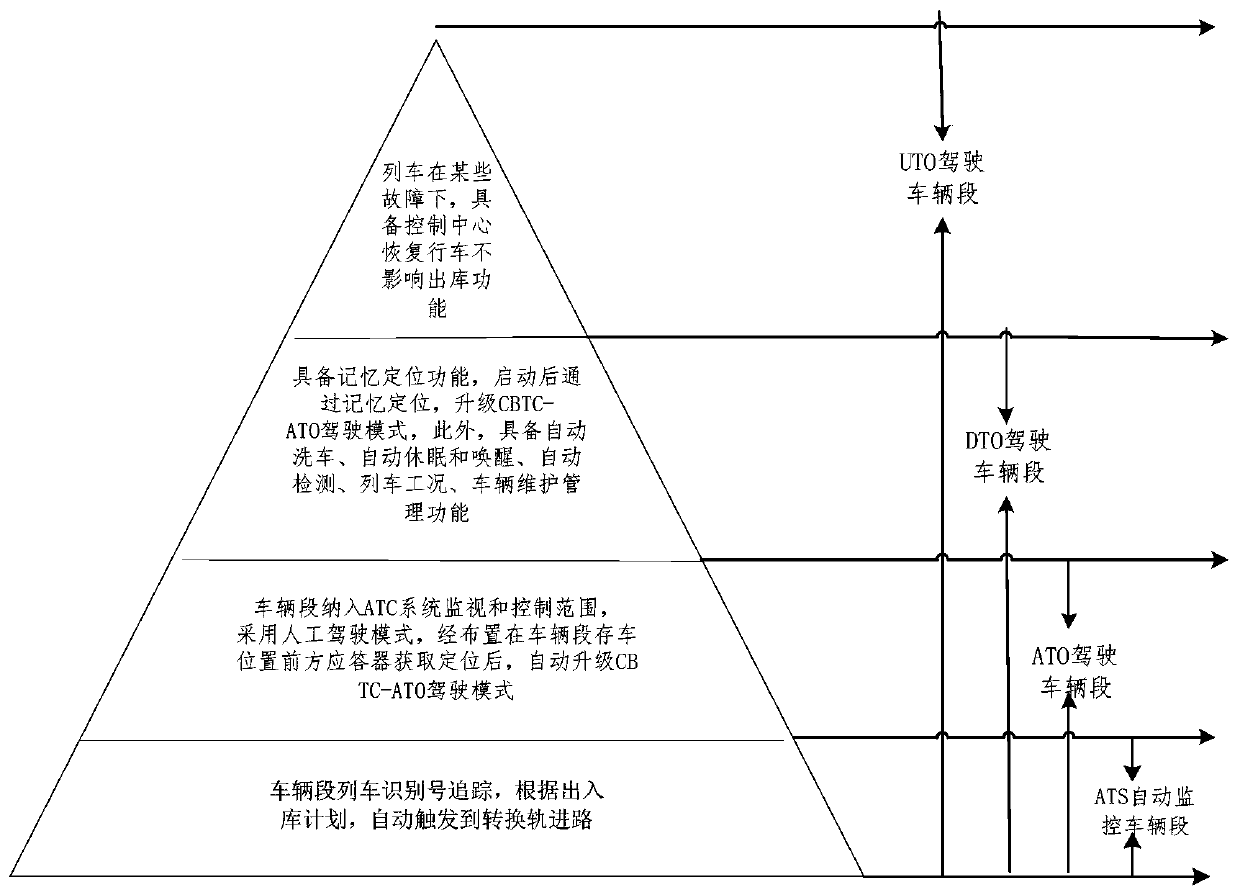

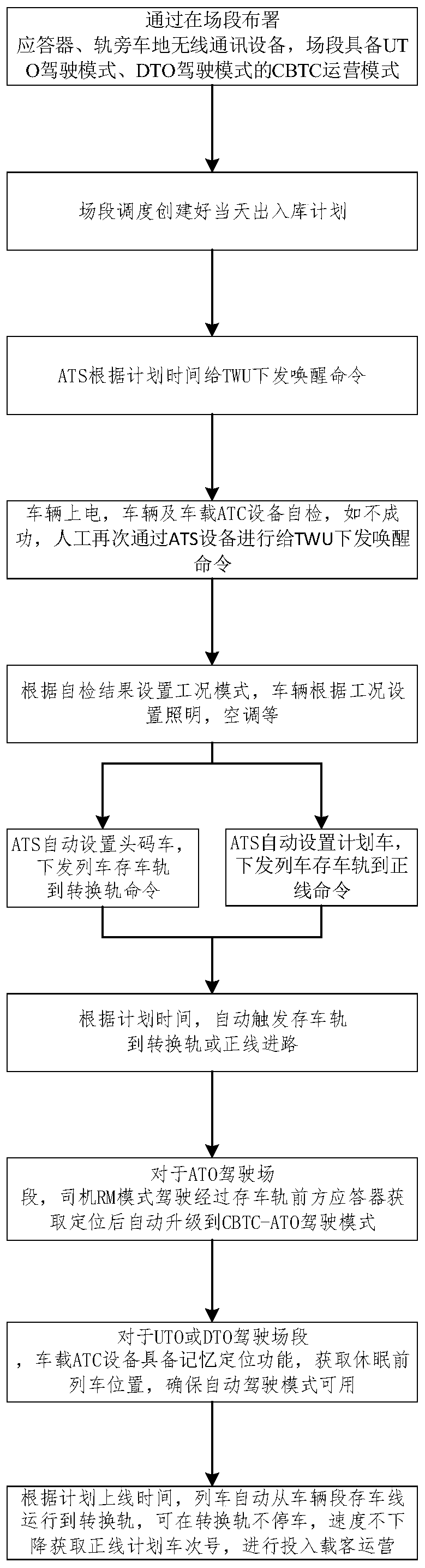

Full-automatic driverless train depot delivery method

ActiveCN110733540AReduce participationRealize automatic outboundAutomatic systemsIn vehicleVia device

The invention relates to a full-automatic driverless train depot delivery method. The method comprises the steps that firstly, a transponder and a vehicle-ground wireless communication trackside device are arranged on the field segment; secondly, a train same-day warehouse out-put and in-put plan is built on an ATS field segment scheduling workstation by a field segment scheduling terminal; thirdly, an ATS device sets time in advance and sends an awakening command to a vehicle-mounted TWU automatically; fourthly, if awakening or self inspection is not successful, the field segment scheduling terminal or dispatching terminal sends out the awakening command to the vehicle-mounted ATC device through the ATS device again; fifthly, a system sets the condition mode according to the self inspection result; and sixthly, according to the train plan on-line time, the ATS device automatically sets a locomotive according to the warehouse out-put and in-put plan, a command from the field segment toa transfer track is issued to a field segment ATC device or through the ATS device, the field segment plan and the main track plan are connected, and the command from the field segment to the main track of the train is issued to the field segment ATC device. Compared with the prior art, the method has the advantage that the train can be in automatic warehouse out-put and in-put under the unmannedcondition.

Owner:CASCO SIGNAL

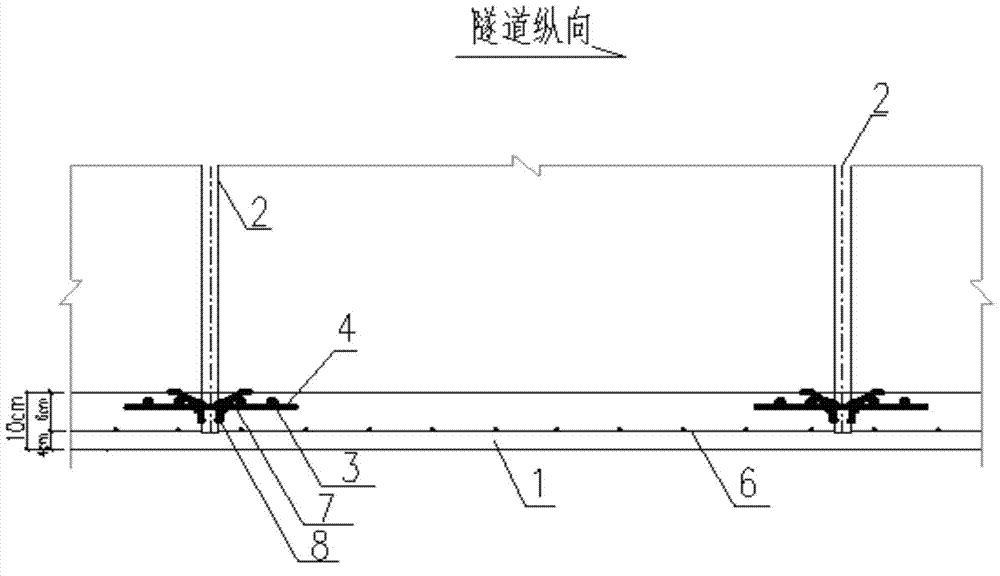

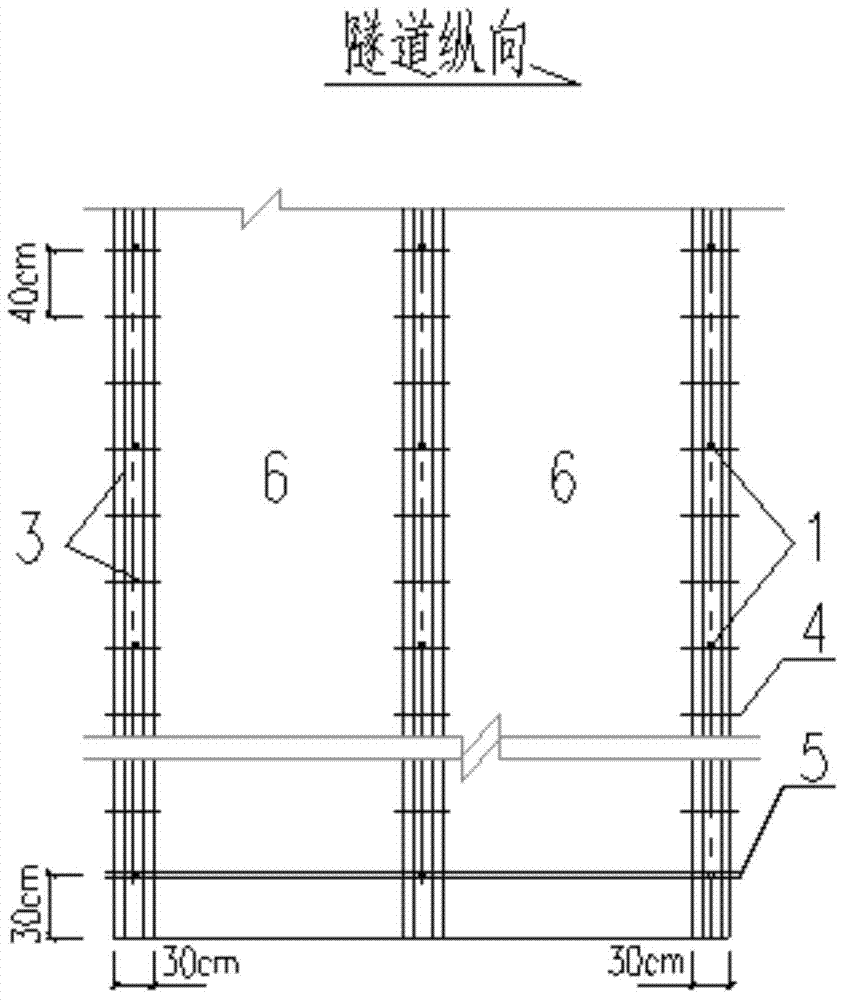

Quick-beam change construction method for existing railway line of railroad

ActiveCN103410103AReduced impact on normal operationsNormal operation impact is minimizedBridge erection/assemblyBridge strengtheningEngineeringCushion

The invention discloses a quick-beam change construction method for an existing railway line of a railroad. The method comprises the following steps: first building a beam change construction bracket platform at the original place below an old beam, and then arranging a slideway system on the bracket platform; then, mounting a temporary support cushion on the outer side of an old beam support; afterwards, removing barriers for beam moving, and moving the new beam onto the slideway system outside the old beam; mounting a temporary support at the bottom of the new beam; lifting a seamless long steel rail in a blocking point, synchronously and transversally moving the new and the old beam so as to move the new beam to the original place of the old beam, fixing the temporary support on the temporary support cushion, and placing the seamless long steel rail down on the new beam for fastening, so as to restore traffic; finally, after the mounting of a permanent support, dismantling the temporary support at the skylight point, so as to allow the permanent support to be stressed. The method can realize the beam change of the existing railway line of the railroad, ensures beam change construction safety, is short in key point time, reduces the influence on the normal operation of the railroad to the utmost, and feasibly and effectively reduces the construction risk.

Owner:WUHAN BRIDGE SPECIAL TECH CO LTD CHINA RAILWAY MAJOR BRIDGE ENG BUREAU

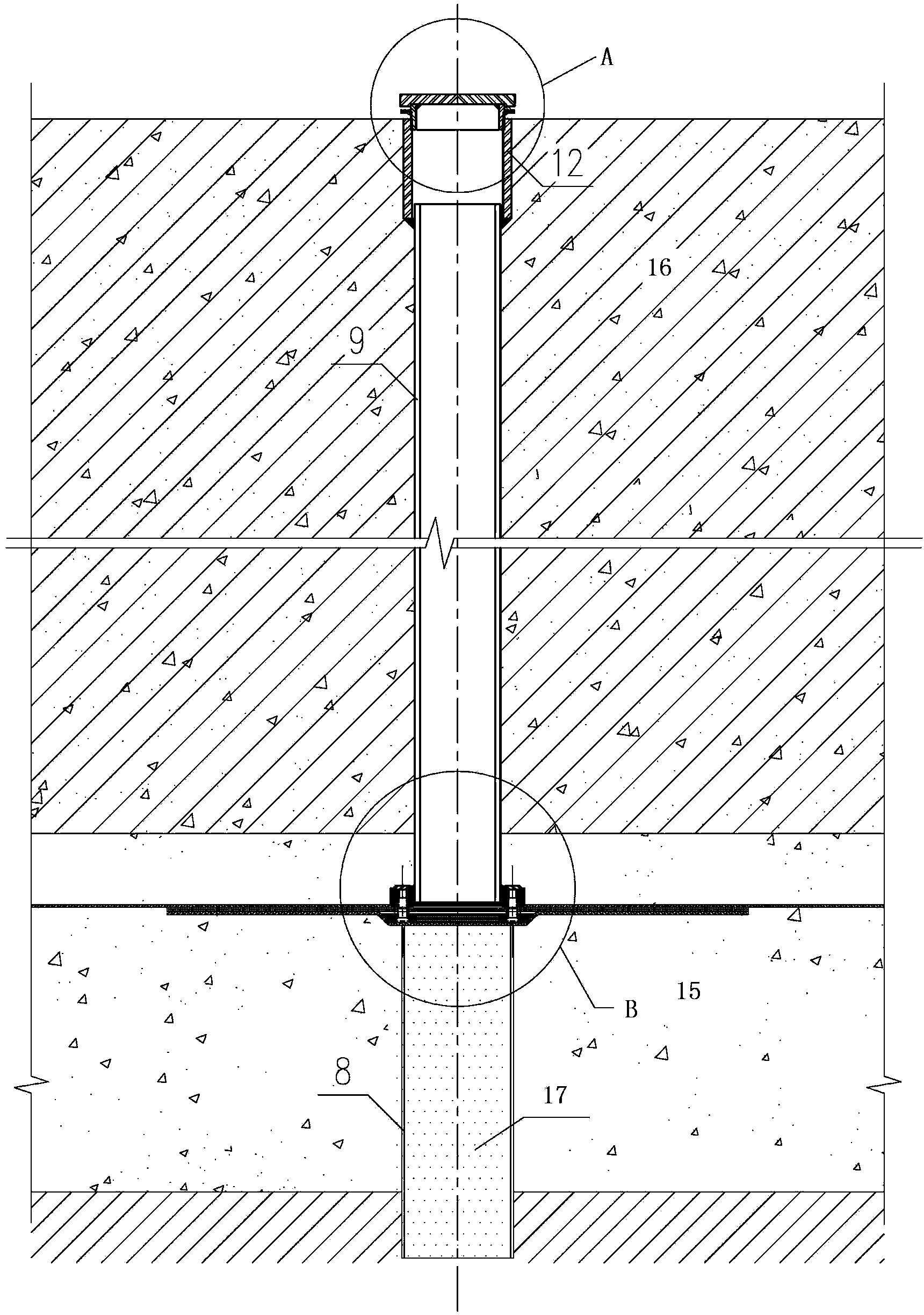

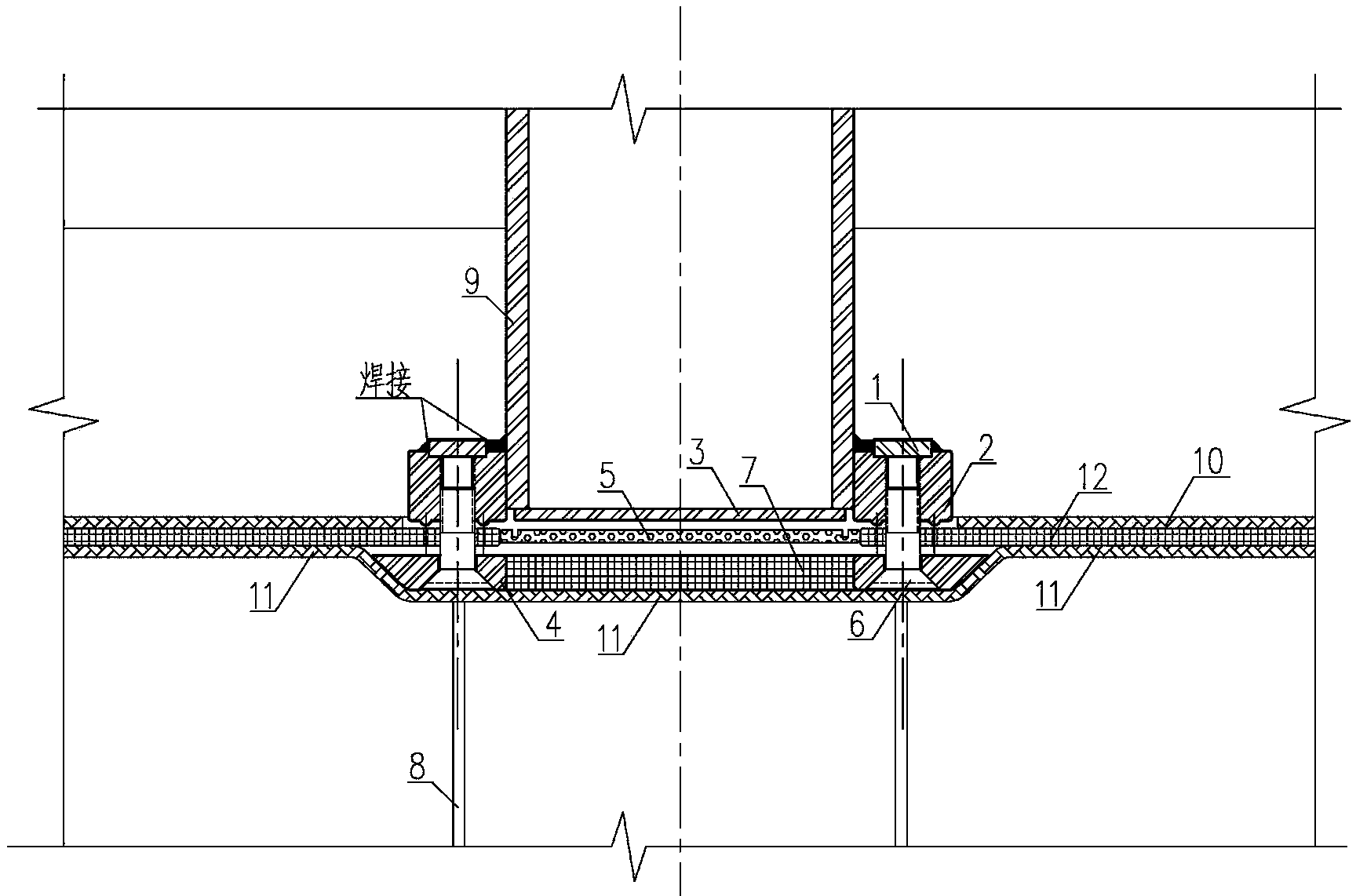

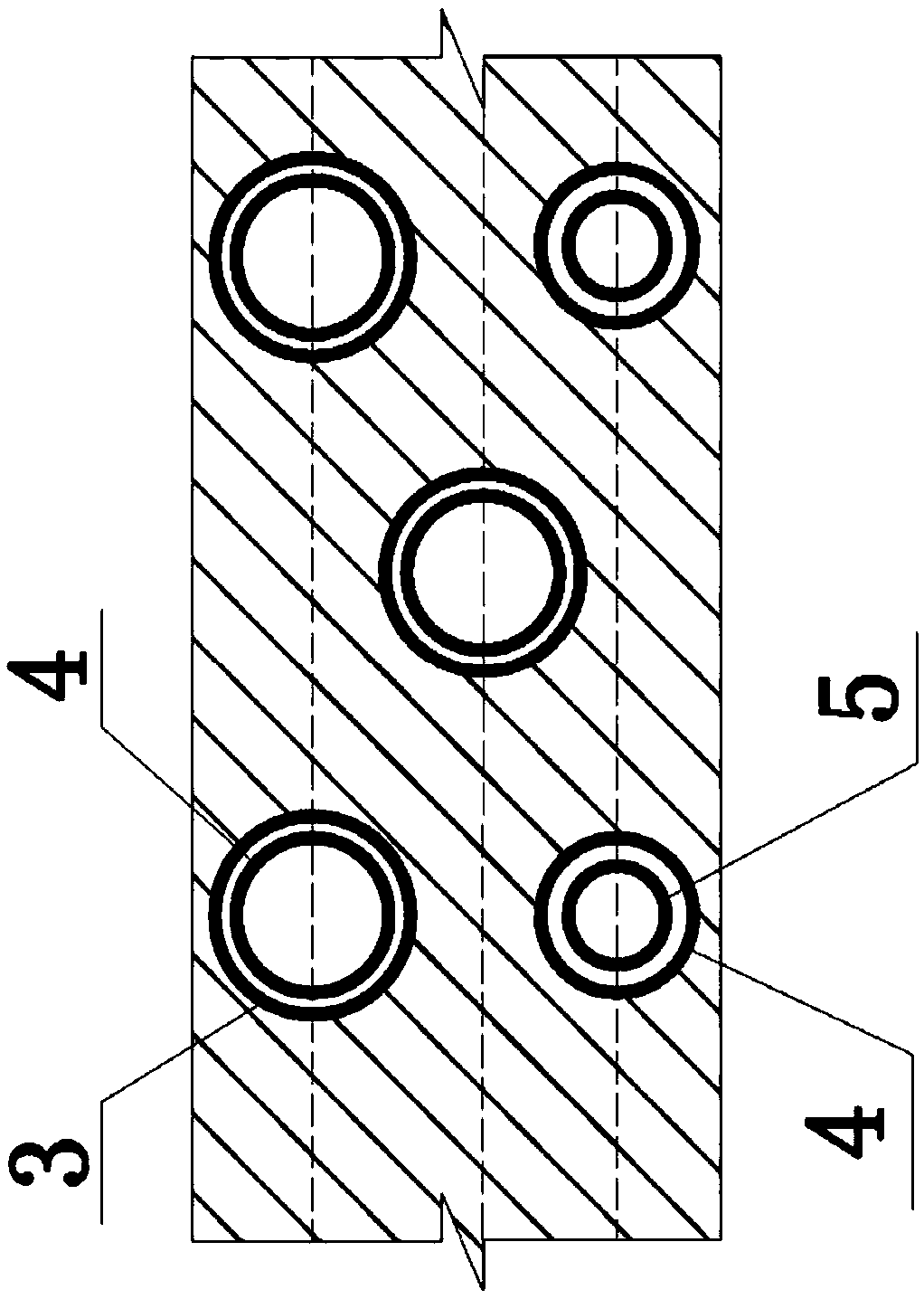

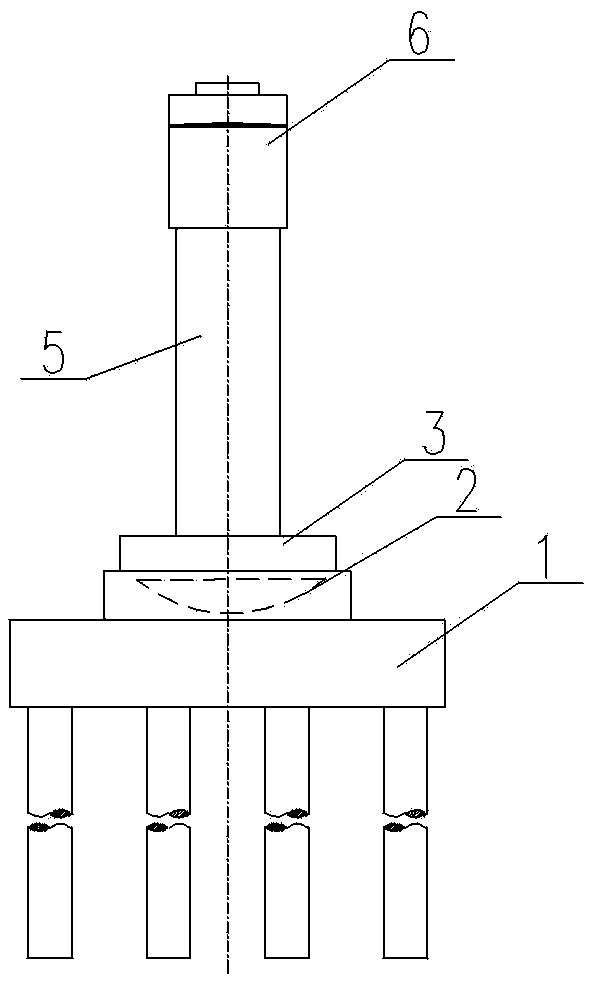

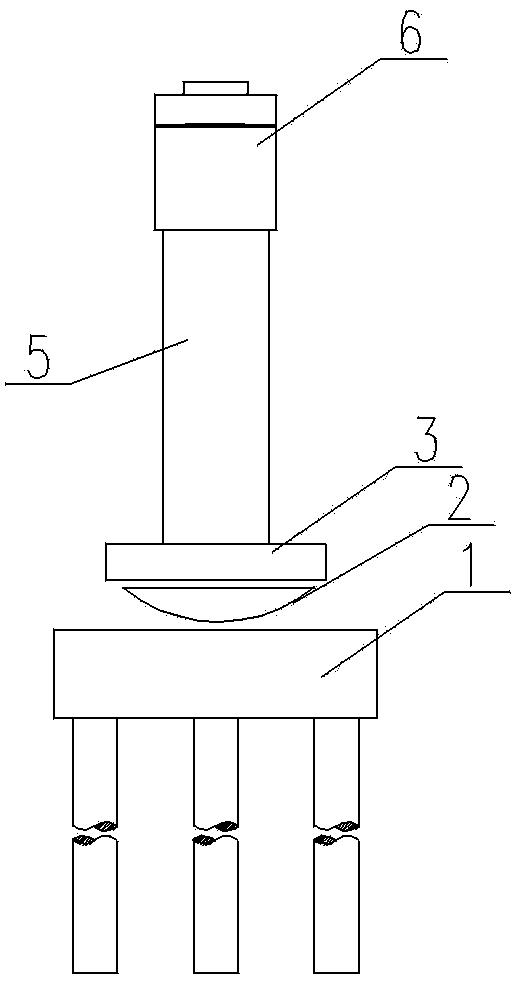

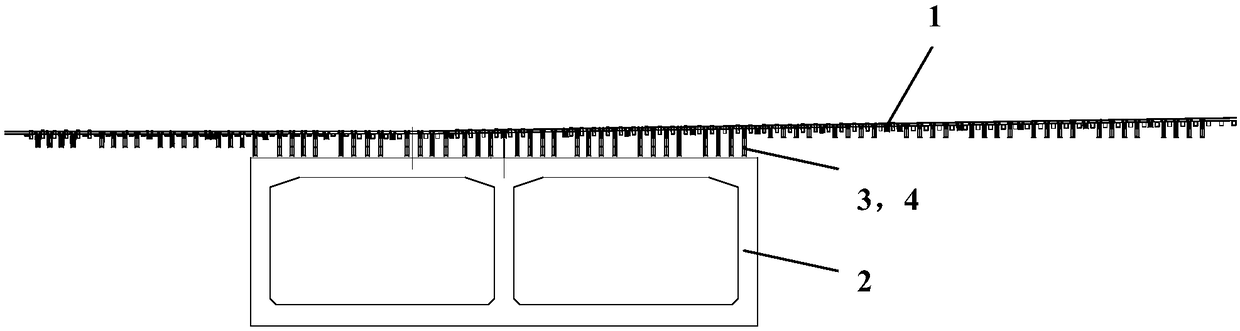

Method for embedment of grouting hole in base plate of underground chamber

ActiveCN103806438AShorten job durationOperational impact is smallProtective foundationSoil preservationEmbedmentRebar

The invention discloses a method for embedment of a grouting hole in a base plate of an underground chamber. The method is characterized by comprising the following steps that (1) a cushion grouting hole embedded pipe is arranged in a concrete cushion of the underground chamber structure; (2) a base plate grouting hole embedded pipe assembly is arranged on the top of the cushion grouting hole embedded pipe, wherein the base plate grouting hole embedded pipe assembly comprises a base plate grouting hole embedded pipe, a grouting hole top sealing cover arranged on the top of the base plate grouting hole embedded pipe, and a grouting hole bottom sealing device arranged at the bottom of the base plate grouting hole embedded pipe; (3) a waterproof layer of the underground chamber is laid up, a plain concrete protective layer is poured, then rebars are bound, and base plate concrete is poured. The method for embedment of the grouting hole in the base plate of the underground chamber has the advantages that during the period of construction completion and operation of the underground chamber, concrete does not need to be removed in a gouging mode in the process of grouting, influence on the externally-wrapped waterproof layer is only caused within the range of the hole diameter of the grouting hole, a grouting pipe can easily, conveniently and directly enter into the soil mass below the base plate and the concrete cushion of the underground chamber, and grouting operation can be carried out.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

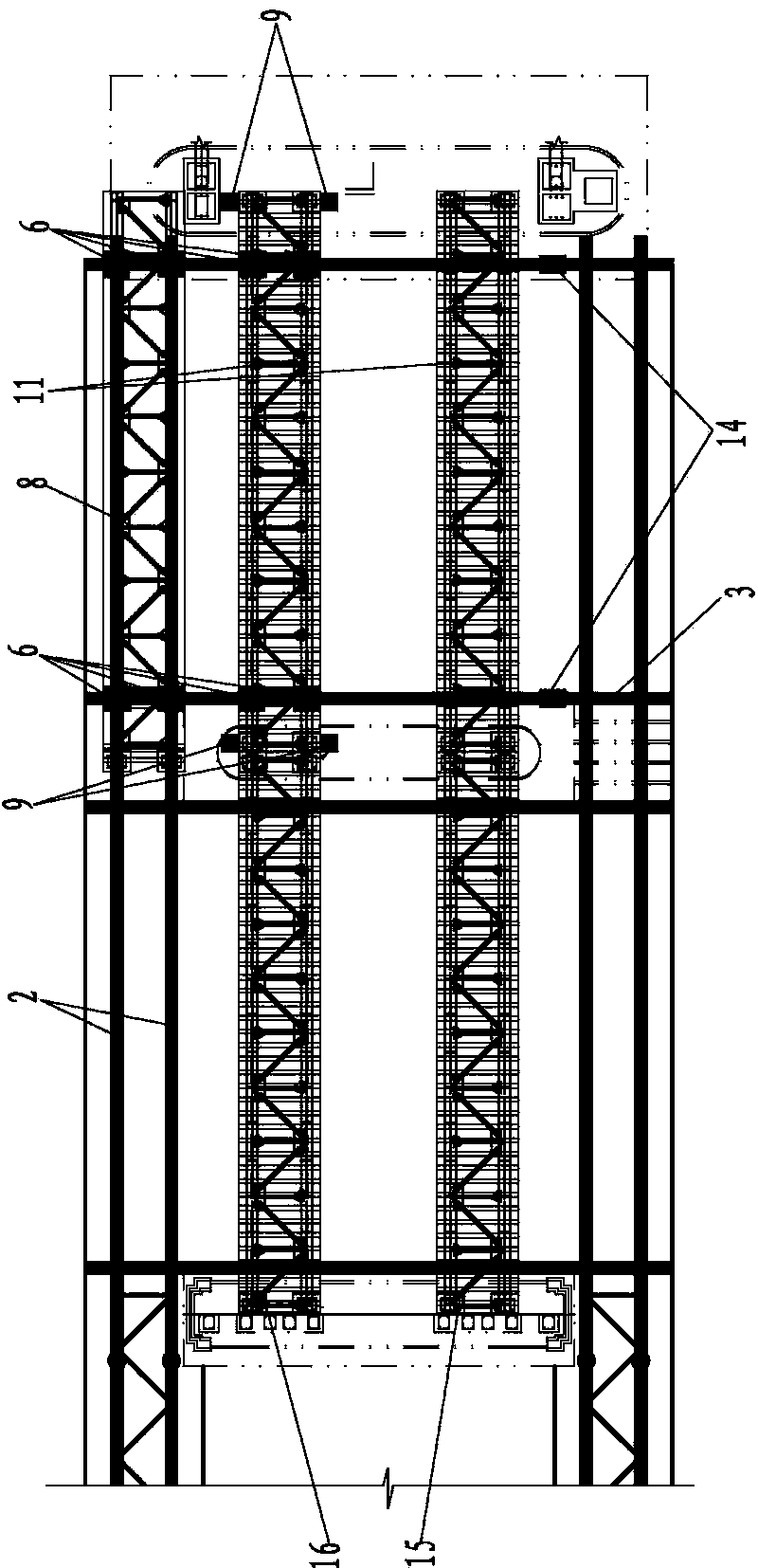

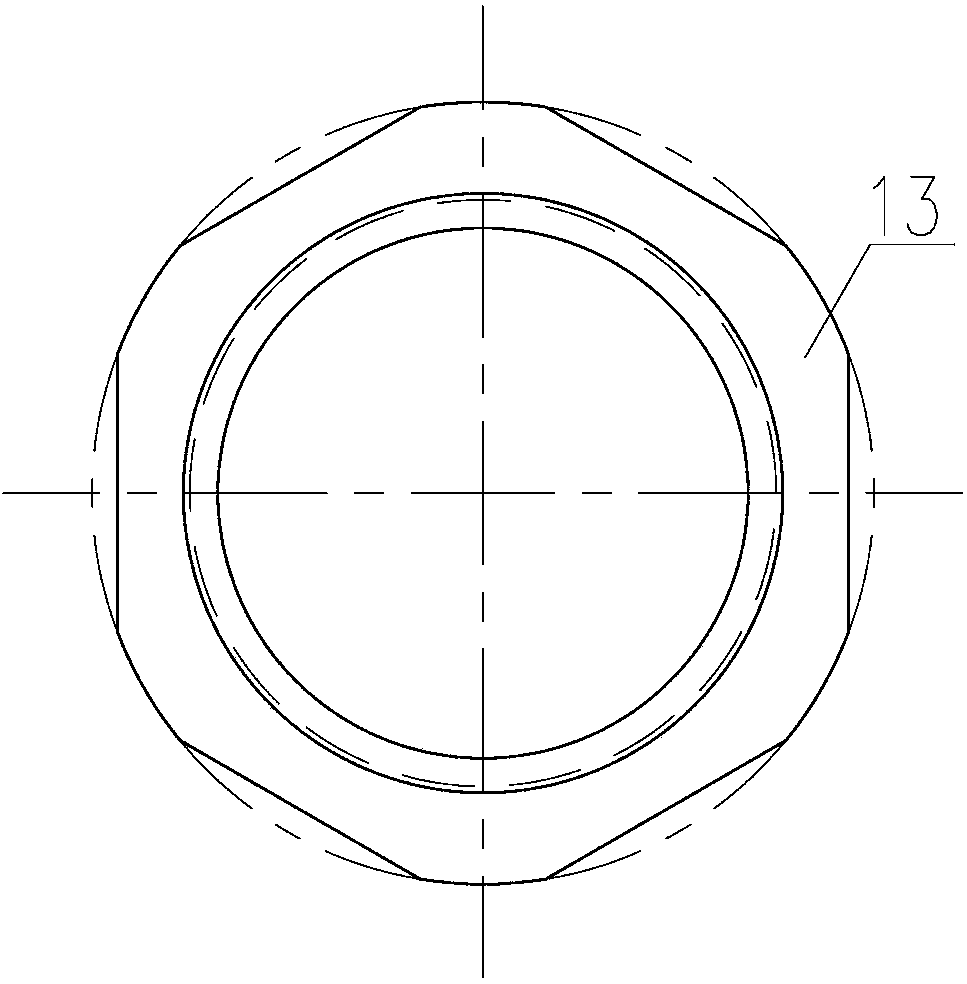

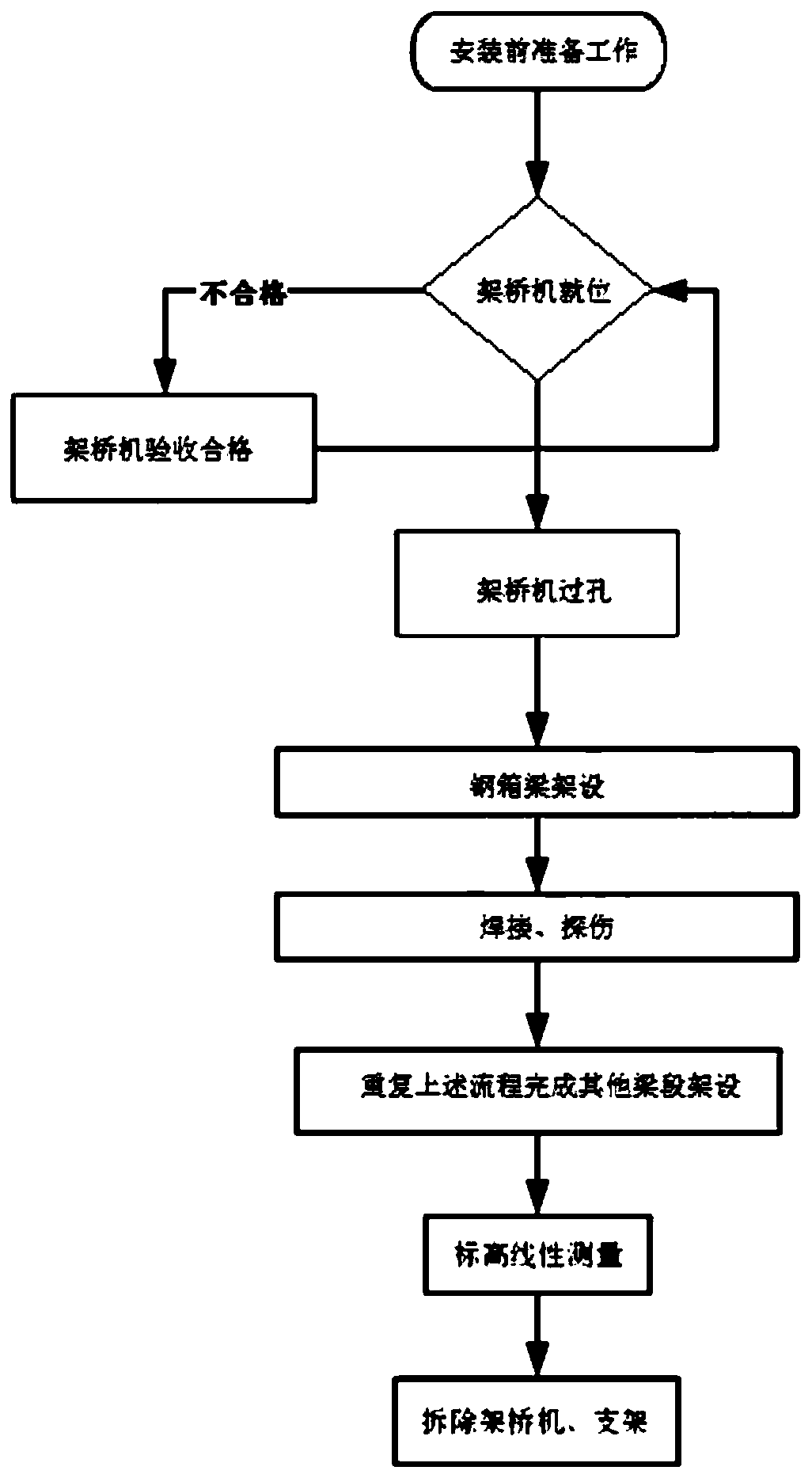

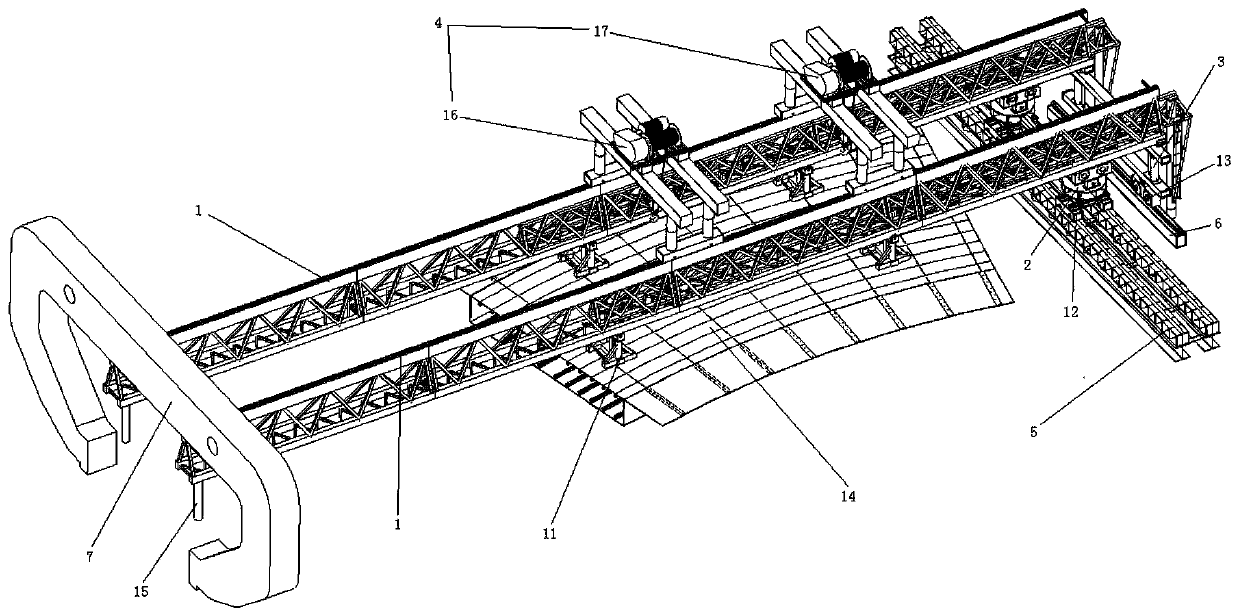

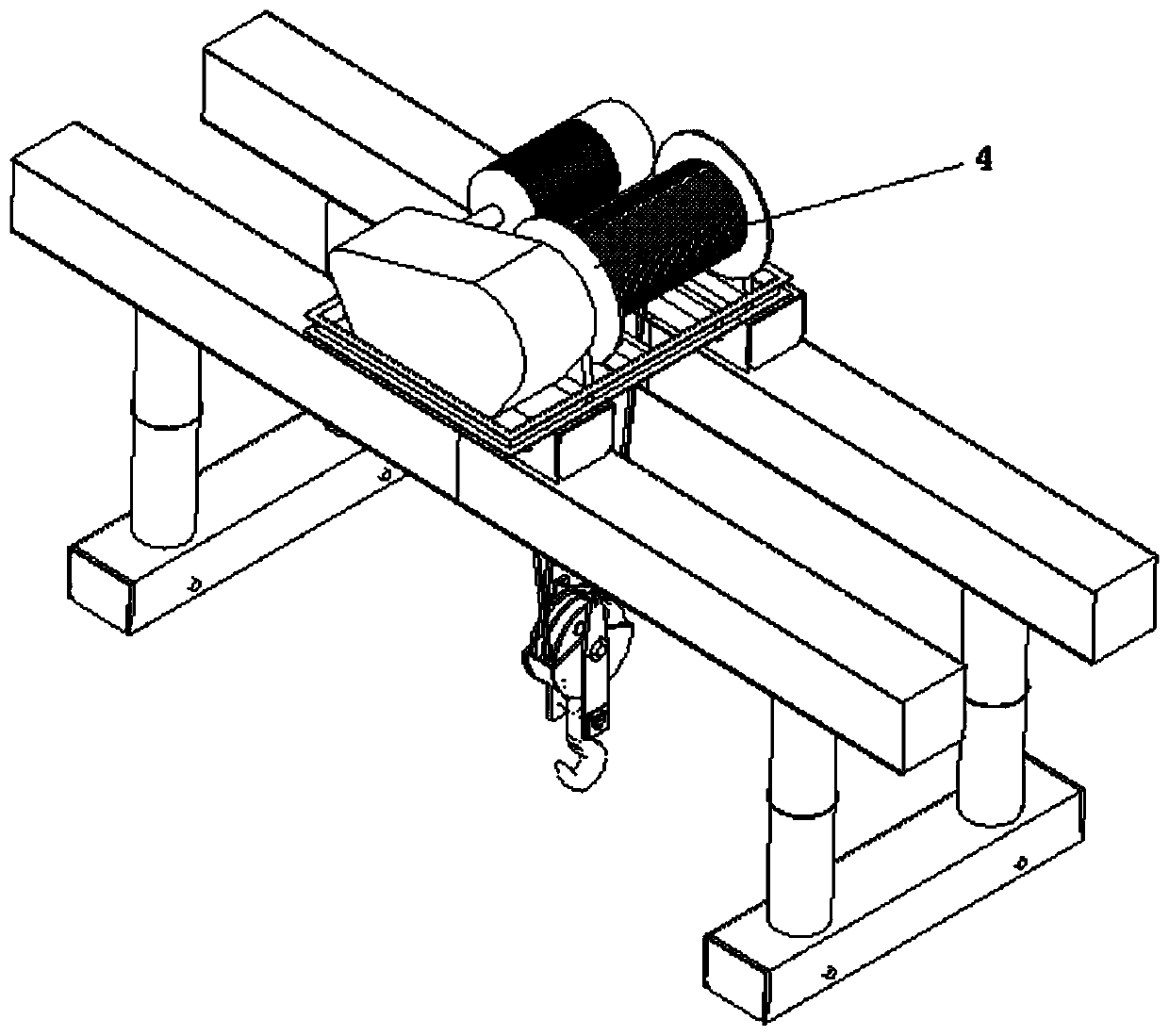

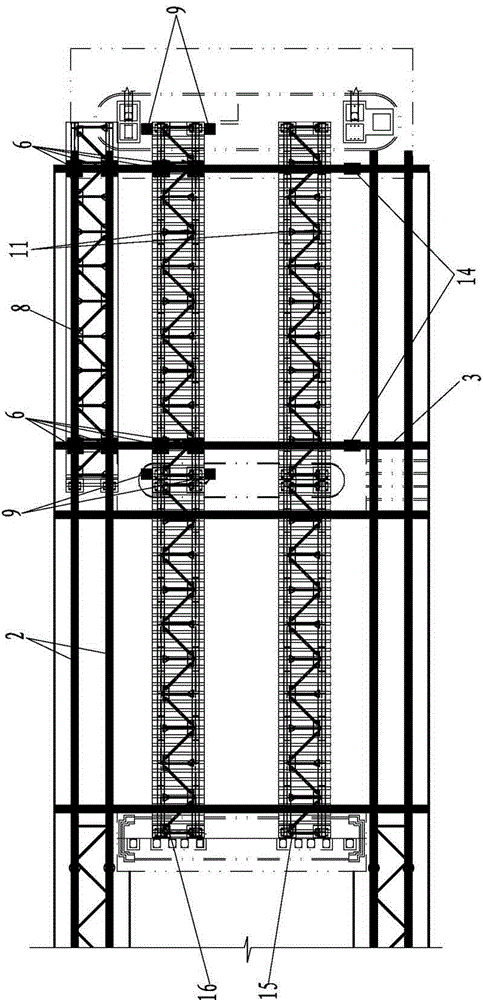

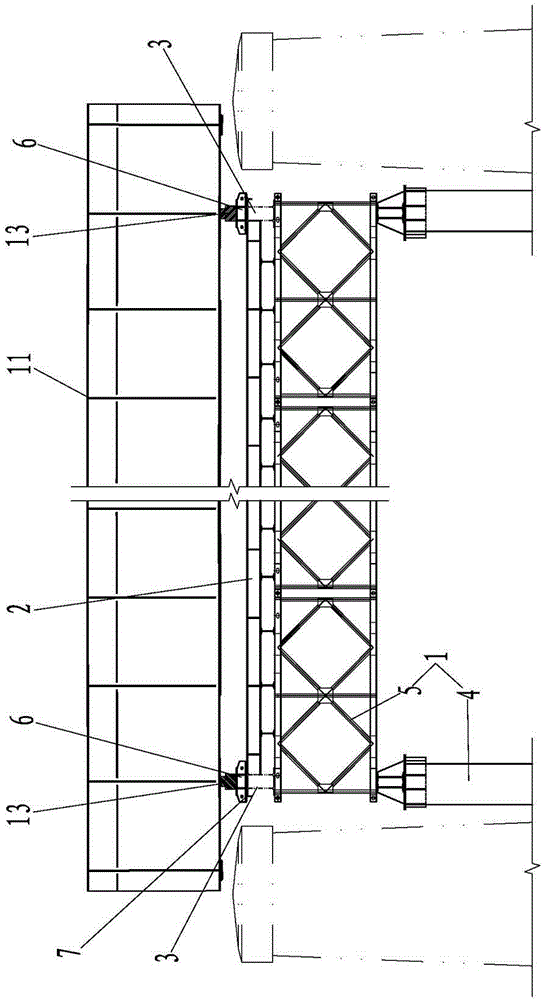

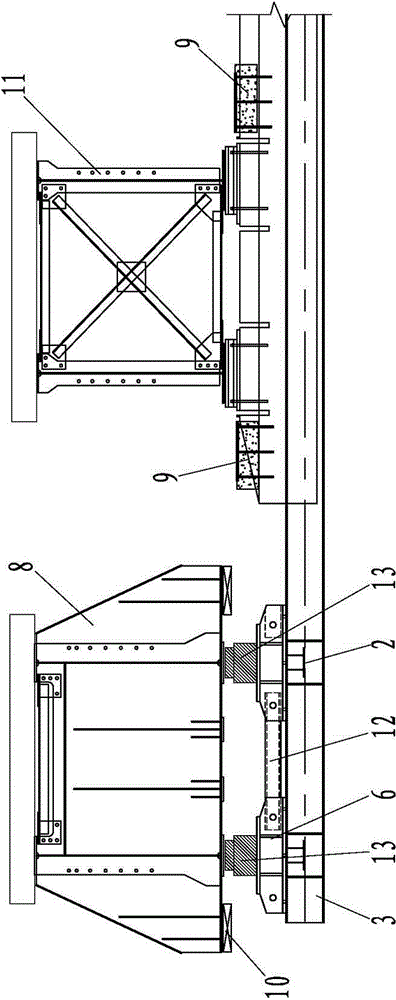

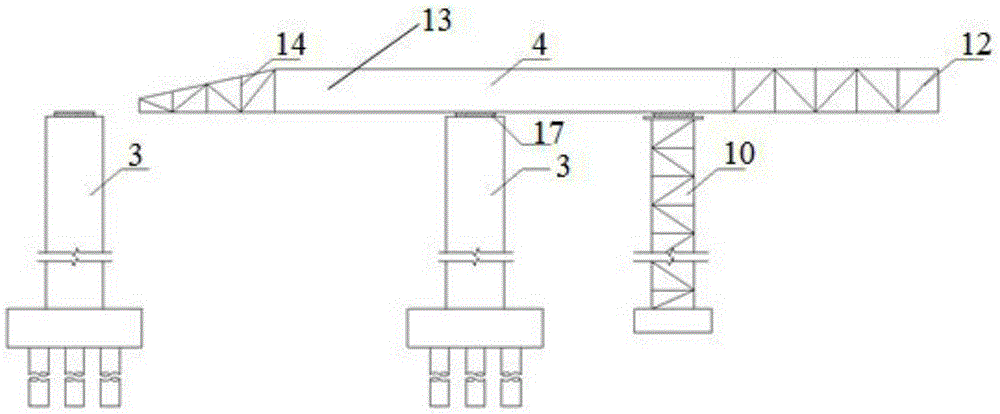

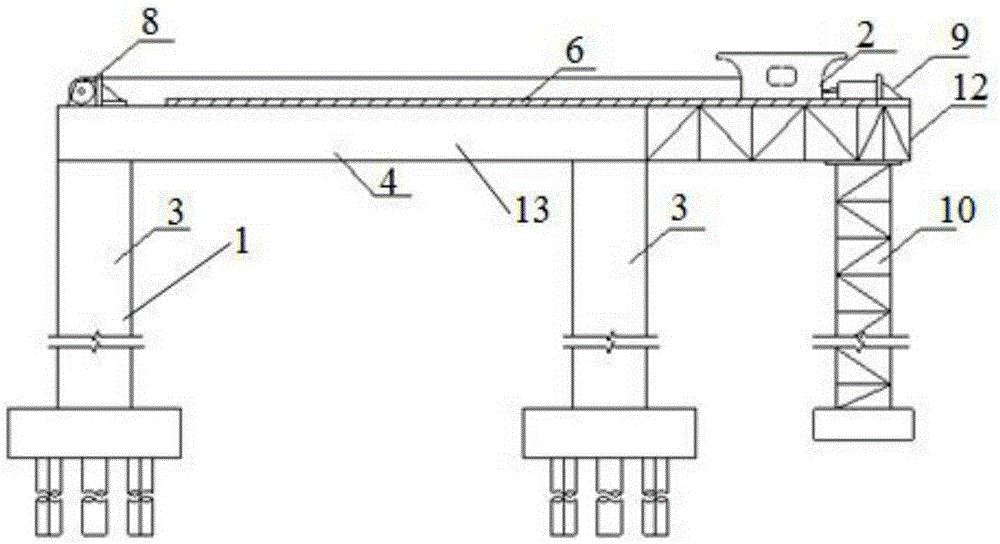

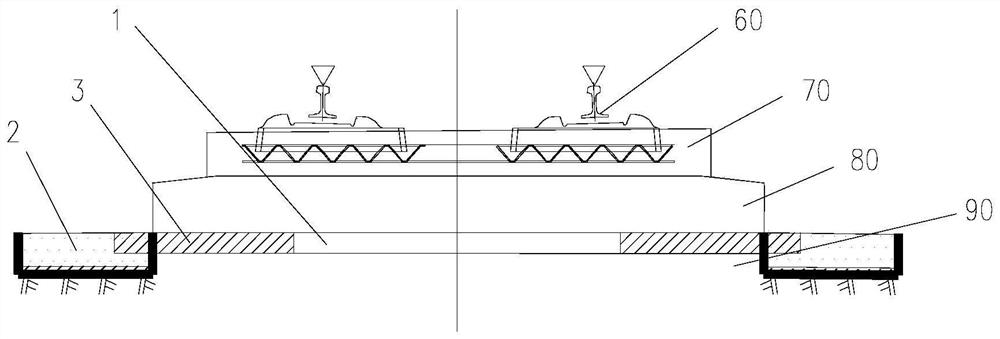

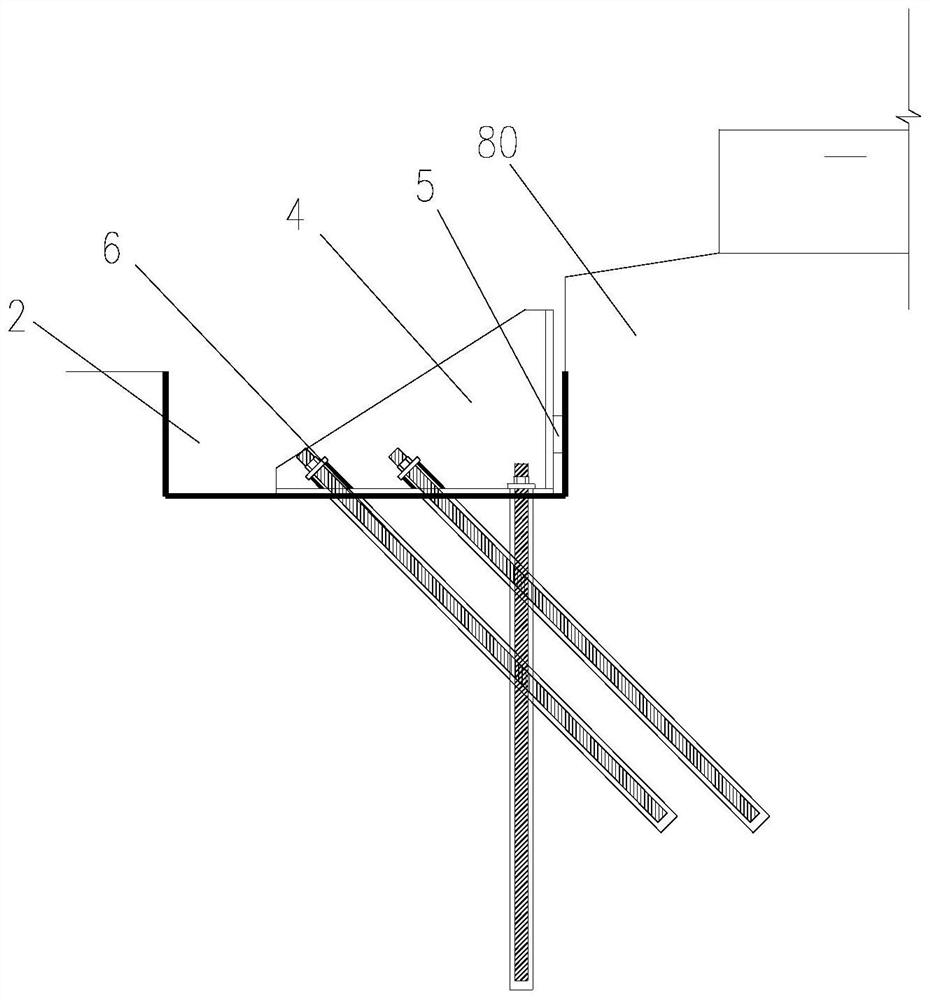

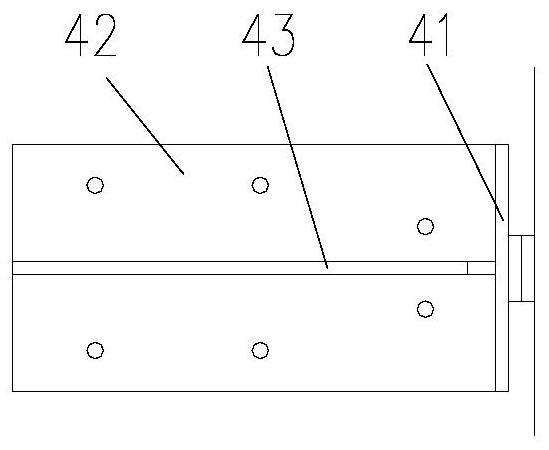

Small-curve-radius steel box girder bridge erecting machine and erecting construction method

ActiveCN111335178ASolve erection problemsAvoid difficultyBridge erection/assemblyArchitectural engineeringStructural engineering

The invention provides a small-curve-radius steel box girder bridge erecting machine and an erecting construction method. The bridge erecting machine comprises a bridge erecting machine main beam, a front supporting leg device arranged at the front end of the bridge erecting machine main beam, a rear supporting leg device arranged at the rear end of the bridge erecting machine main beam, a middlesupporting leg device arranged at the position, close to the rear end, of the bridge erecting machine main beam and a middle supporting leg transverse moving rail arranged in the transverse bridge direction, and the bottom of the middle supporting leg device is installed on the middle supporting leg transverse moving rail. And a front crown block 16 and a rear crown block 17 are arranged on the bridge girder erection machine main beam. When the middle supporting leg sliding block on the middle supporting leg transverse moving rail is moved; when the steel box girder is erected, the girder tailof the main girder of the bridge girder erection machine can move along with the main girder, the rotating angle of the bridge girder erection machine can be adjusted, the whole attitude of the bridge girder erection machine can be adjusted to the steel box girder erection attitude, the steel box girder erected by the bridge girder erection machine in the attitude is the set steel box girder attitude, and the method is suitable for erecting small-curve-radius steel box girders.

Owner:THE THIRD ENG CO LTD OF CHINA RAILWAY SEVENTH GRP

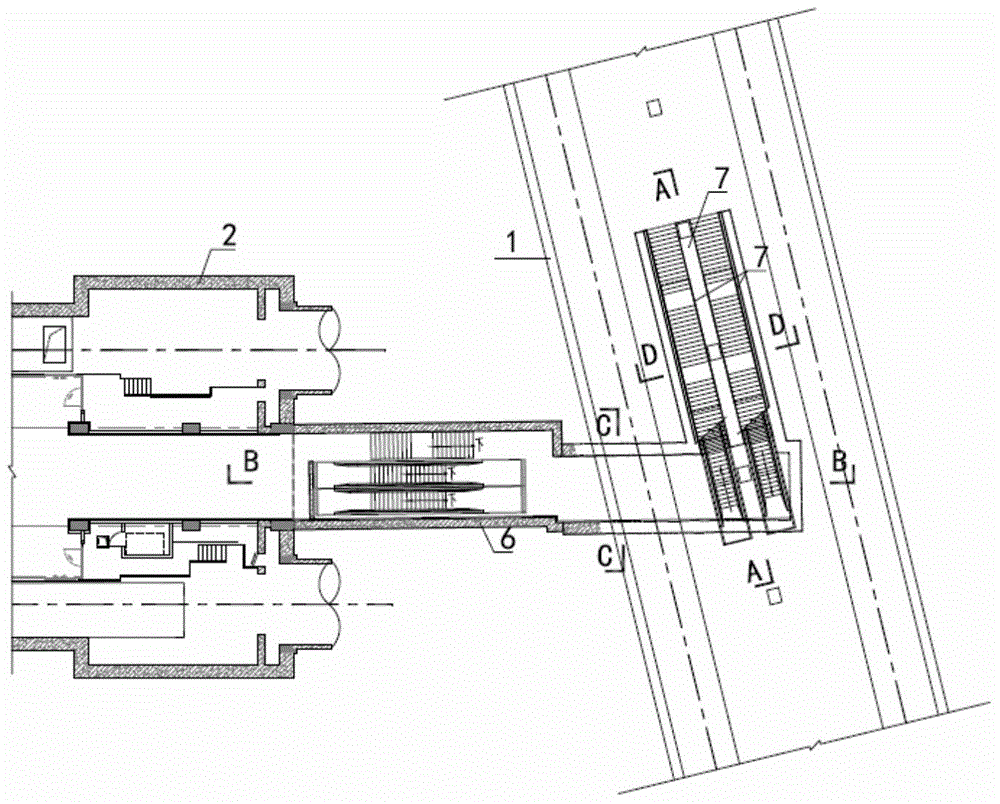

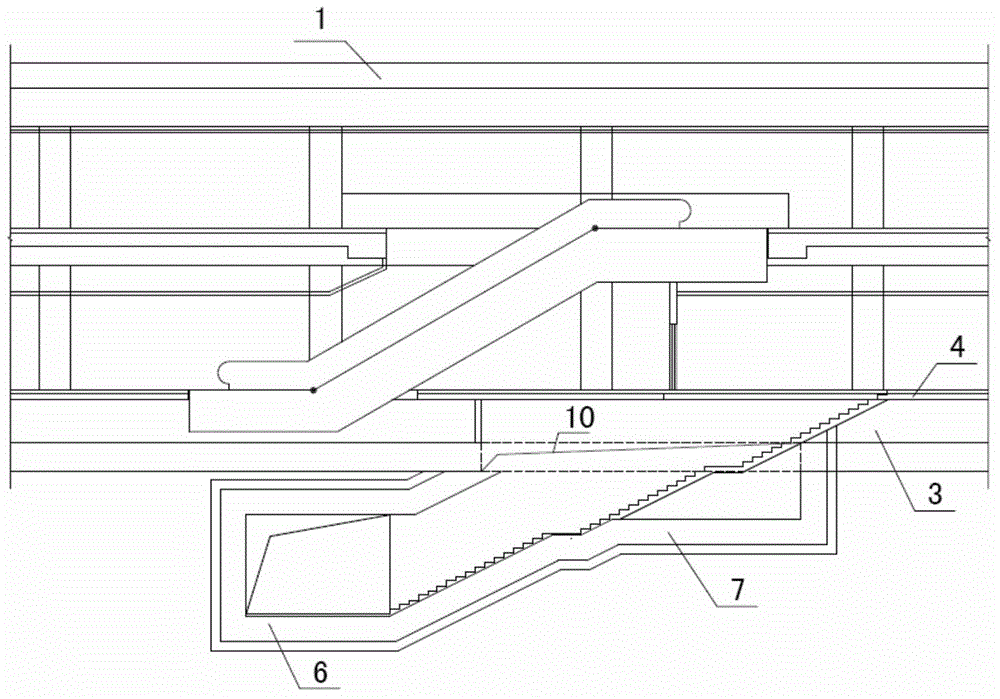

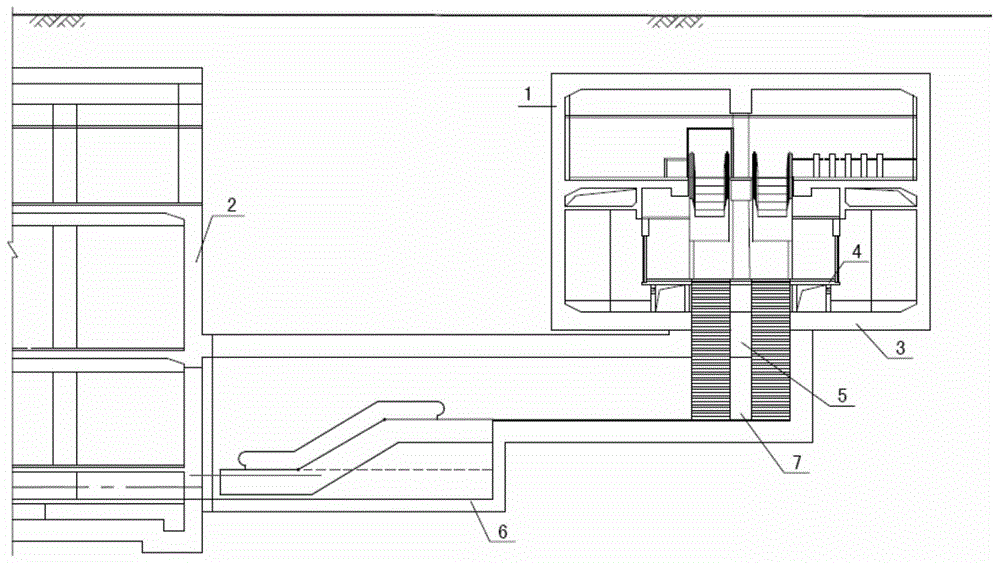

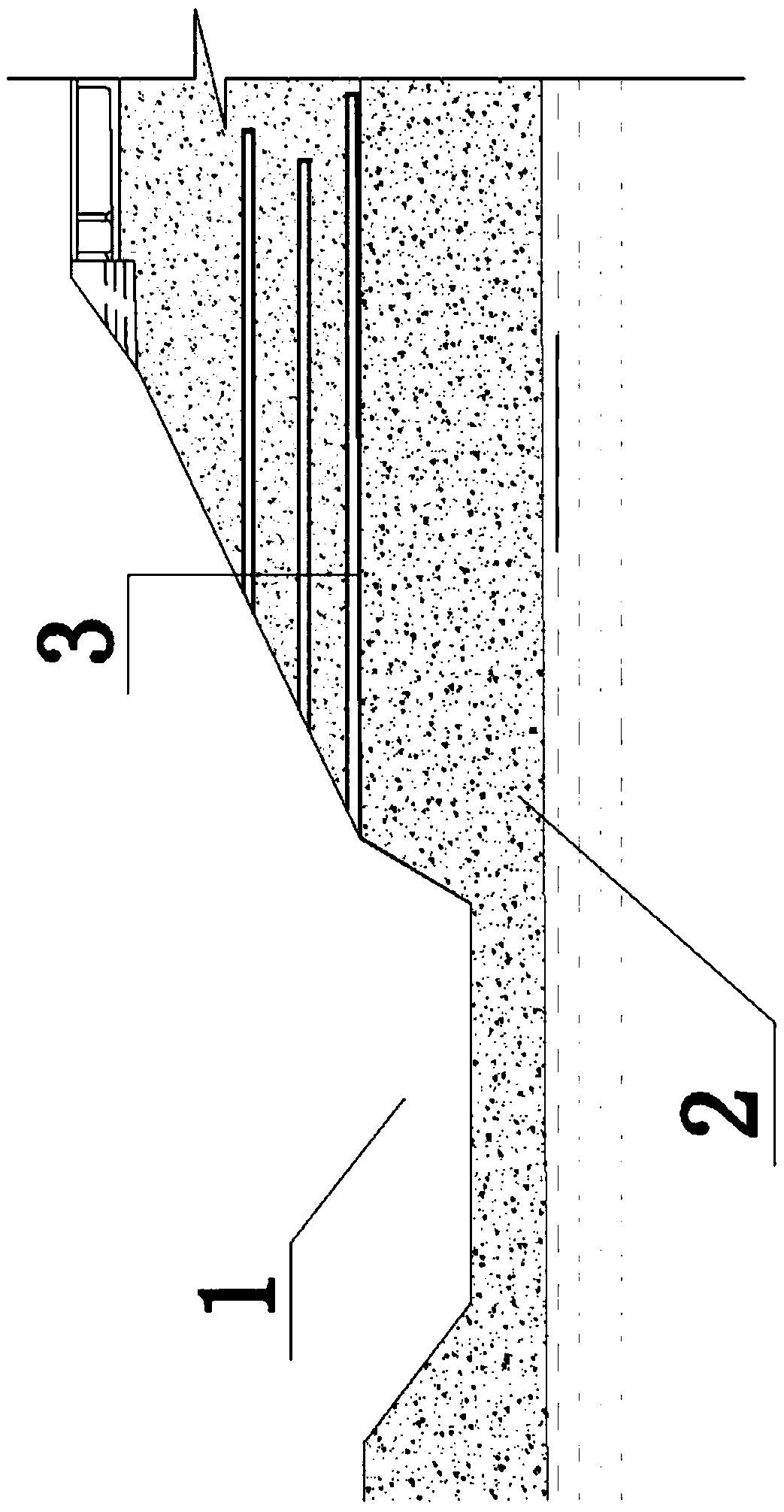

Construction method for implementing transfer between platform floor of existing subway station and platform floor of new subway station

ActiveCN104563158AShort transfer distanceLess transfer timeArtificial islandsExcavationsSubway stationRebar

The invention relates to a construction method for implementing transfer between a platform floor of the existing subway station and a platform floor of a new subway station. The construction method comprises the following steps of constructing the platform floor of the new subway station to a pedestrian path below a structural bottom plate of the existing subway station; reinforcing strata surrounding the pedestrian path; dividing a structural bottom plate longitudinal beam of a passageway which is arranged at a position of a table board of the existing subway station and is connected to the pedestrian path into a left portion and a right portion; respectively constructing the left portion and the right portion; correspondingly constructing surrounding rock of an excavation structure at a position of a structural bottom plate longitudinal beam on a side wall of a constructed pedestrian passage structure; breaking down a waterproof layer, a reinforcement cover, construction preliminary bracings and cross braces, a construction waterproof layer and assembling reinforcements on a structural bottom plate portion of a platform of the existing subway station; connecting a new structure and the existing structure by using embedded steel bars; pouring side walls and middle walls; constructing another structural bottom plate longitudinal beam to obtain a complete passageway structure; finishing construction of the passageway of the pedestrian path; and connecting the platform floor of the existing subway station to the platform floor of the new subway station. A construction process is safe, the practicability is high, and normal operation of the existing subway lines is not affected.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

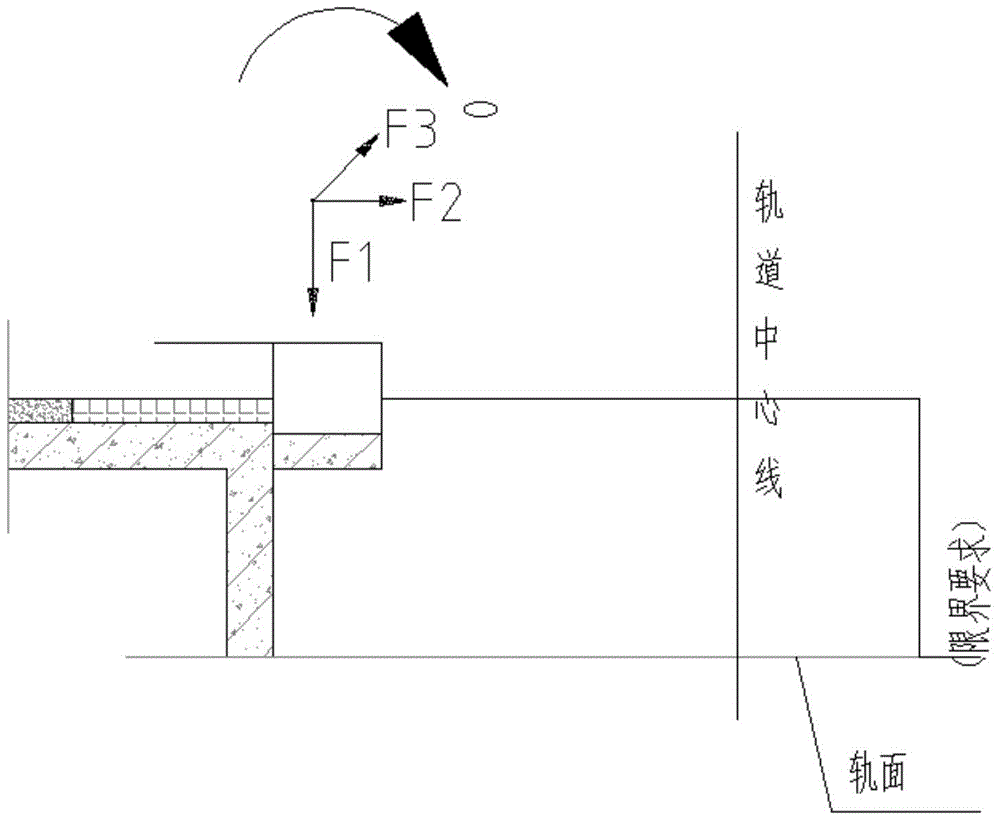

Repair method for high-speed railway roadbed arching deformation

ActiveCN108951308AOperational impact is smallIntegrity guaranteedRailway tracksStress concentrationEngineering

The invention relates to the field of railway roadbed engineering, in particular to a repair method for high-speed railway roadbed arching deformation. A working groove / working grooves meeting the drilling machine drilling operation requirement is / are excavated in one side / two sides of an arching section roadbed; then holes are transversely drilled in the arching section roadbed range, and round pipes with the diameter equivalent to the hole diameter are inserted in the drilling process; along with the increase of the number of the drilled holes, the up-down contact area of a soil body of a layer where the drilled holes are located is reduced, soil body stress concentration is generated, the portions, around the hole walls, of the soil body are squeezed into or collapse into the drilled holes, and roadbed settlement is generated; then, the mode that small-diameter round pipes are used for gradually replacing the large-diameter round pipes is adopted for guaranteeing that roadbed settlement deformation is in a controllable range, and the round pipes inserted in the drilled holes at the last time are used as grouting pipes; after the settlement deformation generated by the roadbed drives the rail surface elevation to reduce to a target value, the drilled holes are filled with cement paste or cement mortar through the grouting pipes; and finally the working groove / working groovesis / are backfilled. By the adoption of the method, construction is convenient and quick, cost is low, normal operation of a railway is not affected, and the method is more practical.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Subway platform reinforcing construction method

InactiveCN105015554AWork reliablyLarge adjustment rangeRailway componentsRailway stationEngineeringExpansion joint

Owner:刘春梅

Method for treating ballastless track subgrade elevation defects

The invention provides a method for treating ballastless track subgrade elevation defects. The method comprises the following steps that S1, the positions and the types of track defects are acquired so as to determine the treatment range; S2, in the treatment range, an adjusting groove is formed below the supporting layer through an underground excavation mode; S3, a track is adjusted to a target elevation; and S4, filling is carried out on the adjusting groove so as to fill the adjusting groove, wherein in the step S2, the adjusting groove extends downwards from the bottom surface of the supporting layer in the vertical direction, the adjusting groove extends in the arrangement direction of the track in the longitudinal direction, and the two sides of the adjusting groove are located outside the corresponding side walls of the supporting layer correspondingly in the transverse direction. According to the method, the economical efficiency is good, and construction can be carried out on the skylight time.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

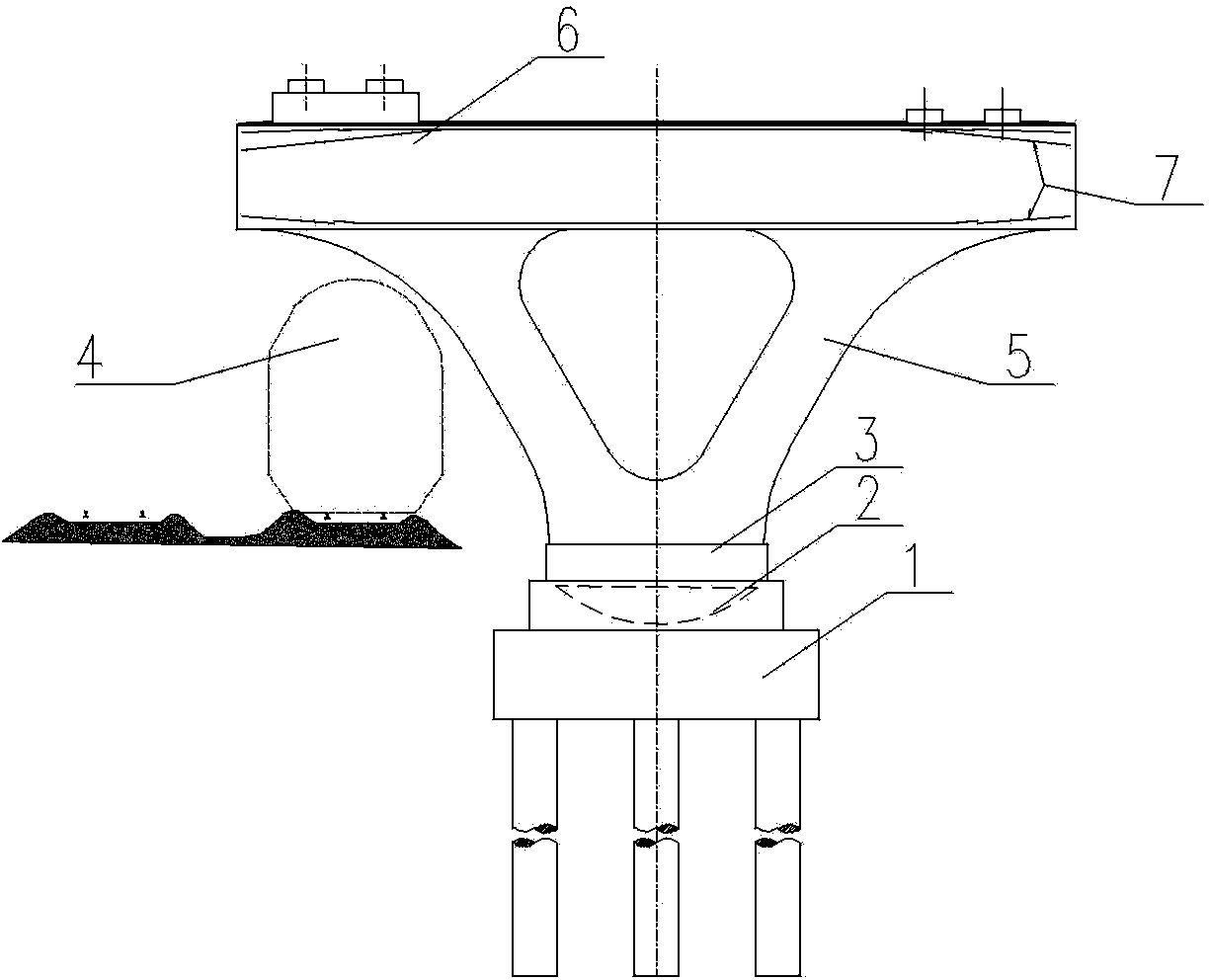

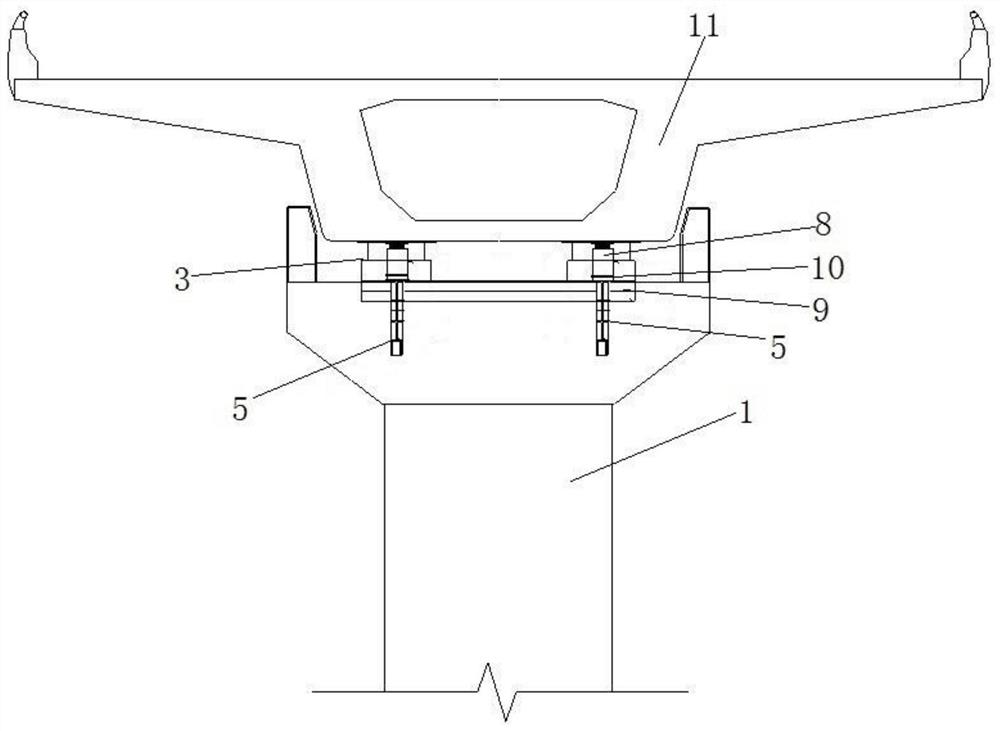

Rotation V-type T-structure bridge pier and construction thereof

ActiveCN104213504AShorten the construction periodReduce operational disruptionBridge structural detailsFoundation engineeringArchitectural engineeringUrban area

The invention relates to a rotation V-type T-structure bridge pier and a construction thereof. When an included angle formed between a line and an existing busy trunk line through vertical crossing is smaller, cross-hole arrangement of a bridge is more difficult. The bridge pier is constructed on one side of the existing trunk line, and comprises a pile foundation, a supporting platform, pier arms and a cover beam from bottom to top, wherein the supporting platform is divided into a lower rotary table and an upper rotary table from bottom to top; a rotary spherical hinge is arranged between the upper rotary table and the lower rotary table; during line operation skylight time, the upper rotary table and the structure rotate to a designed position by taking the rotary spherical hinge as the center, concrete on the outer side of the rotary spherical hinge is poured to form a solid stage, and the lower rotary table and the upper rotary table are fixedly connected together to complete construction. Due to the adoption of a rotation V-type T-structure scheme, the construction only needs to be performed on one side of the existing line, requirements for roads and construction sites on the other side are reduced, the conditions that houses on two sides of the existing line in an urban area are dense and are difficult to remove are facilitated, the removal cost is greatly reduced, and the construction period is guaranteed; meanwhile, due to the adoption of rotation construction, the influence on operation of the existing line is minimized.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

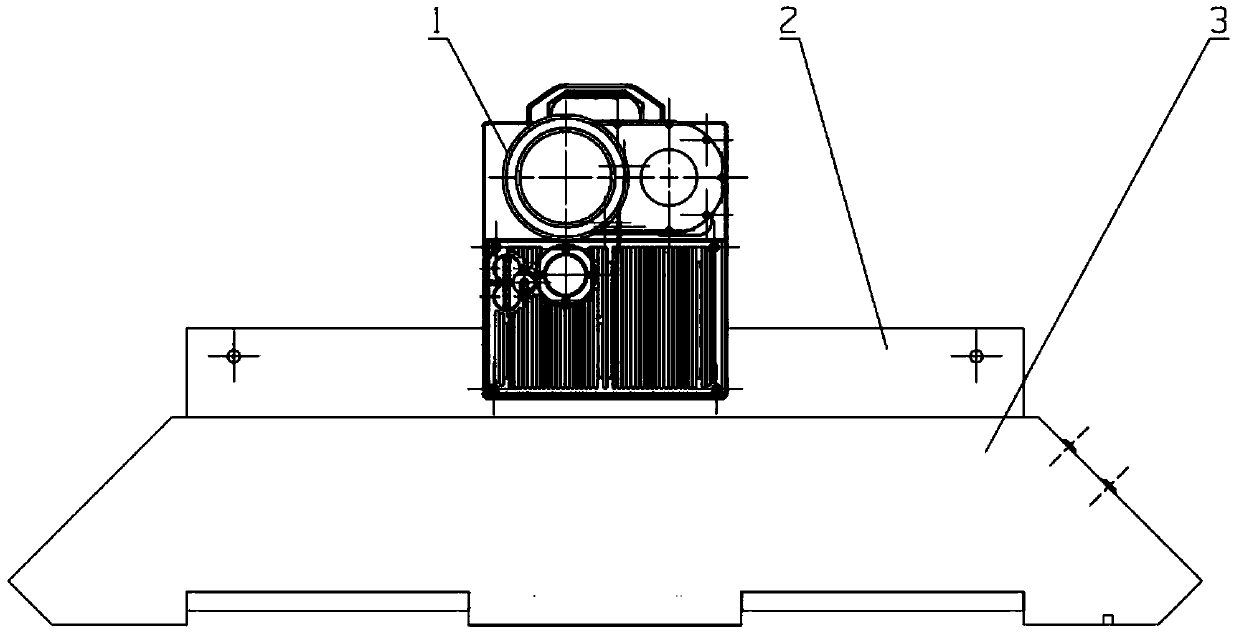

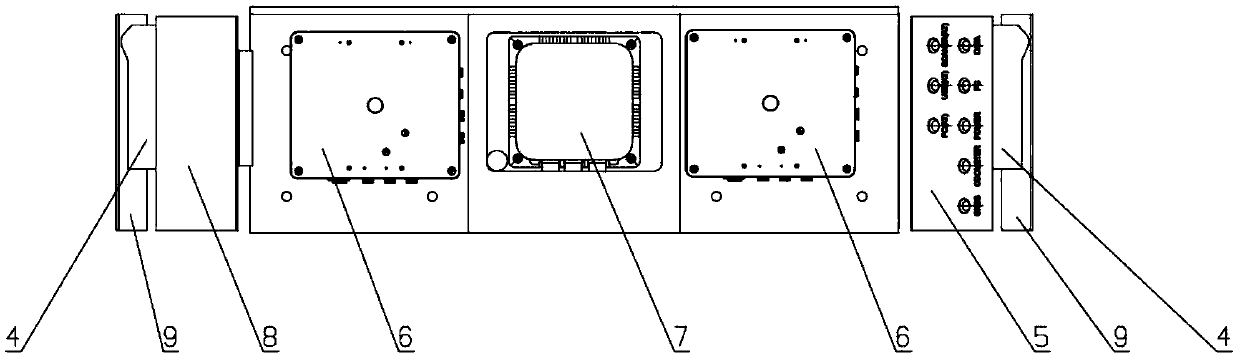

Track detection device based on inertial measurement

InactiveCN110626383AOperational impact is smallImprove efficiencyRailway auxillary equipmentRailway profile gaugesLaser rangingLaser scanning

The invention aims at providing a track detection device based on inertial measurement. The track detection device based on inertial measurement comprises an inertial measurement module; the inertialmeasurement module comprises a laser scanner, an adapter plate, a detection beam, laser range finders, connector interfaces, line boxes and an inertial navigation system, wherein the adapter plate isarranged on the detection beam; the laser scanner is arranged on the adapter plate; the laser range finders are arranged at the two ends of the detection beam; the inertial navigation system is arranged in the middle of the detection beam; the line boxes are arranged in the positions, on the detection beam, on the two sides of the inertial navigation system; and the connector interfaces are formedin the positions, on the detection beam, on the external sides of the line boxes. The track detection device based on inertial measurement has the advantages that the track detection device based oninertial measurement can be mounted on a running train and can also be mounted on a driving trolley to independently operate; and as a vehicle-mounted dynamic detection mode of the track detection device based on inertial measurement has small influences on normal operation, possesses high efficiency and high speed and really reflects the state of infrastructures under a train running condition, the vehicle-mounted dynamic detection mode of the track detection device based on inertial measurement can be used as one of main detection means of safety states of railway and urban rail transit infrastructures.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

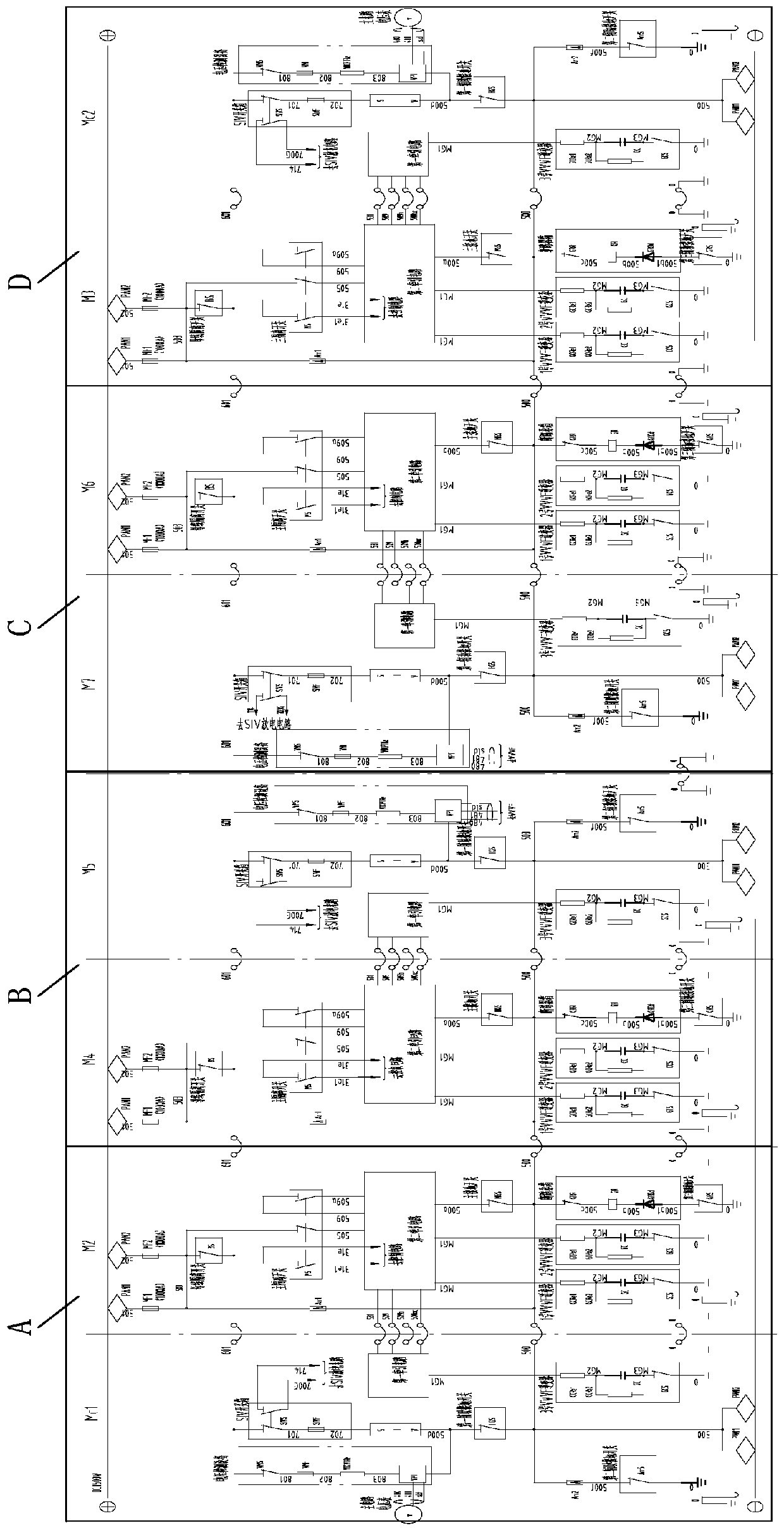

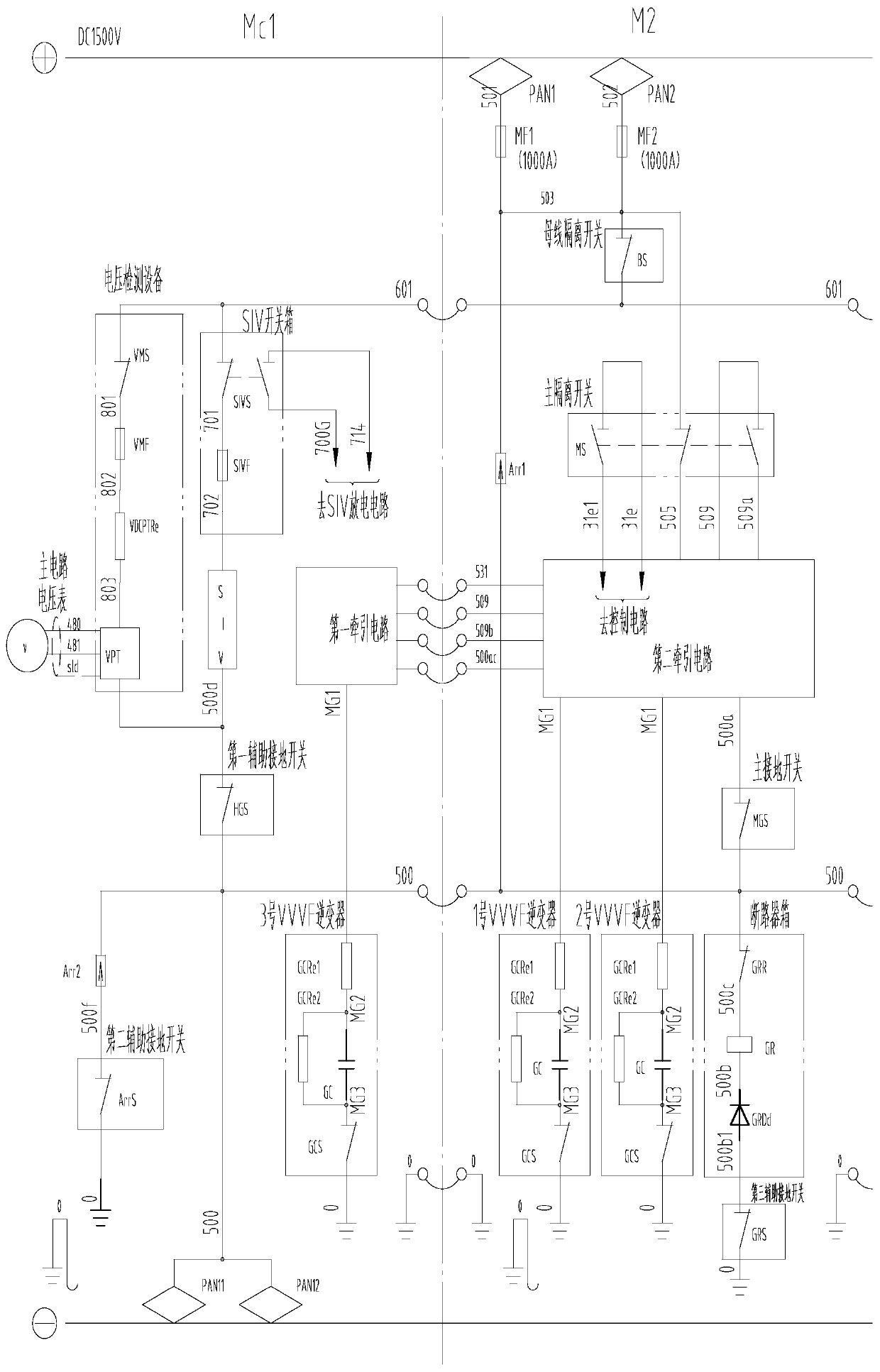

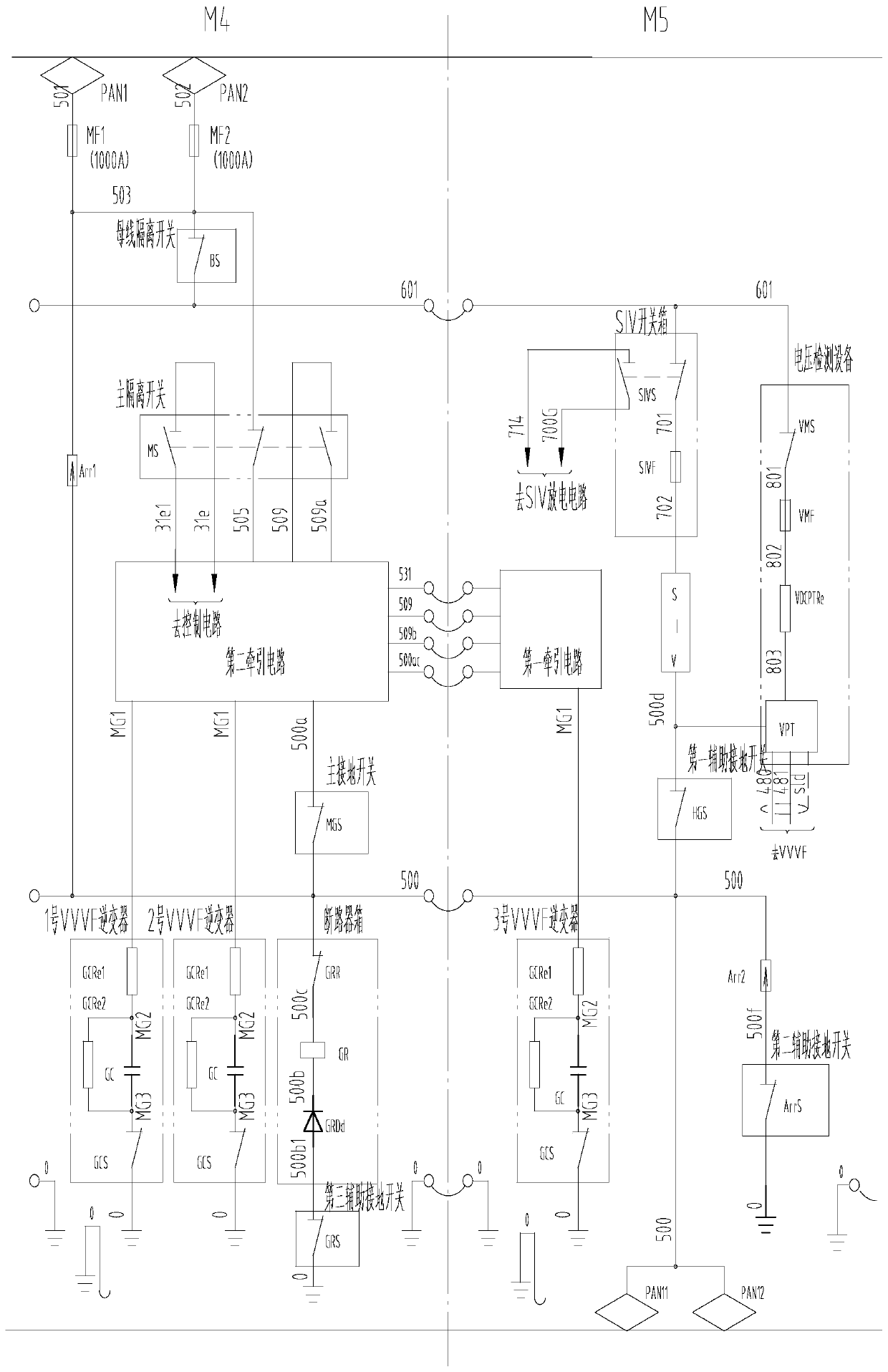

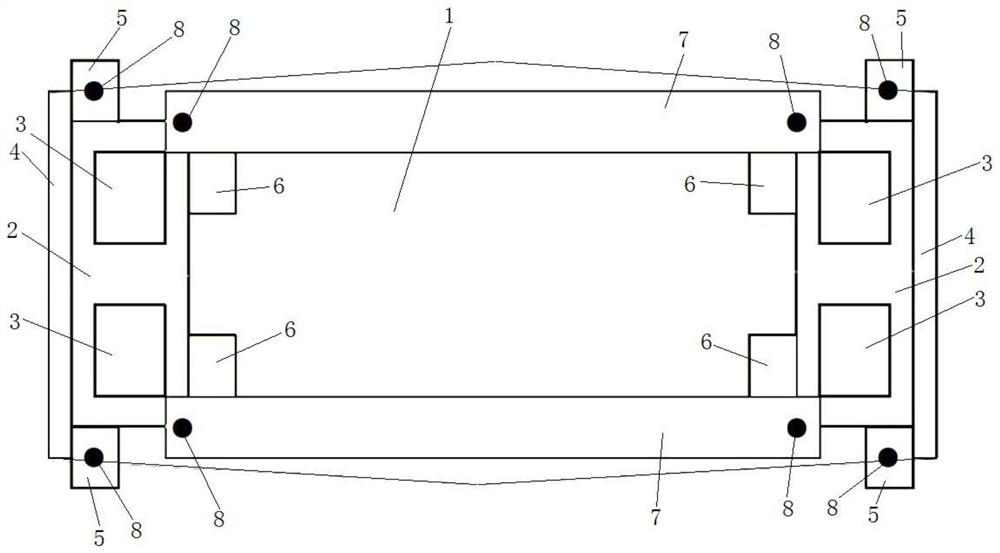

Straddle type monorail vehicle control circuit and straddle type monorail vehicle

ActiveCN110901398AAchieve self-helpEffective rescue capabilityMonorailsElectric devicesMonorailControl theory

The invention provides a straddle type monorail vehicle control circuit and a straddle type monorail vehicle. The straddle type monorail vehicle control circuit comprises a first marshalling vehicle circuit, a second marshalling vehicle circuit and a power supply control circuit. The first marshalling vehicle circuit and the second marshalling vehicle circuit are two mutually independent high-voltage circuits; when one of the first marshalling vehicle circuit and the second marshalling vehicle circuit breaks down, disconnection of high voltage of the marshalling vehicle circuit which breaks down is controlled and achieved through the power supply control circuit, and the marshalling vehicle circuit which does not break down provides high voltage. Through the above scheme, the first marshalling vehicle circuit and the second marshalling vehicle circuit are two mutually independent high-voltage circuits. When one of the circuits breaks down, the circuit of the marshalling vehicle which breaks down can be isolated, the circuit of the marshalling vehicle which does not break down can still operate normally, self-rescue of the vehicle is achieved, more effective rescue capacity and a more flexible rescue mode are achieved, and vehicle rescue is completed in the mode that the influence on operation is minimum.

Owner:CHONGQING CRRC RAILWAY VEHICLES CO LTD

Construction method for replacing disc type support with rail transit plate type support

ActiveCN111827138AOperational impact is smallTime to balance operationsBridge structural detailsBridge erection/assemblyArchitectural engineeringRail transit

The invention discloses a construction method for replacing a disc type support with a rail transit plate type support. The construction method sequentially comprises a preparation stage, a first jacking stage, a padstone replacement stage and a second jacking stage. The preparation stage and the padstone replacement stage complete construction in a non-skylight point, and the first jacking stageand the second jacking stage complete construction in a skylight point; the first jacking stage and the second jacking stage each comprise the steps of upper constraint force relieving, overall jacking, upper constraint force recovering, data collecting after jacking and jacking system disassembling and maintaining; and in the first jacking stage, a plate type support is taken out during overall jacking, and in the second jacking stage, a disc type support is installed during overall jacking. According to the construction method, the support is replaced in the mode of ''not interrupting traffic, longitudinally dividing piers and transversely and synchronously jacking beam bodies'', train skylight points and non-skylight points are fully utilized for construction, and an influence on existing rail line operation is small.

Owner:武汉比邻工程技术有限公司

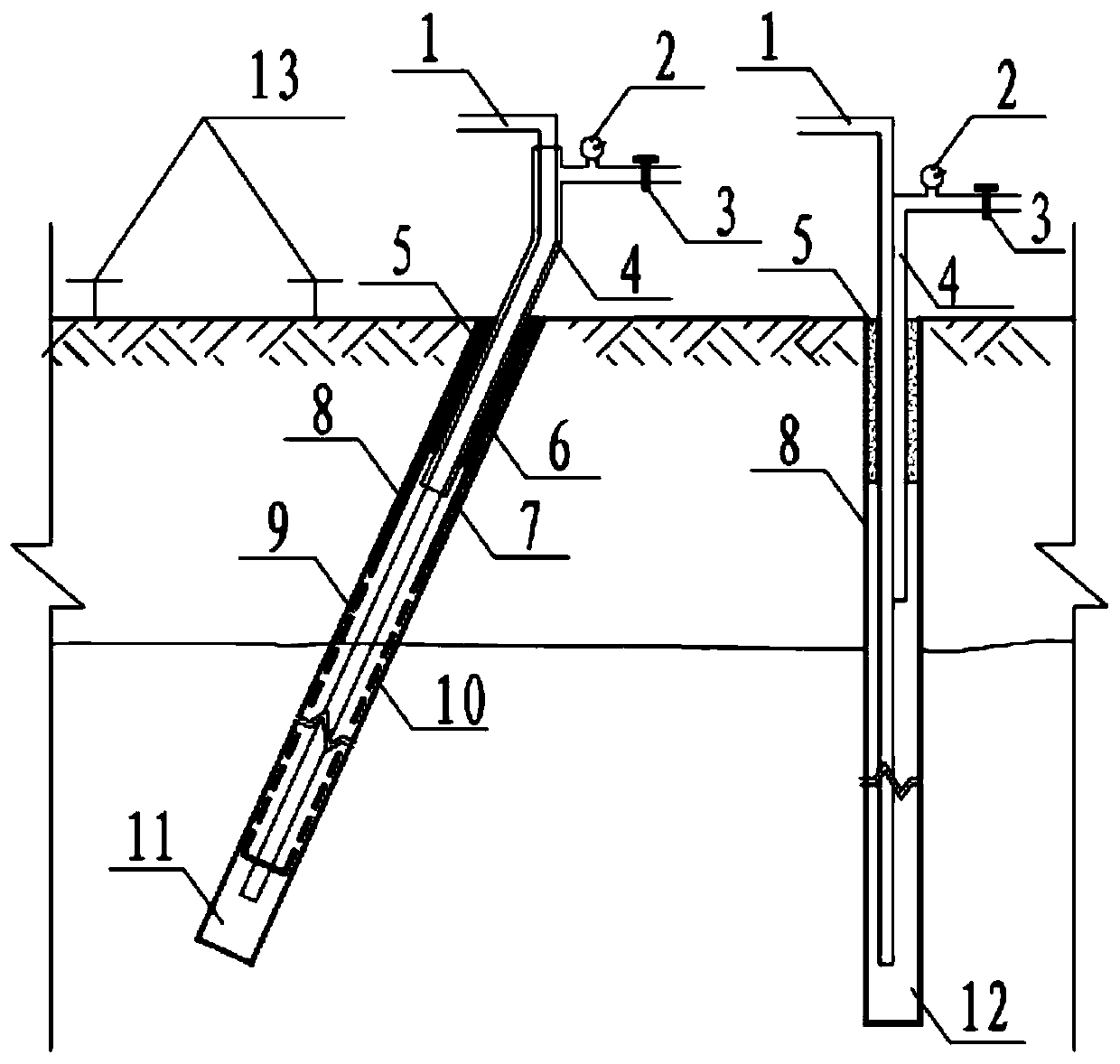

Roadbed karst collapse comprehensive renovation method

InactiveCN111501424AOperational impact is smallPrevent collapseFoundation engineeringTrack maintainenceKarstPressure grouting

The invention discloses a roadbed karst collapse comprehensive renovation method which comprises the following steps: 1, geology in a line range is explored, and karst development conditions are determined in combination with drilling coring and a pressurized-water test; 2, inclined holes and straight holes are drilled in the karst section, the inclined holes are formed in one row on each side ofthe line and obliquely drilled towards the center of the line, and the straight holes are formed in two rows on each side of the line and located in the outer sides of the inclined holes; 3, after drilling is completed, grouting pipes and grout return pipes are arranged for the inclined holes and the straight holes, and hole sealing is conducted; and 4, conducting pressure grouting on the inclinedholes and the straight holes. According to the method, soil cracks and karst caves under the roadbed surface are filled through inclined hole grouting, and roadbed surface collapse under the action of train loads is prevented; the problem of subgrade surface collapse caused by soil body fine material loss due to dynamic water change is solved through straight hole waterproof curtain grouting, thesubgrade karst treatment effect is remarkable, the construction cost is low, the period is short, and the influence on existing railway operation is small.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

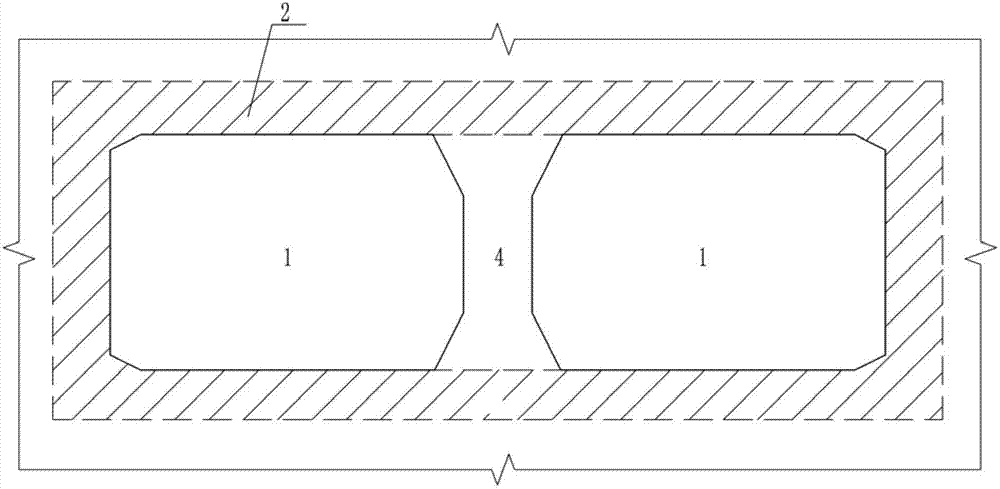

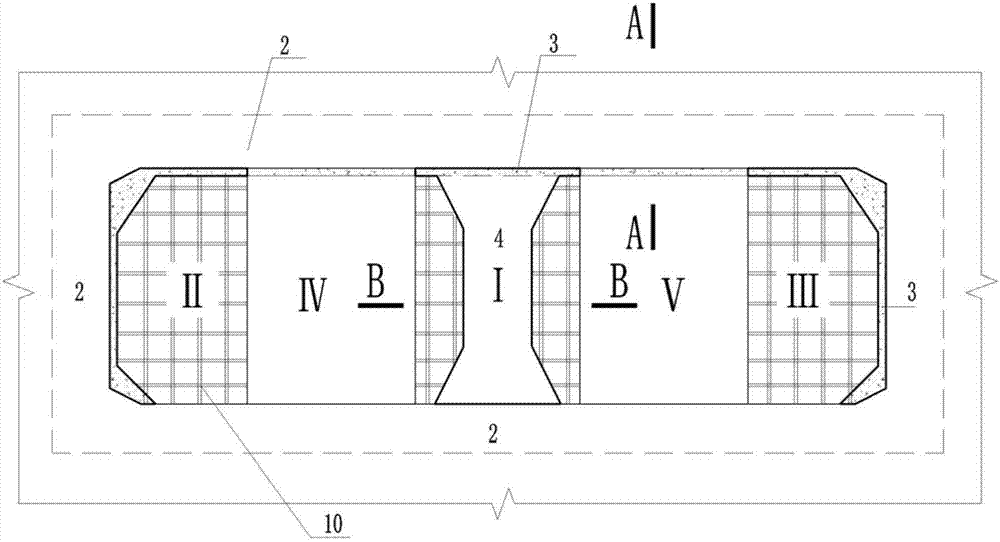

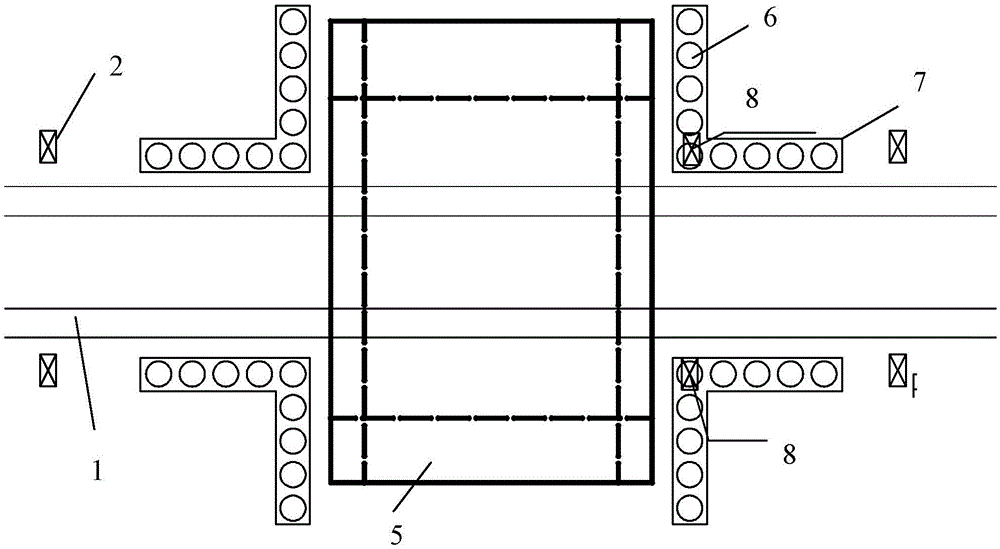

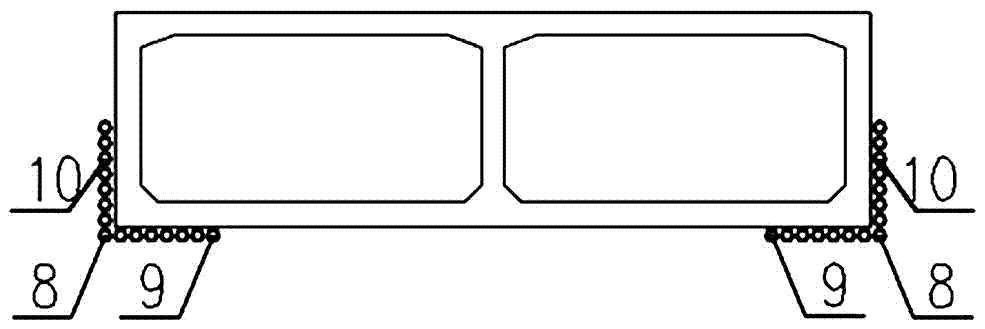

Double-L type pipe-roofing structure control box bridge jacking method

ActiveCN105714686APlay a guiding roleIncrease stiffnessArtificial islandsBridge erection/assemblyEngineeringRailway line

The invention provides a double-L type pipe-roofing structure control box bridge jacking method. Firstly, L type pipe roofs at two sides are jacked, and secondly, a box bridge is jacked, so that a formed double-L type pipe roof is slidden in a slideway space, the jacking operation can be safely and accurately finished, and the technical problem that the operation of existed railway lines is not smooth due to the larger buncning tip phenomenon easily caused by a soft soil foundation during the jacking operation and larger side skylights at two sides of the box bridge during jacking existed in the prior art is solved.

Owner:SHENYANG RAILWAY SURVEY DESIGN CONSULTING CO LTD

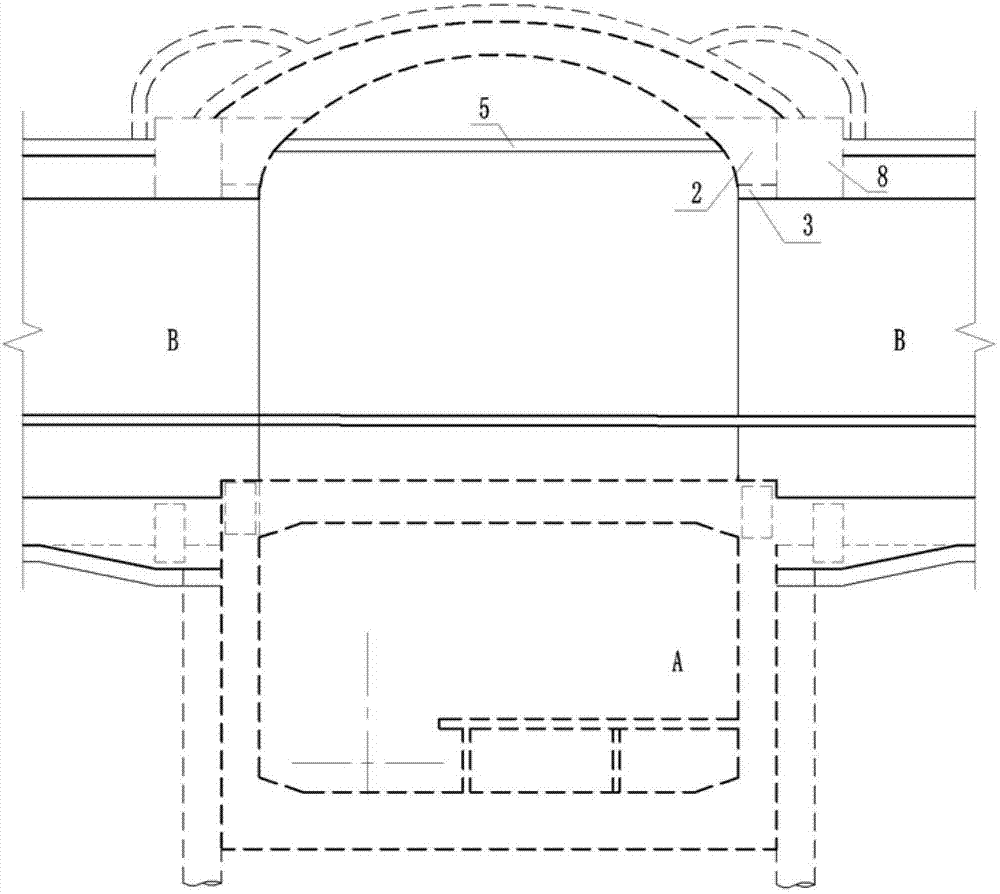

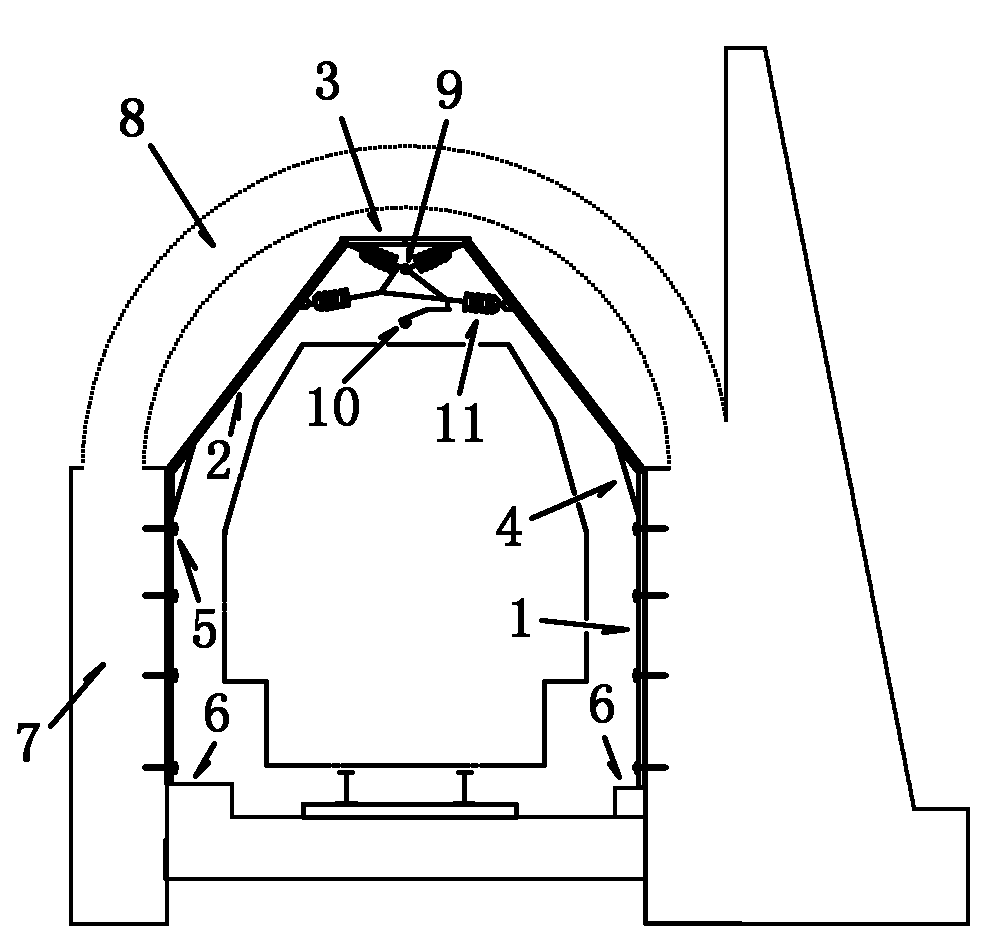

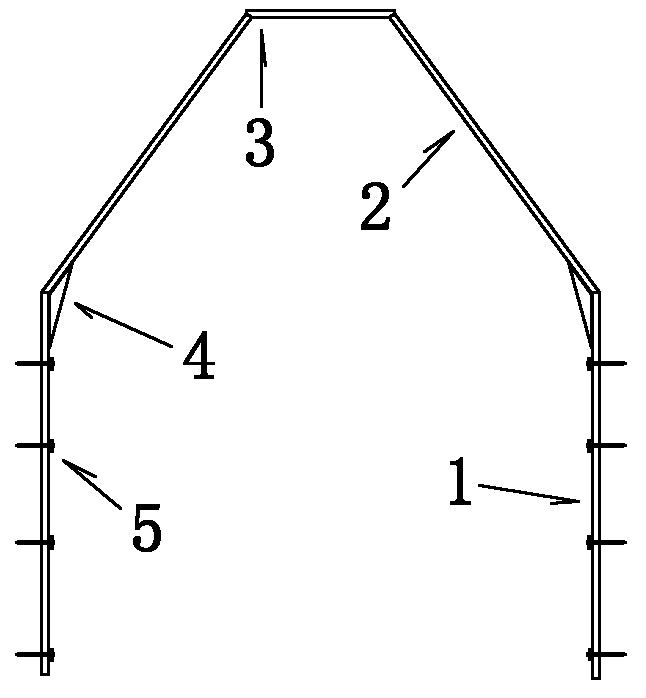

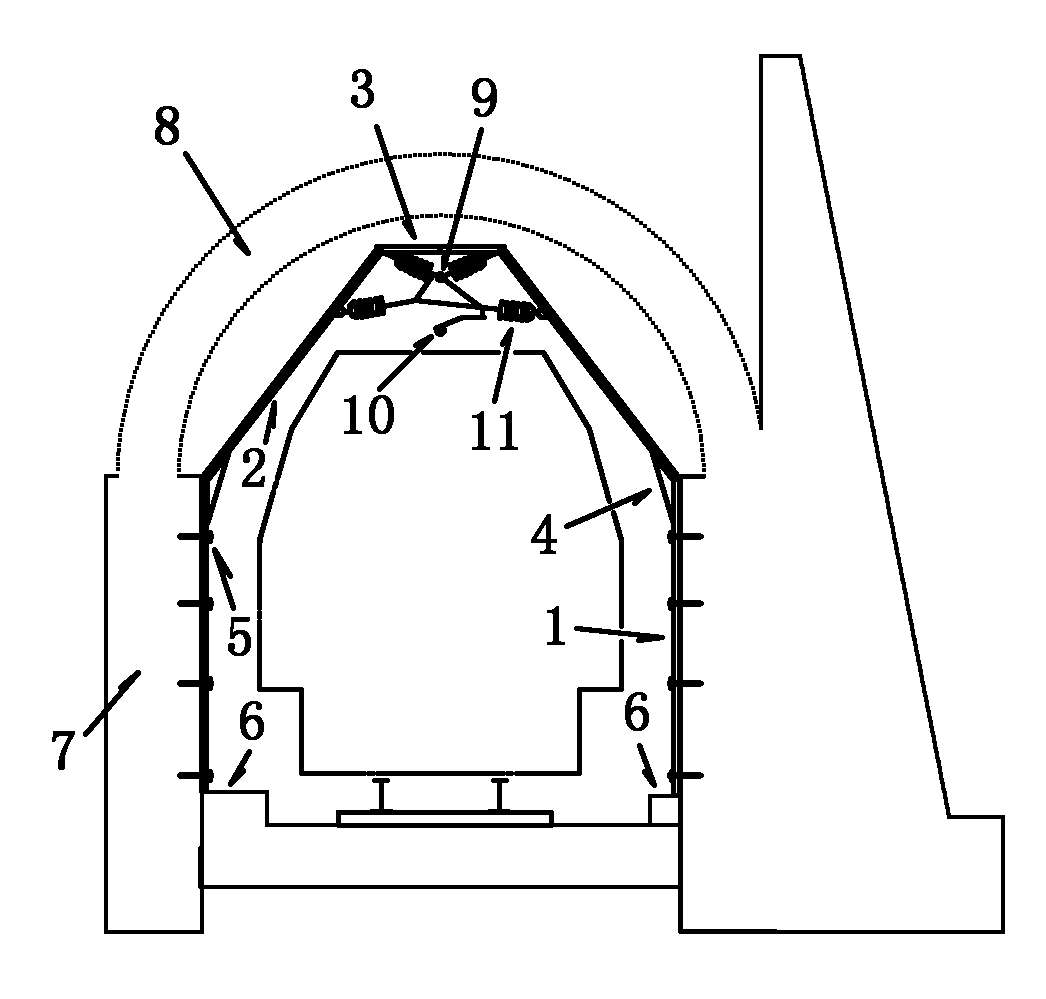

Arched subway station old and new building connection structure and construction method

ActiveCN102943678BIncrease stiffnessConstrained deformationUnderground chambersCompound (substance)Subway station

The invention relates to an arched subway station old and new building connection structure and a construction method. A profile steel pull rod is made of profile steel and divided into two sections which are connected, and a gap is reserved in the middle of the profile steel pull rod and is provided with a bolt fastening mechanism. A plurality of groups of chemical screws are oppositely arranged on the inner side of a bottom girder of an arched ceiling arranged in the range of an opening disposed on the lateral wall of an existing station, a plurality of profile steel pull rods with two ends respectively fixedly provided with wedge-shaped steel plates are fixedly connected with the corresponding chemical screws through the wedge-shaped steel plates, and the profile steel pull rods are connected between the bottom girders arranged on two sides of the arched ceilings and are fixed. The construction method is characterized in that firstly the profile steel pull rods are adopted to exert tensioning force on arched angle portions in advance, then a newly built structure is adopted to reinforce the supporting ceilings, and finally the old structure is demounted in segmented mode. Operation is easy, construction procedure is simple, and control on deformation and internal force conversion of the existing structure is benefited.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

Method of transferring contact suspension for additionally building open-cut tunnel on electrified railway operating line

ActiveCN102139650AShort block timeNormal operation is smallTrolley linesSteel tubeRailway electrification system

The invention relates to a method of transferring a contact suspension for additionally building an open-cut tunnel on an electrified railway operating line. The method includes the steps of: building a section of open-cut tunnel foundation and two pieces of sidewalls close to a to-be-dismantled contact network supporting column; then vertically arranging an arch-shaped steel pipe bracket between the two sidewalls; transferring a contact suspension on the contact network supporting column onto the steel pipe bracket; constructing a whole open-cut tunnel after dismantling the contact network supporting column; and finally transferring the contact suspension onto an arch buttress bracket and dismantling the steel pipe bracket, etc. In the method provided by the invention, the arch-shaped steel pipe bracket as the device for transferring the contact suspension is vertically arranged in the open-cut tunnel under construction, in this way, not only the contradiction occurred due to the traditional contact network supporting column occupying the building site of an open-cut tunnel can be solved, but also the time for locking out a railway line is shortened maximally, so that the influence on the normal operation of electric locomotives is minimum, and at the same time, the construction of an arch ring of the open-cut tunnel can be continued. In addition, the safety of constructors is guaranteed due to a grounding wire laid on the steel pipe bracket.

Owner:CHINA CIVIL ENG CONSTR CORP

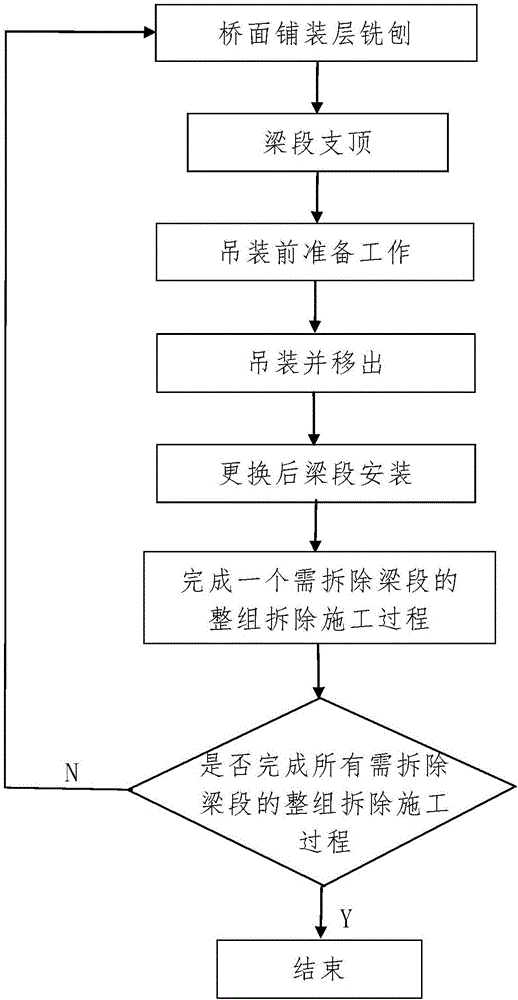

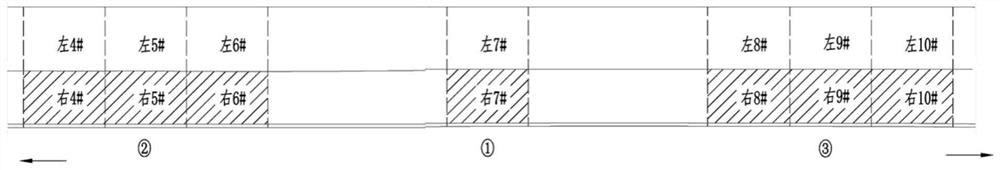

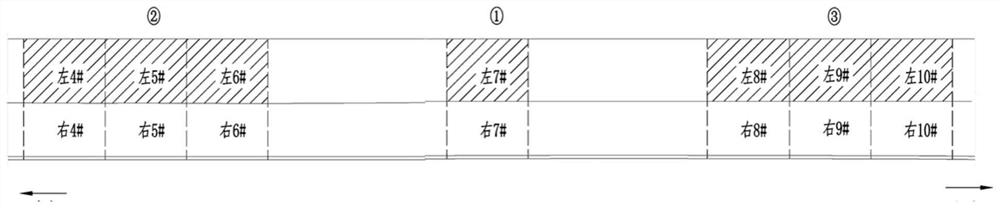

Demolition construction method for bridge superstructure

InactiveCN111979935AReasonably quick to dismantleReduce the impactBuilding repairsBridge strengtheningT-beamArchitectural engineering

The invention discloses a demolition construction method for a bridge superstructure. The demolition construction method mainly comprises the steps of demolition preparation, construction safety enclosure, demolition of a bridge deck crash barrier, demolition of a bridge deck, demolition of a beam plate and site clearing, wherein the demolition of the beam plate comprises main span full-suspendedbeam demolition operation and semi-suspended beam and T beam demolition operation; and the main span full-suspended beam demolition operation and the semi-suspended beam and T beam demolition operation each comprise the steps of removing longitudinal and transverse connection, taking a beam, lowering the beam and transporting the beam. The demolition construction method is basically opposite to the installation process of a bridge, and is convenient to master and implement; and under the conditions that the construction boundary is limited and mechanical equipment and construction conditions do not exist, the construction method is adopted for solving the problem of integral demolition of a beam body, is small in operation influence, ensures the construction safety, and has certain popularization significance.

Owner:武汉比邻工程技术有限公司

Method for changing and transferring catenary rods

ActiveCN106274556AImprove rigidityImprove stabilityTrolley linesTowersEngineeringStructural engineering

The invention relates to a method for changing and transferring catenary rods. The method comprises the following steps of before a frame bridge is jacked, planting lower end parts of steel truss headspan suspension catenary rods into the corners of a top beam; temporarily connecting a guy wire to the tops of the two steel truss headspan suspension catenary rods corresponding to two sides of a railway line; transferring a catenary high-voltage line located on the frame bridge to the guy wire and disassembling the catenary rods; 4) recovering the operation of the railway line, and performing the jacking of the frame bridge by a conventional jacking method; disassembling the steel truss headspan suspension catenary rods from protecting piles and the top beam, hoisting the disassembled steel truss headspan suspension catenary rods to the frame bridge, and assembling the lower ends of the steel truss headspan suspension catenary rods to an anchoring bracket base together; and finally mounting supporting rods on the upper ends of the steel truss headspan suspension catenary rods and arranging the catenary high-voltage line on the supporting rods. The method disclosed by the invention has the effects that the stability is good; the construction is simple and convenient; the complexity and the danger of changing and transferring the catenary rods can be reduced; the influence on the normal operation of a railway can be reduced to minimum, and the cost is reduced; and the problem that the frame bridge in a long span cannot cross the railway is solved, and the technology is advanced.

Owner:CHINA RAILWAY SIXTH GRP TIANJIN RAILWAY CONSTR +1

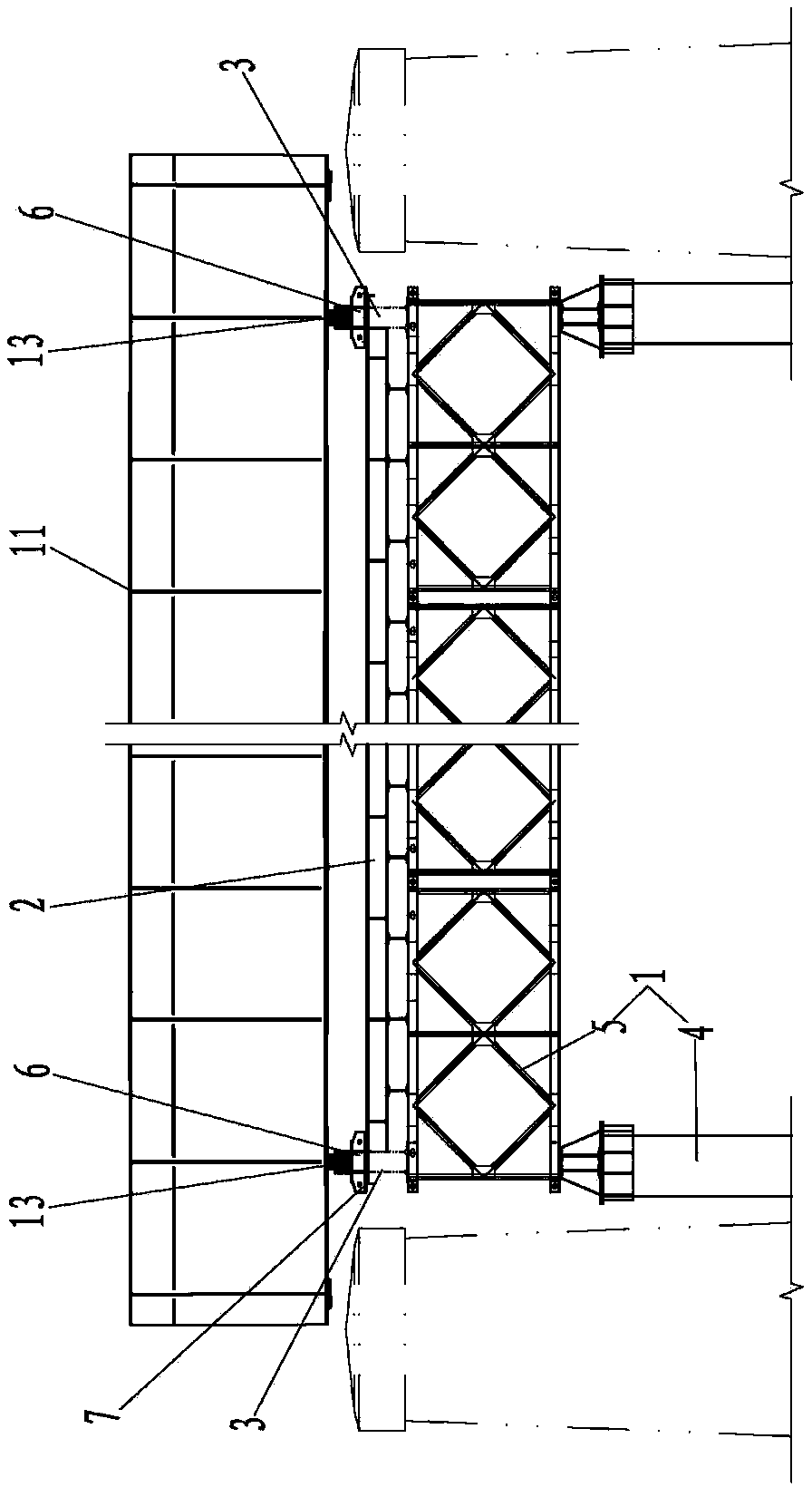

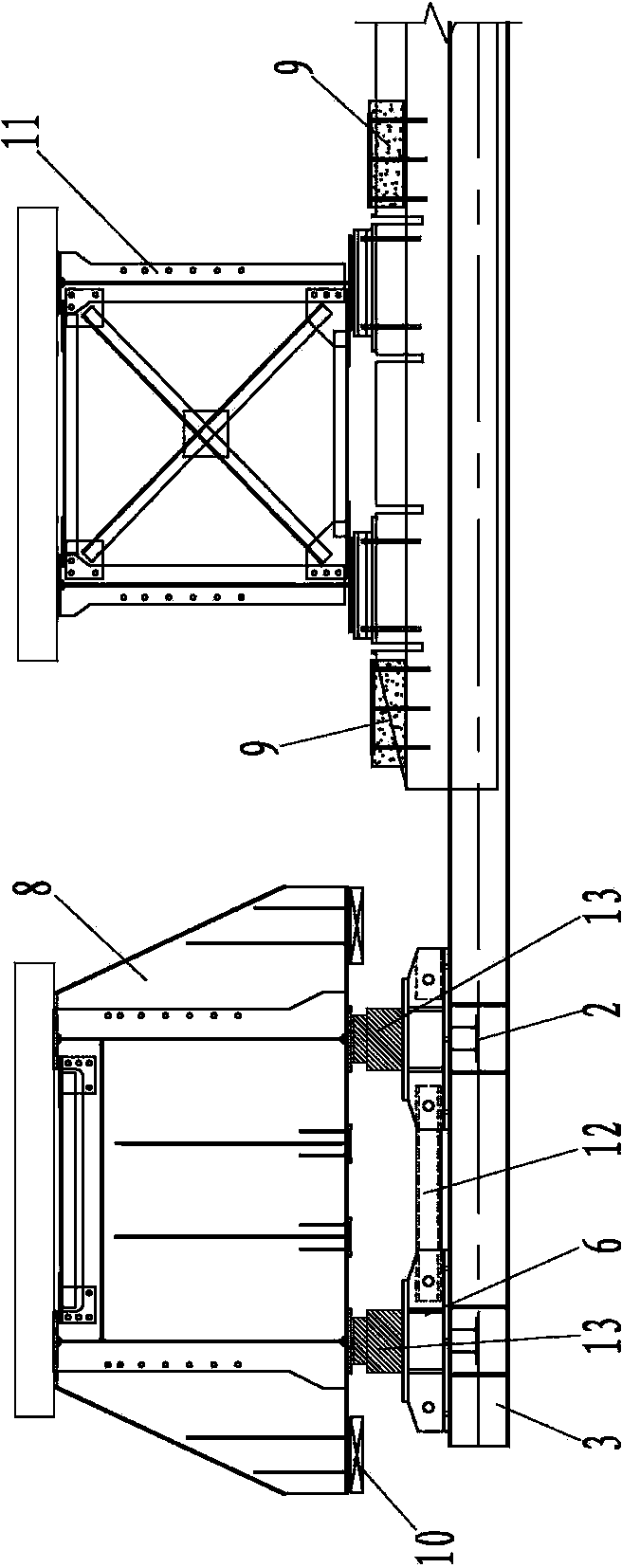

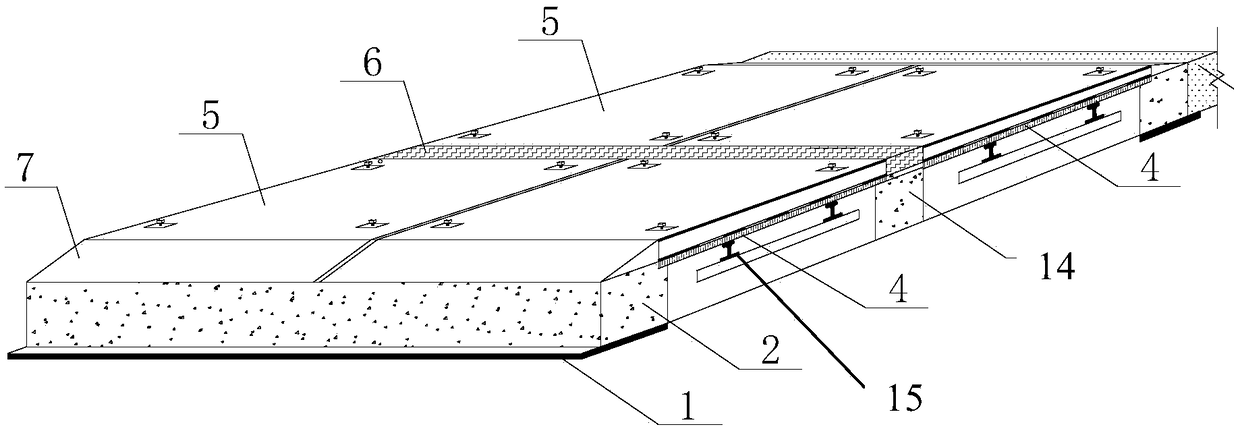

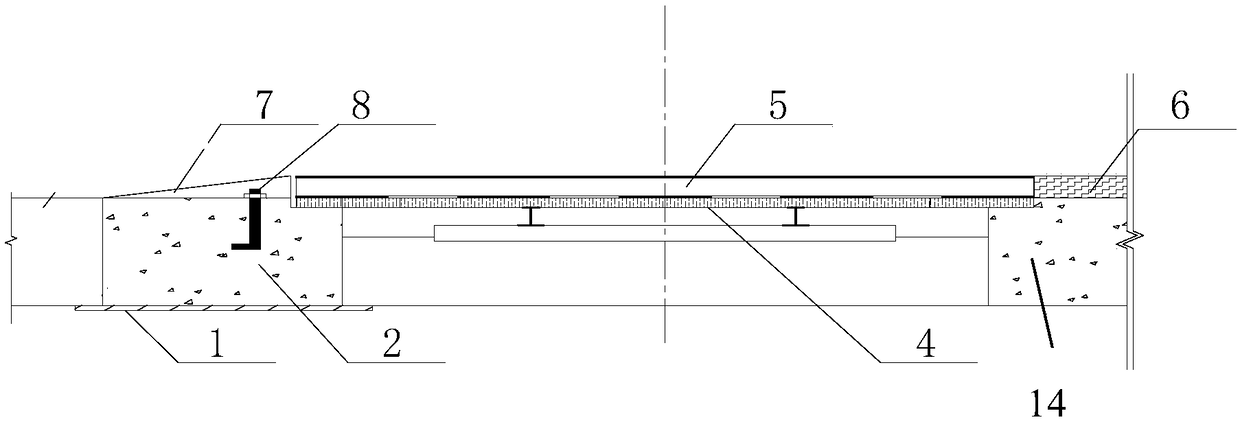

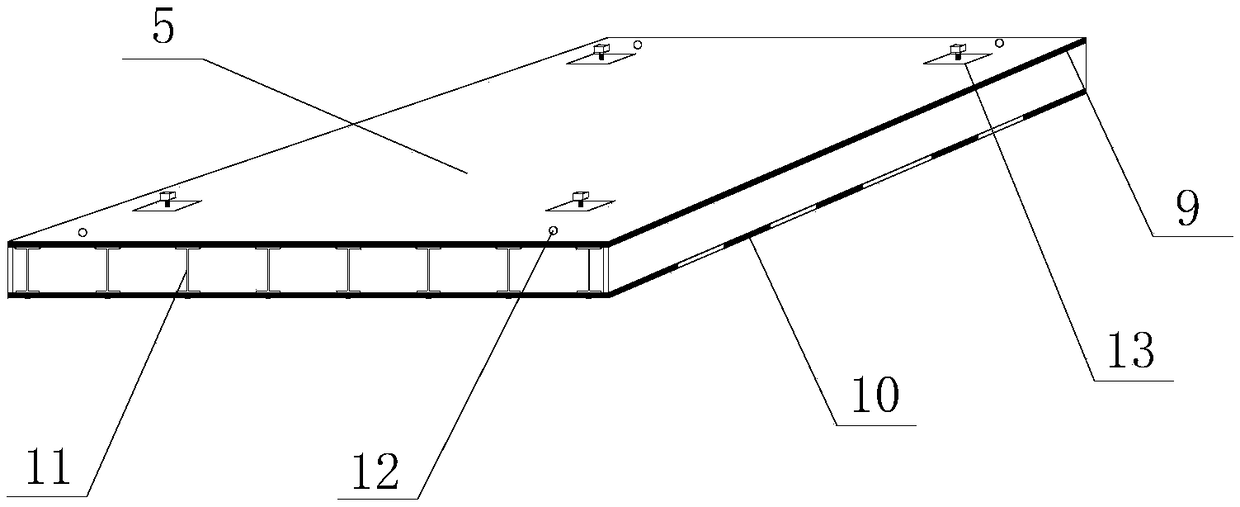

A construction method for transporting beams through railway transition

ActiveCN107604823BOperational impact is smallEnsure transportation safetyBridge erection/assemblyAbutmentShore

The invention relates to a construction method of beam transportation through the transiting of a railway. The construction method comprises the following steps of prefabricating a steel platform; paving protecting steel plates; casting a concrete temporary abutment wall; subsequently connecting beam transportation roads on two sides; paving a square timber wood panel structure; emplacing the traction of the steel platform; paving sleeper piers in gaps of the platform, and placing bevel steel shores at two ends; enabling a beam transportation vehicle to pass through the steel platform; disassembling the steel platform; disassembling the sleeper and the bevel steel shores; disassembling the square timber board; disassembling the concrete temporary abutment wall; disassembling the protectingsteel plates; restoring lines and the like. According to the construction method of the beam transportation through the transiting of the railway disclosed by the invention, the difficult problem that during the construction of a city bridge, a beam transportation vehicle can safely and quickly pass through a conventional railway when the influence of the operation of the conventional railway isreduced. The construction method disclosed by the invention adopts a series of technical measures, so that the safety of tracks of the conventional railway and relative facilities in the whole construction process is guaranteed; the transportation safety of the beam transportation vehicle is guaranteed; the construction risk is reduced; the investment cost is saved; and the beam transportation efficiency is improved.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

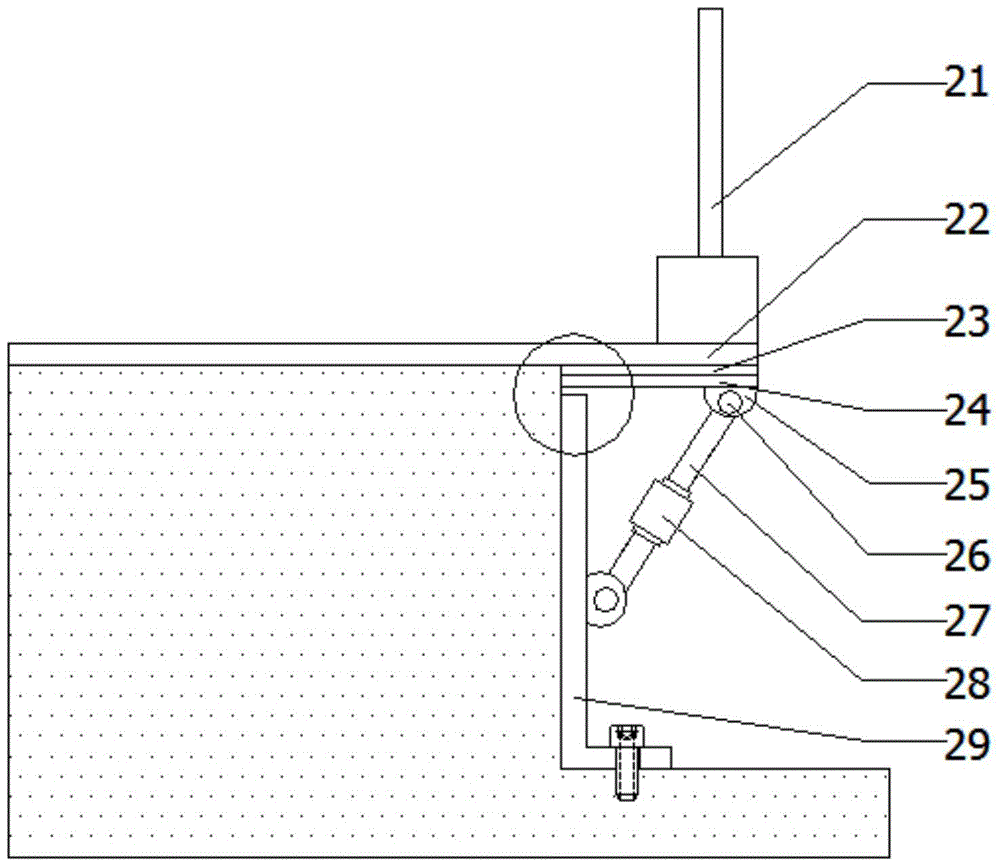

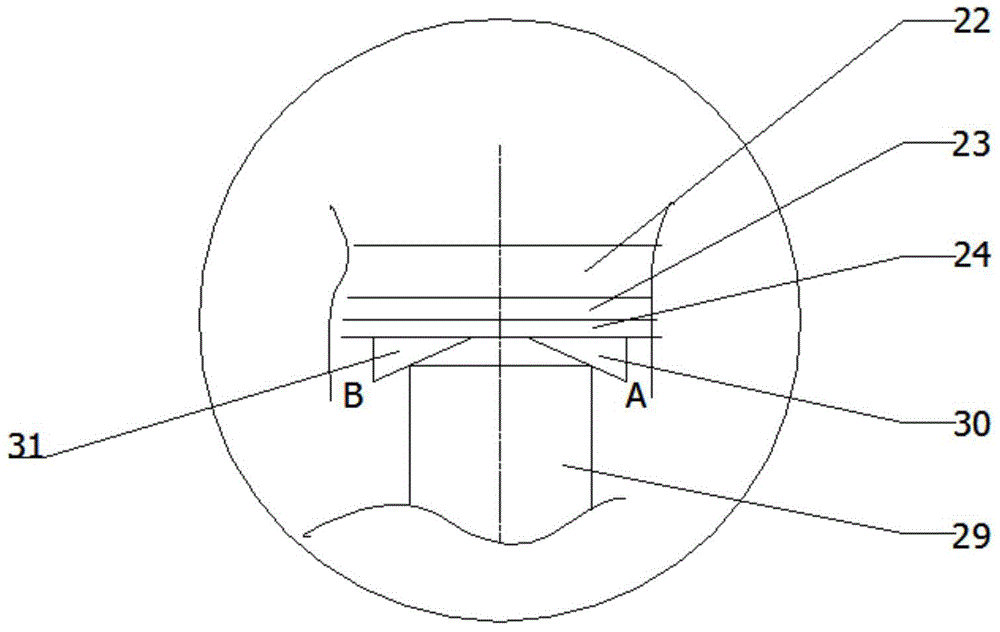

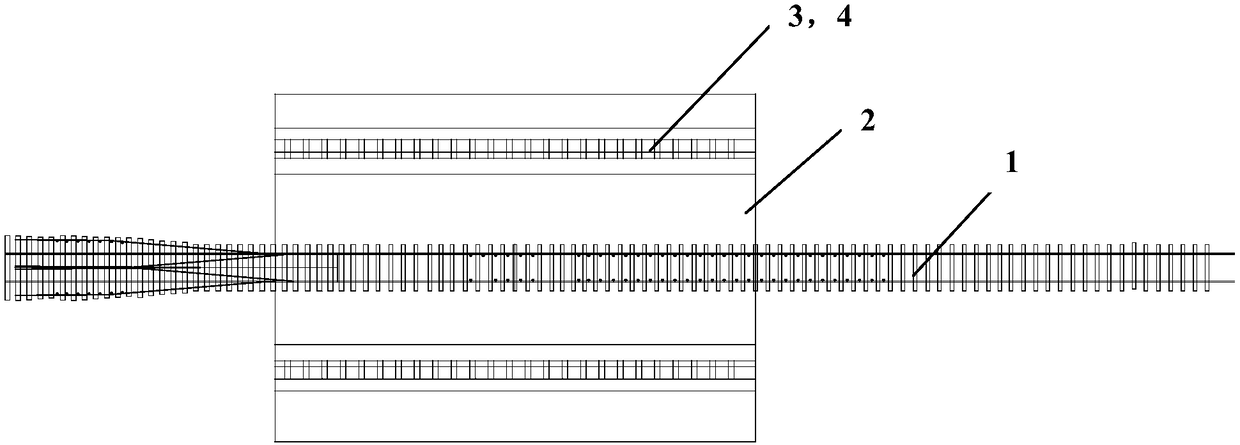

A two-way adjustment device for the deformation of the subgrade bed of a ballastless track high-speed railway, its use method and its construction method

ActiveCN111560798BLittle operational disruptionSave remediation and maintenance costsBallastwaySoil preservationTrackwayArchitectural engineering

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

A construction method for jacking the box under the hump line

ActiveCN107447672BOperational impact is smallShorten the timeArtificial islandsBridge erection/assemblyRebarRetaining wall

Owner:CHINA RAILWAY SIXTH GRP TIANJIN RAILWAY CONSTR +1

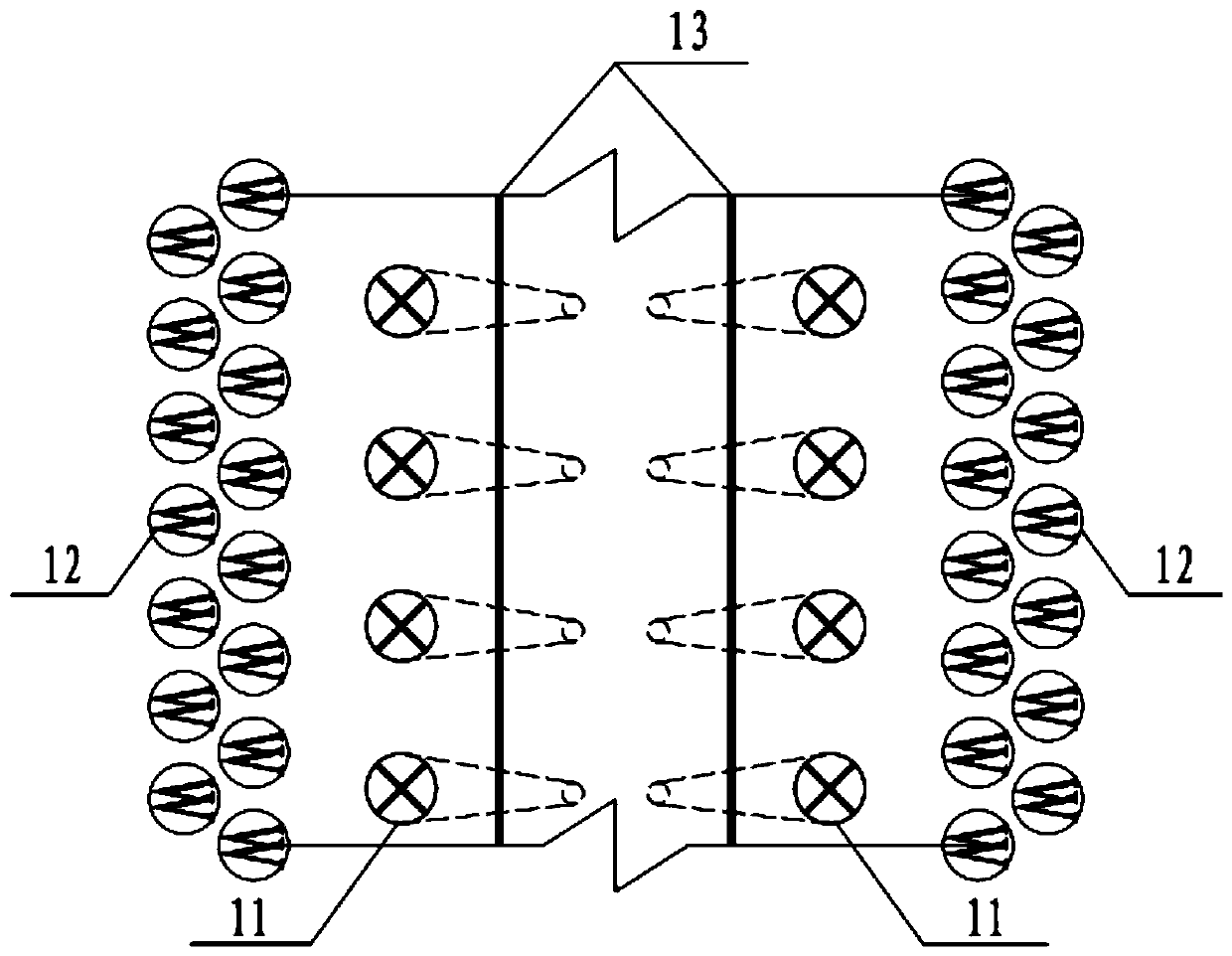

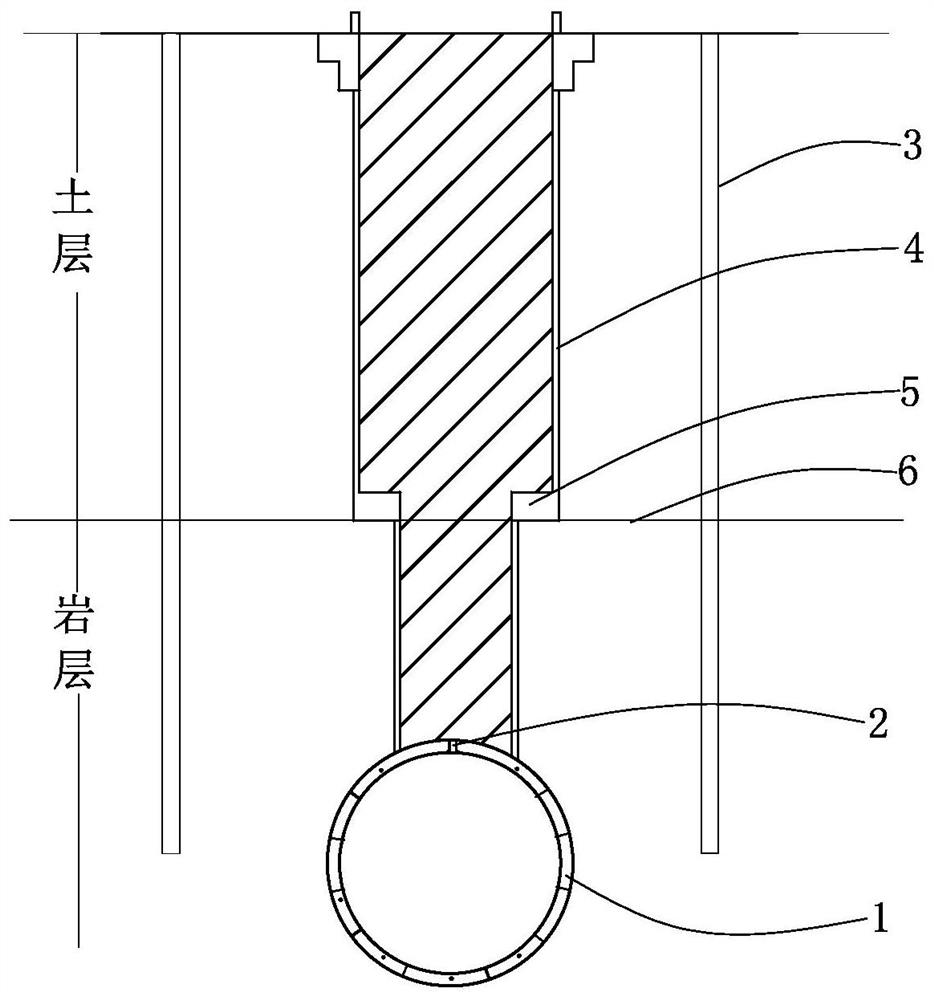

Method for repairing rock stratum shield subway tunnel after accidental breakdown

ActiveCN113605929ARelieve stressOperational impact is smallUnderground chambersHydro energy generationPartial gravityRebar

The invention relates to a method for repairing a rock stratum shield subway tunnel after accidental breakdown. The method adopts a mode of combining a dewatering well and a vertical shaft, the vertical shaft is excavated outside a tunnel to a breakdown point, rebars and concrete of tunnel segments are repaired, the repairing effect is good, and the influence on subway operation in the tunnel can be minimized. The inner diameter of the part, in the upper soil layer, of the vertical shaft is larger than that of the part in the lower rock layer, a backfill material is made of foam lightweight concrete, it is guaranteed that the whole backfill material is light, most gravity can be dispersed into the rock layer, the backfill material is prevented from generating too large pressure to the tunnel segments, and therefore the stress safety of the segment structures is guaranteed.

Owner:ROAD & BRIDGE INT +1

Jacking method of double l-shaped pipe curtain structure control frame bridge

ActiveCN105714686BPlay a guiding roleIncrease stiffnessArtificial islandsBridge erection/assemblyDouble tubeStructural engineering

The invention provides a double-L type pipe-roofing structure control box bridge jacking method. Firstly, L type pipe roofs at two sides are jacked, and secondly, a box bridge is jacked, so that a formed double-L type pipe roof is slidden in a slideway space, the jacking operation can be safely and accurately finished, and the technical problem that the operation of existed railway lines is not smooth due to the larger buncning tip phenomenon easily caused by a soft soil foundation during the jacking operation and larger side skylights at two sides of the box bridge during jacking existed in the prior art is solved.

Owner:SHENYANG RAILWAY SURVEY DESIGN CONSULTING CO LTD

Quick-beam change construction method for existing railway line of railroad

ActiveCN103410103BReduced impact on normal operationsNormal operation impact is minimizedBridge erection/assemblyBridge strengtheningEngineeringSunroof

Owner:WUHAN BRIDGE SPECIAL TECH CO LTD CHINA RAILWAY MAJOR BRIDGE ENG BUREAU

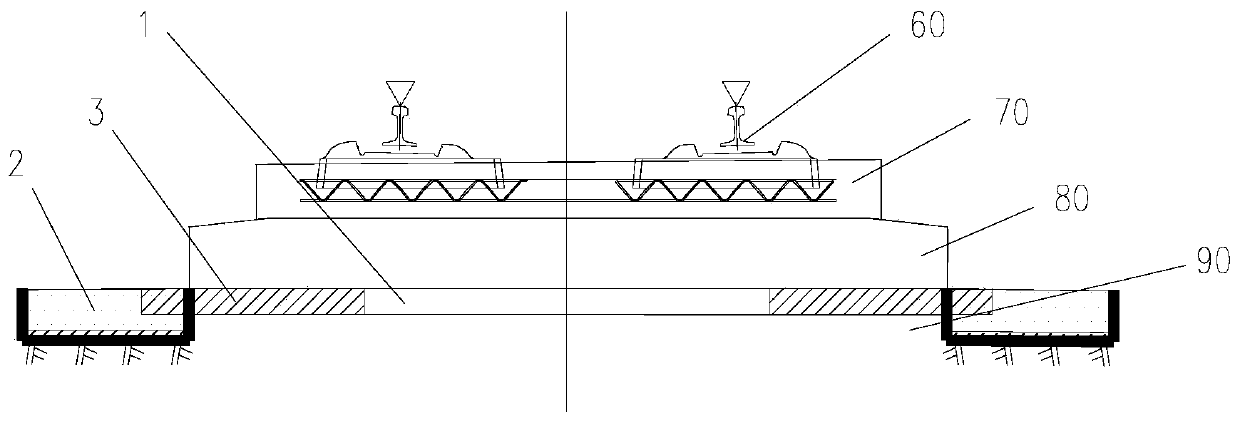

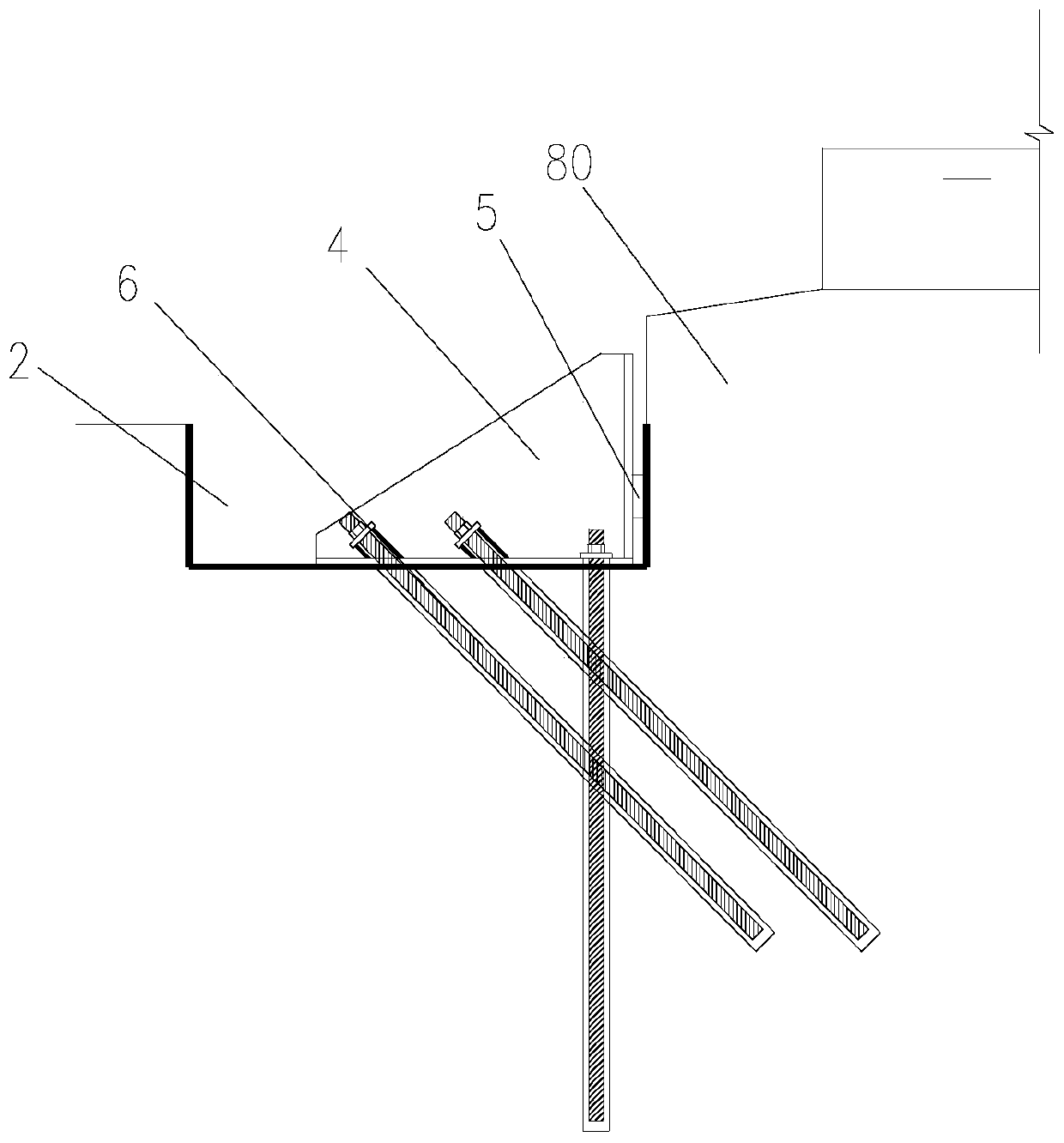

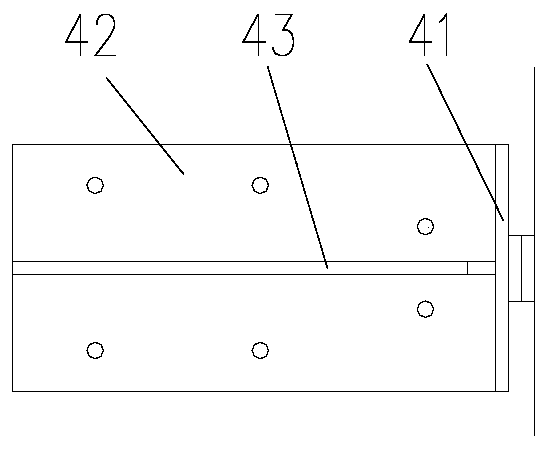

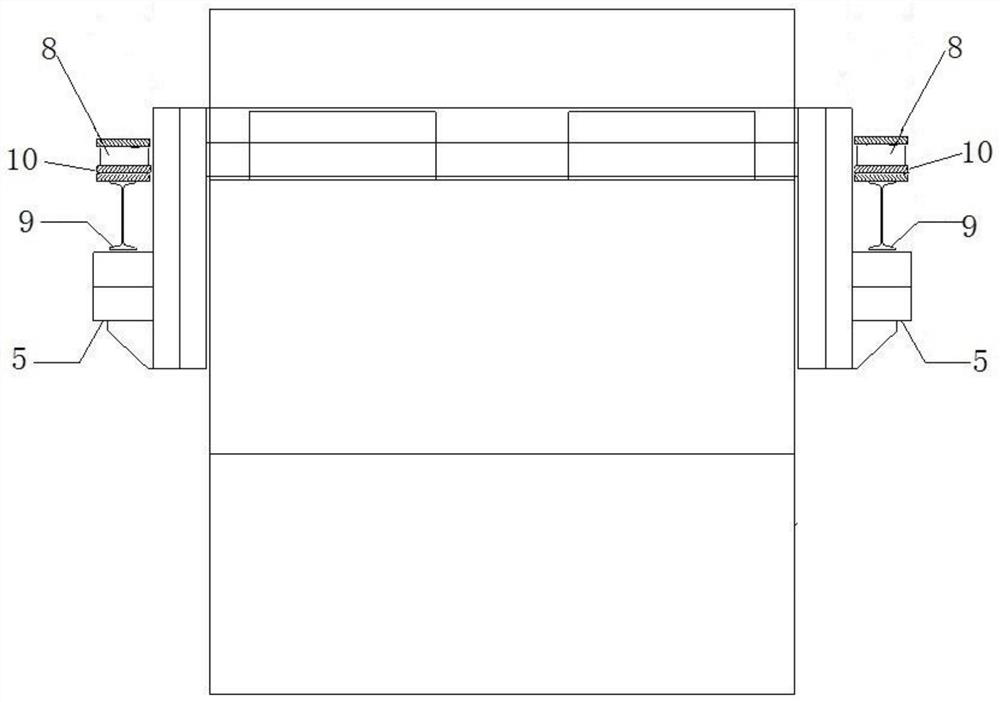

A swivel device and construction method of a small-span high-speed railway small-span bridge with a small angle

ActiveCN104328745BReduce construction difficultyLight weight structureBridge erection/assemblyBuilding constructionHinge angle

The invention discloses a rotating device of a small-span bridge across a high-speed rail at a small angle. The bridge comprises portal piers and a main beam, wherein the portal piers cross an existing railroad, the main beam is arranged on the portal piers along the length direction of the railroad, the portal piers comprise portal pier columns arranged on both sides of the existing railroad and cover beams arranged on the portal pier columns, and the portal piers are arranged in parallel at intervals along the length direction of the railroad. The rotating device is characterized by comprising a chute, a sliding way, a spherical hinge support seat and a pushing device, wherein the chute is formed in the lower surface of the main beam along the longitudinal direction of the main beam, the sliding way is formed in the upper surfaces of the cover beams and corresponds to the chute, and the pushing device is used for enabling the main beam to move along the sliding way. The invention further provides a construction method of the rotating device which utilizes the small-span bridge across the high-speed rail at the small angle. The construction method comprises the steps of constructing the portal pier columns and the cover beams, placing the main beam, horizontally pushing the main beam, rotating the main beam and removing equipment. Stable rotation of the small-span bridge in the process of rotation can be realized, the construction difficulty is less, the construction time is short, the existing railroad is not influenced, and the total construction cost is reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

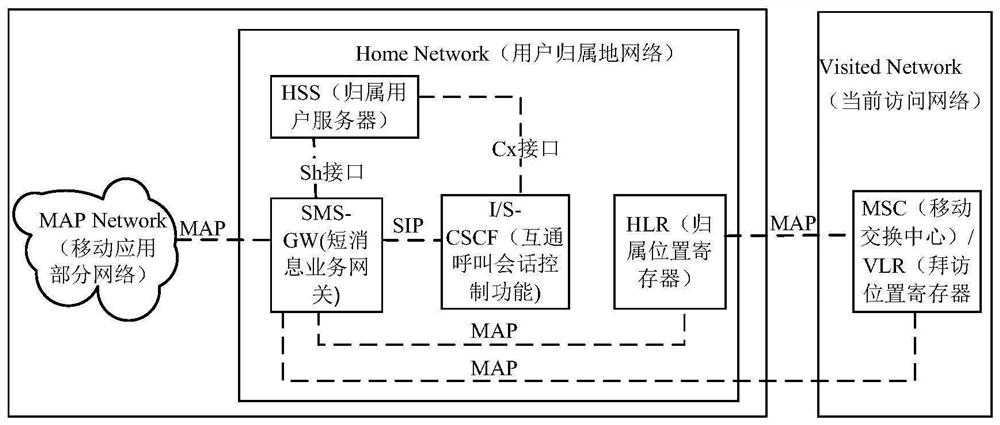

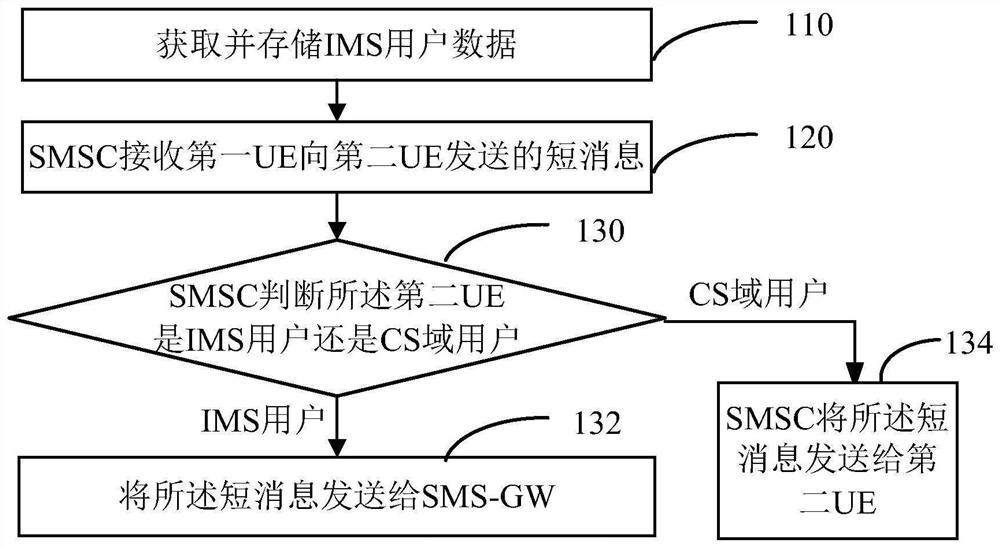

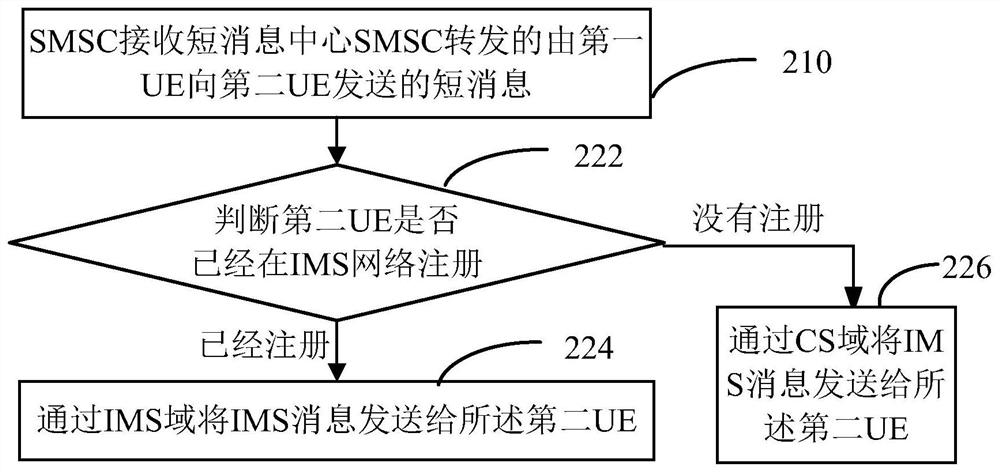

A short message transmission method, device, and system

ActiveCN106792585BOperational impact is smallSolving the Difficulties of Running Short Message ServiceMessaging/mailboxes/announcementsShort Message ServiceEngineering

Owner:ZTE CORP

A method of rectifying elevation disease of ballastless track subgrade

ActiveCN110258189BEasy to adjustSolve archingBallastwayTrack maintainenceTrackwayClassical mechanics

The present invention proposes a method for regulating the elevation disease of the ballastless track subgrade, including: step 1, obtaining the position and type of the track disease to determine the scope of treatment; step 2, within the scope of treatment, digging below the supporting layer Set the adjustment groove; Step 3, adjust the track to the target elevation; Step 4, pour into the adjustment groove to fill the adjustment groove, wherein, in step 2, vertically, the adjustment groove extends downward from the bottom of the supporting layer, and vertically, the adjustment groove Extending along the direction of track laying, laterally, the two sides of the adjustment groove are located outside the corresponding side walls of the supporting layer. This method is economical and can be constructed during the skylight time.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com