Method for treating ballastless track subgrade elevation defects

A ballastless track and track technology, applied in the direction of road, track, track maintenance, etc., can solve the problems of the subgrade soil material being susceptible to external action, limited adjustment ability, affecting railway operation, etc. Adjusting for highly controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

[0030] The application provides a method for controlling the elevation disease of the ballastless track subgrade.

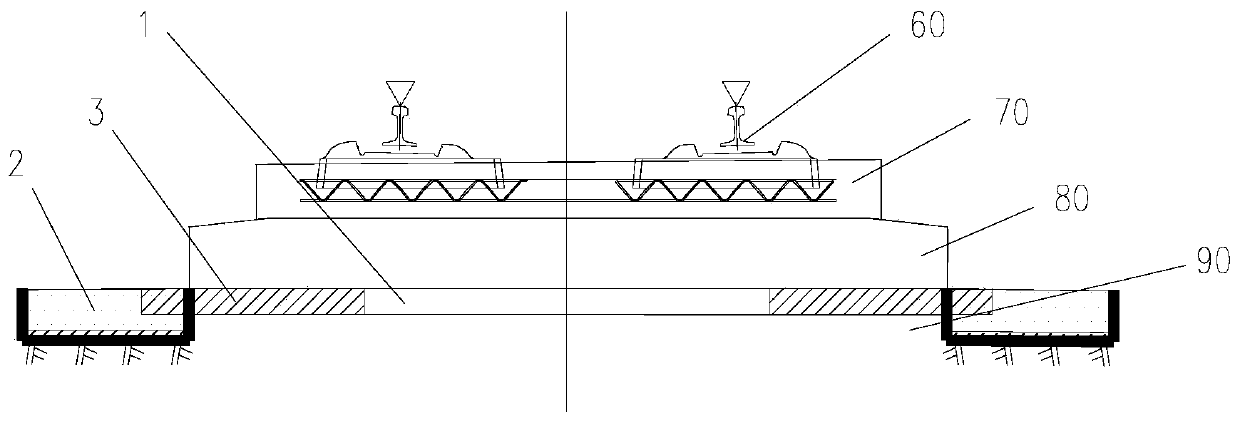

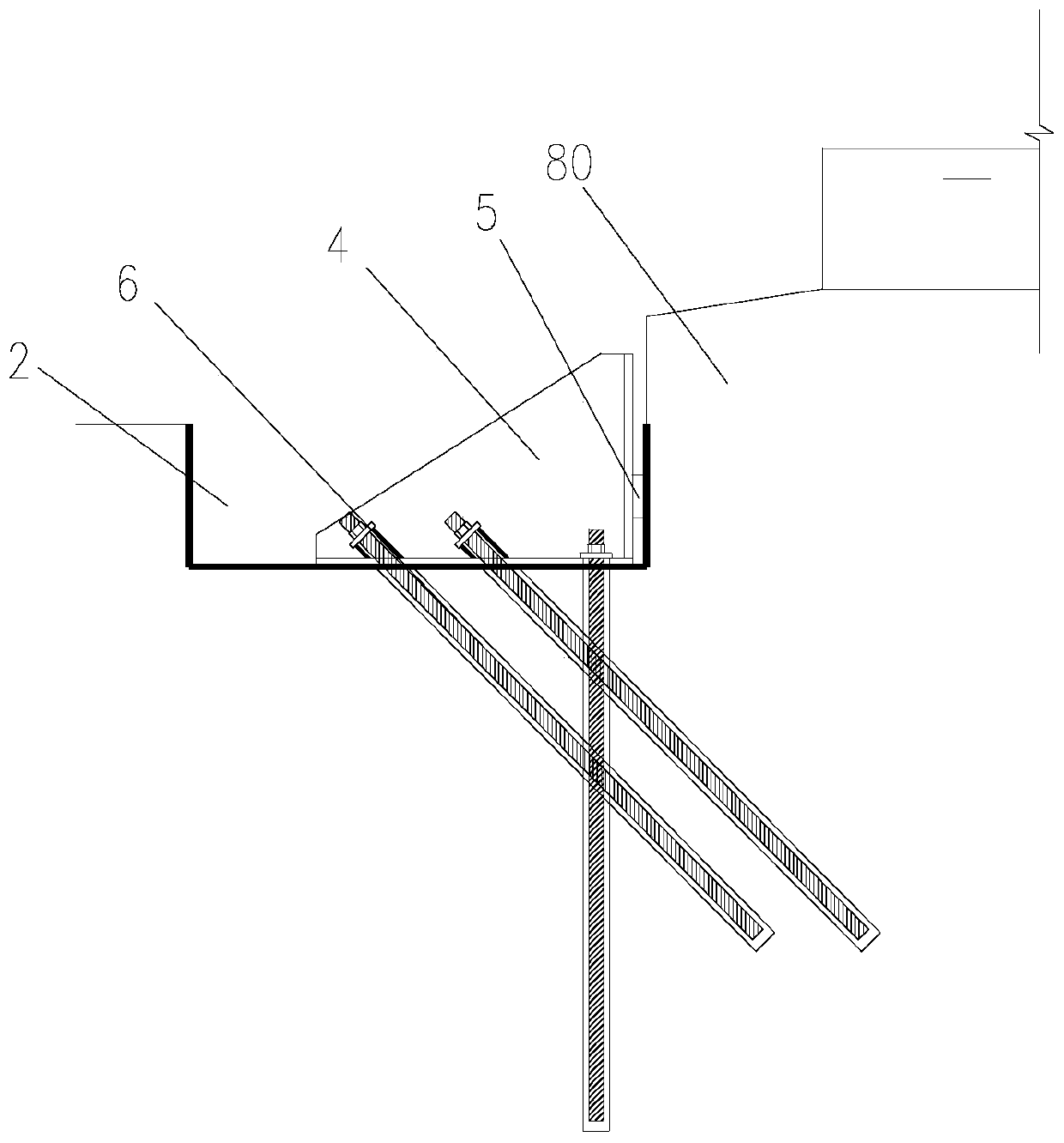

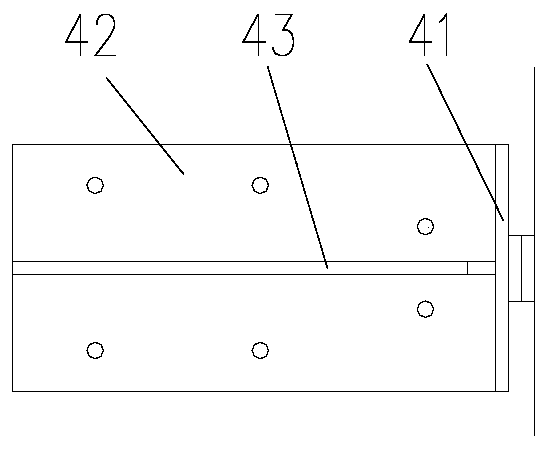

[0031] First of all, the location and type of the track 60 disease are obtained through track detection, so as to determine the scope of remediation and plan the remediation plan. Then, within the remediation range, an adjustment groove 1 is set under the support layer 80 by underground digging, such as figure 1 shown. Vertically, the adjusting groove 1 extends downward from the bottom surface of the supporting layer 80 (that is, the surface of the bed surface layer 90 ). In the longitudinal direction, the adjustment slot 1 extends along the laying direction of the rails 60 , and in the transverse direction, the two sides of the adjustment slot 1 are respectively located outside the side walls of the corresponding support layer 80 . Next, adjust the track 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com