Full-set dismantling and installing construction method of bridge overpassing existing line

A construction method and technology for existing lines, which are applied in the field of the entire group demolition and installation construction of upper-span existing bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

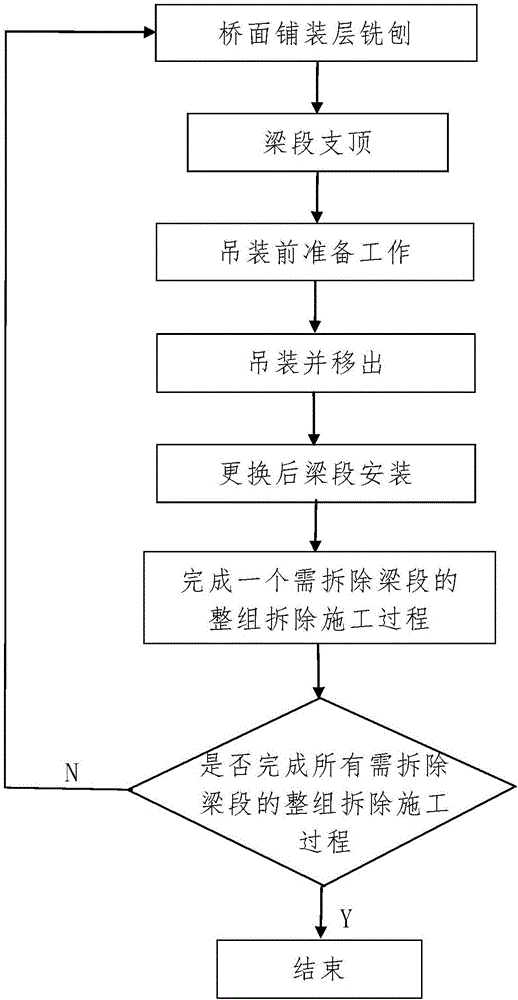

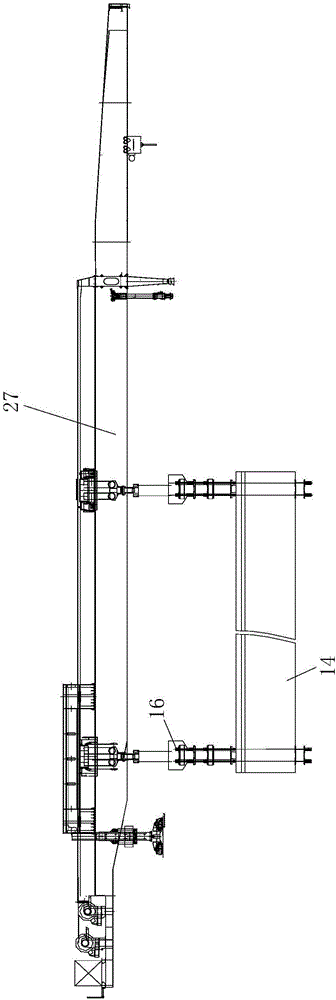

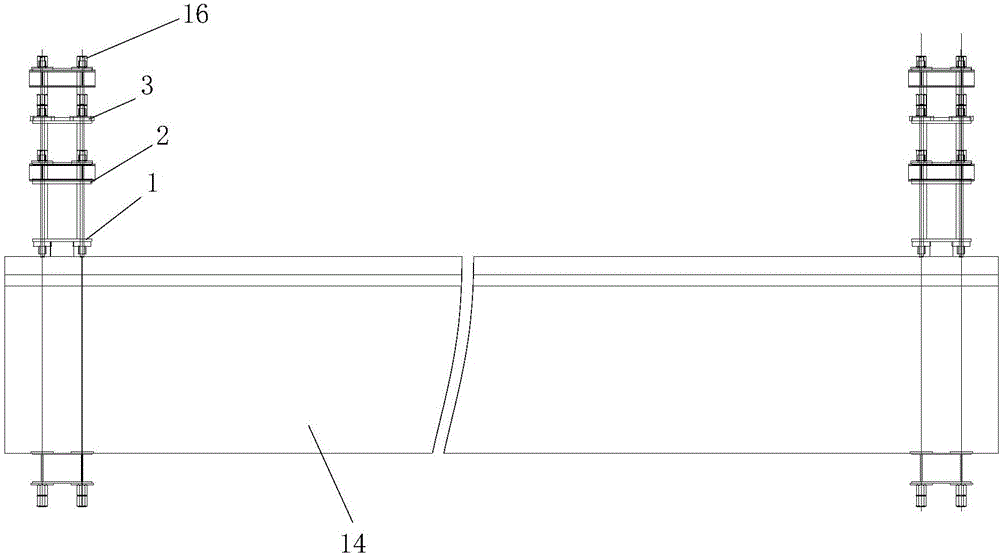

[0064] Such as figure 1A kind of whole group demolition and installation construction method of the existing line bridge with upper span shown, carry out whole group demolition and installation construction respectively to a plurality of beam sections 14 of the old beams to be removed from front to back, and multiple The entire set of beam section 14 is removed and installed in the same way; the old beam to be removed is a bridge girder spanning the existing railway line, and the old beam to be removed is assembled from front to back by a plurality of beam sections 14 to be removed. A plurality of beam sections 14 to be removed have the same structure and are all reinforced concrete beam sections. The beam sections 14 to be removed are assembled from M reinforced concrete T beams 15 from left to right, wherein M is a positive integer and M≥3; the front and rear ends of the beam section 14 to be removed are respectively supported on a supporting pier, and the bridge deck paveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com