Method for repairing rock stratum shield subway tunnel after accidental breakdown

A rock layer and tunnel technology, which is applied in the field of repair after accidental breakdown of subway shield tunnels, can solve the problems of structural strength, low reinforcement ratio of segments, and hidden safety hazards, so as to achieve light backfill materials and ensure stress safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

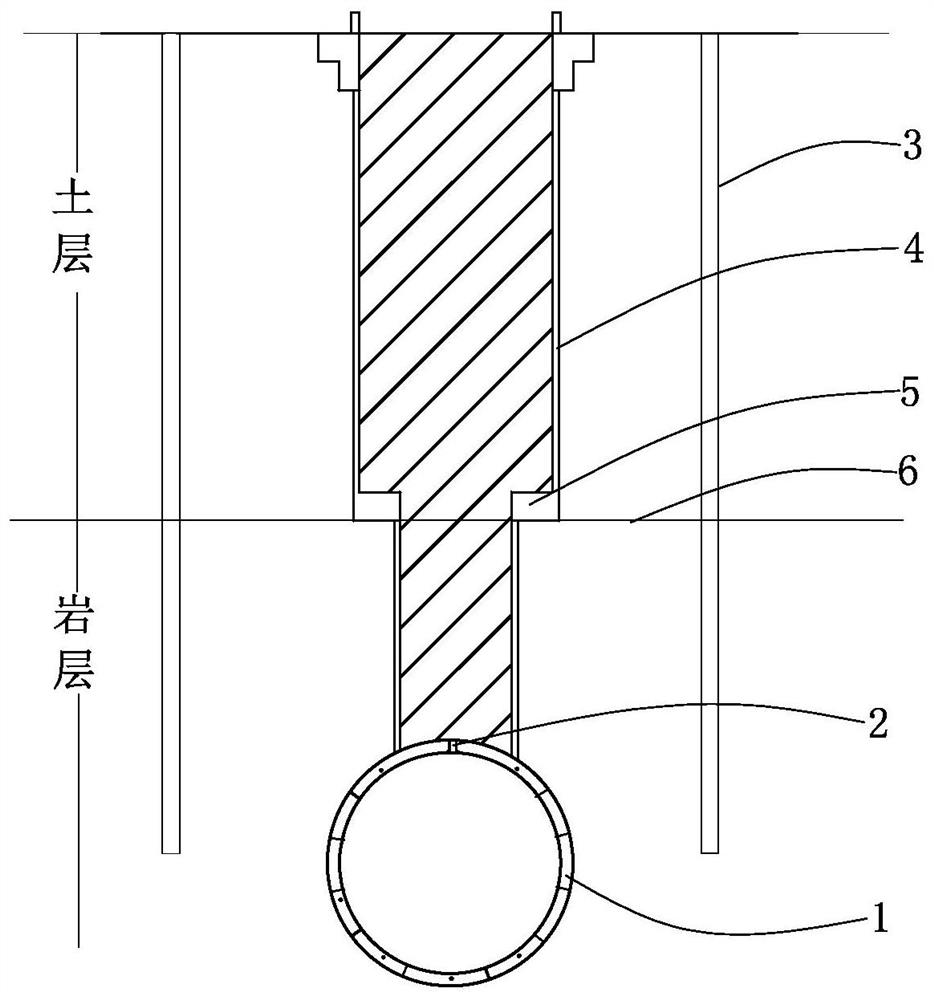

[0014] The invention is applicable to the outside repair method of the shield tunnel under the geological condition of the rock strata. By excavating the vertical shaft, the damage condition of the broken down position of the segments can be fully detected, so that effective repair measures can be taken. Considering that the shaft backfilling material will cause greater pressure on the tunnel segment, which is not conducive to maintaining the structural strength of the segment, the rock formation can be fully utilized to bear the weight of the backfilling material to reduce the pressure of backfilling on the segment. The specific construction method is as follows:

[0015] (1) if figure 1 As shown, the ground point corresponding to the breakdown point 2 of the tunnel 1 is first determined by measurement, and the dewatering well 3 is built on both sides of the ground point for precipitation, so as to prevent water leakage at the breakdown point and create a safe environment for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com