Method of transferring contact suspension for additionally building open-cut tunnel on electrified railway operating line

A technology of electrified railways and open tunnels, applied in the direction of overhead lines, etc., can solve the problems of short impact time, no place to fix contact suspension, and impossible construction of open tunnels, etc., to achieve short blockade time, small normal operation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method for adding open hole transfer contact suspension on the electrified railway business line provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

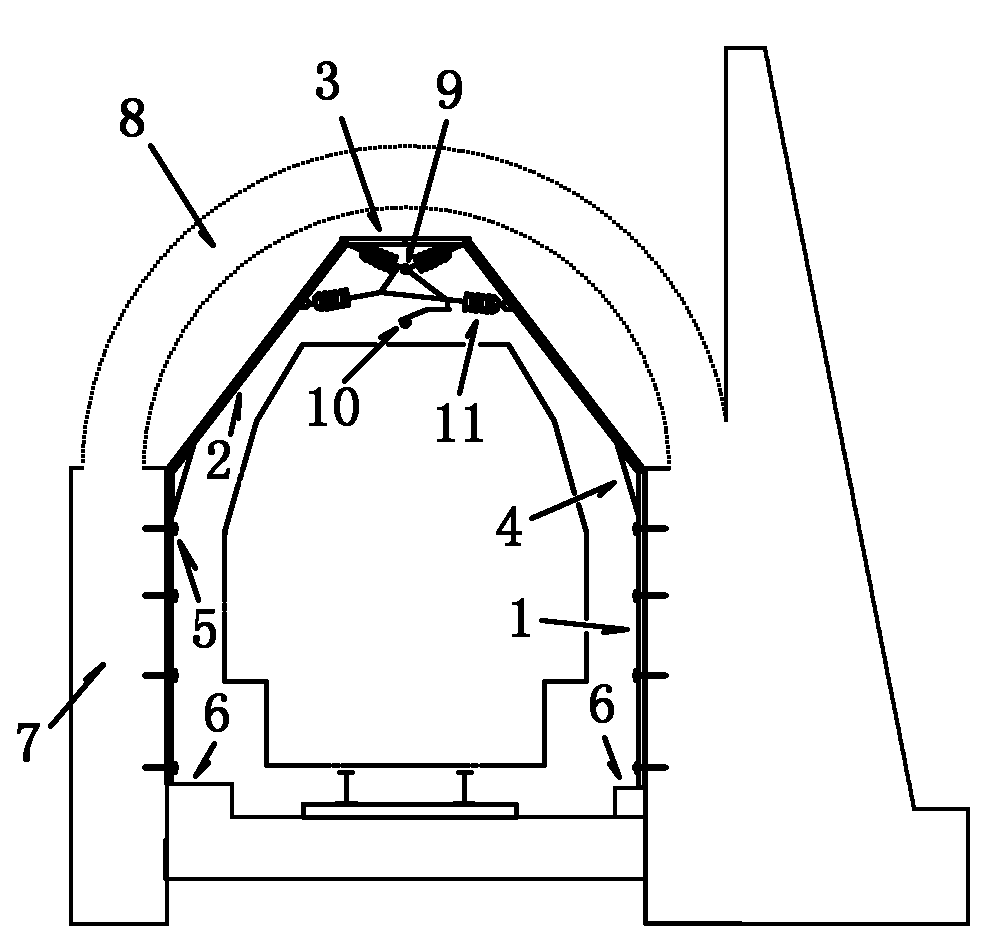

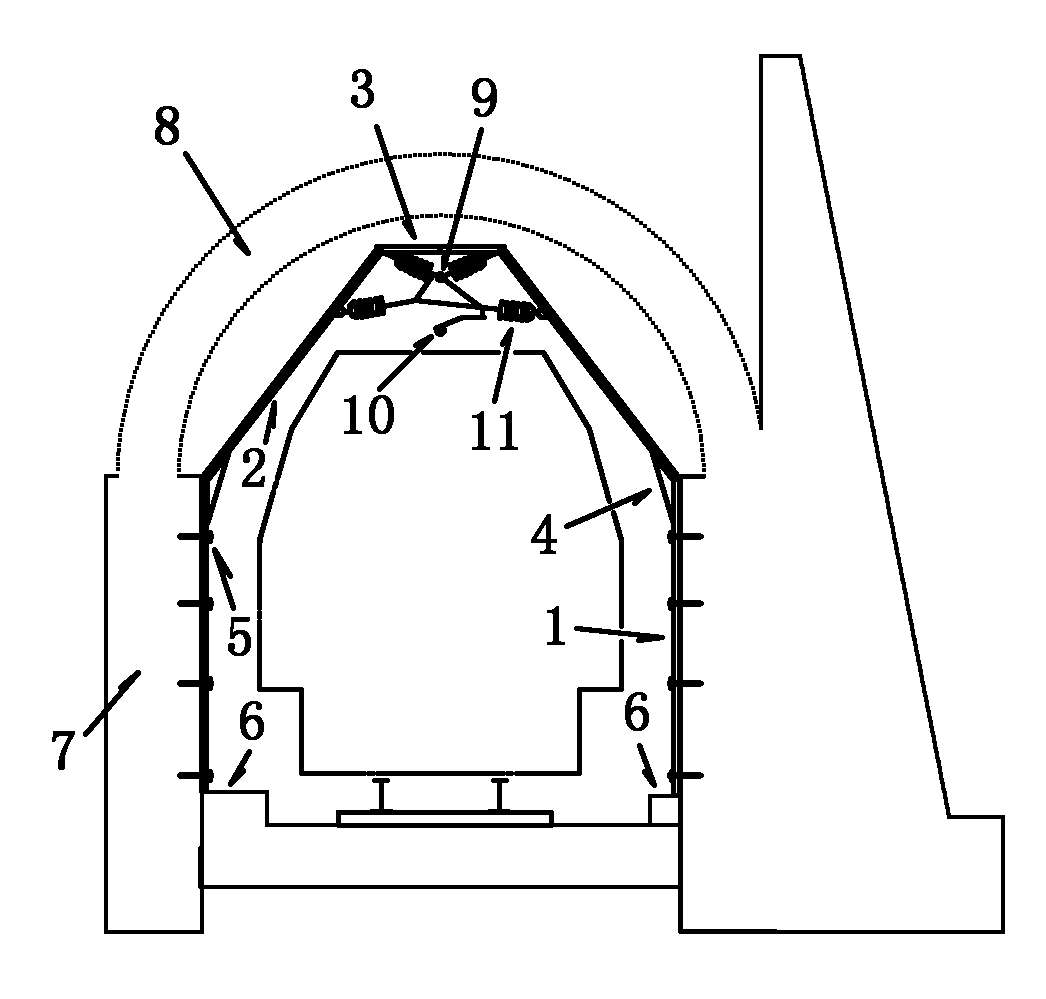

[0021] Such as Figure 1-Figure 2 As shown, the method provided by the invention on the electrified railway business line to increase the construction of the open hole transfer contact suspension includes the following steps carried out in order:

[0022] 1) First, build a section of open hole foundation, two side walls 7 and two side ditch cover plates 6 located at the inner lower part of the two side walls 7 close to the catenary pillar to be removed;

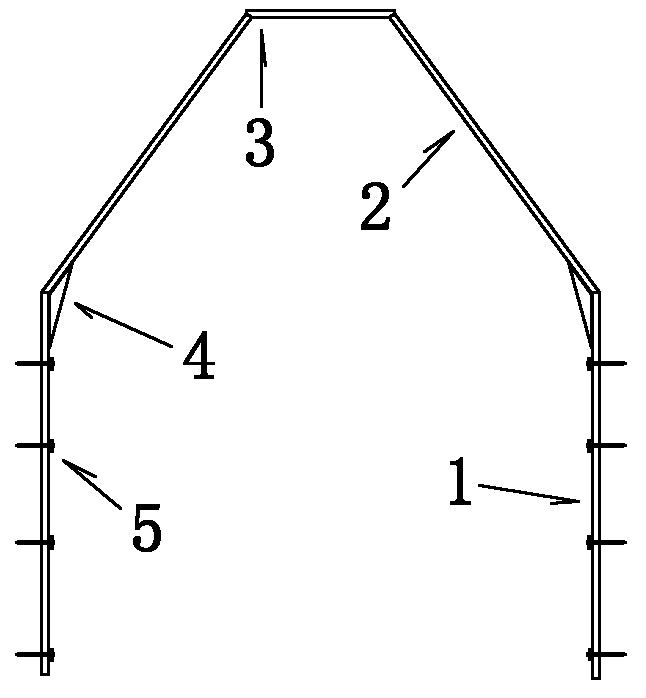

[0023] 2) Make an "arch"-shaped steel pipe support, which includes two vertical poles 1, two diagonal braces 2 and a horizontal bar 3; two vertical poles 1 are placed side by side at a distance; two diagonal braces 2 are symmetrically connected At the upper ends of the two vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com