Repair method for high-speed railway roadbed arching deformation

A technology for high-speed railways and repair methods, which is applied to roads, tracks, buildings, etc., can solve problems such as high impact on track structures, high safety risks, and complex construction, and achieve easy implementation, integrity assurance, and reduced impact on line operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the method for repairing the high-speed railway embankment arch raised according to the present invention, its specific implementation, structure And its effect, detailed description is as follows.

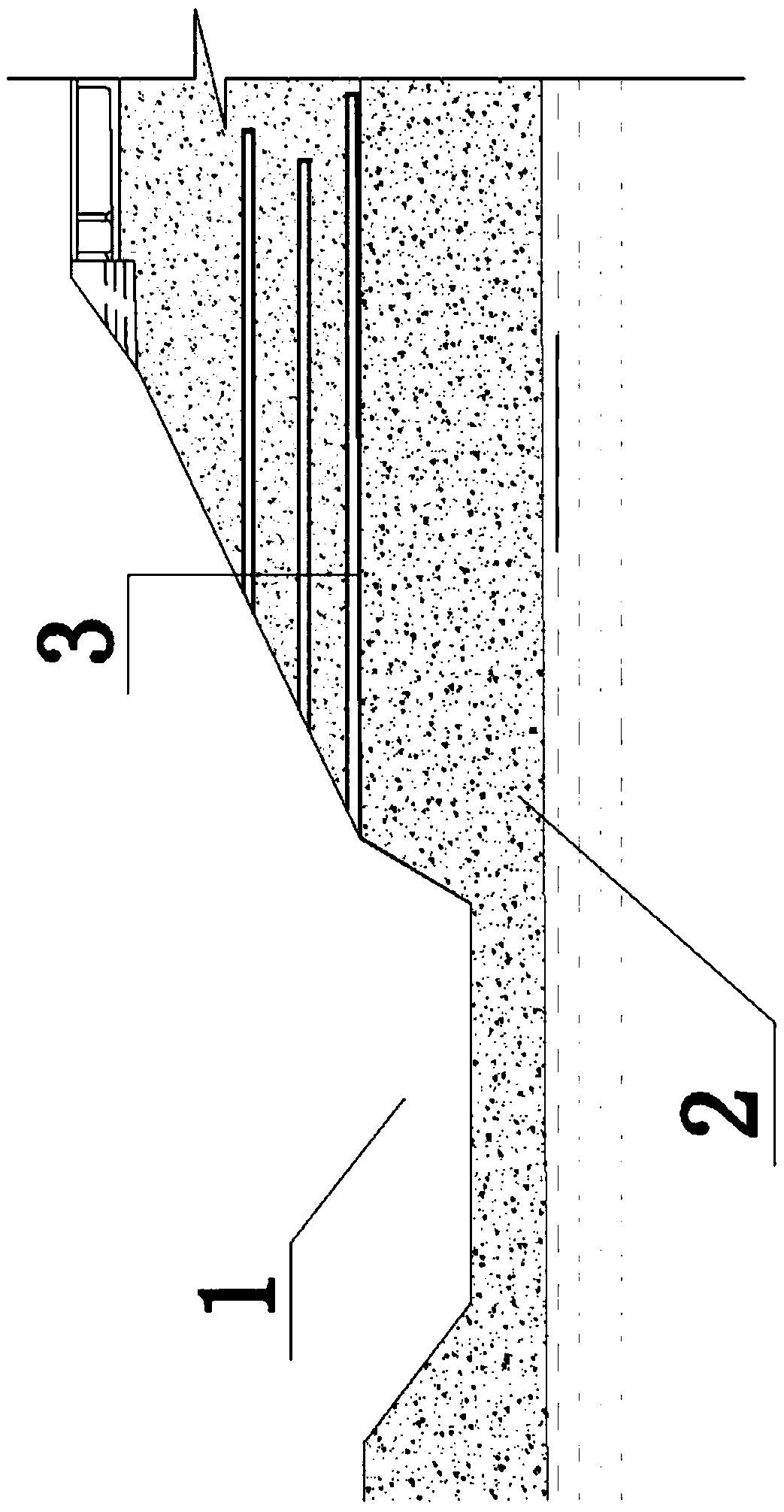

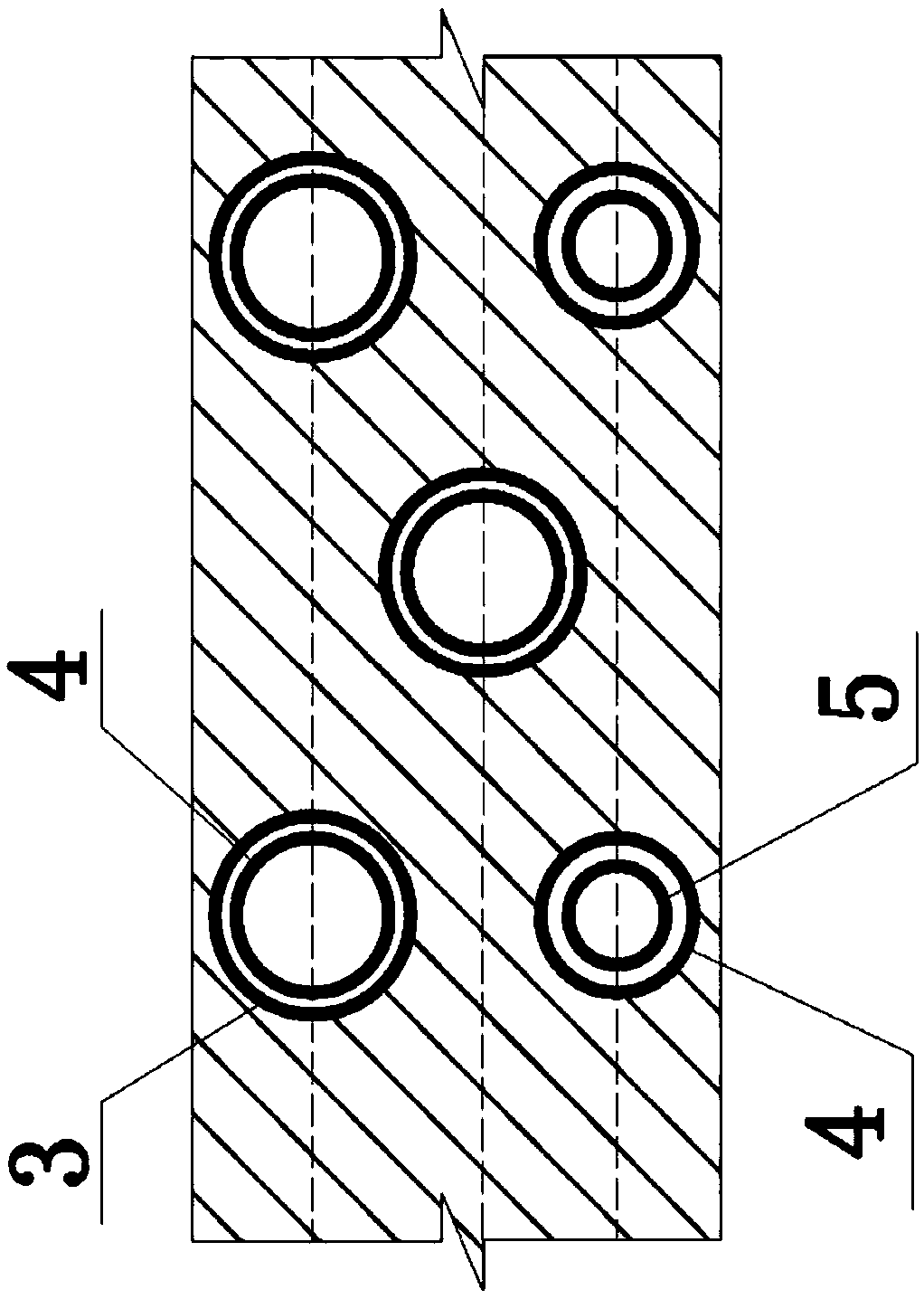

[0045] see figure 1 , figure 2 Shown, a preferred embodiment of the present invention is a track high-speed railway embankment arching disease treatment method. The rectification steps are:

[0046] Step 1: Dig a working slot. In this embodiment, firstly, a working groove 1 is excavated on one side or both sides of the roadbed 2 in the upper arch section to meet the drilling operation requirements of the drilling rig.

[0047] Step 2: Measure the track elevation. Measure the elevation of the track, determine the amount of arching deformation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com