A swivel device and construction method of a small-span high-speed railway small-span bridge with a small angle

A small-angle, high-speed rail technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of complex manufacturing and processing of swivel devices, high precision requirements for structural rotation control, and large tonnage of bridge structures. The effect of construction efficiency, light weight and great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

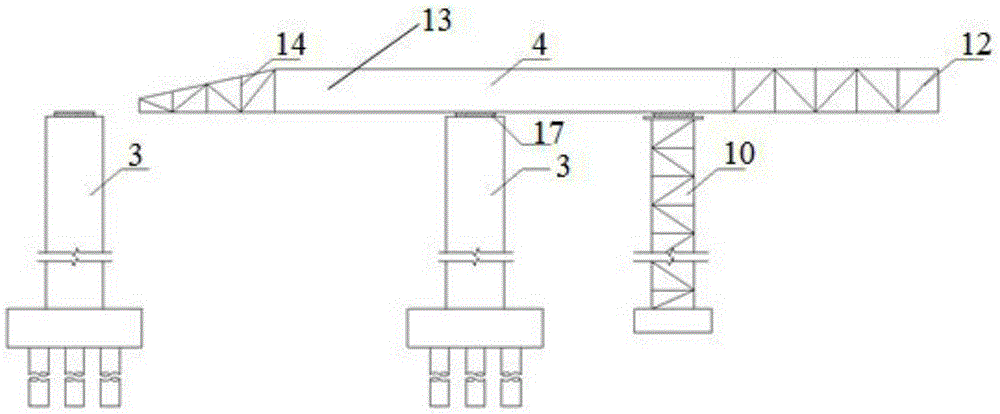

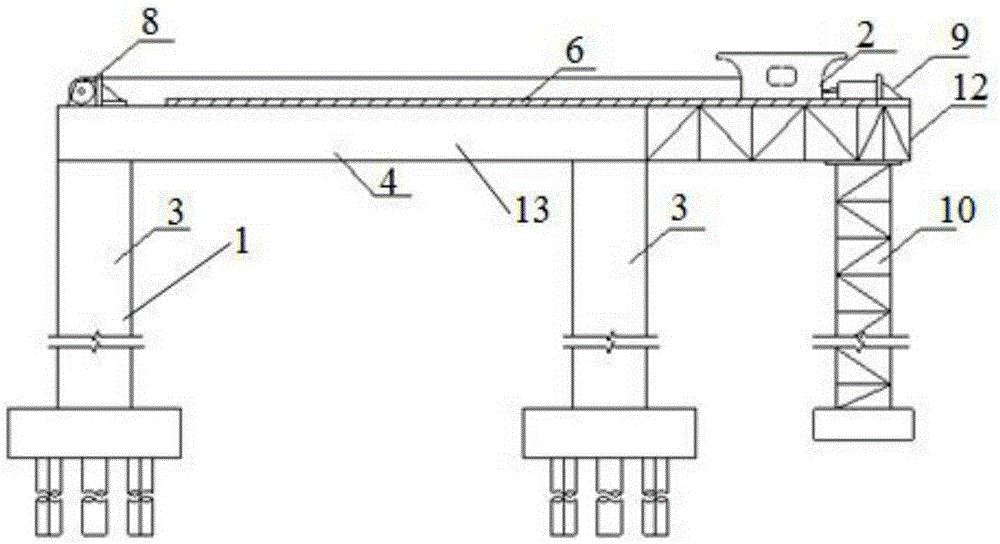

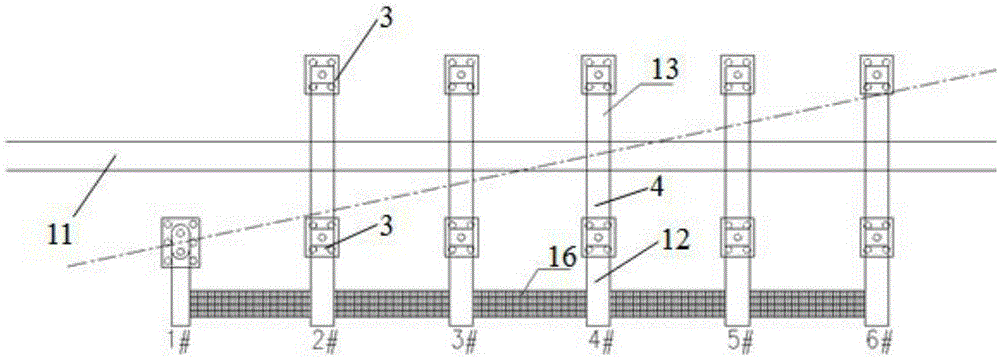

[0040] A swivel device for a small-span bridge that spans a high-speed rail at a small angle, such as Figure 1-2 As shown, the portal pier 1 includes the portal pier column 3 and the cover beam 4 on the portal pier column 3 arranged on both sides of the existing line 11, the portal pier 1 is arranged at intervals in parallel along the road length direction, and the road length direction That is, the length direction of the existing line 11, the main beam 2 is placed on the cover beam 4 along the length direction of the road. The cover beam 4 includes a cover beam body 13 and a back beam 12 connected to the rear of the cover beam body 13. A temporary pier column 10 is arranged on the outside of the portal pier column 3. The pier column 3 is on a straight line, and the back beam 12 is erected on the temporary pier column 10 . The des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com