Rotation V-type T-structure bridge pier and construction thereof

A bridge pier and swivel technology, which is applied in the direction of basic structure engineering, bridges, bridge parts, etc., can solve the problems such as the difficulty of realizing the construction road and construction site of the portal pier scheme, the inability to guarantee the construction period, and the large impact on the operation of existing lines. Achieve the effect of reducing maintenance and repair work, saving demolition costs, and beautiful and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in combination with specific embodiments.

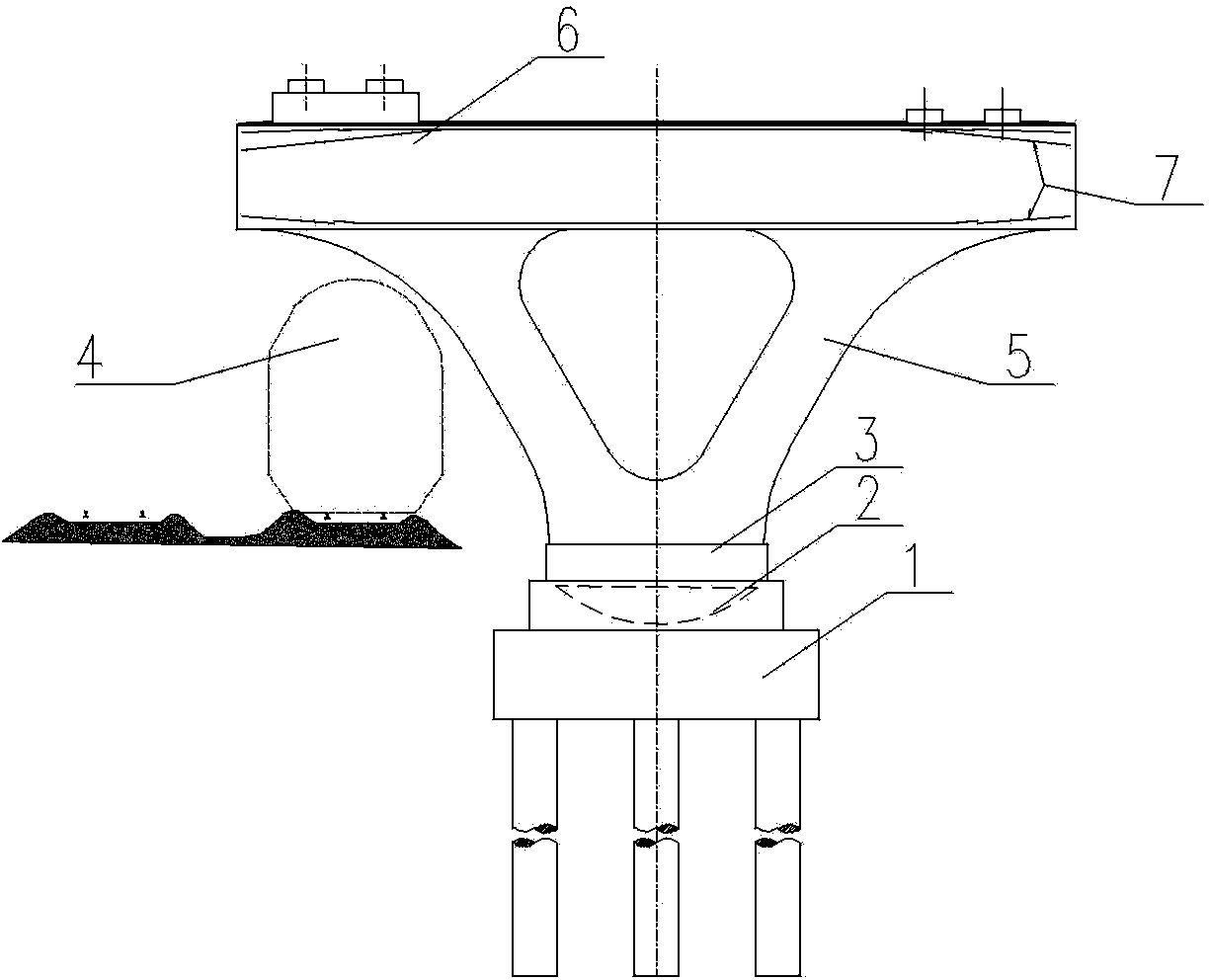

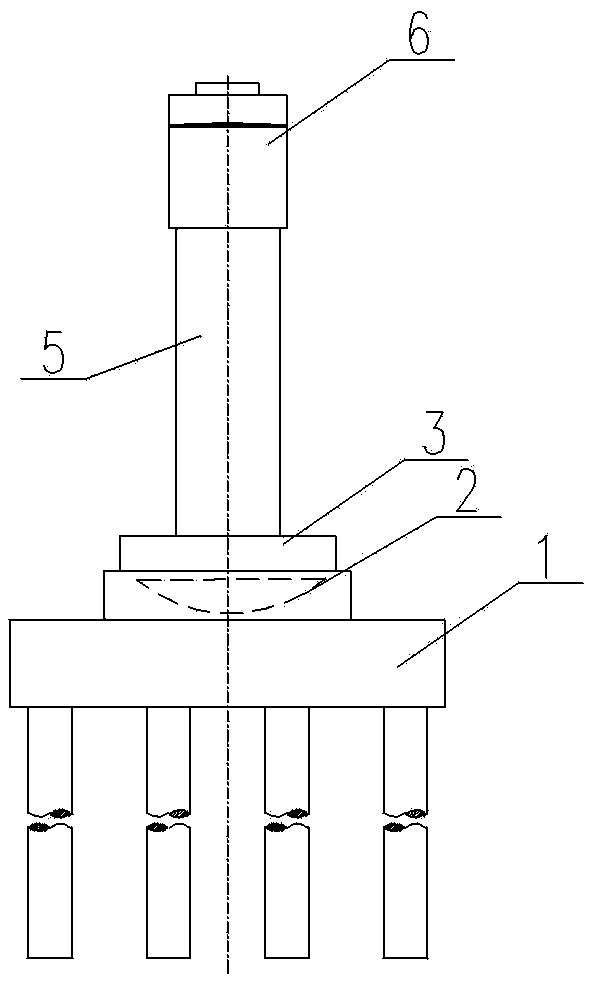

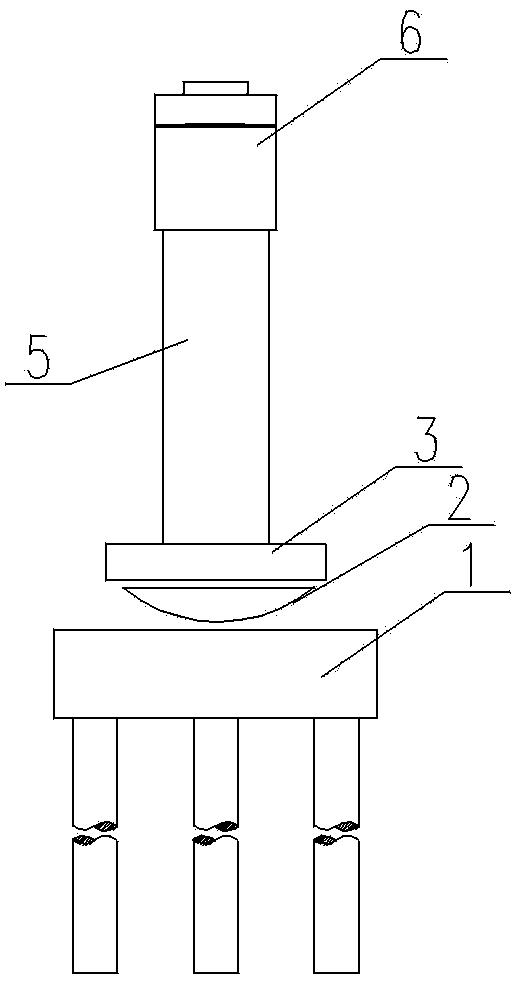

[0029] The invention relates to a swivel V-shaped T-structure bridge pier, which consists of a pile foundation, a cap, a pier arm 5 and a cover beam 6 from bottom to top. From bottom to top, the bearing platform is the lower turntable 1 and the upper turntable 3. The bottom of the upper turntable 3 is fixed with a rotating ball hinge 2. The rotating ball hinge 2 is placed in a spherically concave rotating groove set on the top surface of the lower turntable 1. The lower turntable 1 Concrete is poured on the outer side of the rotating spherical hinge 2 between the upper turntable 2 and forms a consolidation section. There are two pier arms 5, which are arranged in a "V" shape between the cap beam 6 and the cap, and the upper and lower ends of the pier arm 5 are connected with the cap beam 6 and the cap with arc chamfers. An inverted triangle gap is formed between the pier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com