Patents

Literature

44results about How to "Low demolition cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

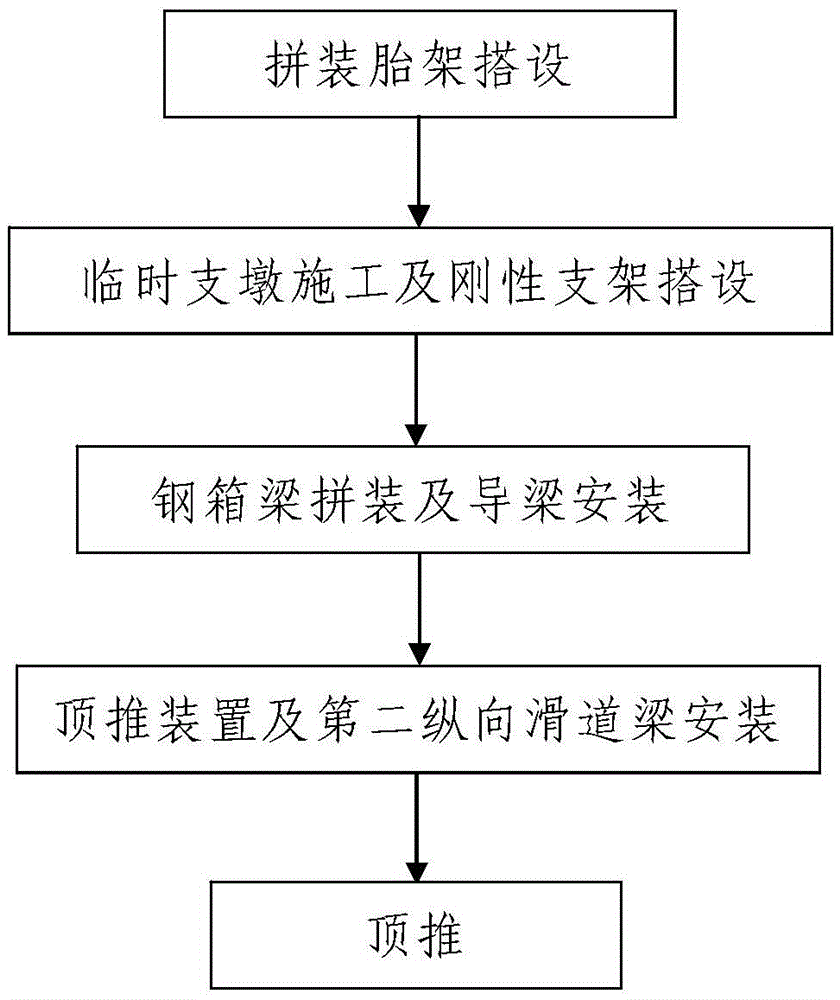

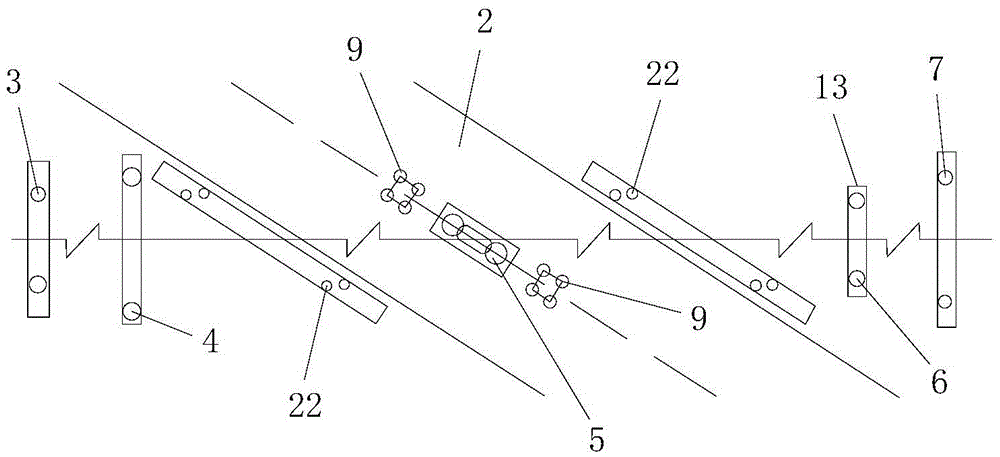

Incremental launching construction method for large-span steel box girder spanning constructed road

ActiveCN105568866AThe method steps are simpleSimple and fast operationBridge erection/assemblyButtressSteel box girder

The invention discloses an incremental launching construction method for a large-span steel box girder spanning a constructed road. An incremental launching steel box girder spans the constructed road, is supported by five permanent buttresses, and is formed by a plurality of steel box girder segments which are spliced back to front; the five permanent buttresses are all uncovered girder double-cylinder pillars; the uncovered girder double-cylinder pillars respectively consist of two cylindrical buttresses which are supported below the left side and the right side of the steel box girder; the incremental launching construction method for the incremental launching steel box girder comprises the following steps: I, splicing jig frames; II, constructing temporary buttresses and rigid brackets; III, splicing the steel box girder and mounting guide beams; IV, mounting an incremental launching device and a second longitudinal slideway beam; V, performing incremental launching. The method disclosed by the invention is simple in step, reasonable in design, simple and convenient to construct and good in use effect, and by constructing the rigid brackets on the outer sides of the buttresses and mounting a longitudinal slideway and a transverse deviation correcting device, the incremental launching construction of the large-span steel box girder can be easily, conveniently and rapidly completed.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

Method for removing reinforced concrete support beams in foundation pit support

InactiveCN104404965AShorten the construction periodFast constructionExcavationsLow noiseReinforced concrete

The invention relates to a method for removing reinforced concrete support beams in a foundation pit support. The method is characterized by comprising the following steps: preserving expansion holes in the support beams, cutting two slots in each support beam before removing the support beams, and cutting off stirrups on the upper parts of the support beams; finishing the actions of preparing a blasting agent, stirring uniformly and pouring into each expansion hole within specified time, controlling the temperature of the blasting agent at 10-30 DEG C, standing for 24 hours, performing simple crushing on the support beams, manually cutting off steel bars in the support beams after crushing of the support beams, and cleaning and transporting waste residues left after crushing of the support beams. The method has the characteristics of safety, rapidness in construction, freeness from vibration and flying rocks, low noise, easiness in operation, and the like; the removing construction period of the support beams in the foundation pit support can be effectively shortened, the economic input is reduced greatly, and the method has important significance to engineering construction.

Owner:ZHEJIANG OCEAN UNIV

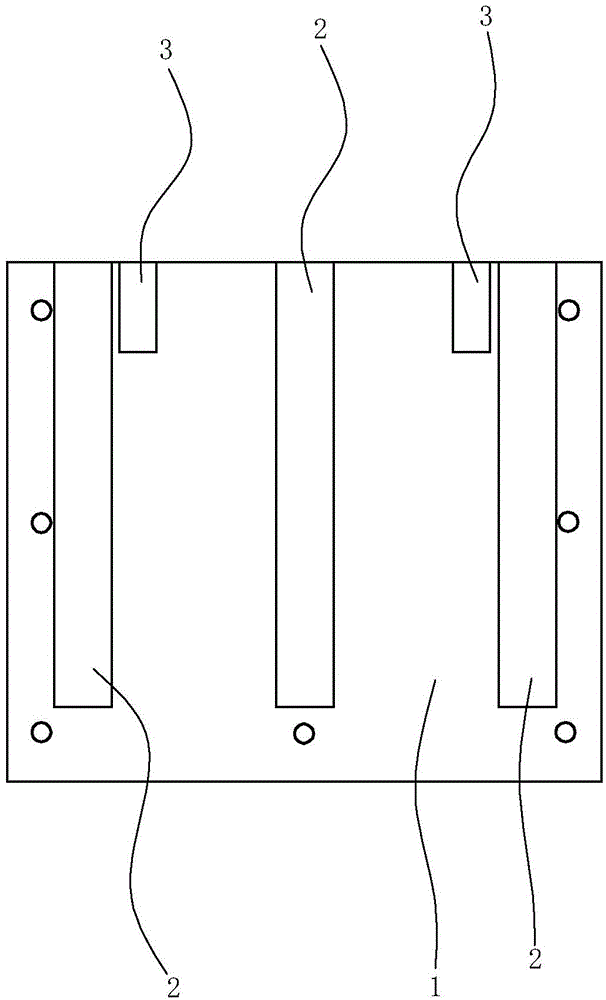

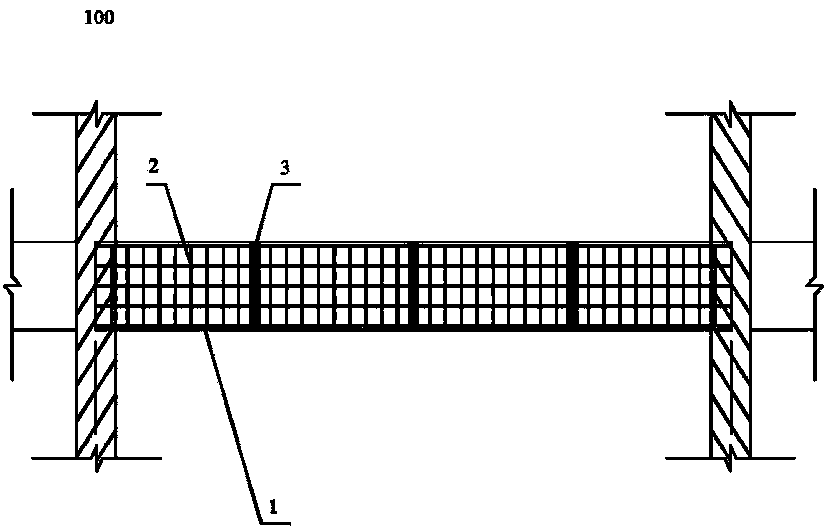

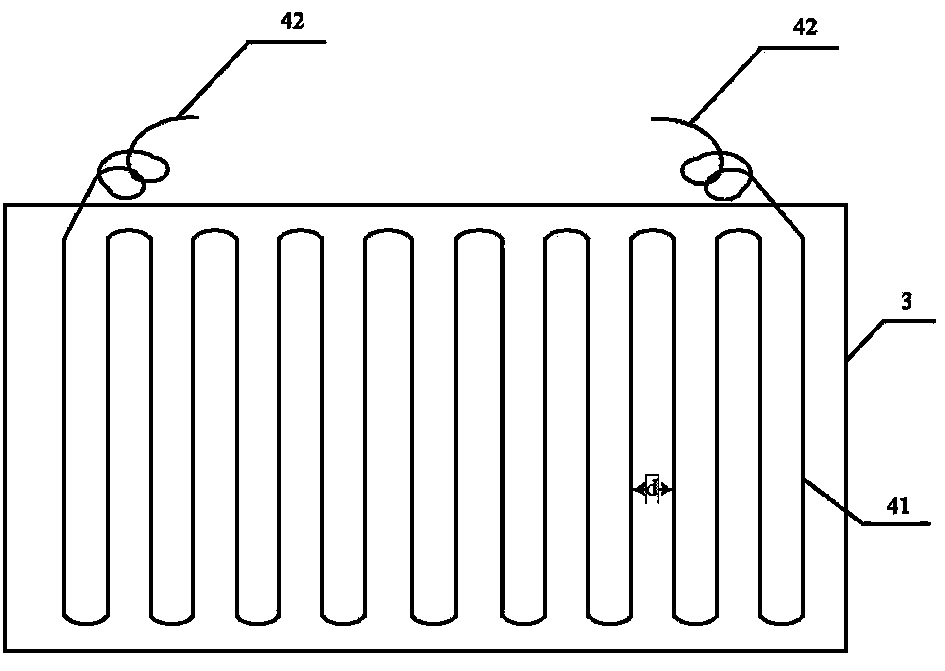

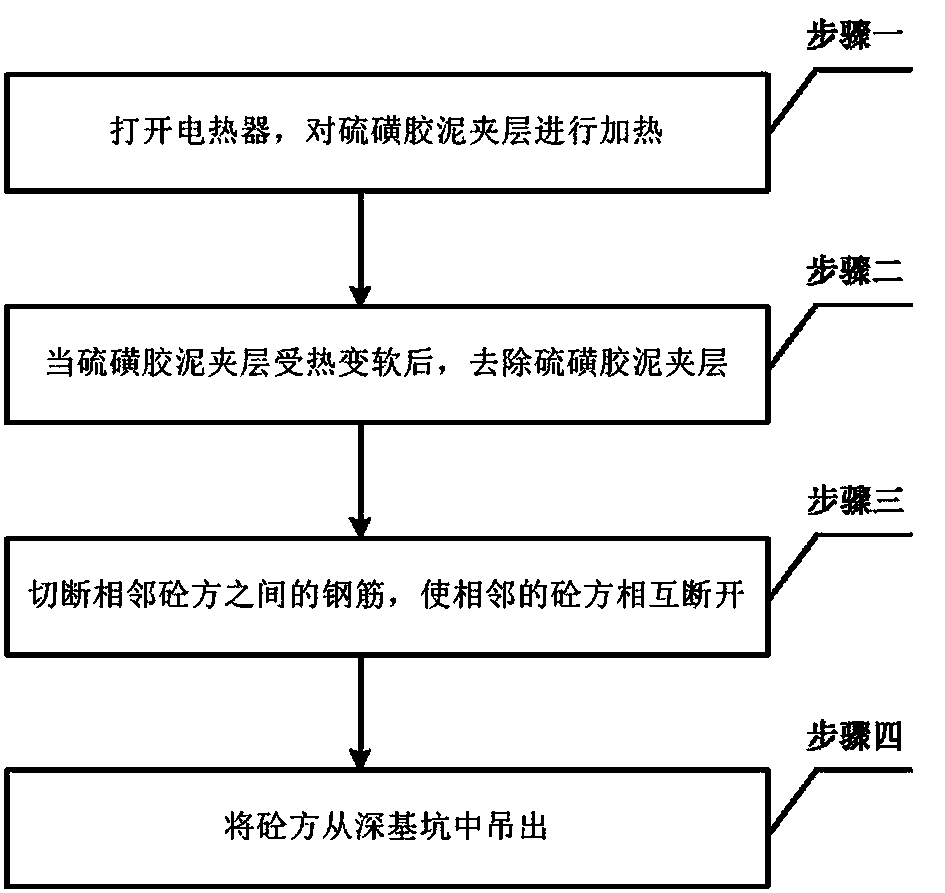

Deep foundation pit support and removing method thereof

The invention provides a deep foundation pit support and a removing method of the deep foundation pit support, and belongs to the field of building construction. The deep foundation pit support comprises a plurality of sections of concrete cubic blocks and a plurality of reinforcing steel bars. Every two adjacent concrete cubic blocks are bonded through a sulphide mastic interlayer. The reinforcing steel bars penetrate through the concrete cubic blocks and the sulphide mastic interlayers. An electric heater is pre-buried in each sulphide mastic interlayer. The removing method of the deep foundation pit support comprises the steps of (1) starting the electric heaters to heat the sulphide mastic interlayers, (2) when the sulphide mastic interlayers are heated to become soft, removing the sulphide mastic interlayers to expose the reinforcing steel bars penetrating through the adjacent concrete cubic blocks, (3) cutting off the reinforcing steel bars between the adjacent concrete cubic blocks to enable the adjacent concrete cubic blocks to be mutually separated, and (4) lifting out the concrete cubic blocks from a deep foundation pit. When the deep foundation pit support and the removing method of the deep foundation pit support are used, the removing cost of the deep foundation pit support can be effectively reduced on the premise that the removing efficiency and environmental protection are kept.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

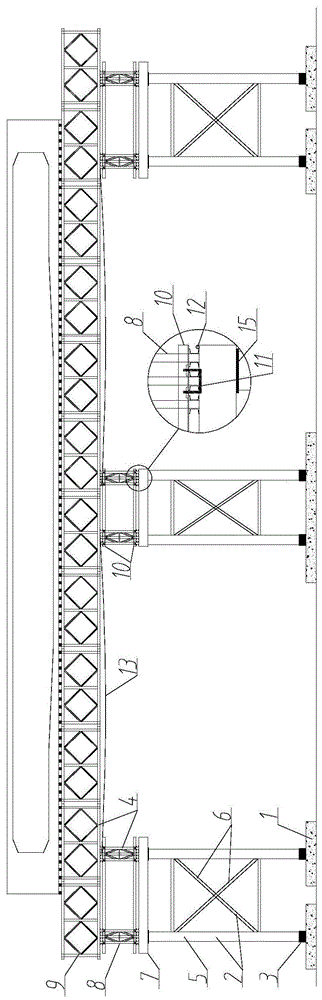

Self-dropping type box girder steel pipe bailey door opening bracket and supporting method thereof

ActiveCN103469733AEliminate uneven settlementAvoid crackingBridge erection/assemblyButtressReinforced concrete

Owner:CCFEB CIVIL ENG

Pumped storage power plant tail water retained rock step blasting safety protection method

The invention discloses a pumped storage power plant tail water retained rock step blasting safety protection method, and relates to an underwater rock step blasting safety protection method. A bladder curtain and porous stoplog gates are constructed outside a rock step to be blasted; the bladder curtain consists of a plurality of steel pipes; two rows of holes are bored on each steel pipe; and each steel pipe is connected with an air pipe of an air compressor. The porous stoplog gates consist of a steel frame and bamboo rafts; I sections are arranged on both sides of the stoplog gate of eachhole; the two sides of each I section are fixed on round flow splitting support piers through steel plates and expansion bolts; each stoplog gate is in welded connection through channel steel, the I sections and angle bars; a layer of vertical bamboo gangway is spread on the water inlet surfaces of the stoplog gates; and simultaneously safety nets are arranged on the tops of flow splitting support piers on the top and both sides of a single hole stoplog gate. The method adopts the proposal of arranging the bladder curtain plus the steel frame, the bamboo rafts and the safety nets to replace aproposal of the stoplog gate, has scientific and reasonable design, protects a trash rack and a tail gate against the damage and the influence of the blasting, and brings about easy spoil removal, short manufacturing and installation time limits, and low manufacturing, installation and demolition cost.

Owner:STATE GRID CORP OF CHINA +2

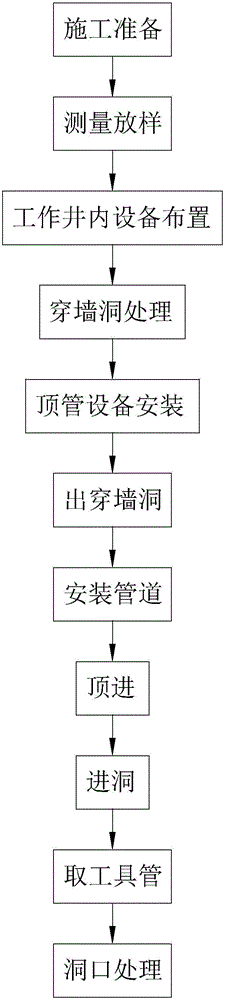

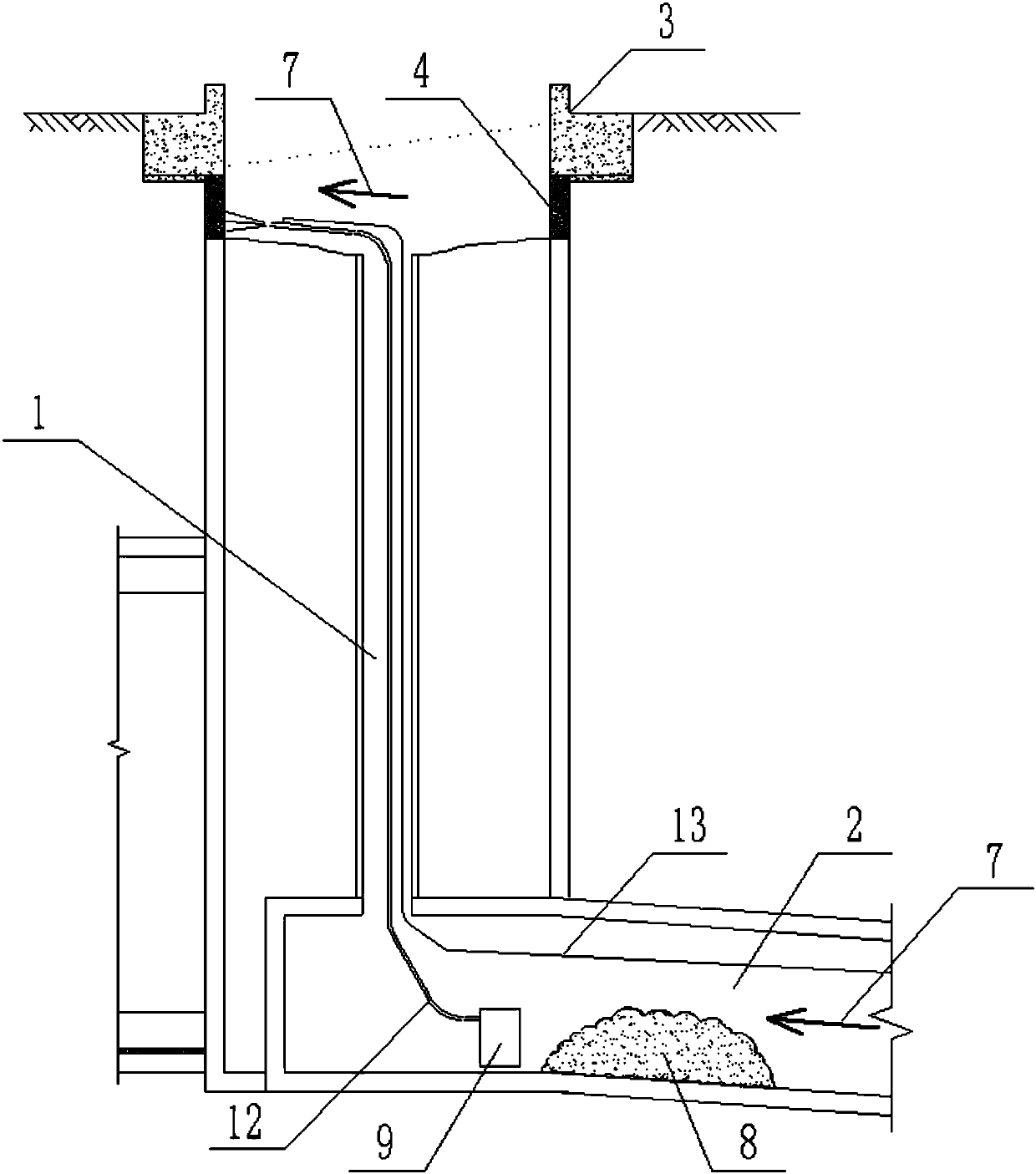

Soil pressure balancing method

ActiveCN106122589AImprove corrosion resistanceImprove hydraulic performancePipe laying and repairSoil scienceUnderground pipeline

The invention discloses a soil pressure balancing method. The problems that in the jacking pipe operation process, over-excavation and under-excavation may happen when a face earthwork is excavated, a surrounding soil body is likely to be disturbed, the road on the ground is damaged, a building sinks and deforms, and an underground pipeline is broken are solved. According to the technical scheme, the soil pressure balancing method is characterized by comprising the following steps that firstly, construction preparation is made; measuring and setting-out are conducted; thirdly, equipment is arranged in a work well; fourthly, wall penetrating hole treatment is conducted; fifthly, jacking pipe equipment is installed; sixthly, a jacking pipe penetrates out of a wall penetrating hole; seventhly, pipeline installation is conducted; eighthly, jacking is conducted; ninthly, the jacking pipe enters the hole; tenthly, a tool pipe is taken out; and eleventhly, hole treatment is conducted. By means of the soil pressure balancing method, over-excavation and under-excavation generated when the face earthwork is excavated are reduced, the disturbance to the surrounding soil body is reduced, the damage to the road on the ground is reduced, and meanwhile the phenomena that the building sinks and deforms and the underground pipeline is broken are reduced.

Owner:天鸿建设集团有限公司

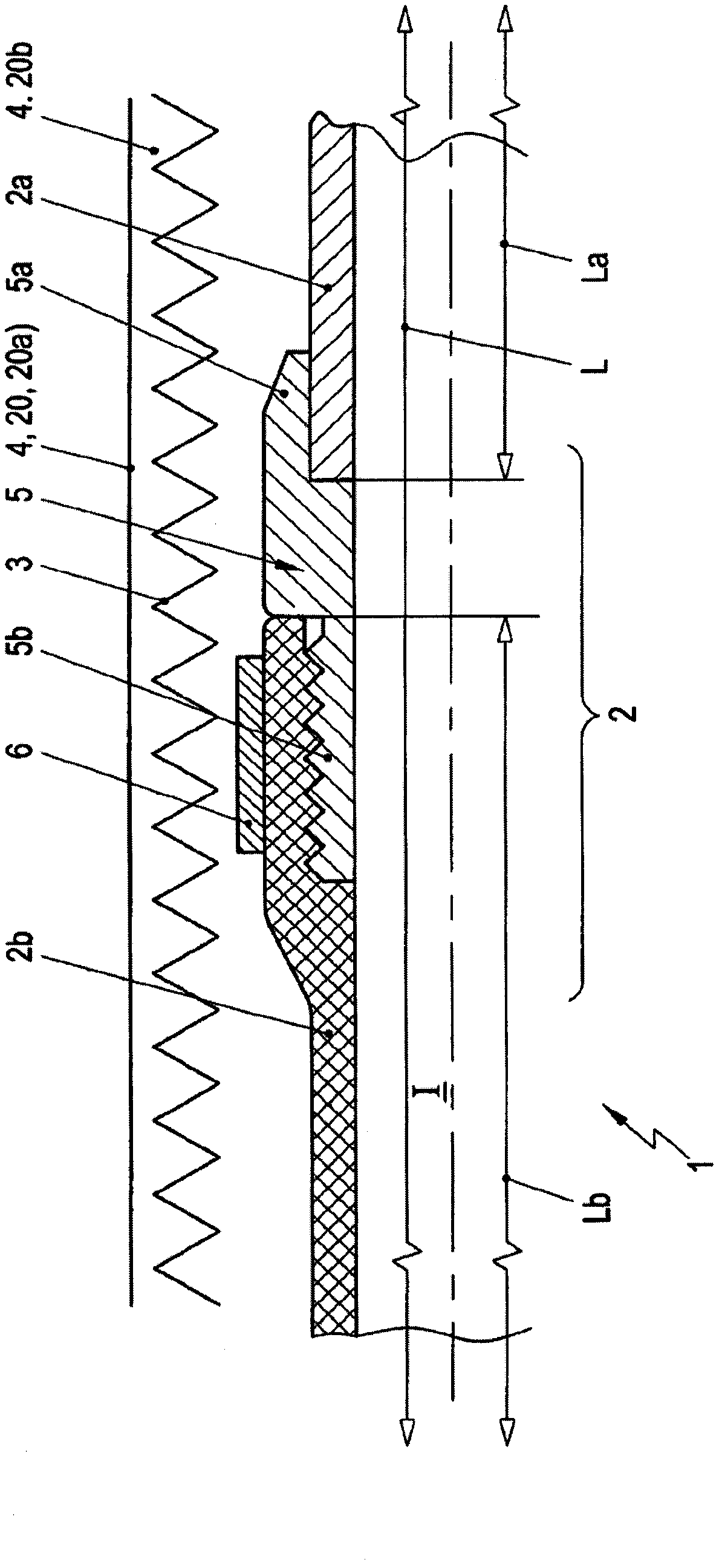

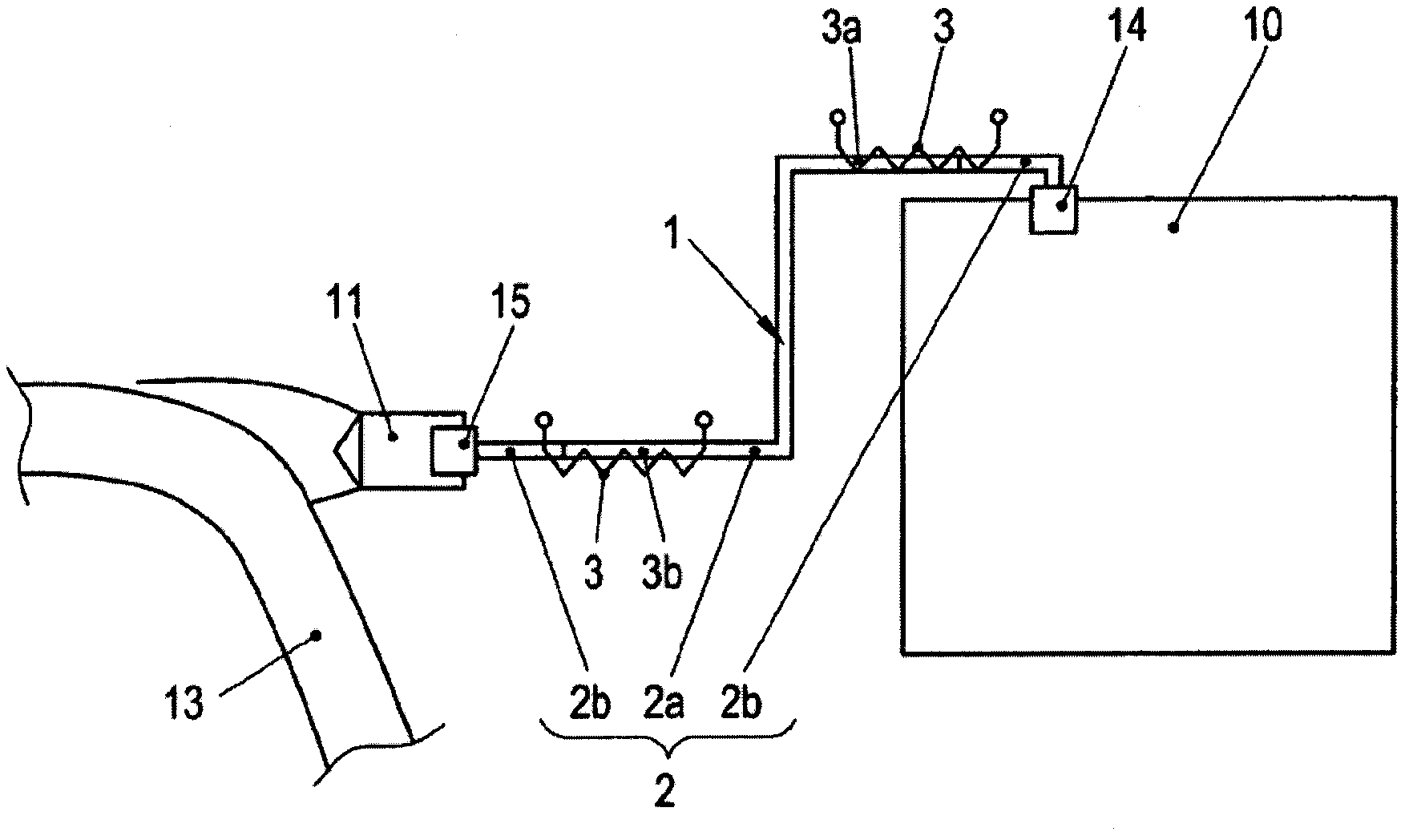

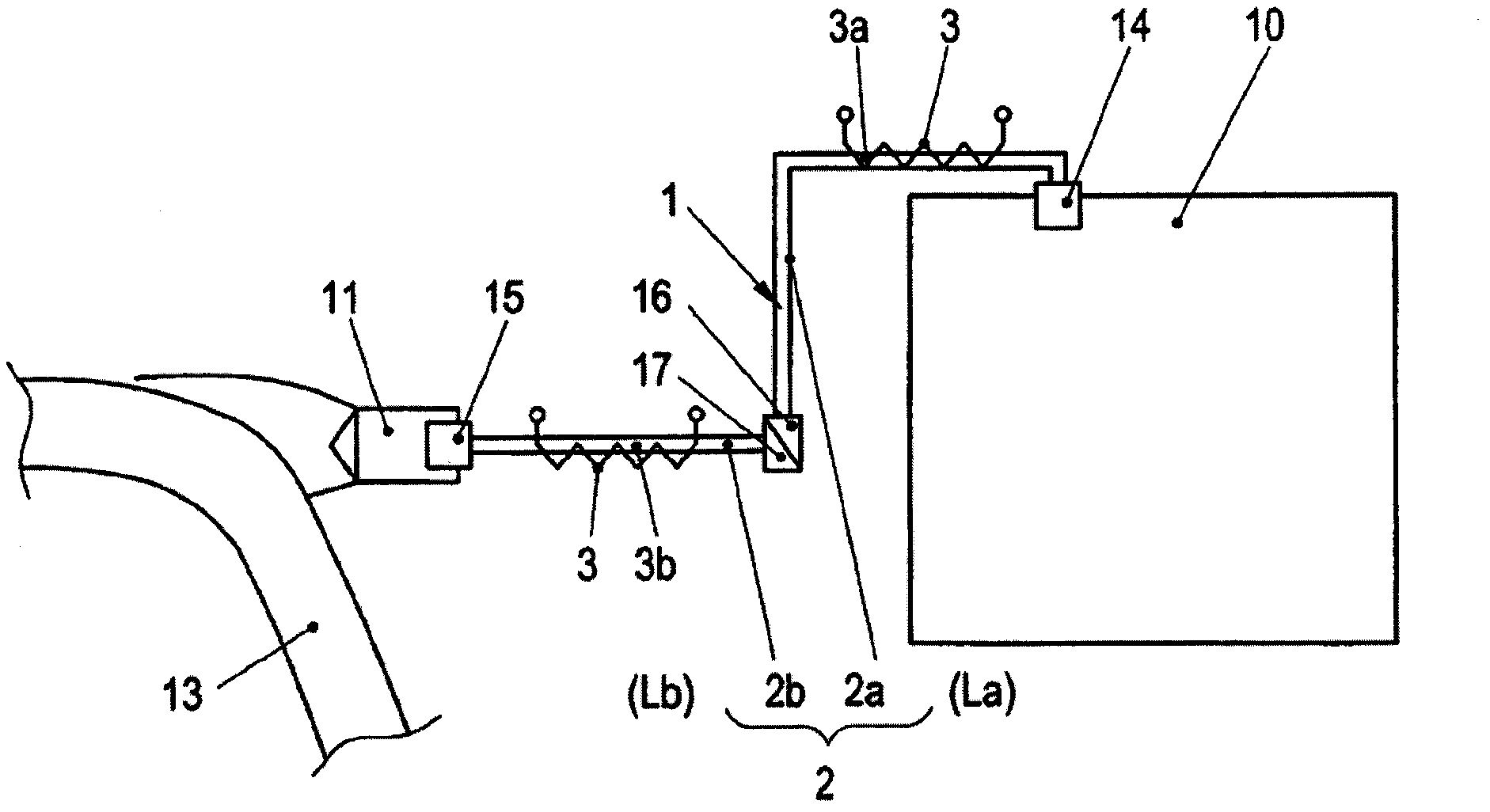

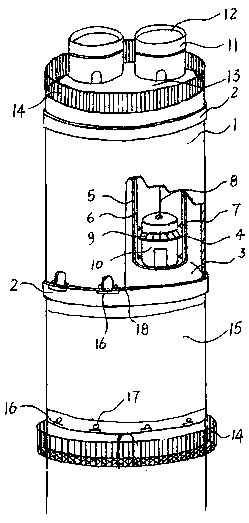

Heatable fluid line, use thereof and method for producing same

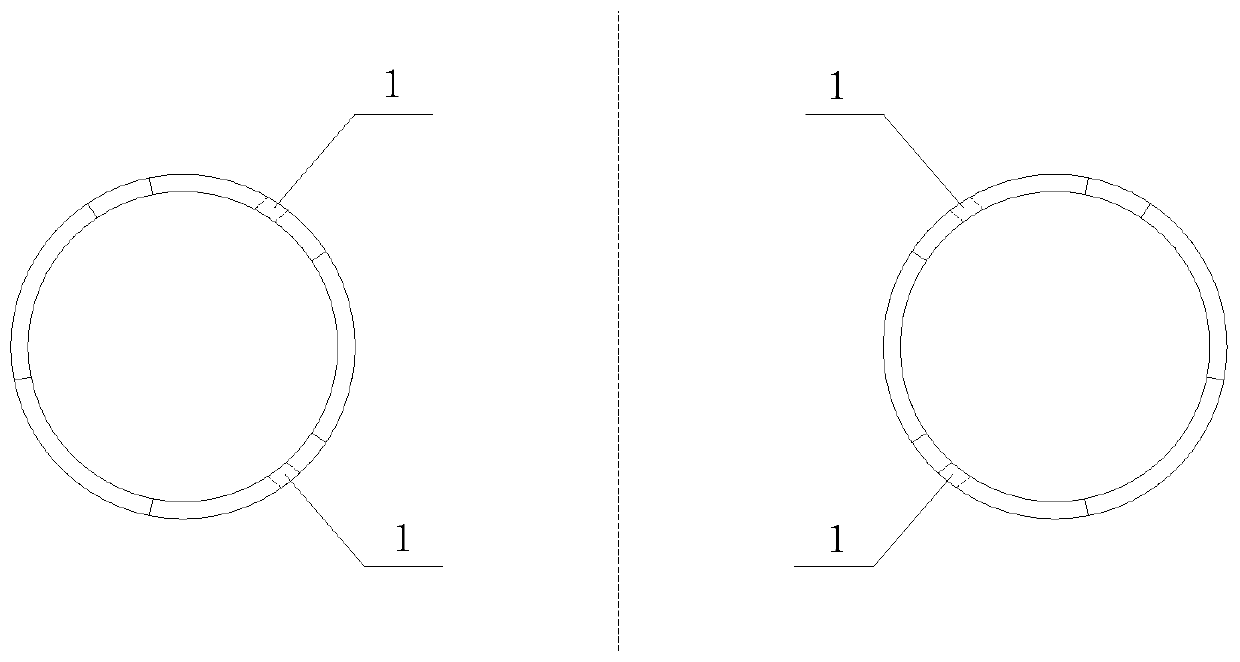

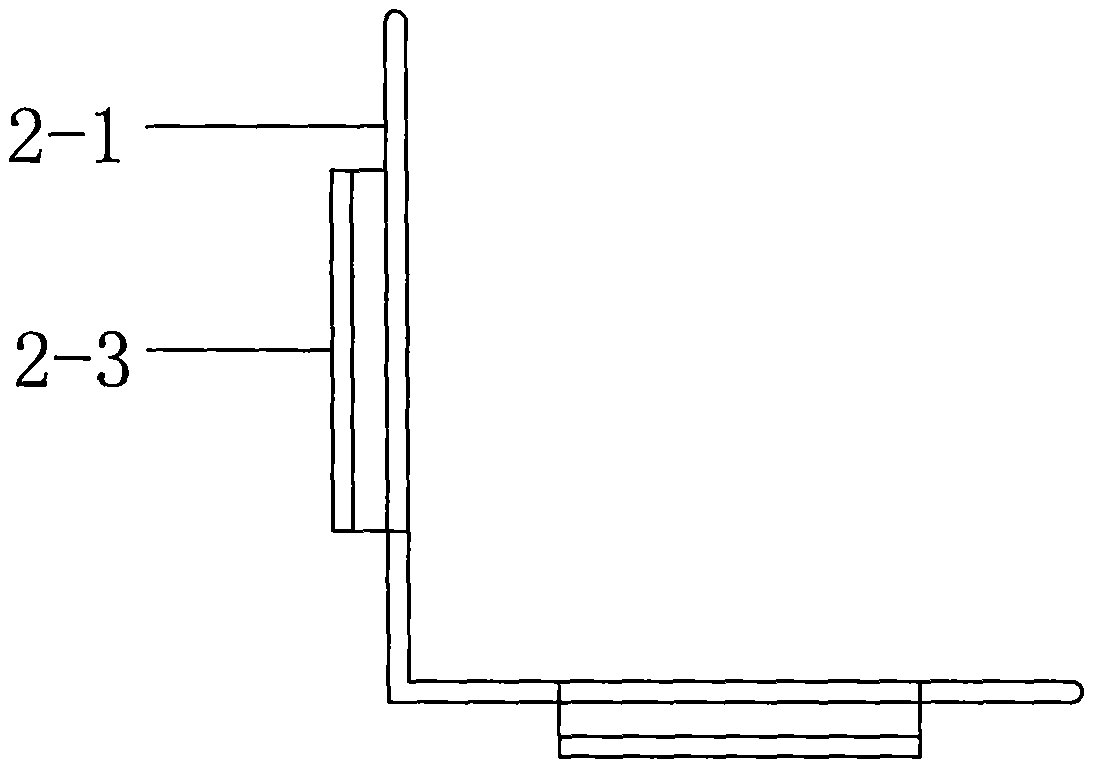

ActiveCN103282712AImprove carrying capacityLow demolition costInternal combustion piston enginesExhaust apparatusElectrical conductorFluid coupling

The invention relates to a heatable fluid line (1) comprising at least one pipeline (2, 218) and at least one electrical heating conductor (3, 224) extending over at least a partial section of the length (L) of the pipeline. In order that the fluid line (1) fulfills increased requirements in respect of resistance to high temperatures, compensation of pressure pulsations and / or compression resistance, while being less complex to produce and assemble and / or connect, according to the invention the pipeline (2, 218) has at least two longitudinal sections (2a, 202, 2b, 204) which are designed differently in respect of the material properties and / or design thereof, namely at least one first longitudinal section (2a, 202) which consists of a first material which comprises a first polymer and a second longitudinal section (2b, 204); which consists of a second material which comprises a second polymer, wherein the material of the second longitudinal section (2b, 204) is more flexible and / or has a higher resilience than the material of the first longitudinal section (2a, 202). The described method for producing such a fluid line according to the invention relates to an adaptive attachment of the heating conductor (3, 224) on the outside of the pipeline (2, 218) which permits the heating conductor (3, 224) to be wound around fluid coupling and / or connector parts, in particular the housings thereof (14, 15, 16, 17, 21, 22, 33, 34, 50, 51, 52, 53, 206, 208, 210, 212, 230, 232, 244, 246) by means of which the line (1) is assembled, without strand separation.

Owner:VOSS AUTOMOTIVE

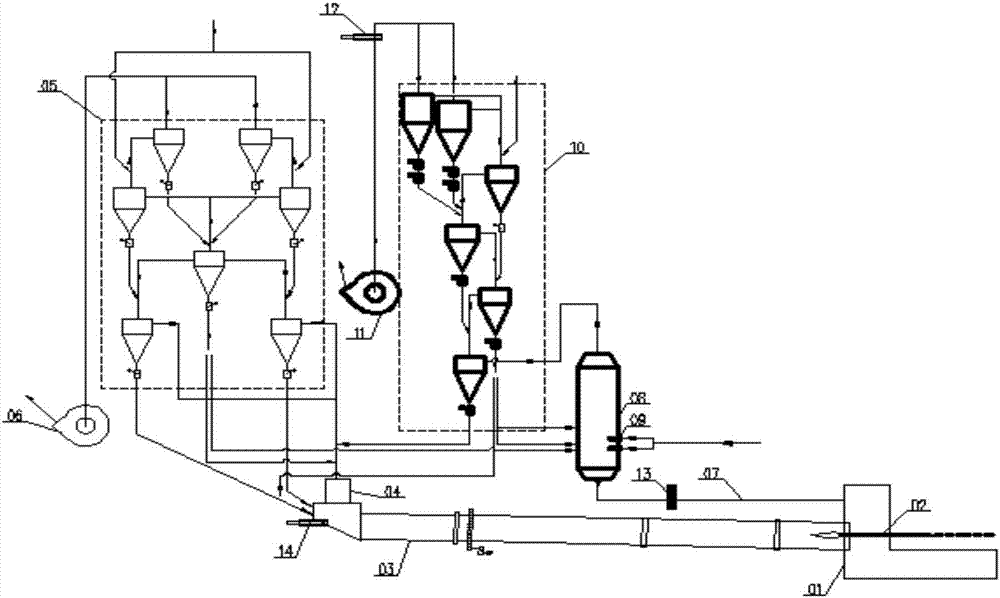

Energy saving and emission reduction transformation method for transforming cement cyclone preheater kiln into outside-kiln precalcining kiln

ActiveCN107084617AReduce workloadIncrease speedRotary drum furnacesPreheating chargesCycloneCombustor

The invention discloses an energy saving and emission reduction transformation method for transforming a cement cyclone preheater kiln into an outside-kiln precalcining kiln. A tertiary air duct (07), an offline calcining combustor (08), a calcining combustor burner (09), a five-stage preheater (10), a fresh air high-temperature fan (11), a normal temperature gas analyzer (12), a tertiary air gate valve (13) and a high temperature gas analyzer are newly built on the basis of an original cyclone preheater rotary kiln line, wherein a new preheater system and an old preheater system serve cement production jointly. The original kiln shutdown duration of eight months is shortened to 2-3 months, the cost of detaching of an old preheater is reduced, raw materials of the old preheater are wholly conveyed into the offline calcining combustor, the in-kiln calcining rate of the raw materials is increased to 90% or over from original 100% of in-kiln calcining through the offline calcining combustor, and the raw materials of the new preheater enter the kiln through an original feed-end chamber. After the cyclone preheater kiln is transformed into the precalcining kiln, 100% of fuel of a kiln head is reduced to 40%, the amount of NOx generated by the kiln head at a high temperature environment is reduced, and the method can quickly change the cement production process and achieve the yield increase, energy saving and emission reduction effects for a cement sintering system.

Owner:BEIJING TRIUMPH INT ENG

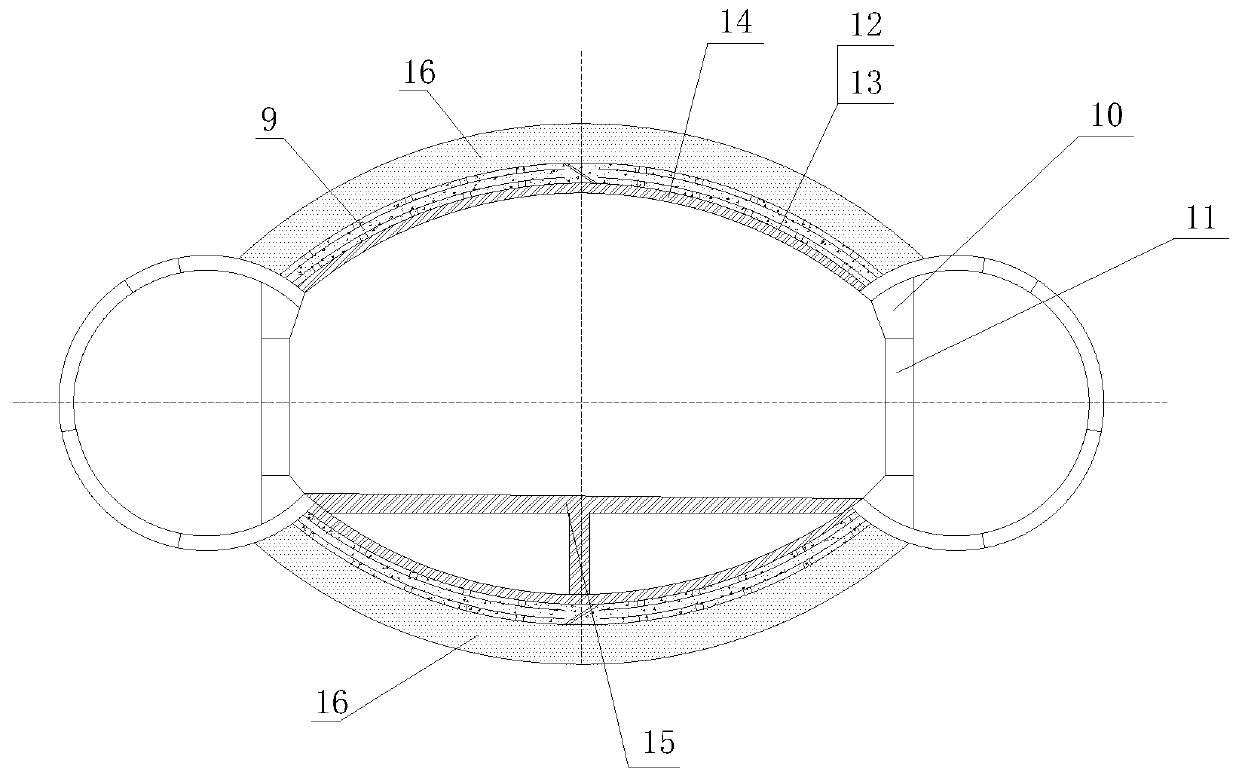

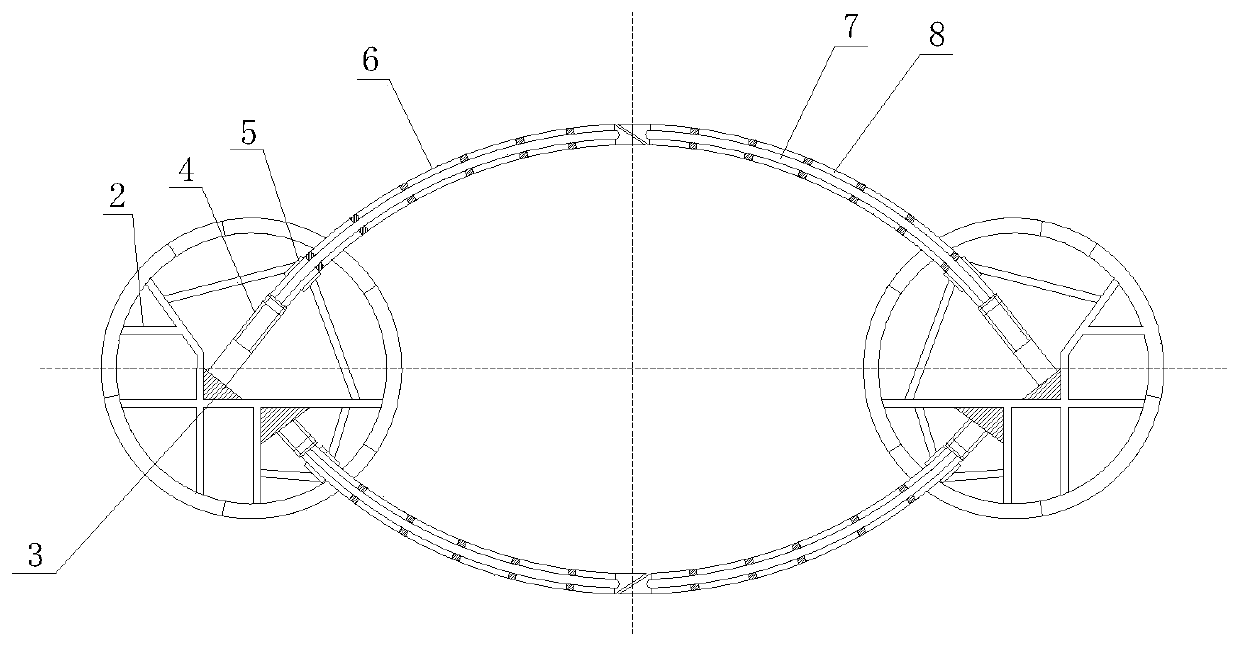

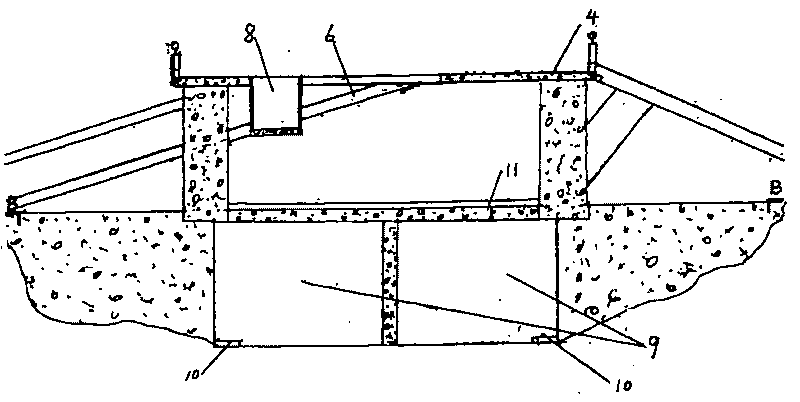

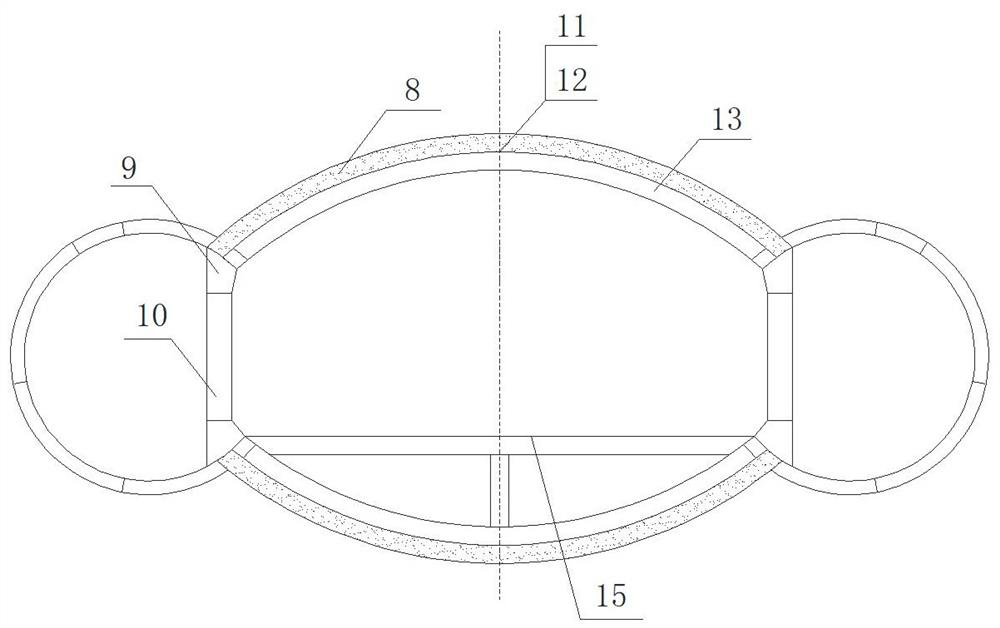

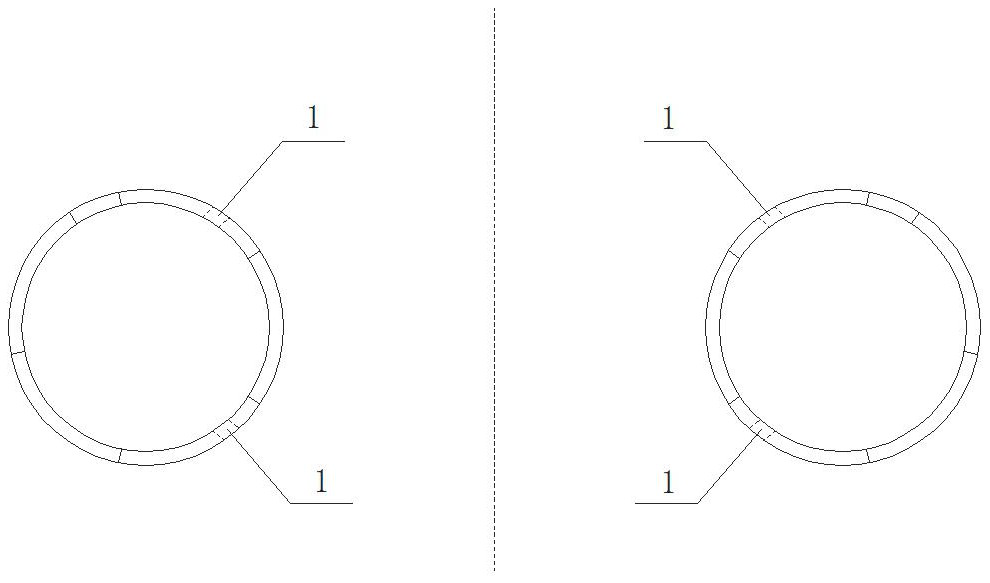

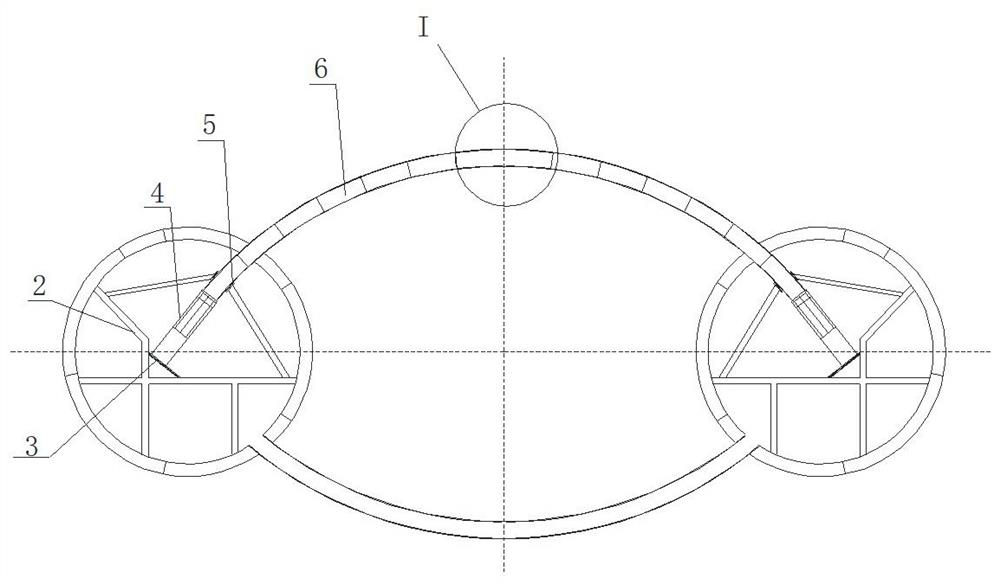

Soft soil stratum subway station expansion method and structure based on inserted beam freezing method

ActiveCN111305851AStabilized soil structureImprove construction efficiencyUnderground chambersTunnel liningSoil scienceStructural engineering

The invention provides a soft soil stratum subway station expansion method and structure based on an inserted beam freezing method. The soft soil stratum subway station expansion structure comprises shield tunnels, a middle platform connected between the two parallel shield tunnels and communicating with the shield tunnels, and frozen soil layers wrapping the outer side of the middle platform; themiddle platform comprises a top lining unit, a bottom lining unit, side columns and a structural bottom plate, the top lining unit and the bottom lining unit are arranged between the shield tunnels and are symmetrical up and down, and the frozen soil layers are distributed along the arched outer surfaces of the top lining unit and the bottom lining unit; the two side ends of the bottom lining unit and the two side ends of the top lining unit are connected and supported through the side columns; and the structural bottom plate is arranged above the bottom lining unit and is kept on the same horizontal plane with the two ends of the bottom lining unit. The method solves the problem of large deformation of subways and surrounding soil caused by serious soil moving in an expansion mode, and has the advantages of being high in construction efficiency, short in construction period and high in safety.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

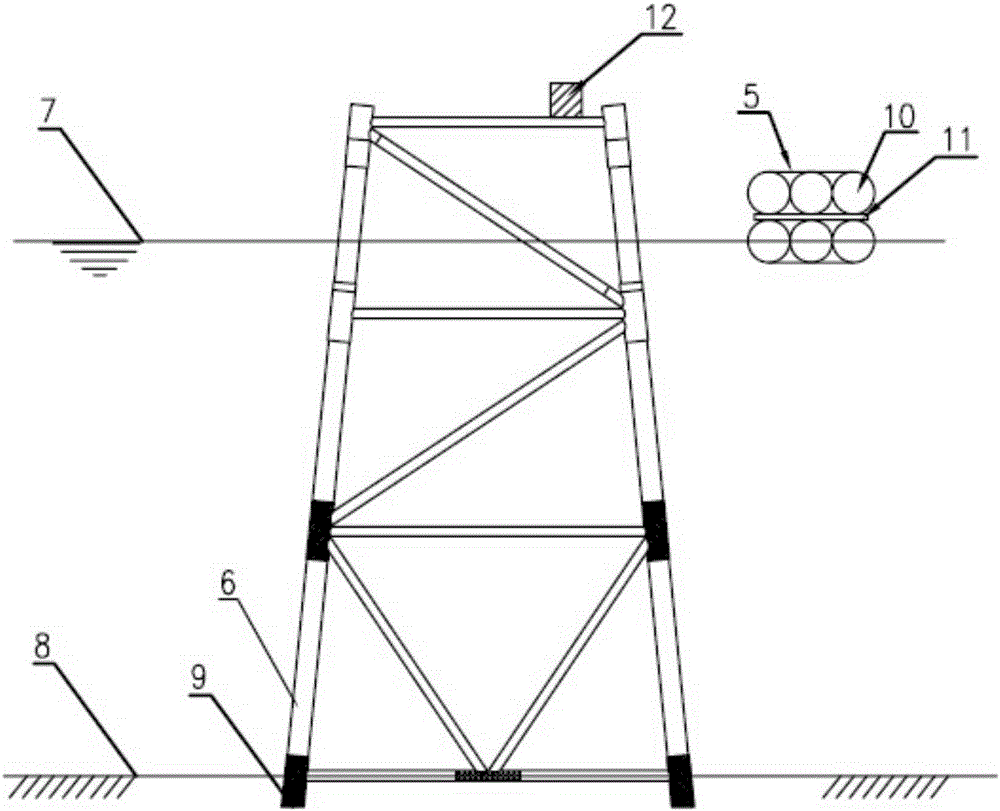

Method for dismantling discarded jacket through air bags

ActiveCN105200970AImprove demolition efficiencyLow demolition costArtificial islandsUnderwater structuresEngineeringRemote control

A method for dismantling a discarded jacket through air bags comprises the following steps: 1, dismantling preparation is performed on the discarded jacket; 2, a plurality of air bag groups are lowered into water and are connected to form a whole air bag floating aiding unit; 3, the air bag floating aiding unit and a local control panel arranged at the top of the discarded jacket are connected, so that the remote control panel can realize controlling and monitoring functions; 4, the air bag floating aiding unit is inflated to be in a pressure maintaining state; 5, a workboat is connected with the discarded jacket and tows the discarded jacket away from the site. The method has the advantages that the dismantling efficiency can be improved greatly and the dismantling cost is reduced; the offshore construction risks are reduced; meanwhile, the completeness of the discarded jacket can be kept, the construction risks caused by jacket disassembly are reduced, and the air bags are recyclable, so that the engineering cost can be reduced substantially.

Owner:CHINA NAT OFFSHORE OIL CORP +1

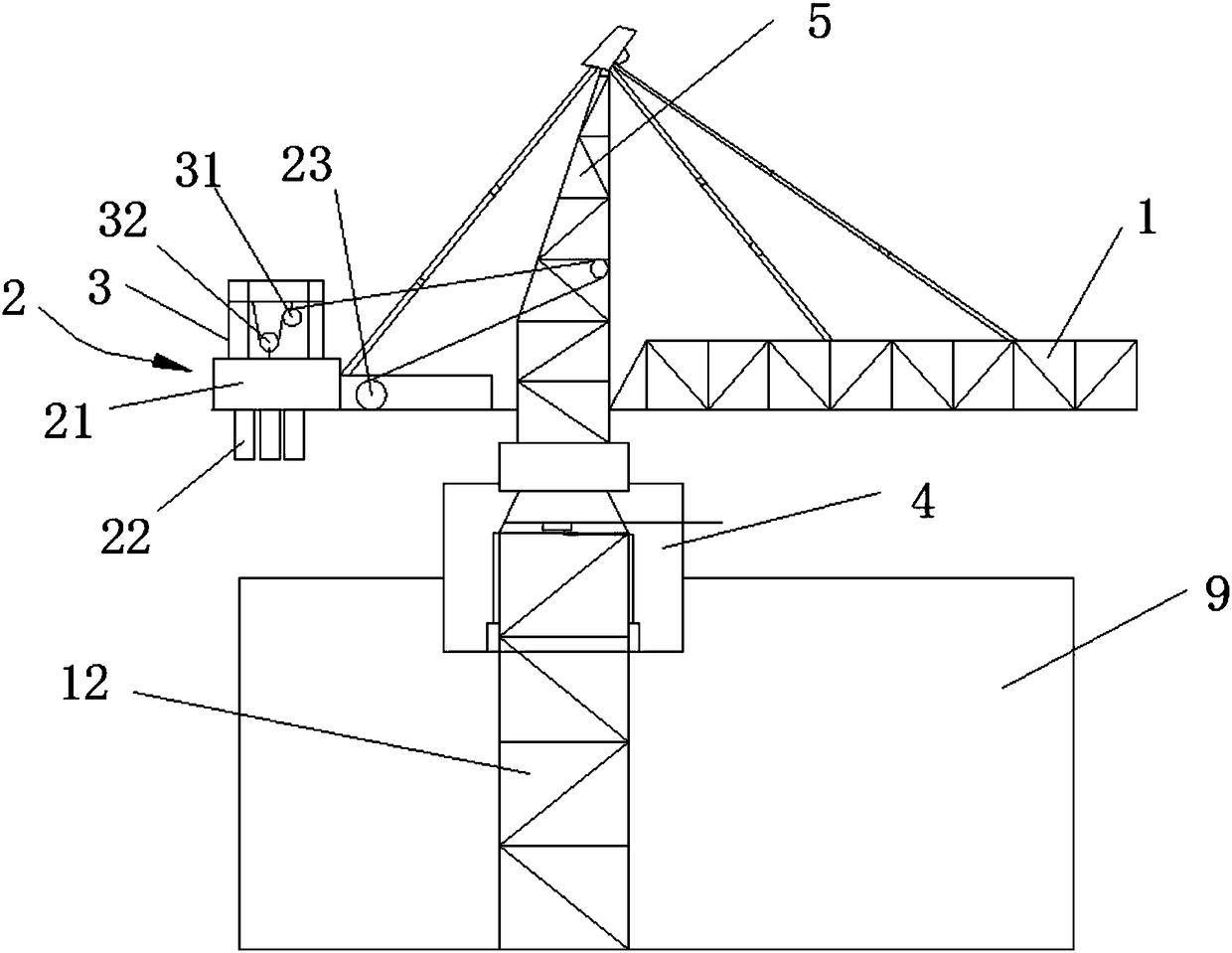

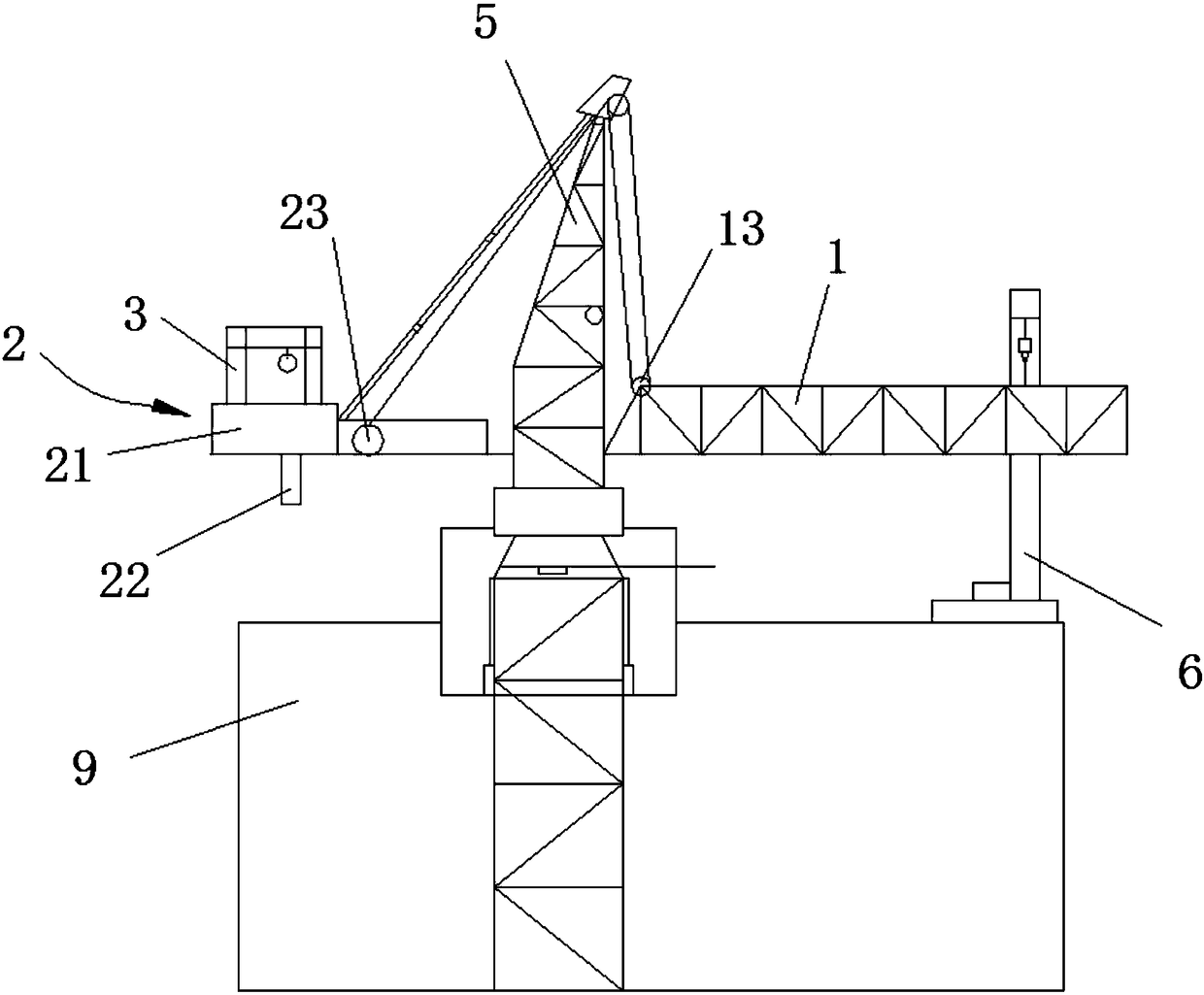

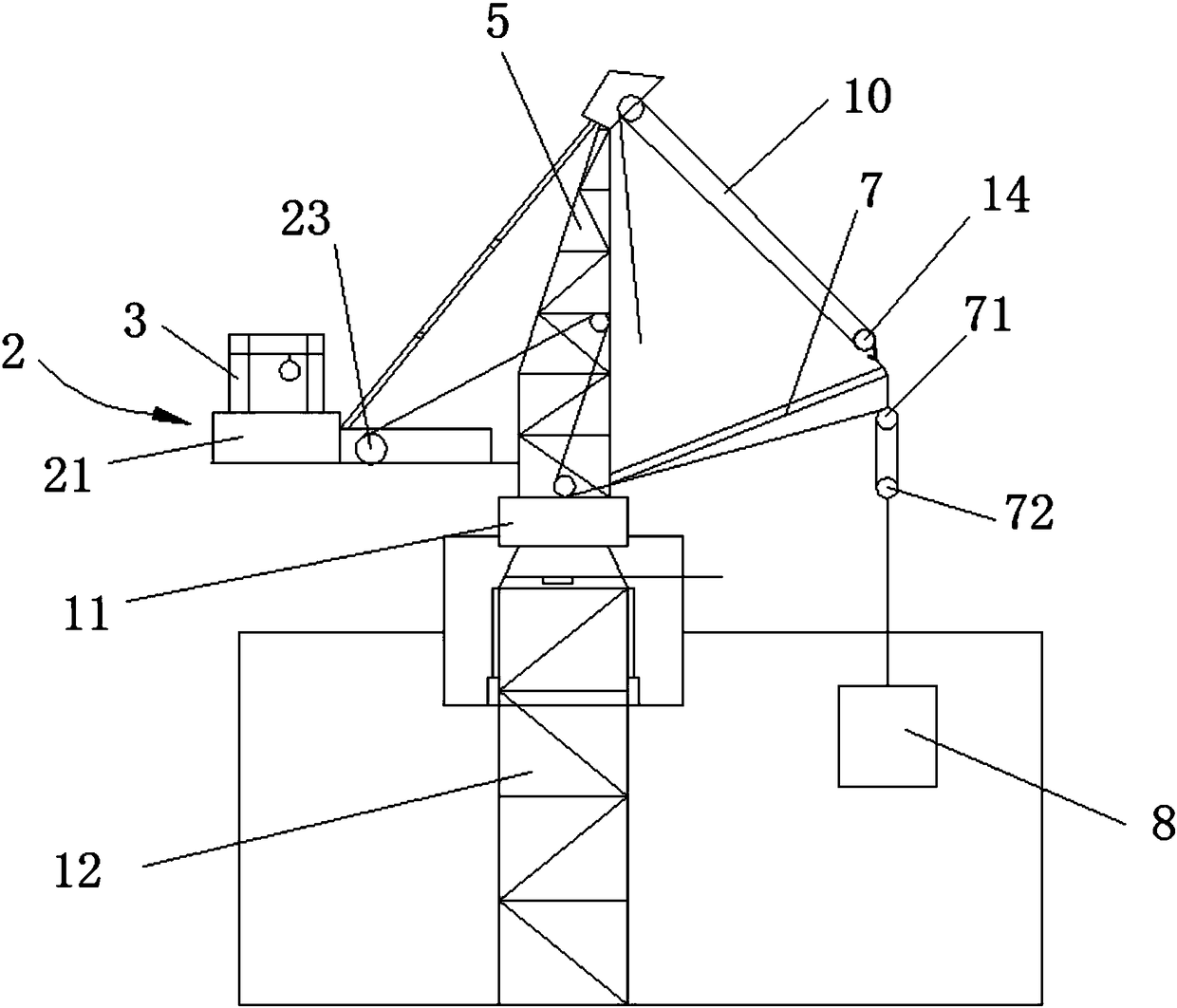

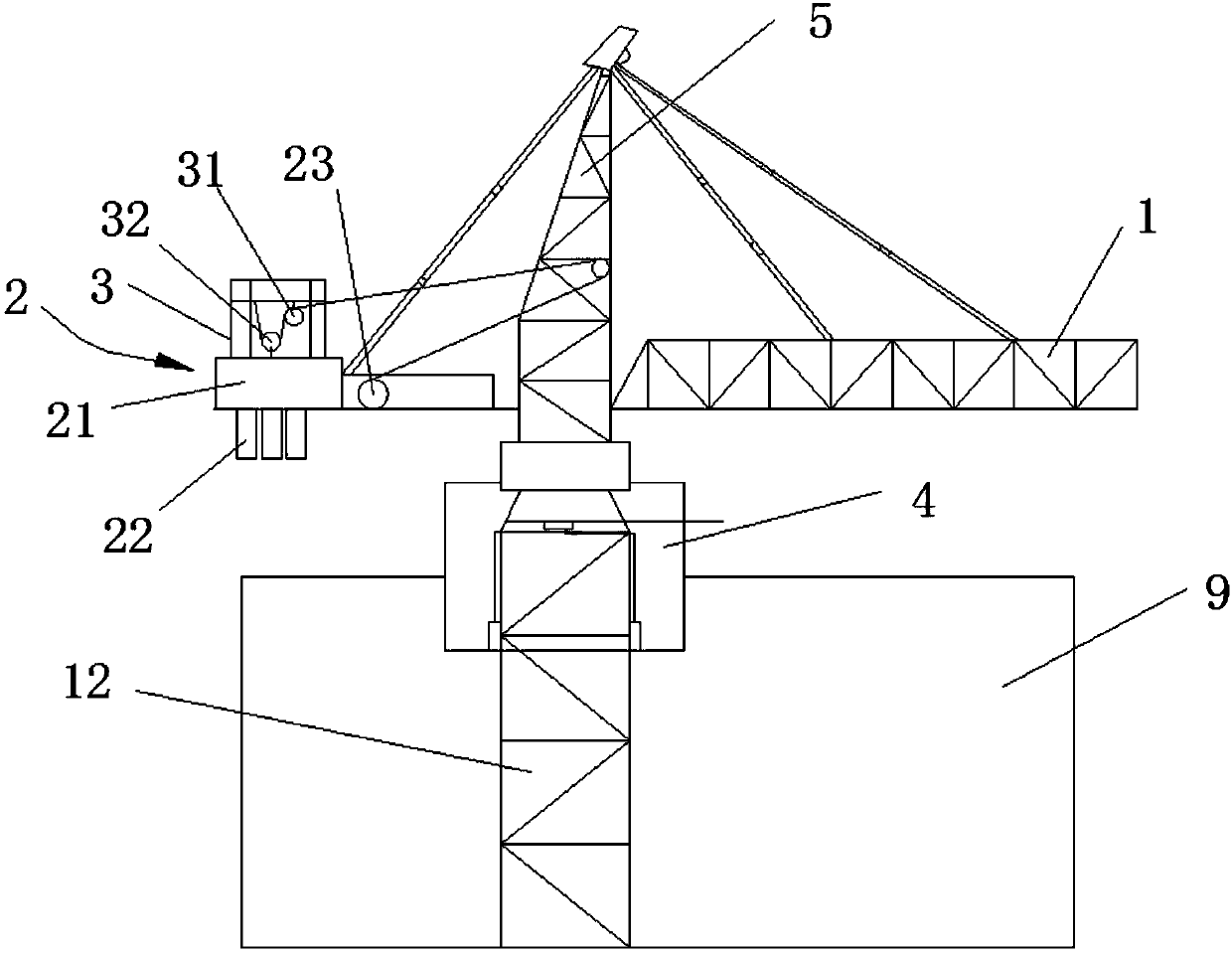

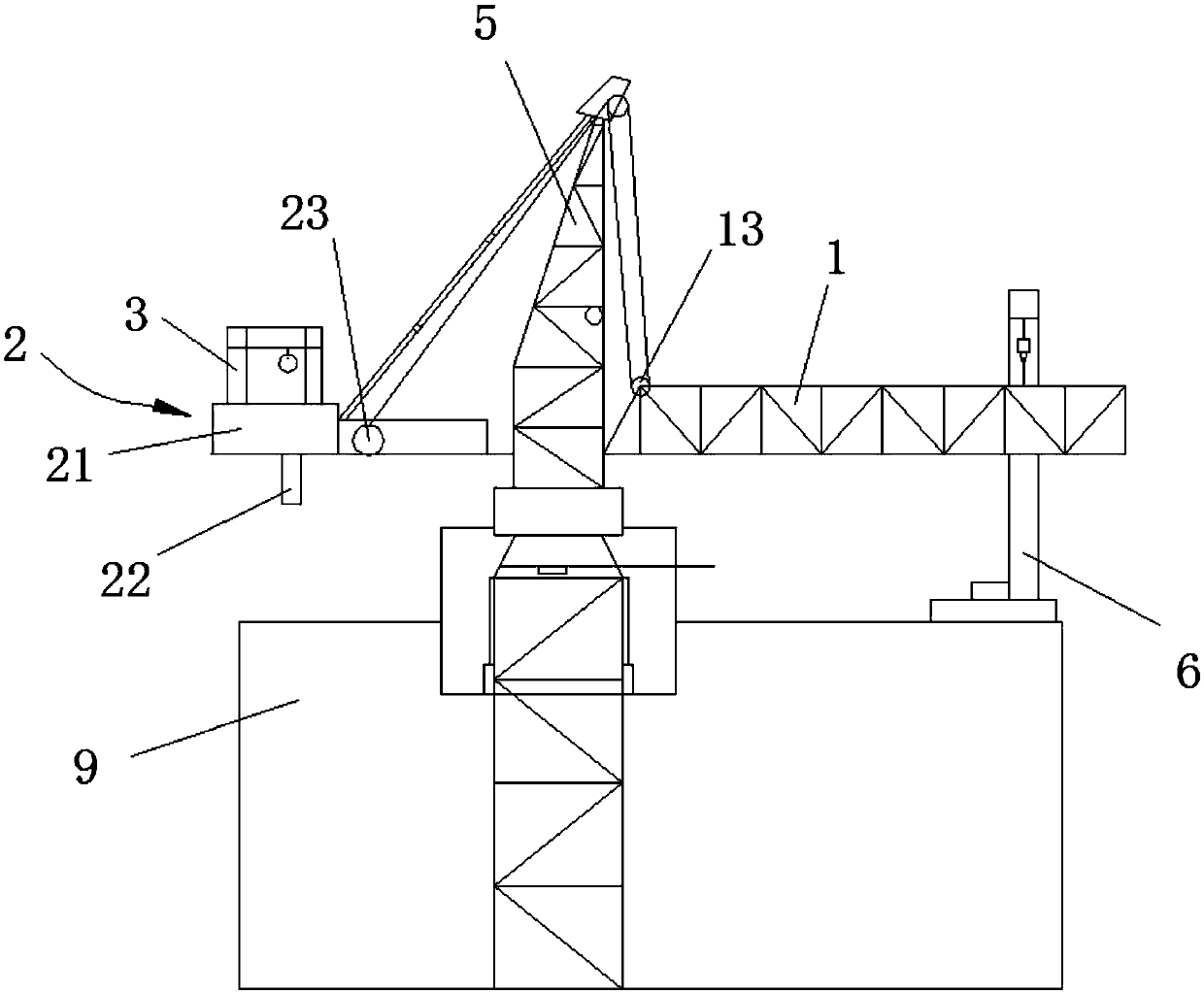

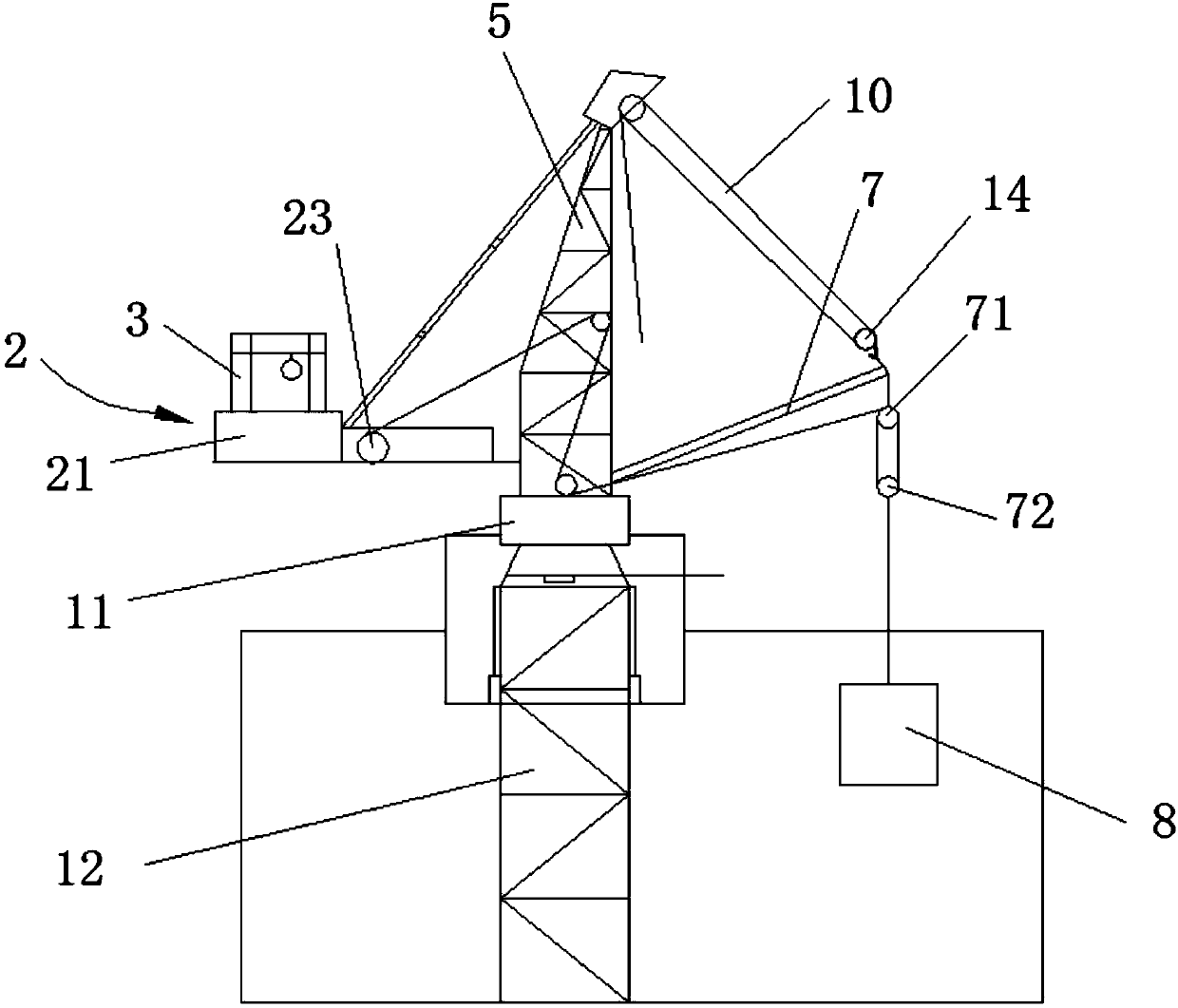

Disassembling method of adhesion type tower crane under narrow terrain

The invention provides a disassembling method of an adhesion type tower crane, being capable of reducing the disassembling cost of the adhesion type tower crane under a narrow terrain, and belonging to the technical field of building construction. The disassembling method of the adhesion type tower crane under the narrow terrain comprises the following steps: (a) disassembling a surplus balancingweight; (b) disassembling a hoisting jib; (c) balancing the tower crane; (d) disassembling a tower body; (e) disassembling a balance arm, a tower cap and a rotary mechanism. According to the disassembling method provided by the invention, no large-scale hoisting equipment is required during a tower crane disassembling process, so that the disassembling cost of the tower crane is lower.

Owner:中电建宁夏工程有限公司

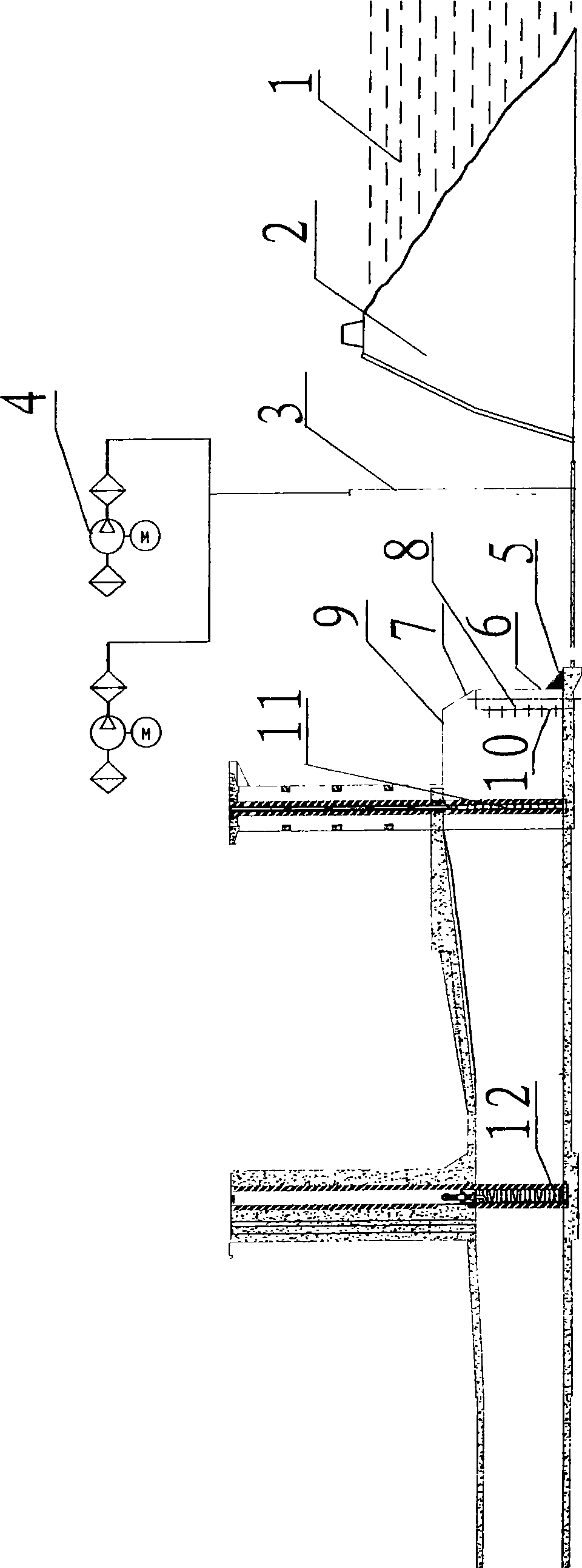

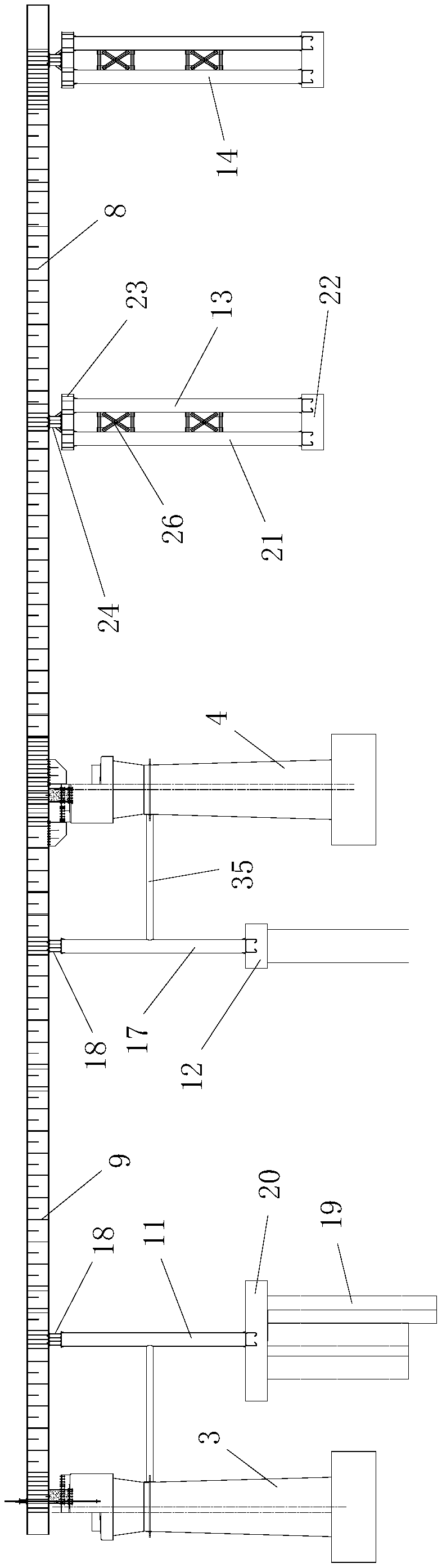

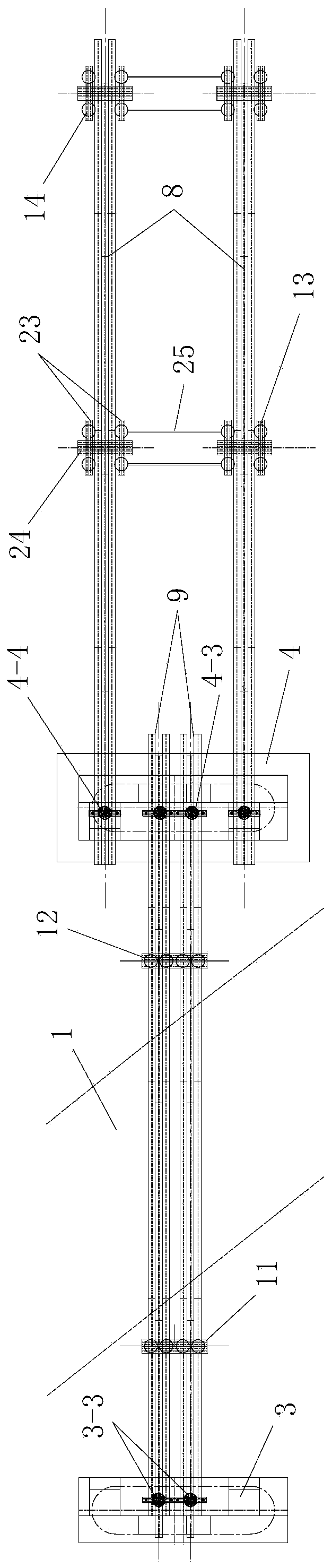

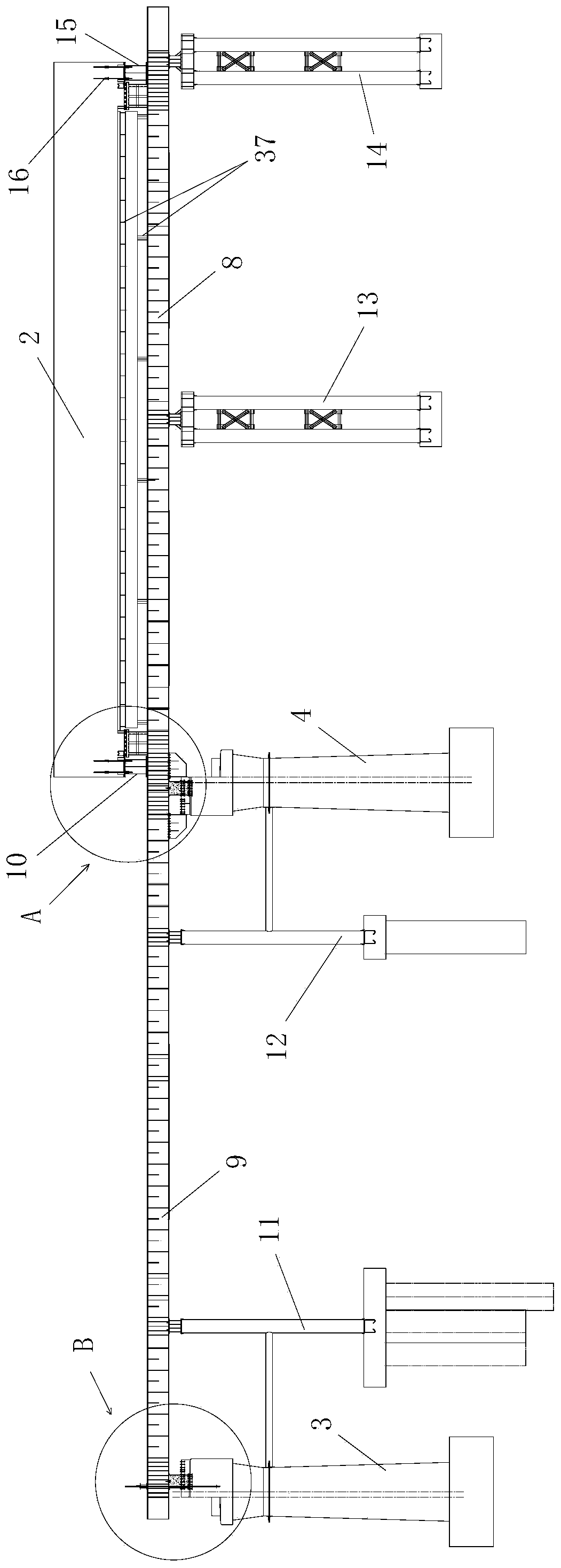

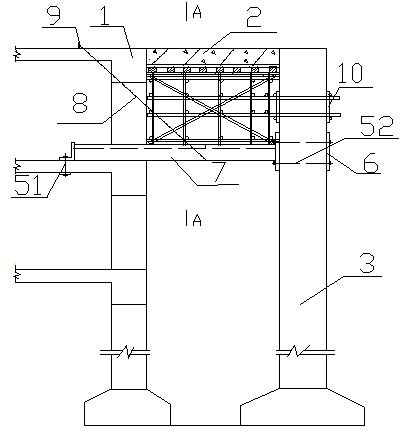

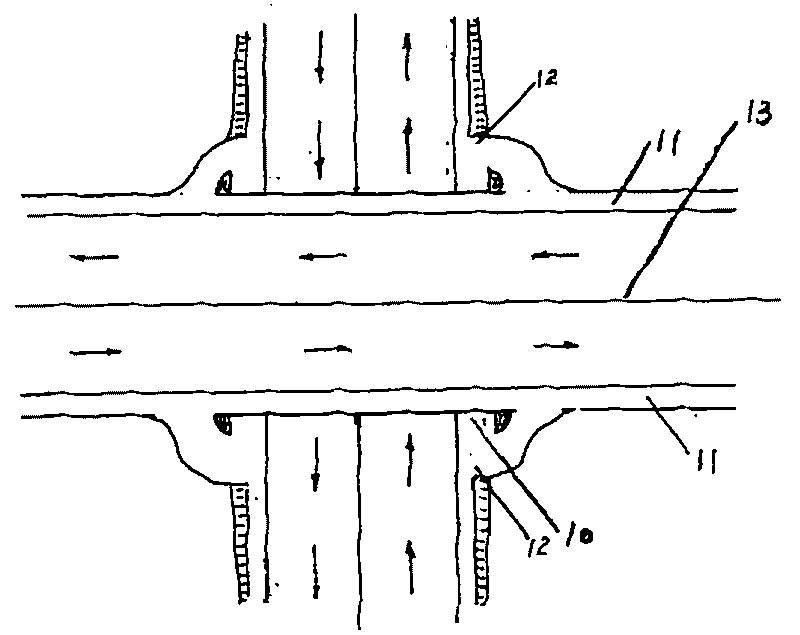

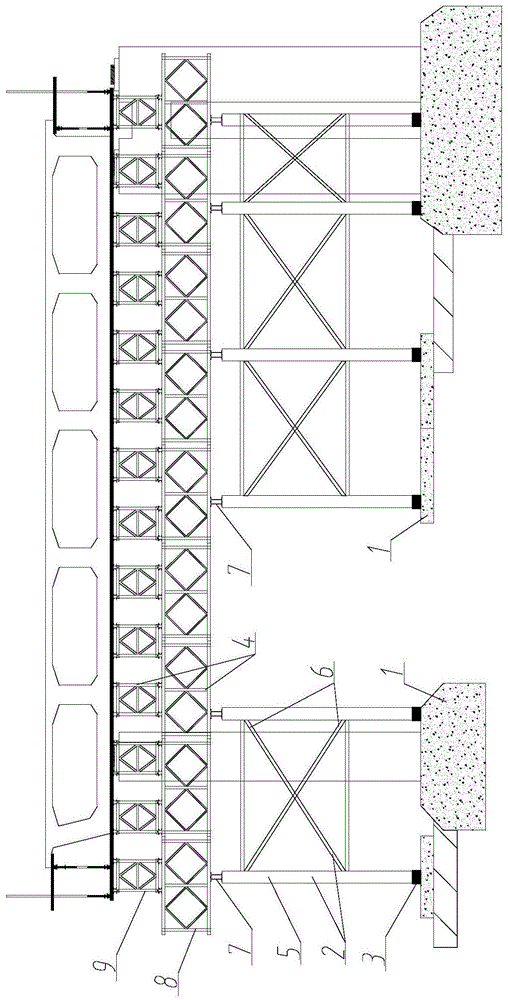

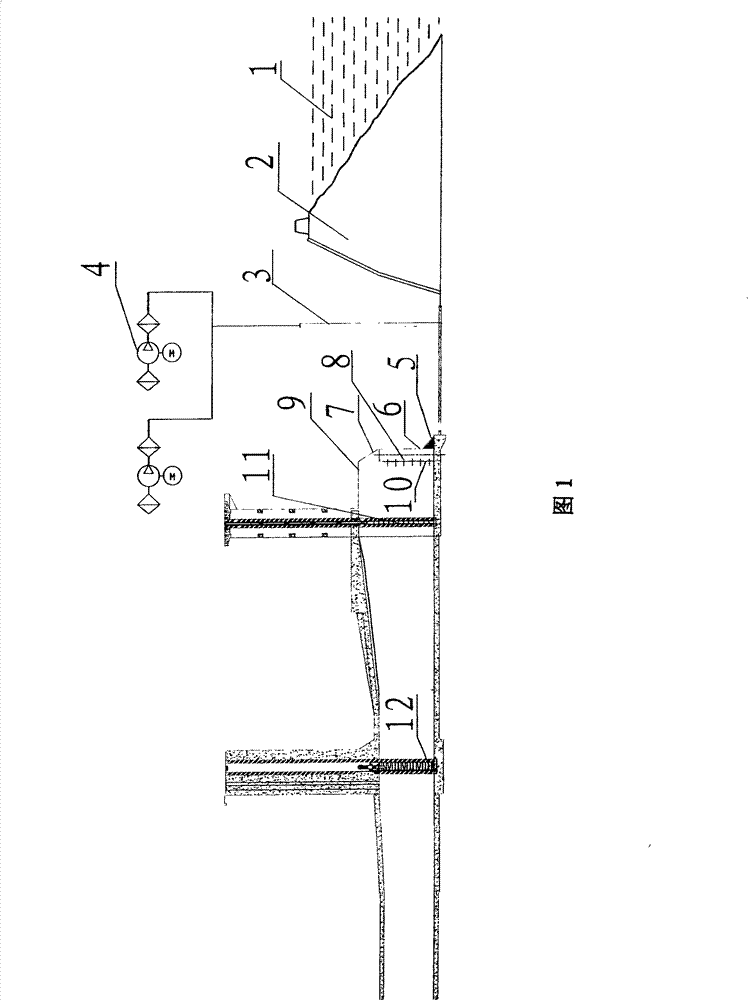

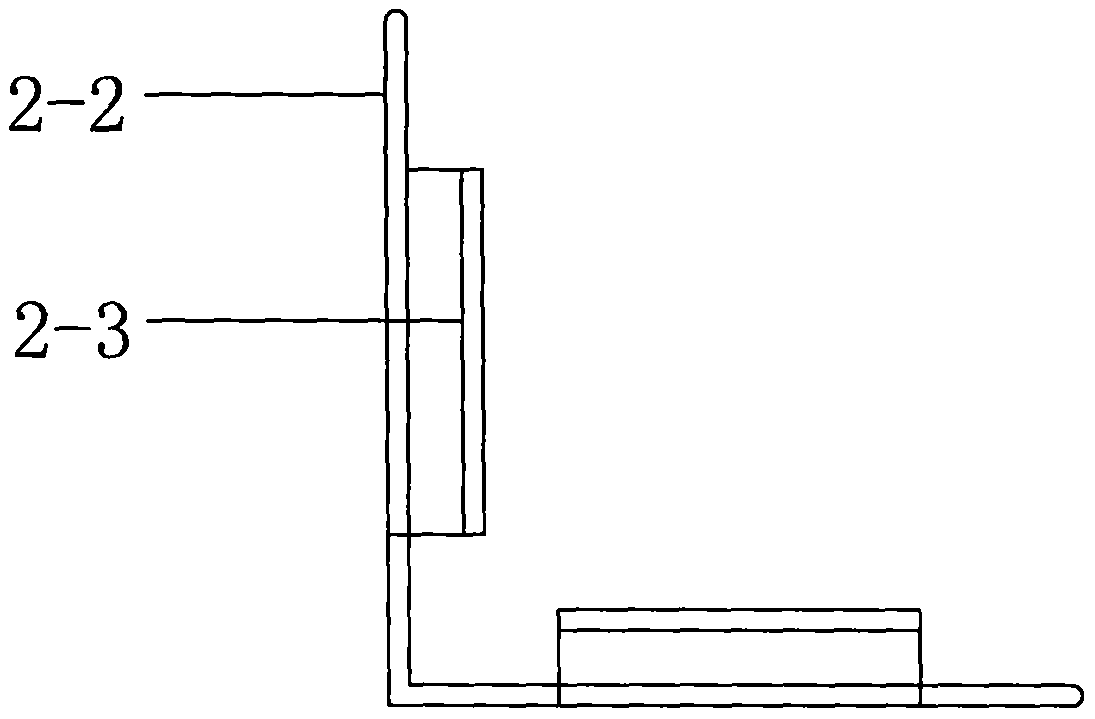

Existing-road-crossing cast-in-situ trough beam three-point sliding jacking construction method

ActiveCN109778700AReasonable structural designEasy to operateBridge erection/assemblyCross bridgeWorkload

The invention discloses an existing-road-crossing cast-in-situ trough beam three-point sliding jacking construction method. The method comprises steps of 1, pier and temporary pier construction; 2, slideway beam erection; 3, horizontal crossbeam layout; 4, trough beam cast-in-situ construction; 5, traction device installation; 6, jacking; 7, beam dropping. According to the method, design is reasonable, construction is easy, and the use effect is good; two back slide beams and one front slide beam are used for forming a three-point longitudinal passage, and horizontal cross beams are laid at the bottoms of the front end and the back end of the cast-in-situ trough beam respectively, the problem that deformation of the slide beams on the to sides is asynchronous in existing-road-oblique-crossing cast-in-situ trough beam jacking construction can be effectively solved; in addition, temporary piers are constructed on the two sides of an existing road in the cross bridge direction respectively, the temporary pier construction workload can be effectively reduced, and the cost can be effectively reduced; meanwhile, the influence on use of the existing road can be effectively reduced or evenavoided.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

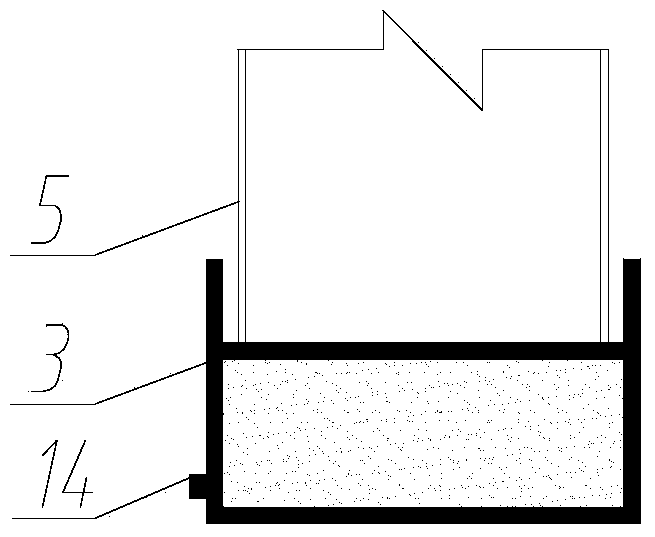

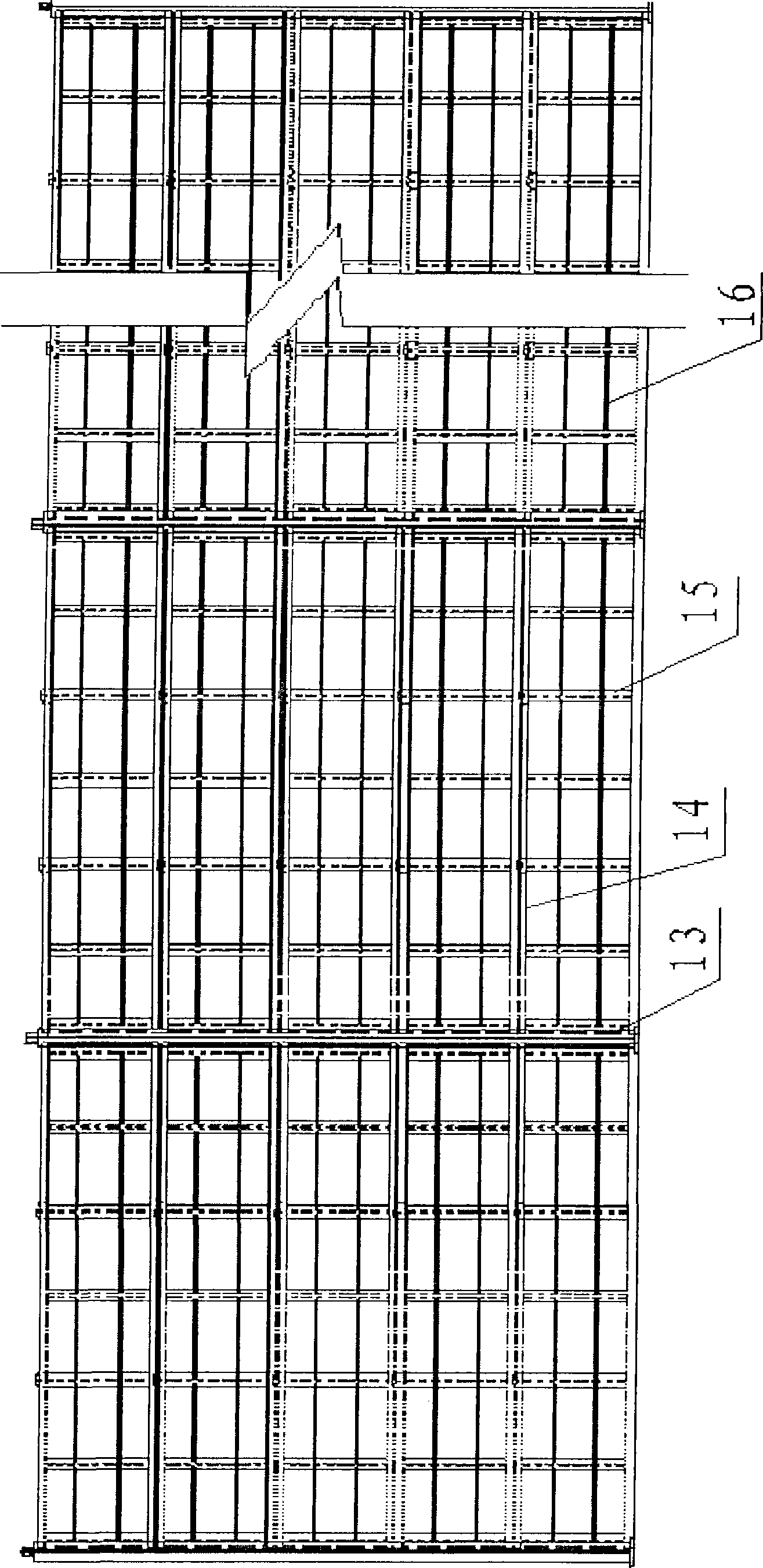

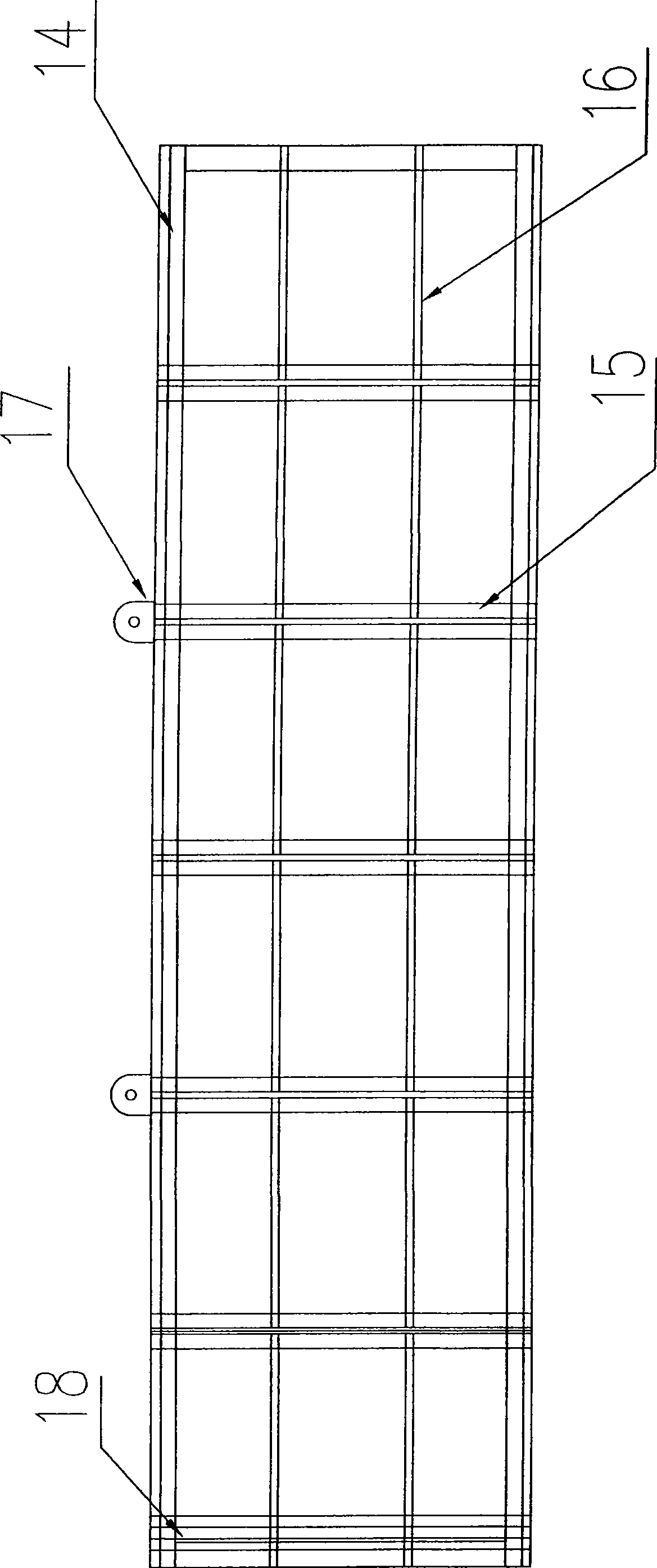

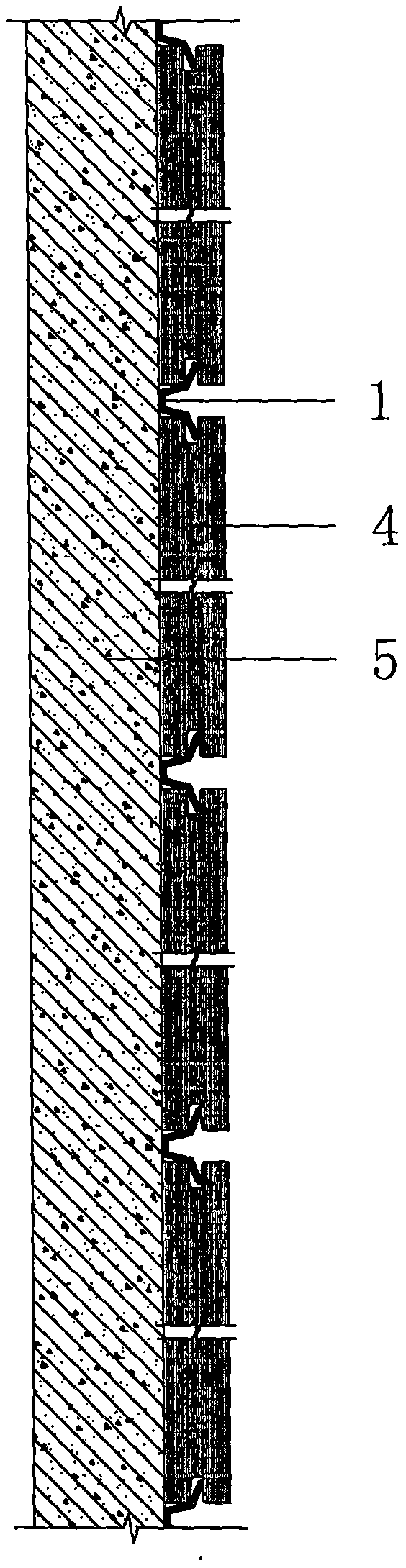

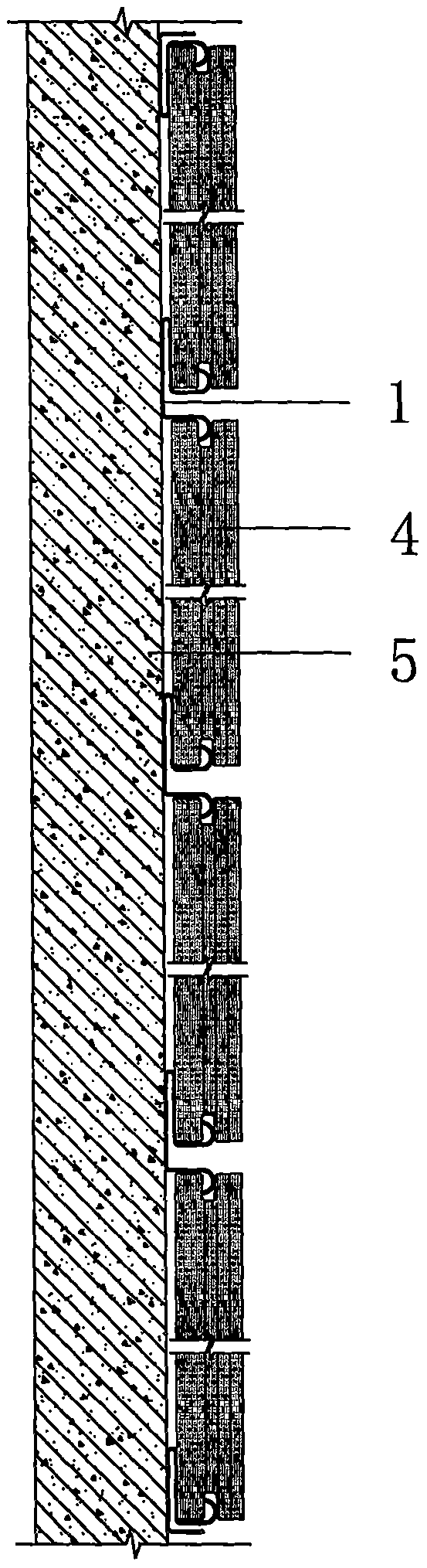

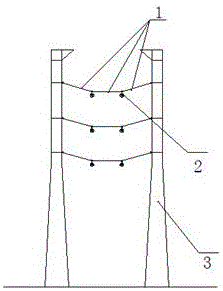

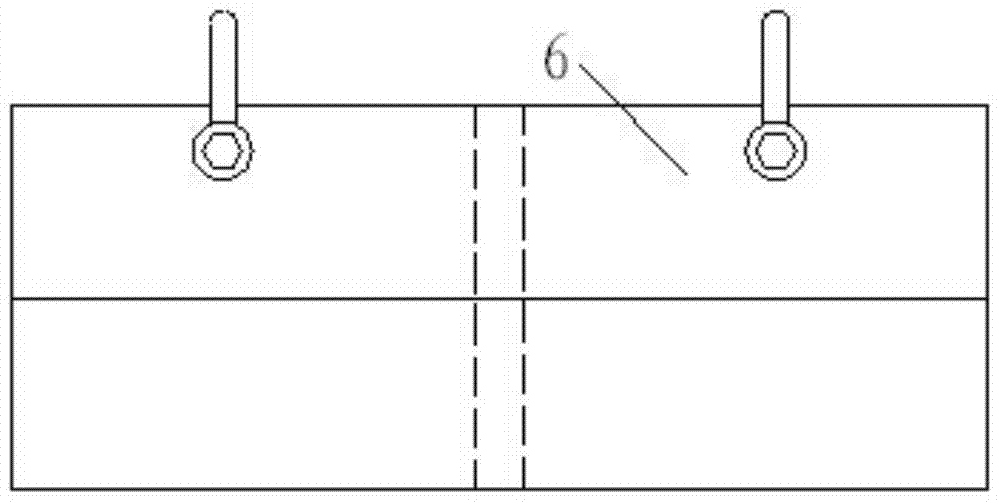

Construction method of large-height small-sized cast-in-place concrete beam slab

InactiveCN102619335ALow demolition costEasy to assemble and disassembleForms/shuttering/falseworksBuilding material handlingFalseworkFloor slab

The invention discloses a construction method of a large-height small-sized cast-in-place concrete beam slab. The large-height small-sized cast-in-place concrete beam slab comprises a floor foundation built by using multiple layers of floor slabs and a concrete framework column. The method comprises the following steps of: preserving a bolt hole on a concrete framework column which is opposite to a lower layer slab of the floor on which a concrete beam slab is required to be poured; arranging a channel steel support beam between the lower layer slab of the floor on which the concrete beam slab is required to be poured and the preserved bolt hole, and connecting and fixing the two ends of the support beam by using bolts; arranging a steel wire rope on the middle part of the support beam, and fixing the other end of the steel wire rope on a hoisting ring embedded into the floor on which the concrete beam slab is required to be poured; building a template support beam on the support beam; fixedly arranging a template on the template support frame; building a protective net; and pouring. Due to the adoption of the construction method, the building height of a scaffold is reduced greatly, a large quantity of frame pipes and fasteners are saved, and material cost, manual installation cost and detaching cost are reduced.

Owner:河北省第二建筑工程有限公司

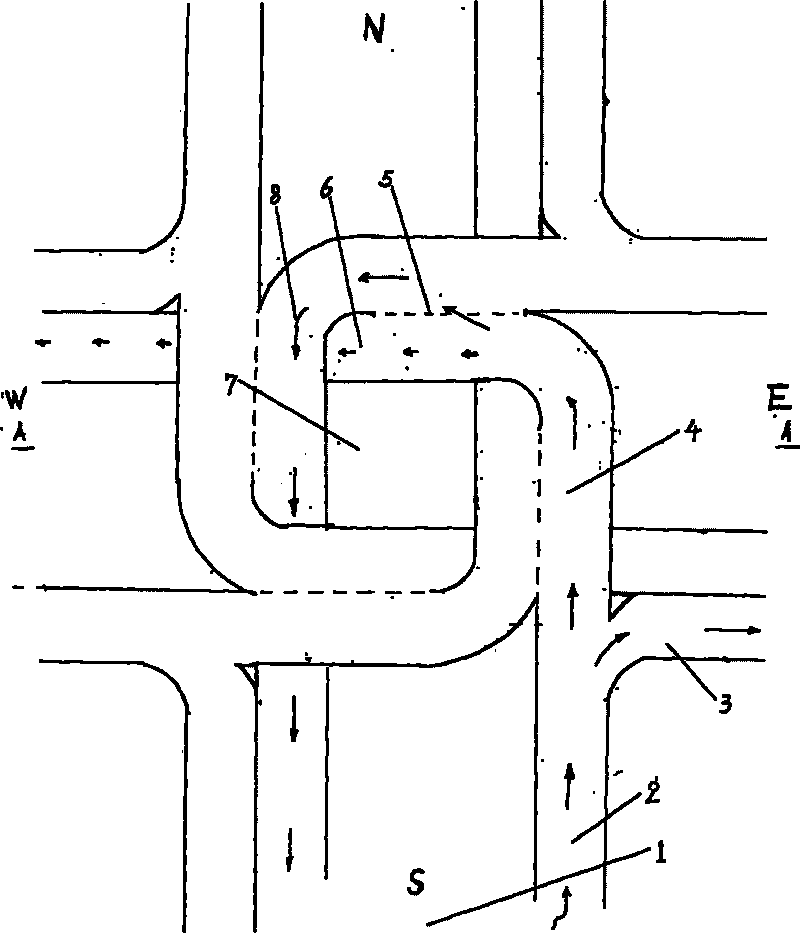

Universal compact road overpass

The invention discloses a universal compact road overpass. In the invention, ascending right uphill roads (2) are arranged on the right side of a forward roadway (1) next to the overpass, the forward direction of the right uphill roads (2) are connected with interchange whirl roads (4), and the right direction of the right uphill roads (2) are connected with the arranged right turning roads (3); the external roadway of the whirl road is connected with the arranged downhill back roads (8) to a turning back direction; the inner road of the whirl road is connected with the arranged left turning downhill roads (6) to the left direction; the downhill back road on each direction is converged with left turning downhill roads on the overpass; and an open yard (7) is arranged among the left downhill roads. In the invention, motor vehicles and pedestrians can travel on respective way, with no need of stopping and waiting, thereby meeting smooth traffic and avoiding accidents, in addition, the universal compact road overpass has the advantages of little occupied floor area, little space usage and simple structure.

Owner:杨文臣

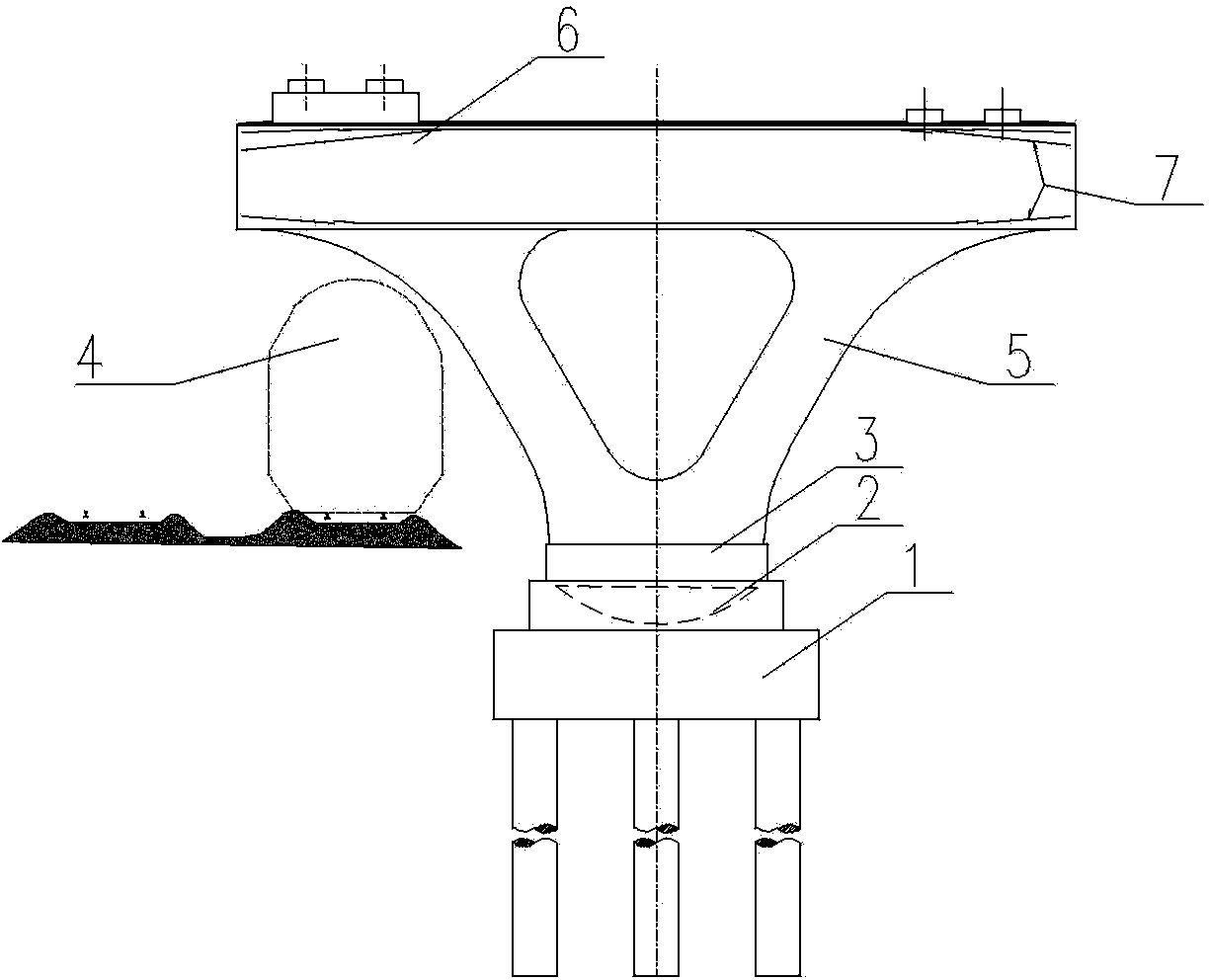

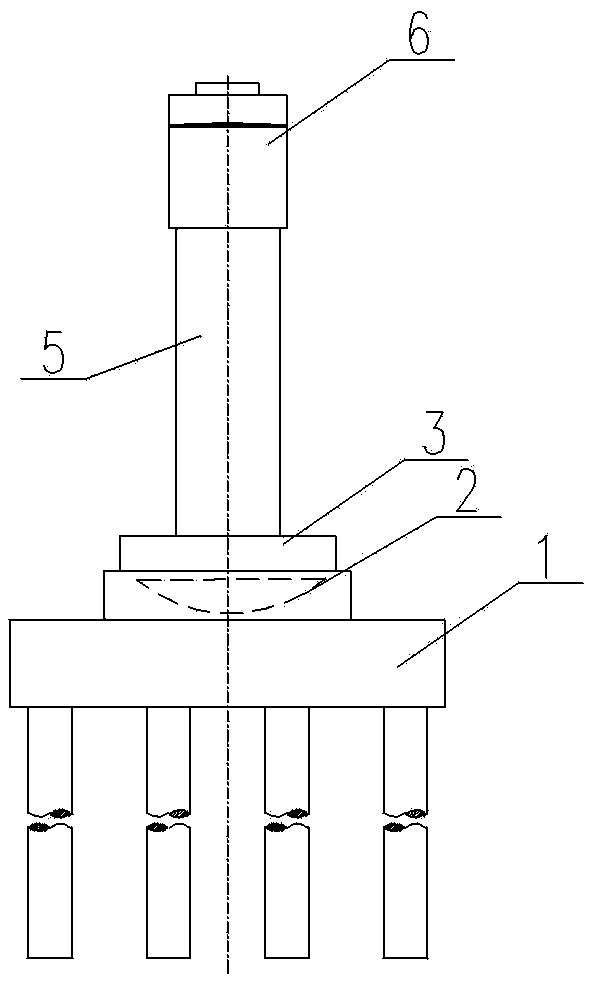

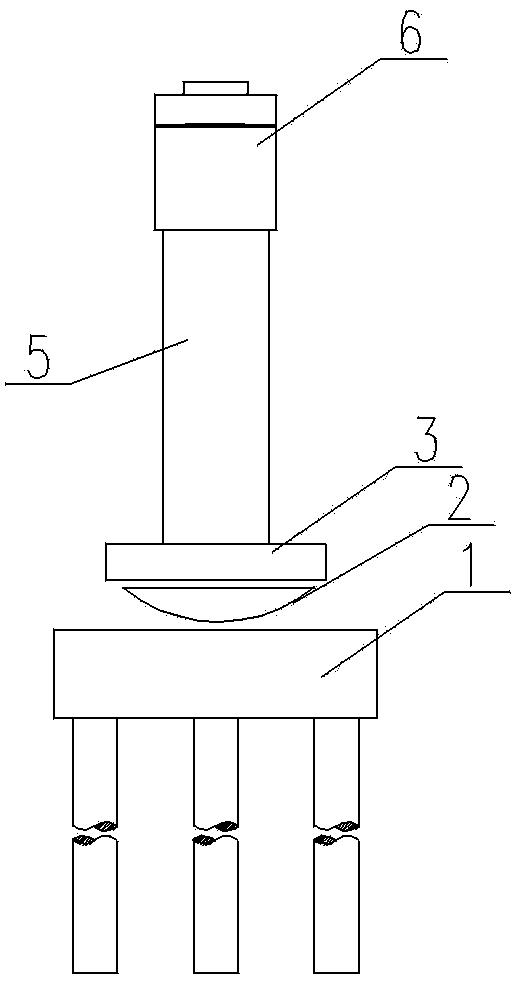

Rotation V-type T-structure bridge pier and construction thereof

ActiveCN104213504AShorten the construction periodReduce operational disruptionBridge structural detailsFoundation engineeringArchitectural engineeringUrban area

The invention relates to a rotation V-type T-structure bridge pier and a construction thereof. When an included angle formed between a line and an existing busy trunk line through vertical crossing is smaller, cross-hole arrangement of a bridge is more difficult. The bridge pier is constructed on one side of the existing trunk line, and comprises a pile foundation, a supporting platform, pier arms and a cover beam from bottom to top, wherein the supporting platform is divided into a lower rotary table and an upper rotary table from bottom to top; a rotary spherical hinge is arranged between the upper rotary table and the lower rotary table; during line operation skylight time, the upper rotary table and the structure rotate to a designed position by taking the rotary spherical hinge as the center, concrete on the outer side of the rotary spherical hinge is poured to form a solid stage, and the lower rotary table and the upper rotary table are fixedly connected together to complete construction. Due to the adoption of a rotation V-type T-structure scheme, the construction only needs to be performed on one side of the existing line, requirements for roads and construction sites on the other side are reduced, the conditions that houses on two sides of the existing line in an urban area are dense and are difficult to remove are facilitated, the removal cost is greatly reduced, and the construction period is guaranteed; meanwhile, due to the adoption of rotation construction, the influence on operation of the existing line is minimized.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Subway station extension method and structure based on concrete-filled steel tube beam insertion method

InactiveCN112302666AImprove construction efficiencyImprove securityUnderground chambersTunnel liningArchitectural engineeringEngineering

The invention relates to a subway station extension method and structure based on a concrete-filled steel tube beam insertion method. The subway station extension method comprises the steps that a transverse through middle platform is built between existing bidirectional parallel shield tunnels to form an extension structure; and corresponding upper through holes and lower through holes are obliquely formed in segments of the two shield tunnels, jacking bent steel pipes are inserted from the through holes to be transversely connected to serve as external supports, a lining structure is constructed after soil is excavated on the inner side, and through connection is achieved after the segments at shield tunnel connectors are detached. Small expansion, downward storey addition and step-by-step expansion can be achieved, and the subway station extension method is suitable for expansion of subway stations with strict control over ground displacement and ground surface settlement and construction of shallow soil, soft stratums and large-span underground spaces.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

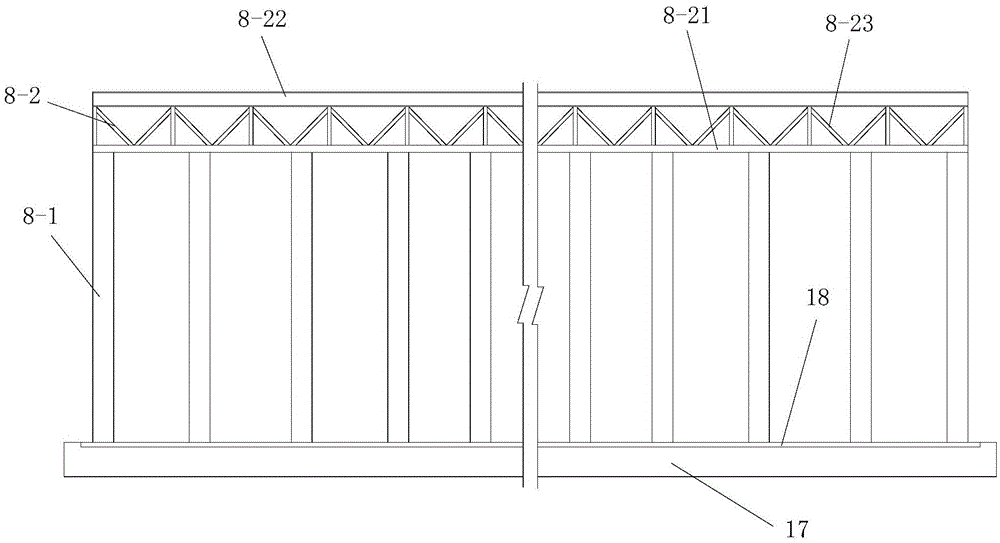

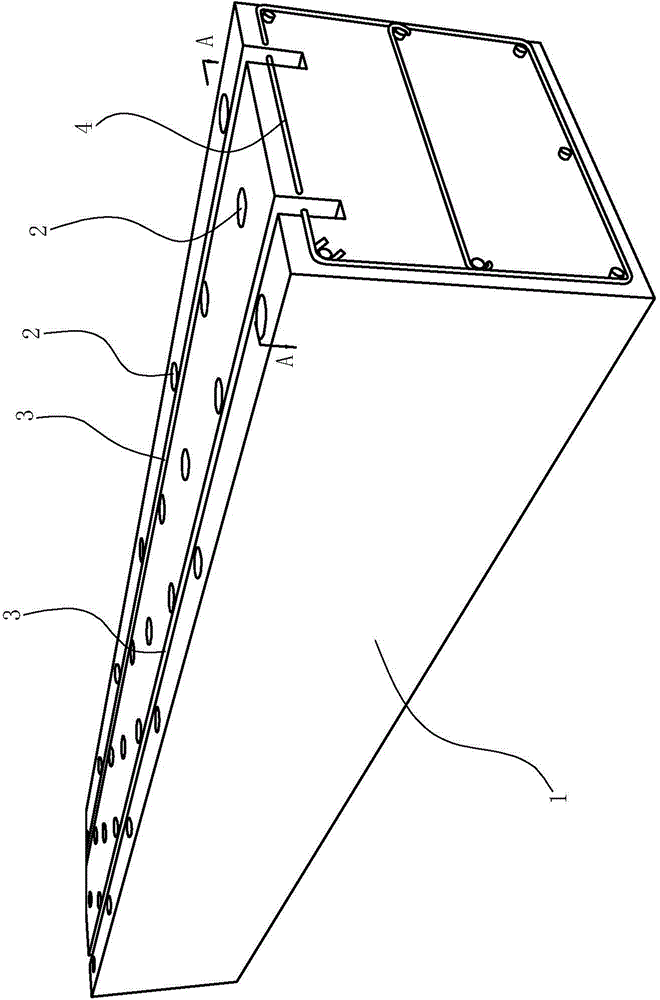

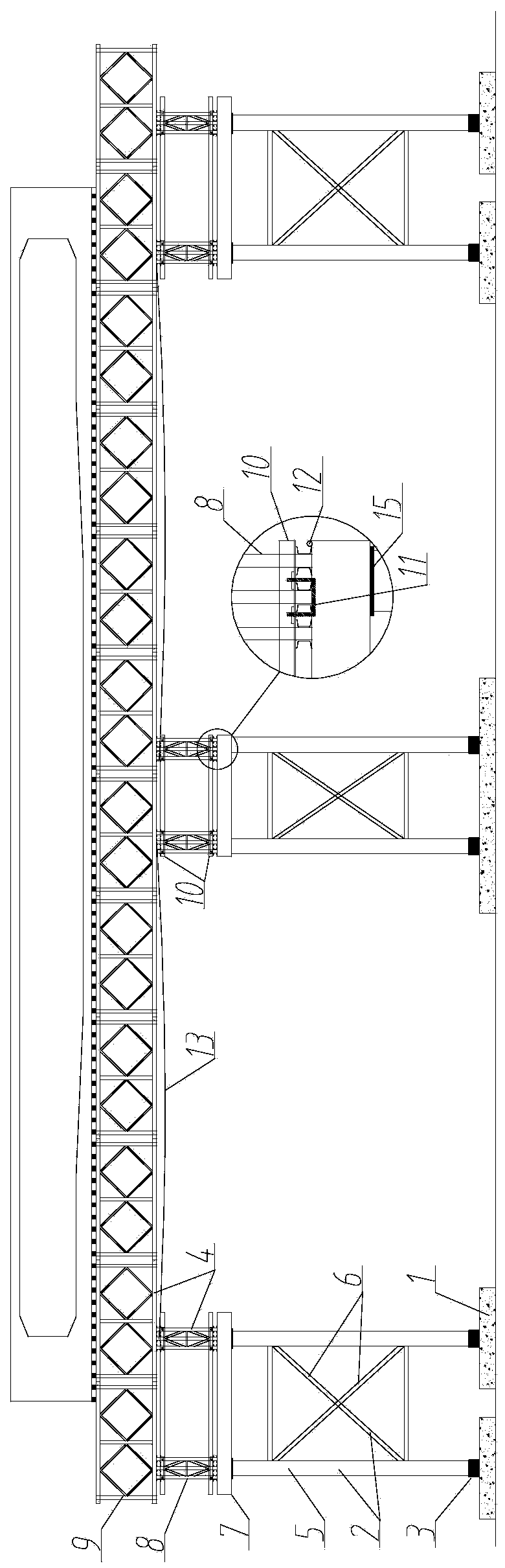

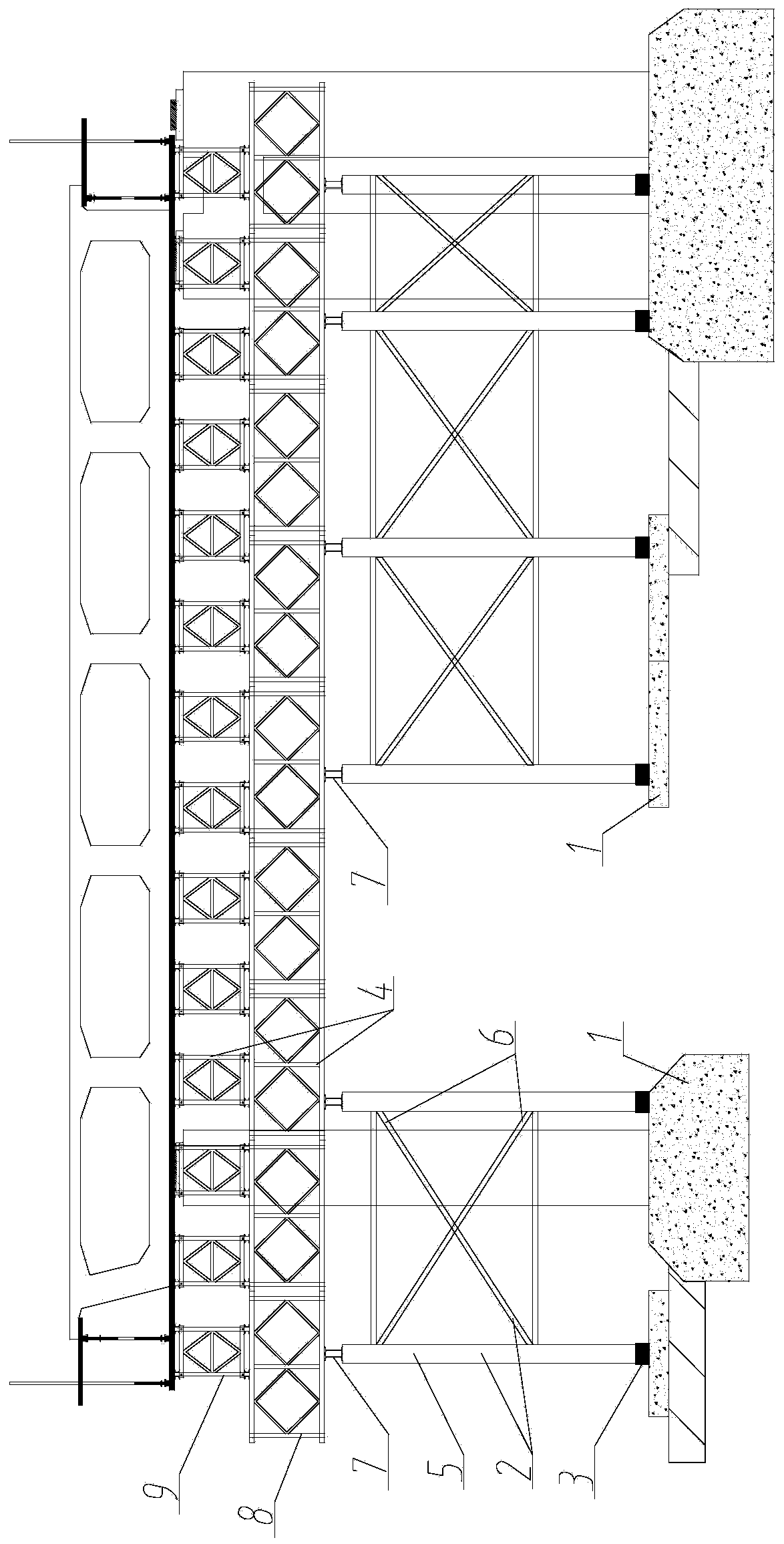

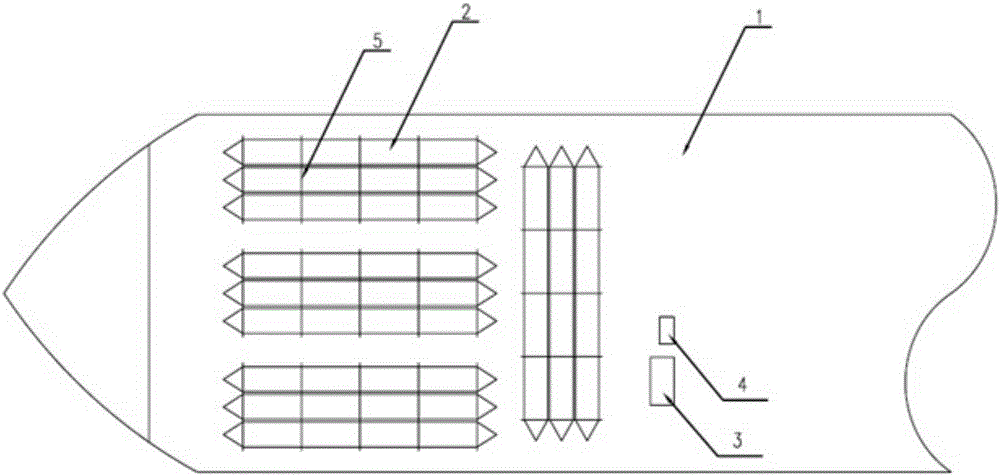

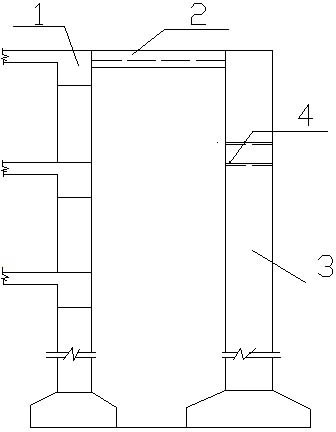

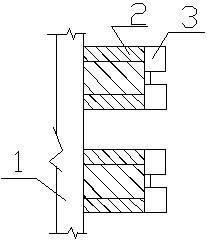

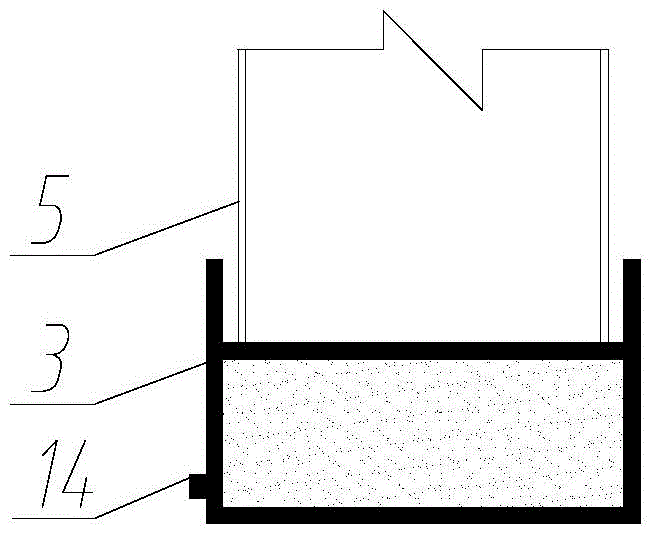

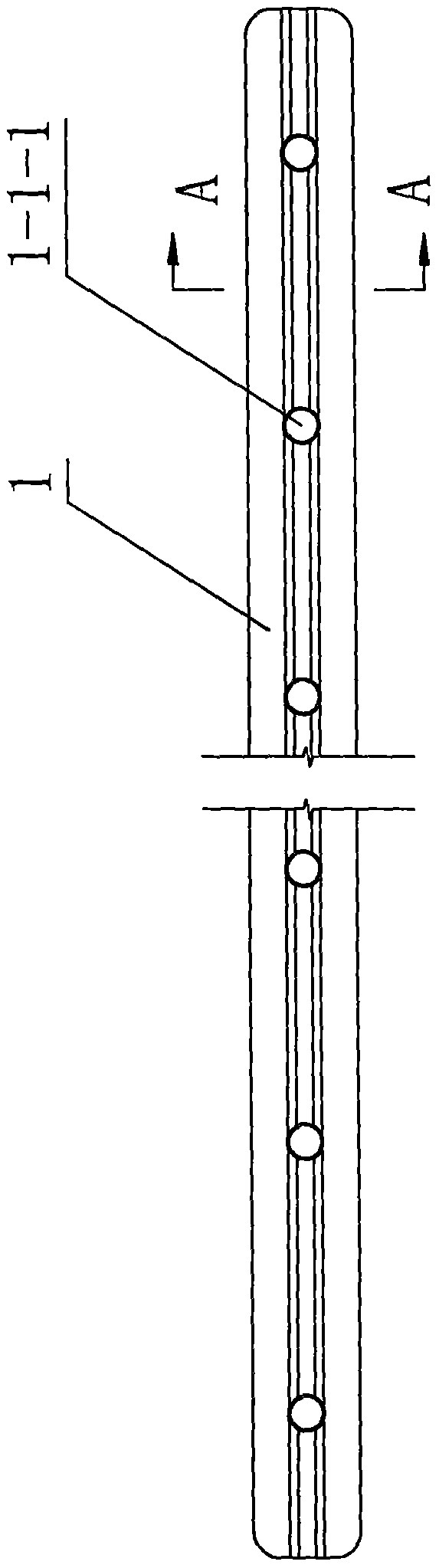

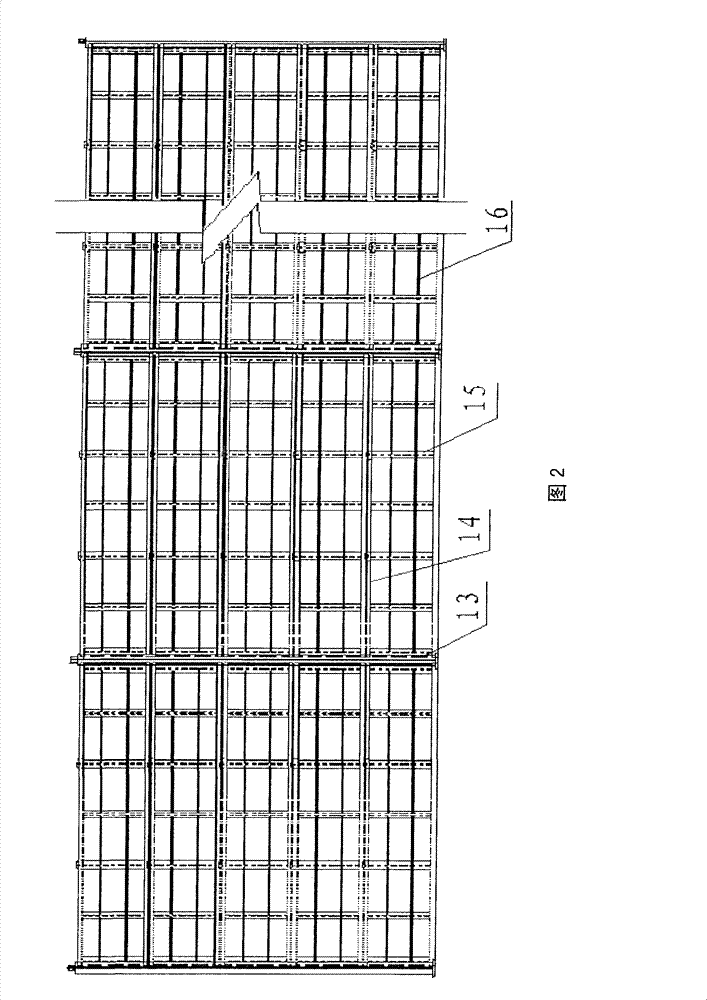

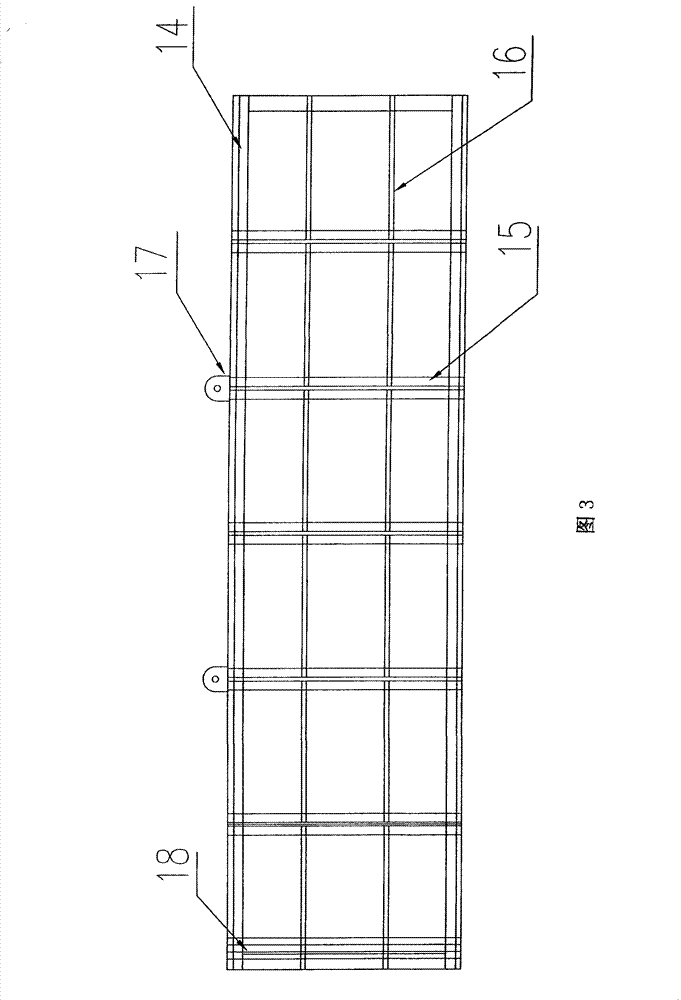

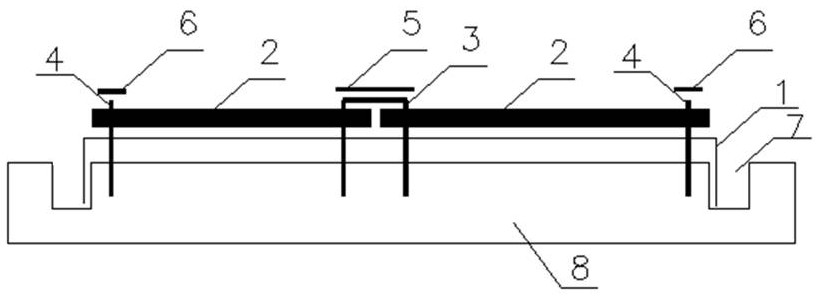

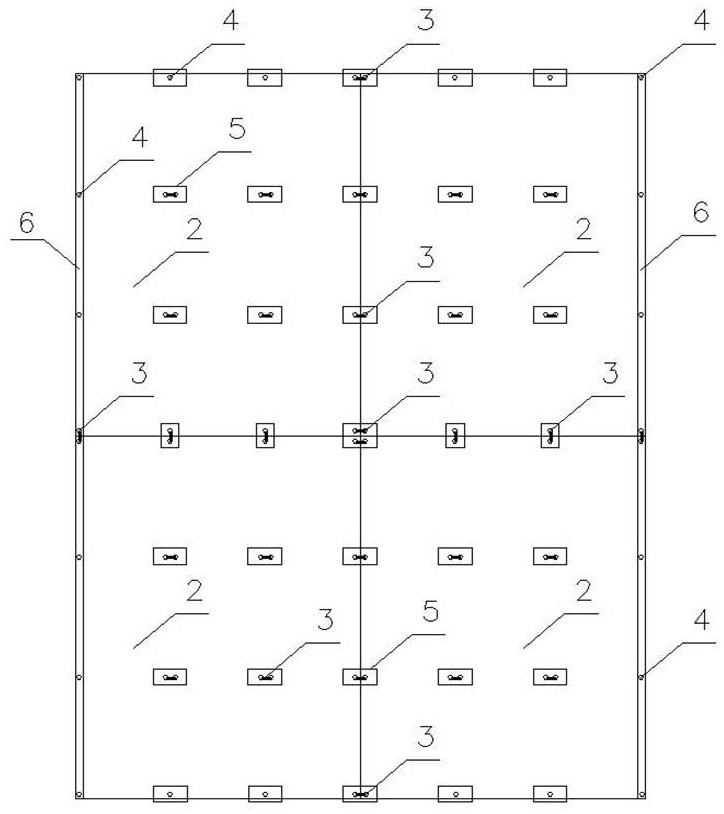

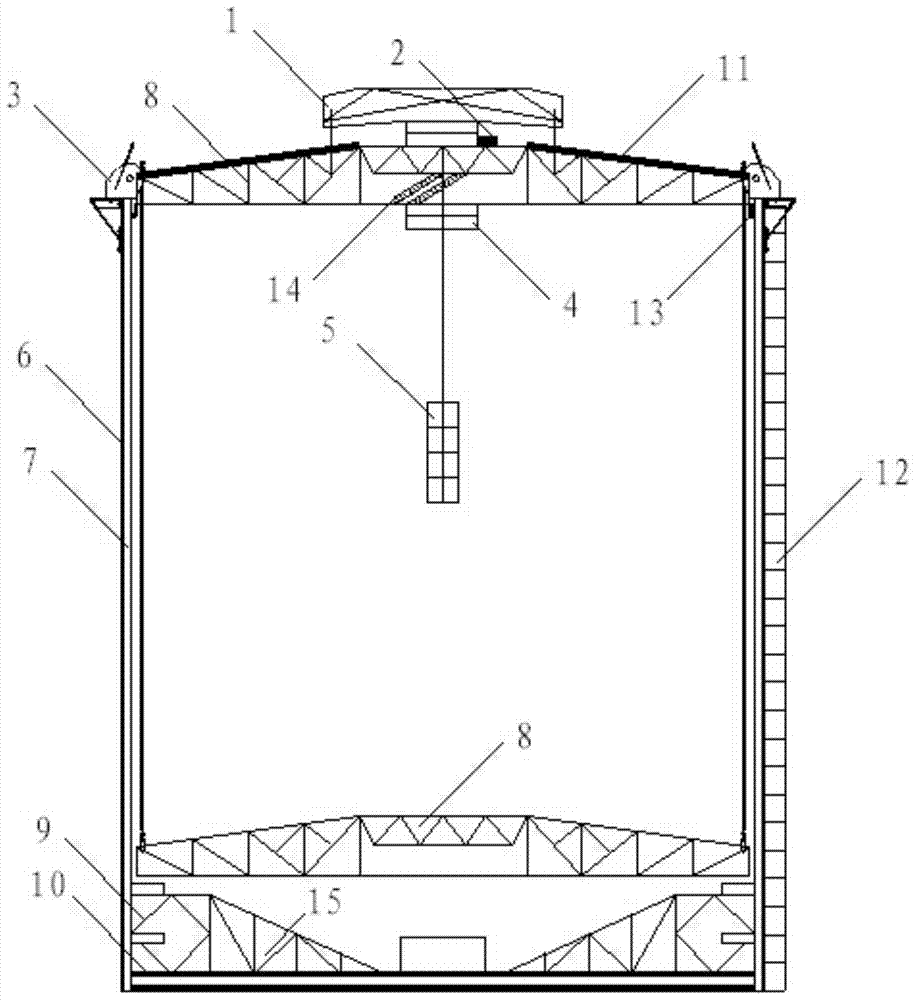

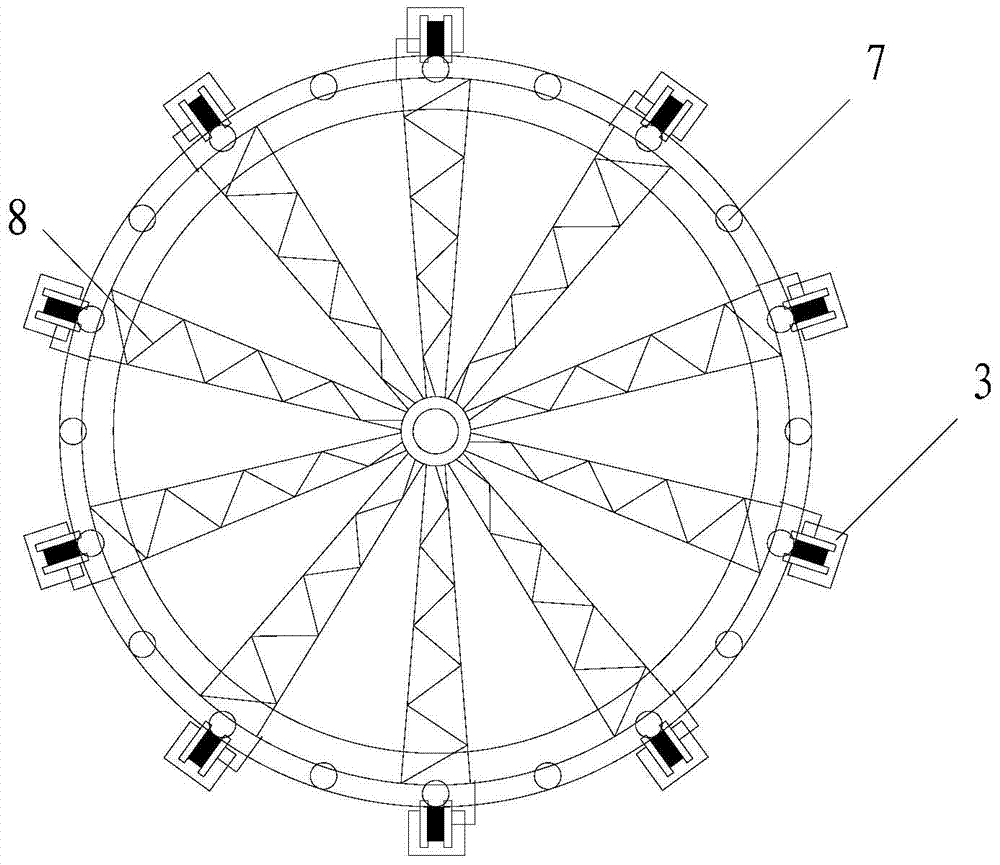

A self-falling box girder steel pipe Bailey door opening bracket and its supporting method

ActiveCN103469733BEliminate uneven settlementAvoid crackingBridge erection/assemblyButtressReinforced concrete

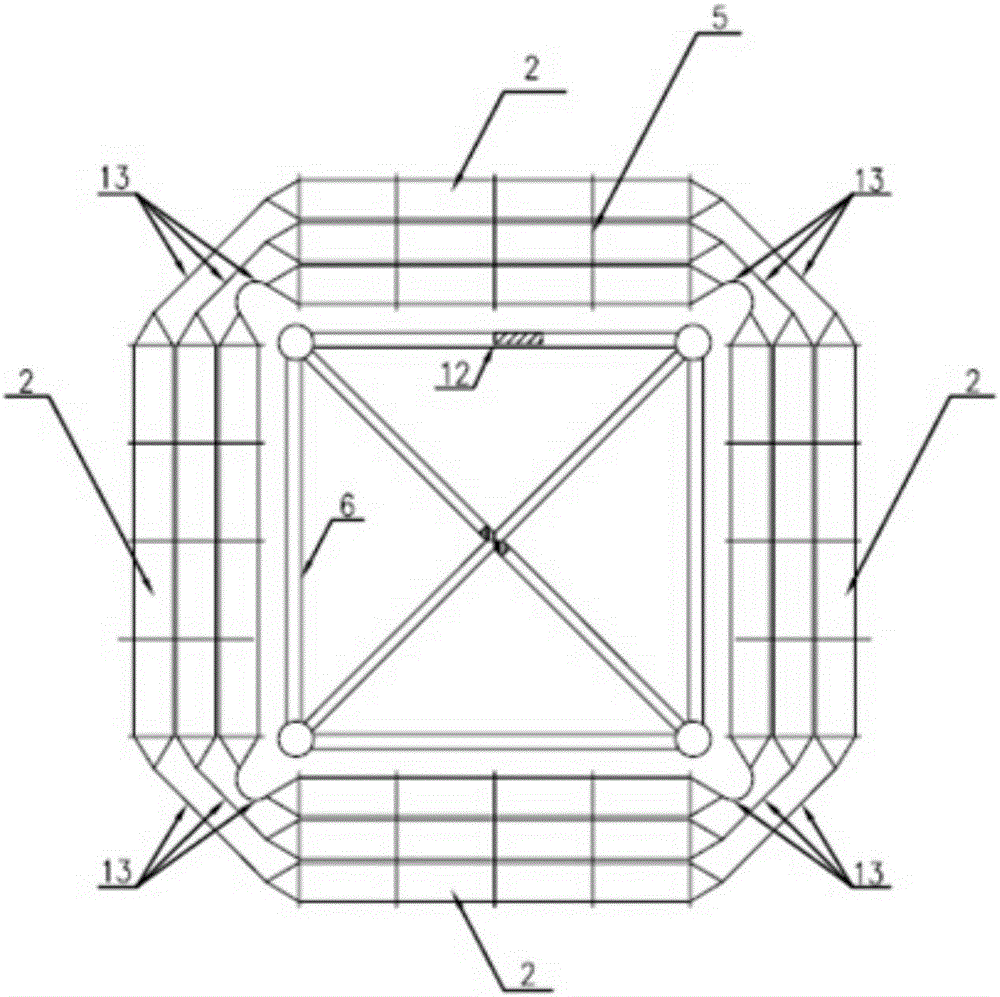

The invention discloses a self-dropping type box girder steel pipe bailey door opening bracket and a supporting method thereof. The bracket comprises a reinforced concrete foundation (1), wherein a plurality of steel buttress piers (2) are arranged on the reinforced concrete foundation (1) and are connected with the reinforced concrete foundation (1) through sand boxes (3); bailey truss components (4) are arranged on the steel buttress piers (2); the steel buttress piers (2) and the bailey truss components (4) are combined to form a bailey door opening. Due to the fact that the structure of the bracket is toolized and modularized and the self-dropping characteristic of the sand boxes is applied, a casting box girder bracket can be assembled and disassembled within about 7 days, and the construction speed is increased; due to the adoption of the technology that the whole sand boxes fall into a die, the workload of work high above the ground for de-molding the bracket is reduced by over 90 percent, and the safety of construction is greatly improved.

Owner:CCFEB CIVIL ENG

Center joint fixed member for fabricated integrated wall tile system and assembly method thereof

The invention discloses a center joint fixed member for a fabricated integrated wall tile system and an assembly method thereof, and relates to the technical field of installation methods of fabricated wall tiles. The center joint fixed member for the fabricated integrated wall tile system and the assembly method thereof solve the problems that an existing wet pasting method of the wall tiles haspoor working environment, long construction period and high labor cost, and workers are susceptible to pneumoconiosis; and an existing dry hanging method of the wall tiles has cumbersome installation,high labor and material costs, large space occupied by keels on the back portions of the wall tiles and reduced utilization rate of indoor space. Vertical members are positioned at internal and external angles of a wall, an L-shaped clamping piece is mounted on each pair of longitudinal fish-scale-shaped punching holes of the vertical members in a clamped mode, and a plurality of transverse members I are arranged between every two adjacent vertical members. Clamping slots matched with first supporting ends and second supporting ends of the transverse members I are formed in the upper and lower end surfaces of the wall tiles correspondingly, and the wall tiles are mounted on every two adjacent transverse members I. The center joint fixed member of the fabricated integrated wall tile systemand the assembly method thereof are used for fabricating the fabricated integrated wall tile system.

Owner:王圣保

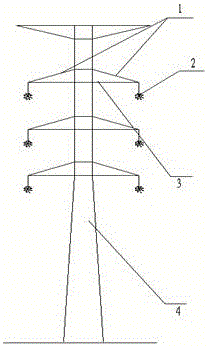

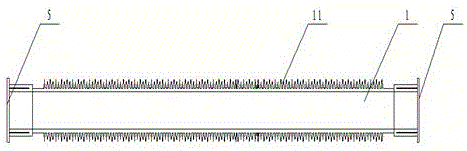

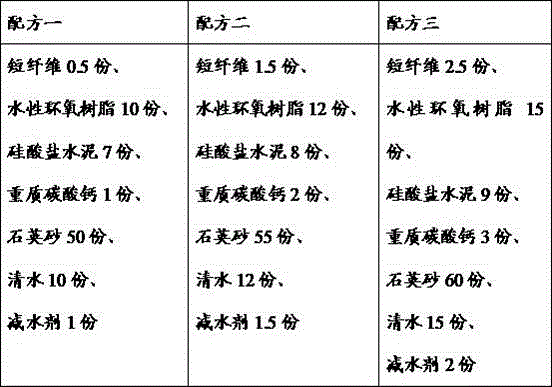

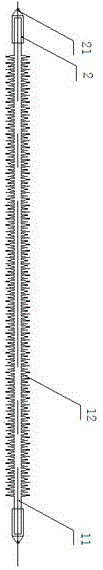

Umbrella skirt type cement-based composite insulated cross arm and manufacturing technology thereof

InactiveCN106567604ALow running costLower the altitudeTowersManufacturing technologyUltra high voltage

The invention discloses an umbrella skirt type cement-based composite insulated cross arm. The umbrella skirt type cement-based composite insulated cross arm is of a triangular outline structure and is formed in the manner that three cement-based composite insulated components and three rigid components are connected through flanges. Power fitting strings are hung at the ends of the insulated cross arm. The cement-based composite insulated components are manufactured in a one-time forming manner through a centrifugal process. Besides, an umbrella skirt structure is formed on the surface of each cement-based composite insulated component in a one-time manner. In this way, the umbrella skirt type cement-based composite insulated cross arm has not only the insulated function but also the characteristics of a supporting structure and can replace an insulator and a steel cross arm which are adopted in a transmission line iron tower formerly, the umbrella skirt type cement-based composite insulated cross arm can reduce the line corridor distance and the height of the iron tower under the condition of meeting the use requirements of cross arms of extra-high-voltage transmission line iron towers, ultra-high-voltage transmission line iron towers and high-voltage transmission line iron towers, and therefore the operation cost of transmission lines can be effectively reduced.

Owner:CHANGSHU FENGFAN POWER EQUIP

Pumped storage power plant tail water retained rock step blasting safety protection method

The invention discloses a pumped storage power plant tail water retained rock step blasting safety protection method, and relates to an underwater rock step blasting safety protection method. A bladder curtain and porous stoplog gates are constructed outside a rock step to be blasted; the bladder curtain consists of a plurality of steel pipes; two rows of holes are bored on each steel pipe; and each steel pipe is connected with an air pipe of an air compressor. The porous stoplog gates consist of a steel frame and bamboo rafts; I sections are arranged on both sides of the stoplog gate of each hole; the two sides of each I section are fixed on round flow splitting support piers through steel plates and expansion bolts; each stoplog gate is in welded connection through channel steel, the I sections and angle bars; a layer of vertical bamboo gangway is spread on the water inlet surfaces of the stoplog gates; and simultaneously safety nets are arranged on the tops of flow splitting support piers on the top and both sides of a single hole stoplog gate. The method adopts the proposal of arranging the bladder curtain plus the steel frame, the bamboo rafts and the safety nets to replace a proposal of the stoplog gate, has scientific and reasonable design, protects a trash rack and a tail gate against the damage and the influence of the blasting, and brings about easy spoil removal, short manufacturing and installation time limits, and low manufacturing, installation and demolition cost.

Owner:STATE GRID CORP OF CHINA +2

Transverse integral component for assembled integrated wall-tile system and assembling method thereof

The invention discloses a transverse integral component for an assembled integrated wall-tile system and an assembling method thereof, and relates to the field of wall-tile processing, assembled devices and assembling installing technologies. By means of the transverse integral component for the assembled integrated wall-tile system and the assembling method thereof, the problems that in an existing wall-tile wet combining method, the work environment is poor, the construction period is long, the labor cost is high, and workers are subject to pneumoconiosis are solved; the problems that in anexisting wall-tile dry hanging method, installing is tedious, the labor cost and the material cost are high, occupied space of wall-tile back fitting keels is large, and the using rate of indoor spaceis reduced are solved. According to the transverse integral component for the assembled integrated wall-tile system and the assembling method thereof, vertical components are fixedly connected with wall corners, a clamping piece I is clamped on every pair of longitudinal scale punched holes of a vertical component, multiple transverse components I are arranged between the two adjacent vertical components, elastic protection films are arranged on the backs of wall tiles, each wall tile is installed between the two adjacent transverse components I, and clamping grooves in the upper end face andthe lower end face of each wall tile are matched with a first hook and a second hook of the corresponding transverse component I respectively. The transverse integral component for the assembled integrated wall-tile system and the assembling method thereof are used for assembling of an assembled integrated wall-tile system.

Owner:王圣保

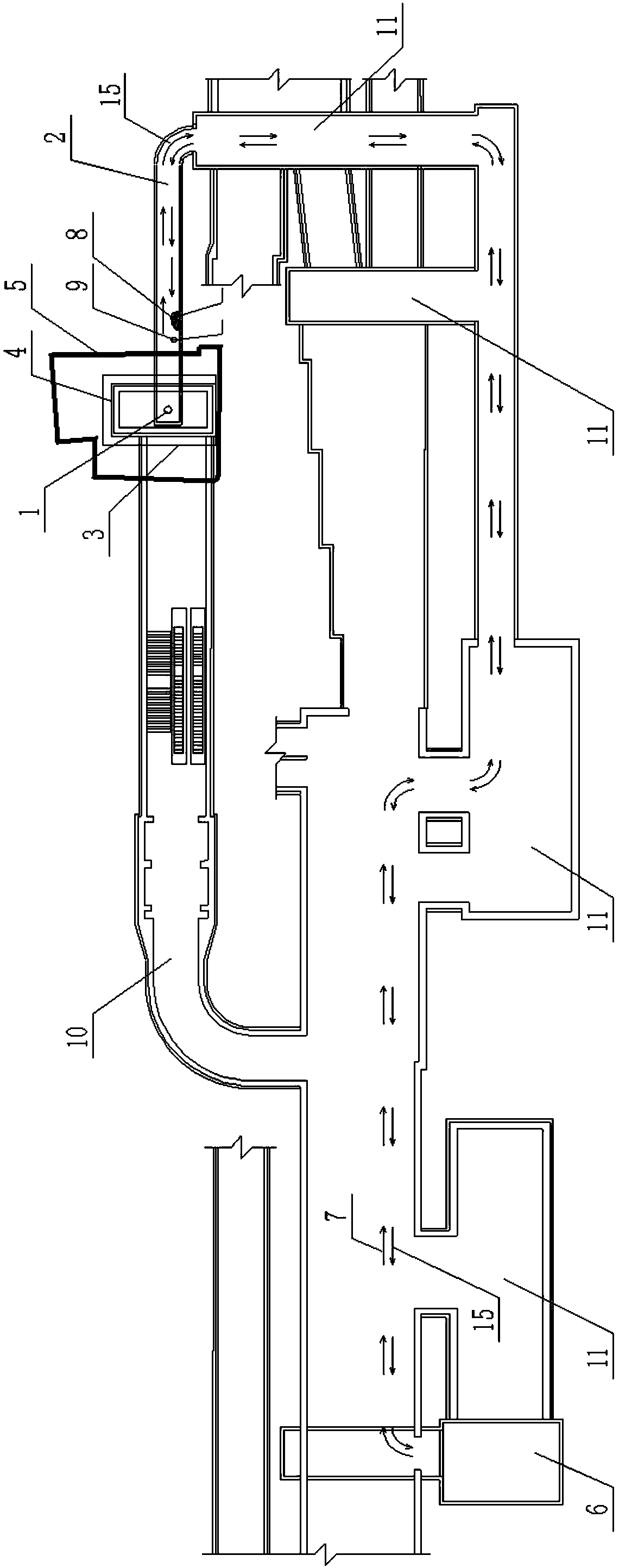

Vertical shaft excavation construction method adopting mode of downhole soil outlet and feeding

InactiveCN107893659AReduce construction site areaSolve the demolition problemShaft liningUnderground spaceEngineering

The invention discloses a vertical shaft excavation construction method adopting a mode of downhole soil outlet and feeding. The vertical shaft excavation construction method comprises the following steps that a vertical shaft hole and a construction channel are constructed in a construction site, and the bottom of the vertical shaft hole is made to communicate with an existing underground space through the construction channel; a vertical shaft is excavated outside the vertical shaft hole from top to bottom; soil masses generated in vertical shaft excavation are made to pass through the vertical shaft hole and the construction channel sequentially and then transported out from an existing vertical shaft arranged in the underground space; and in the vertical shaft excavation process, firstly, the top of the vertical shaft is excavated, an opening locking ring is constructed, then, the vertical shaft continues to be excavated downwards, meanwhile, concrete mixed materials are made to pass through the existing vertical shaft, the underground space and the construction channel sequentially and then transported to the bottom of the vertical shaft hole, and a concrete retaining wall isconstructed for the shaft wall of the excavated part, located below the opening locking ring, of the vertical shaft through a shotcrete anchorage machine arranged at the bottom of the vertical shaft hole. The area of the construction site is decreased greatly, the demolition problem is solved, and the phenomenon of resident disturbance caused by demolition, noise, dust, road occupation and the like is reduced.

Owner:SUBWAY ENG CO LTD OF CHINA RAILWAY 16TH CONSTR BUREAU +2

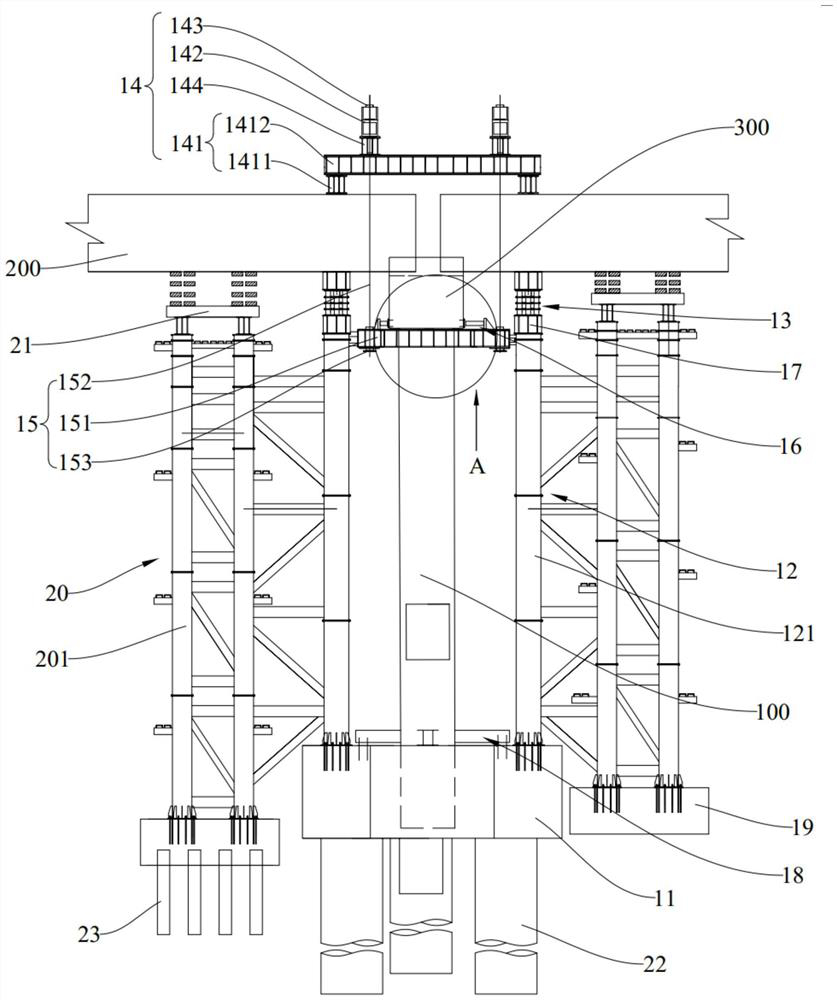

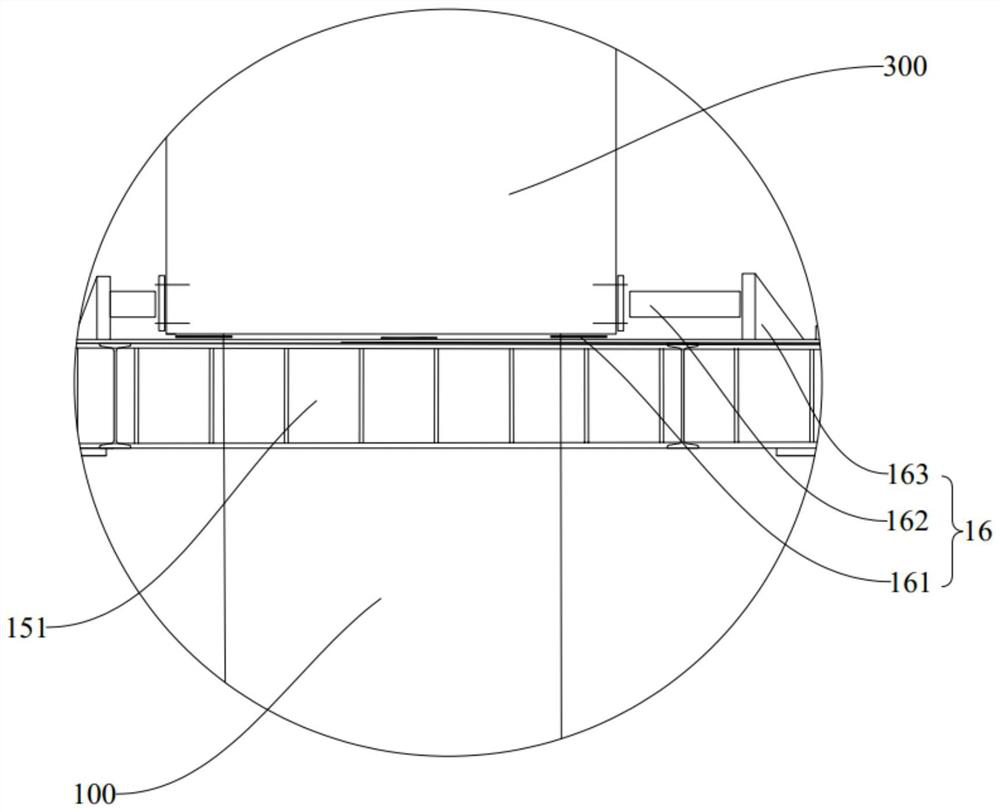

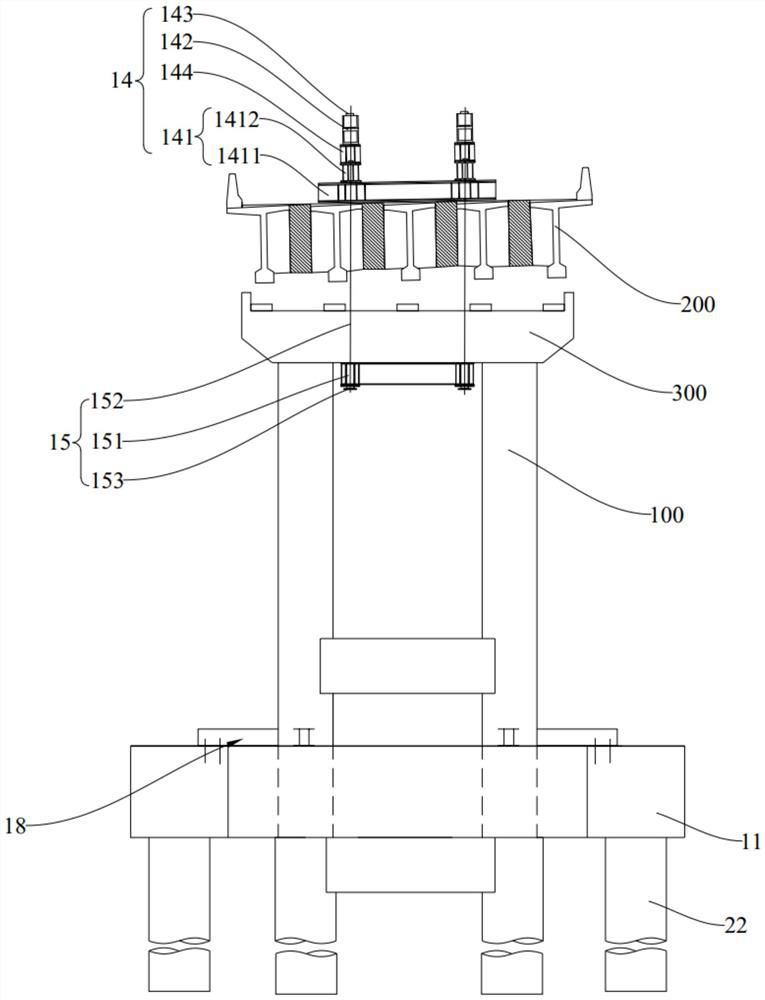

Bridge resetting bracket and bridge resetting method

PendingCN113279341ALow demolition costLow costBridge structural detailsBridge erection/assemblyT-beamArchitectural engineering

The invention belongs to the technical field of bridge construction, and discloses a bridge resetting support and a bridge resetting method. The bridge resetting support comprises a first bearing platform, a first supporting frame, jacking devices, a lifting device, a suspension device and a horizontal position adjusting device. The first bearing platform is arranged at the bottom end of the pier column, a preset hole penetrating through the first bearing platform in the height direction of the first bearing platform is formed in the middle of the first bearing platform, and the pier column penetrates through the preset hole. The first supporting frames are arranged on the first bearing platform, and the first supporting frames are arranged on the two sides of the pier column. The jacking devices are arranged at the top ends of the first supporting frames. The lifting device is arranged at the top end of the T-beam. The suspension device comprises a joist and a connecting piece, the joist is arranged at the bottom end of the cover beam, the bottom end of the connecting piece is connected with the joist, and the top end penetrates through the T beam to be connected with the lifting device. When the bridge is reset, the pier column and the bent cap do not need to be dismantled and rebuilt, construction cost and safety risks are reduced, working hours are reduced, and the requirement for emergency construction can be better met.

Owner:ROAD & BRIDGE EAST CHINA ENG

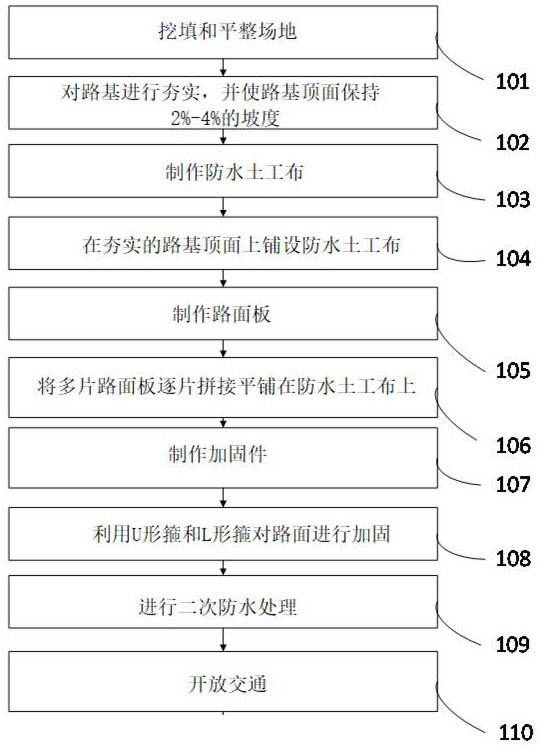

Construction method for quickly building road

InactiveCN112112022AEffectively drain stagnant waterNo pollution in the processSingle unit pavingsPaving detailsArchitectural engineeringStructural engineering

The invention discloses a construction method for quickly building a road. The construction method comprises the following step that a site is dug, filled and leveled; the roadbed is tamped; waterproof geotextile is manufactured; grooves are dug in the two sides of the roadbed, the top face of the compacted roadbed is flatly laid with the waterproof geotextile, the ends of the waterproof geotextile extend into the grooves, then the grooves are backfilled with natural plain soil layer by layer, and compaction is conducted layer by layer; road slabs are manufactured, and a plurality of anchoringholes are formed in the middles and the edges of the road slabs; the road slabs are installed, specifically, the multiple road slabs are spliced and flatly laid on waterproof geotextile one by one, anti-skid lines of the road slabs face upwards, and slab joints of the multiple road slabs and hole positions of the anchoring holes are aligned; reinforcing parts are manufactured, wherein the reinforcing parts are U-shaped hoops and L-shaped hoops; the U-shaped hoops and the L-shaped hoops are used for reinforcing the road surface; secondary waterproof treatment is carried out; and the traffic isput into service.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

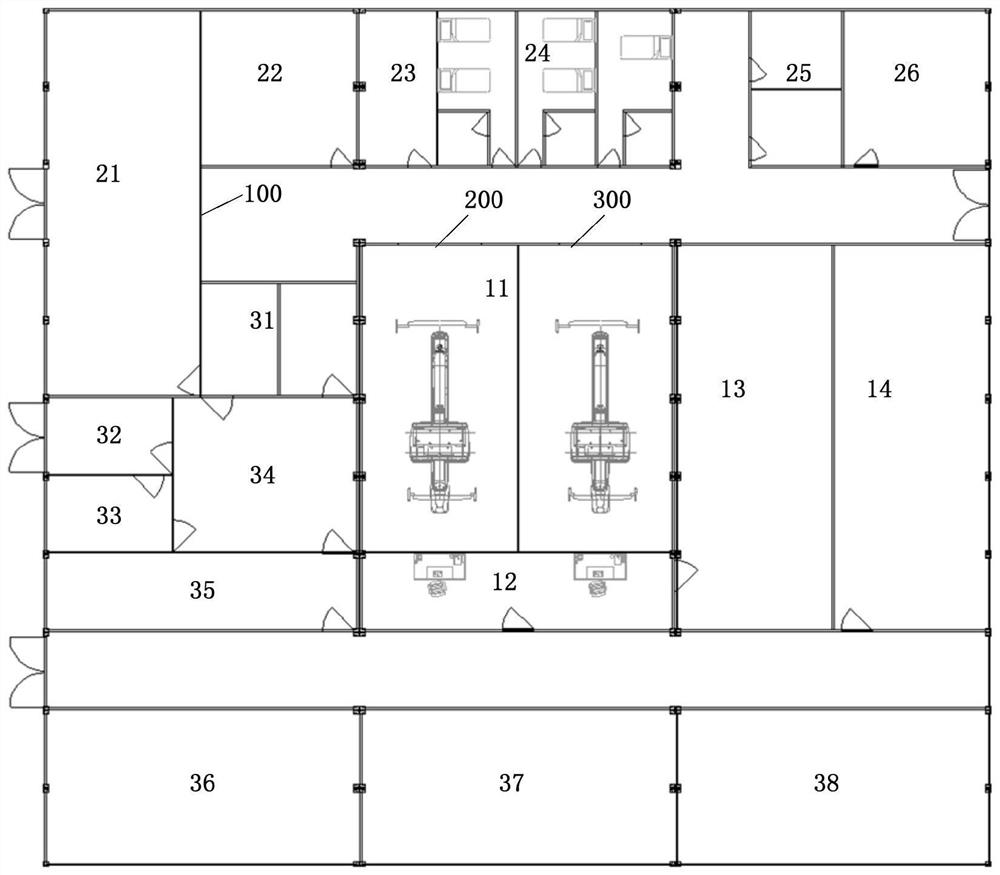

Modularized consulting room for PET/SPECT equipment

InactiveCN111827735ALong-term useQuick assemblyHospitalsBuilding constructionsPharmacy medicineRadioactive contamination

The invention provides a modularized consulting room for PET / SPECT equipment. The modularized consulting room comprises an examination module for performing PET / SPECT relevant examination on a patient, a patient activity module for providing an activity space for the patient, a drug storing and applying module for storing and applying drugs, and a medical care preparation module for providing a preparation work space for medical care personnel, wherein the examination module, the patient activity module, the drug storing and applying module and the medical care preparation module can be disassembled and assembled on site and can be directly partitioned by walls in which radiation shielding parts are disposed. The modularized consulting room for the PET / SPECT equipment is obtained, and allthe modules can be disassembled and assembled on site, so that the PET / SPECT equipment can be conveniently transferred and relocated together with the modularized consulting room; and all the modulesin the modularized consulting room are partitioned by the walls in which the radiation shielding parts are disposed, so that the problem that radioactive contamination is likely to happen during diagnosis and treatment with the PET / SPECT equipment.

Owner:北京国原新技术有限公司

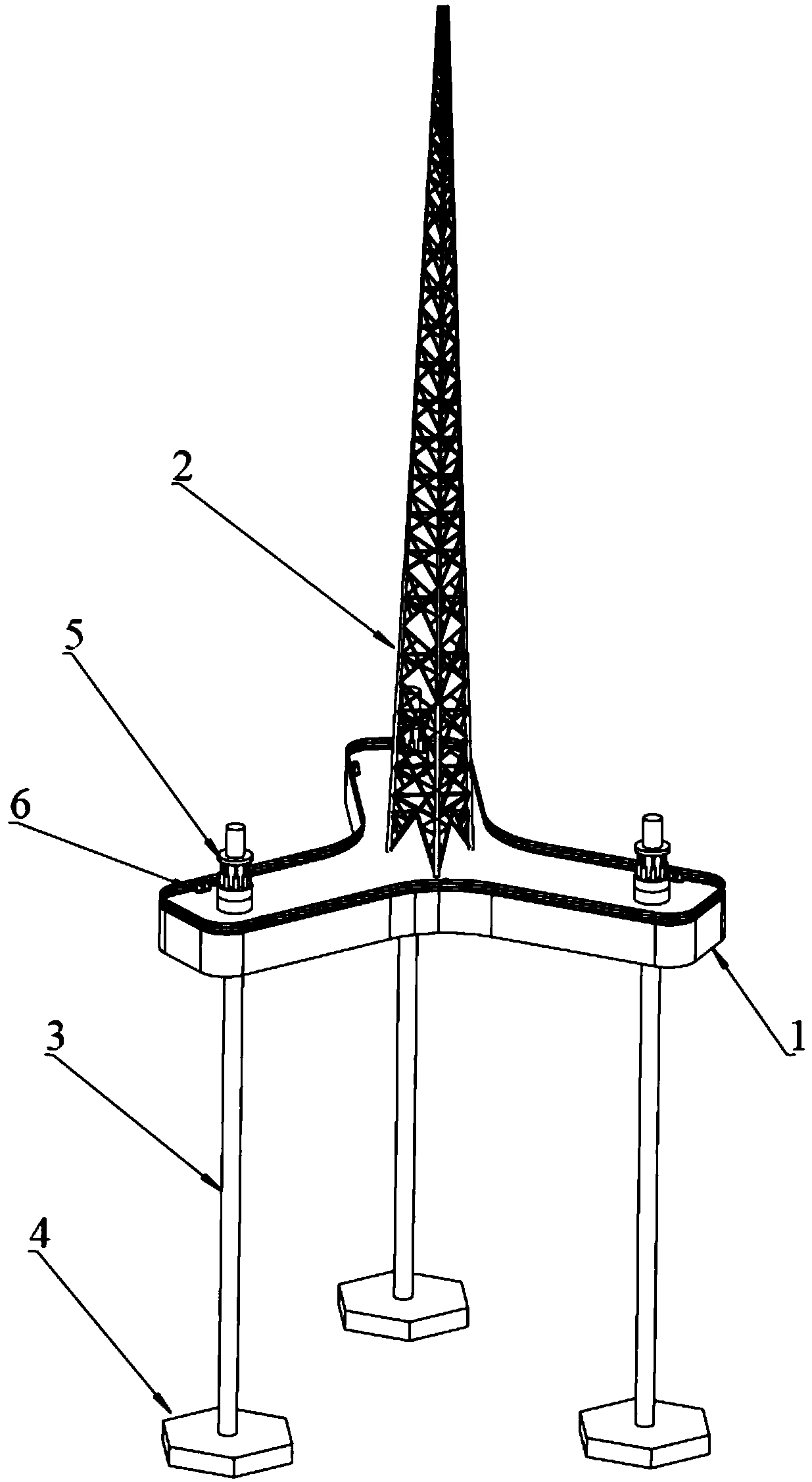

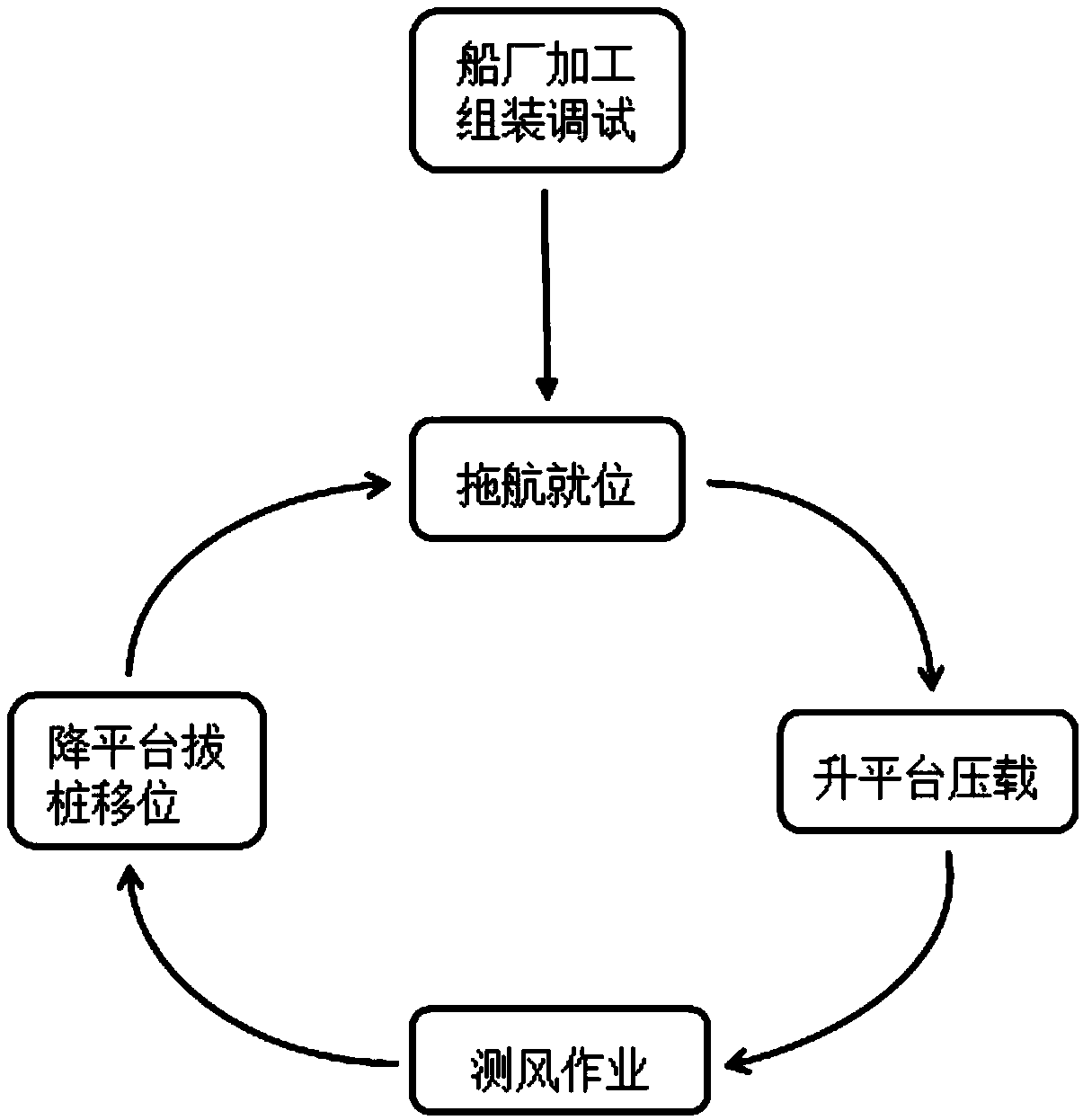

Installation and wind measurement method for movable offshore wind measurement device

InactiveCN109024523AReduce noiseShort construction periodArtificial islandsUnderwater structuresEngineeringTower

The invention discloses an installation and wind measurement method for a movable offshore wind measurement device. The offshore wind measurement device comprises a wind measurement tower structure, aplatform structure, a lifting device and a pile leg structure. The installation and wind measurement method for the movable offshore wind measurement device comprises the steps that (1) assembly is carried out on land; (2) towing in place is carried out; (3) the platform structure is lifted for ballasting; (4) after the platform structure is in place, the wind measurement operation can be carriedout; and (5) the platform structure is lowered, pile legs are pulled out, and displacement is carried out. Through the installation and wind measurement method for the movable offshore wind measurement device, the overall migration and reuse of the offshore wind measurement system can be effectively realized, and the advantages of no piling, short construction period, low wind measurement cost and free demolition are achieved.

Owner:广东华蕴新能源有限公司

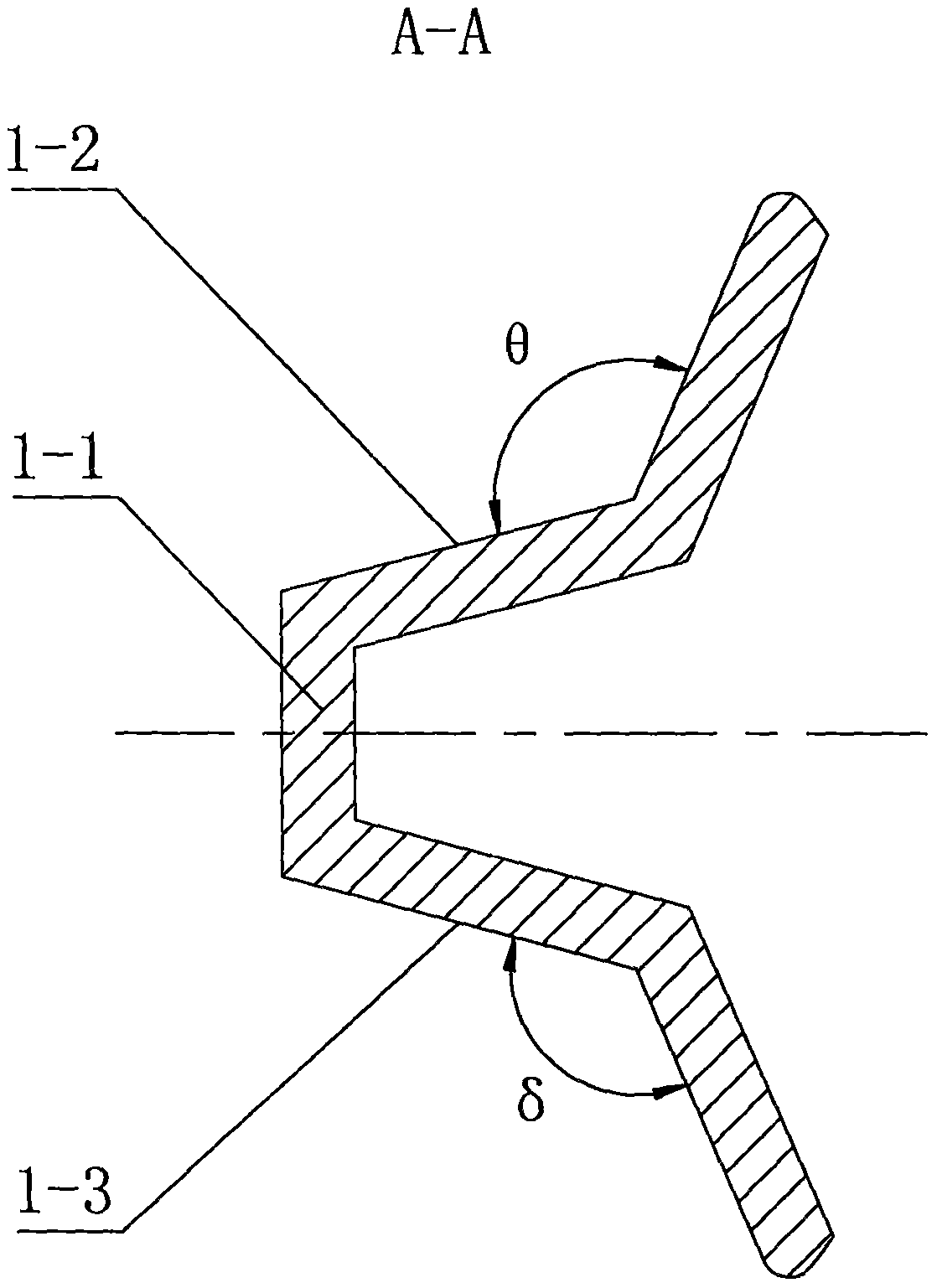

Three-pipe type flexible composite insulated cross arm

The invention discloses a three-pipe type flexible composite insulated cross arm. The three-pipe type flexible composite insulated cross arm is formed in the mode that three pipe-type insulated cross arm parts are connected with one another in a hinged mode, and each pipe-type insulated cross arm part comprises a composite material insulated inner core pipe and an umbrella skirt on the side surface of the composite material insulated inner core pipe of pressure gel. In this way, according to the three-pipe type flexible composite insulated cross arm, a design concept of a former rigid insulated cross arm is abandoned, a flexible structure which is formed in the way that the three pipe-type insulated cross arm parts are connected with one another in a hinged mode is adopted, the cross arm only bears axial tension and can freely rotate in the line direction, and load working on an iron tower under a disconnection condition is reduced; and meanwhile, the three-pipe type flexible composite insulated cross arm has enough mechanical strength and good ageing resistance and corrosion resistance performance, and using by high-voltage and ultra high voltage lines is met.

Owner:CHANGSHU FENGFAN POWER EQUIP

Dry Man type gas cabinet removal method

ActiveCN105133857BReduce riskReduce pollutionVariable capacity gas holdersBuilding repairsWorking environmentEnvironmental engineering

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Abandoned chimney reuse method

InactiveCN109653525APublicityIndelible thoughts of consolationBuilding repairsTowersFireworksEngineering

The invention discloses an abandoned chimney reuse scheme. According to the scheme, a chimney can be reserved and built into a support platform for advertising and fireworks setting off and can becomea landmark building in an area with the chimney, waste is turned into wealth, an excessive demolition (chimney blasting) expense can be saved, occupied area is small, and the scheme is economical andalso comforts the indelible thought of citizens.

Owner:NINGBO ZHENHAI YIFULAI CULTURE CREATIVE

Demolition method of attached tower crane in narrow terrain

The invention provides a disassembling method of an adhesion type tower crane, being capable of reducing the disassembling cost of the adhesion type tower crane under a narrow terrain, and belonging to the technical field of building construction. The disassembling method of the adhesion type tower crane under the narrow terrain comprises the following steps: (a) disassembling a surplus balancingweight; (b) disassembling a hoisting jib; (c) balancing the tower crane; (d) disassembling a tower body; (e) disassembling a balance arm, a tower cap and a rotary mechanism. According to the disassembling method provided by the invention, no large-scale hoisting equipment is required during a tower crane disassembling process, so that the disassembling cost of the tower crane is lower.

Owner:中电建宁夏工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com