Construction method of large-height small-sized cast-in-place concrete beam slab

A construction method and concrete technology, which are applied in the fields of formwork/formwork/work frame, on-site preparation of building components, and processing of building materials, etc., can solve the problems of uneconomical, long and slender support frame, and many unsafe factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

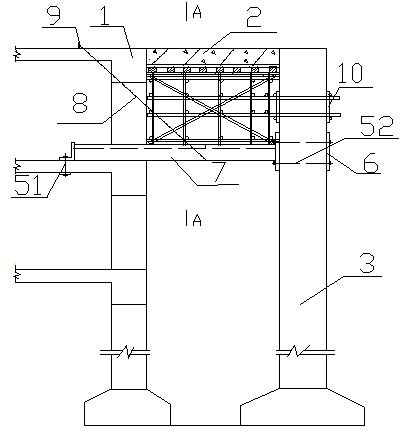

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

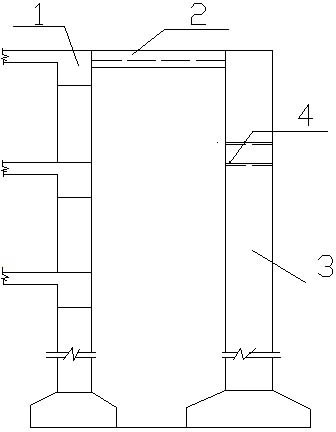

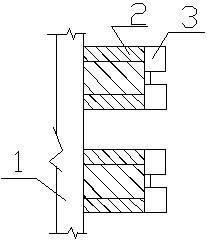

[0024] The construction method of small cast-in-place concrete beams and slabs with large height, such as image 3 , Figure 4 As shown, it includes a floor foundation constructed of multi-layer slabs, and poured concrete frame columns are set on one side of the floor. According to construction requirements, such as figure 1 , figure 2 As shown, the cast-in-place concrete beam slab 2 must be poured between the floor slab 1 of a certain floor and the concrete frame column 3 of the corresponding floor. Described construction method comprises the steps:

[0025] a. Bolt holes are reserved on the concrete frame column, and the position of the bolt hole is opposite to the lower floor of the floor where the concrete beam slab needs to be poured; that is, if the concrete beam slab is to be poured at the seventh floor, the bolt Holes are reserved on the concrete frame c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com