Construction method for quickly building road

A construction method and road technology, applied to roads, roads, road signs, etc., can solve the problems of cumbersome and complicated installation procedures, poor driving comfort, inconvenient transportation and installation, etc., and achieve the effects of simple and fast construction, low demolition costs, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

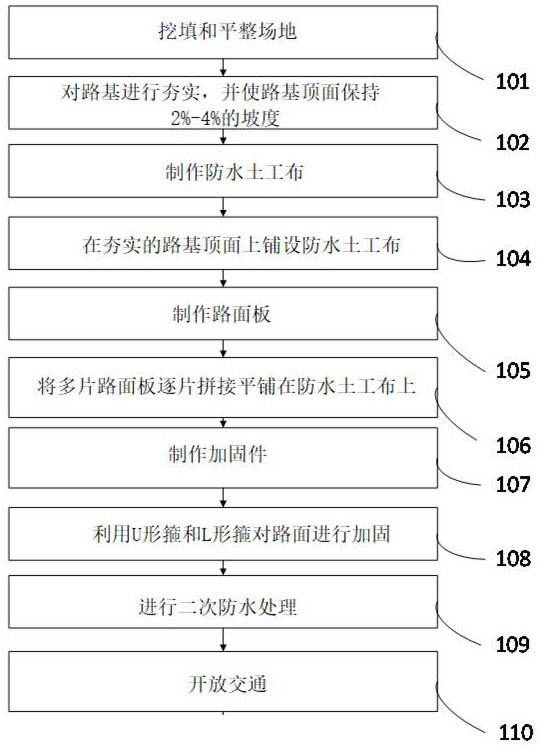

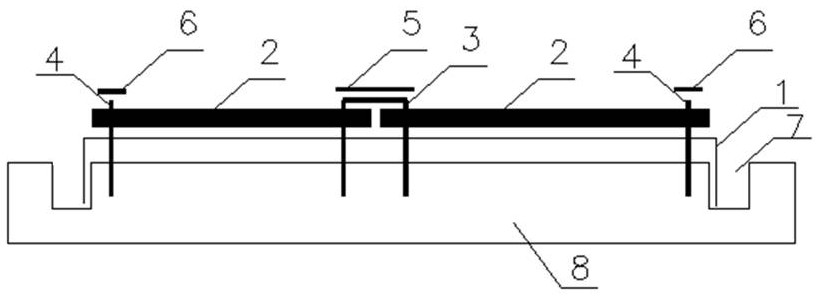

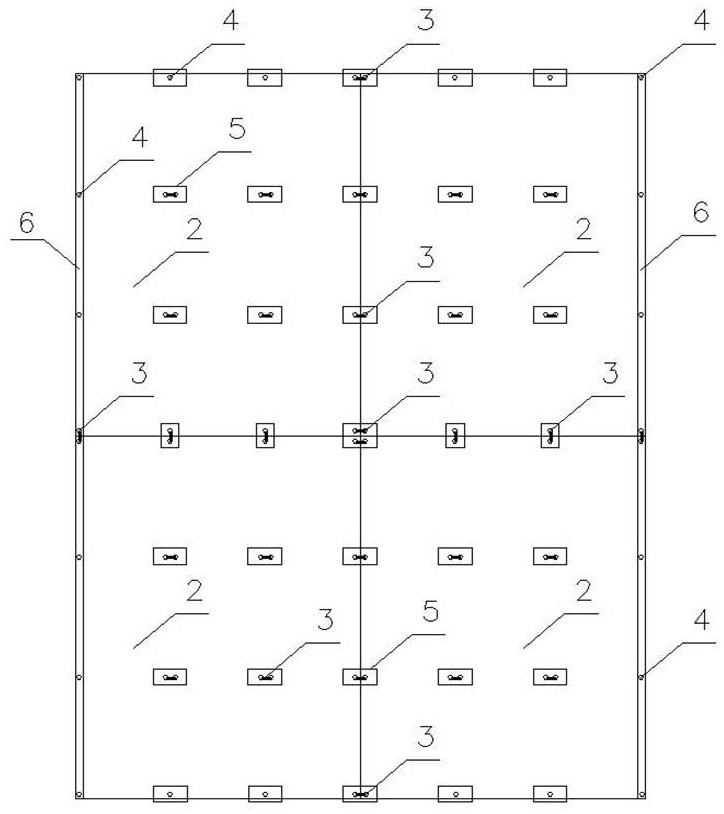

[0025] Such as Figure 1-3 Shown, according to the construction method that is used for fast road construction of preferred embodiment of the present invention, comprises the following steps:

[0026] Step 101: Excavating, filling and leveling the site: Excavating, filling and leveling the site by manual or mechanical means according to the elevation required by the design.

[0027] Step 102: Use a road roller or a dynamic compaction machine to tamp the subgrade 8, and keep the top surface of the subgrade 8 at a slope of 2%-4%, so that rainwater can be smoothly discharged from the road surface.

[0028] Step 103: Fabricate a waterproof geotextile 1, wherein the top and bottom surfaces of the waterproof geotextile 1 are made of wear-resistant and anti-damage materials, and the middle layer is made of plastic waterproof cloth.

[0029] Step 104: laying waterproof geotextile 1 on the top surface of the compacted roadbed 8: Excavating grooves 7 on both sides of the roadbed 8, spr...

Embodiment 2

[0042] According to the construction method for road fast construction of preferred embodiment of the present invention, comprises the following steps:

[0043]Proceed to step 101. Preferably, a bulldozer is used to level the site, and then a smooth road roller is used to reciprocate and roll over three times until the vehicle passes through the concave wheel base. For clay, sandstone, expansive soil, loess, saline soil, and frozen ground, it can be directly leveled and rolled. For the soft soil subgrade, first excavate the soft soil part 60 cm below the ground, and replace it with non-soft soil materials, such as clay, sand, loess, saline soil, frozen soil and other materials. For the silt subgrade, all the silt can be excavated and replaced with other soil, or the ground can be leveled after laying rubble in the silt.

[0044] Proceed to step 102, and use a smooth road roller to tamp the roadbed 8.

[0045] Proceed to step 103, fabricate the waterproof geotextile 1 in the ...

Embodiment 3

[0054] According to the construction method for road fast construction of preferred embodiment of the present invention, comprises the following steps:

[0055] Proceed to step 101, use a bulldozer to level the site, and then use a smooth road roller to reciprocate for more than three times, and roll the roadbed until the vehicle passes through the base stamp without the concave wheel.

[0056] Proceed to step 102, and use a smooth road roller to tamp the roadbed 8.

[0057] Proceed to step 103, manufacture the waterproof geotextile 1 in the factory, the top surface and the bottom surface of the waterproof geotextile 1 are made of polyethylene woven cloth, the middle interlayer is made of plastic waterproof cloth, and the thickness of the plastic waterproof cloth is selected as 0.03mm.

[0058] Carry out step 104, excavate groove 7 on both sides of subgrade 8, the width of groove 7 is 0.3m, the depth of groove 7 is 0.3m, and the layered thickness of backfilling natural plain s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com