Patents

Literature

40results about How to "Low basic requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

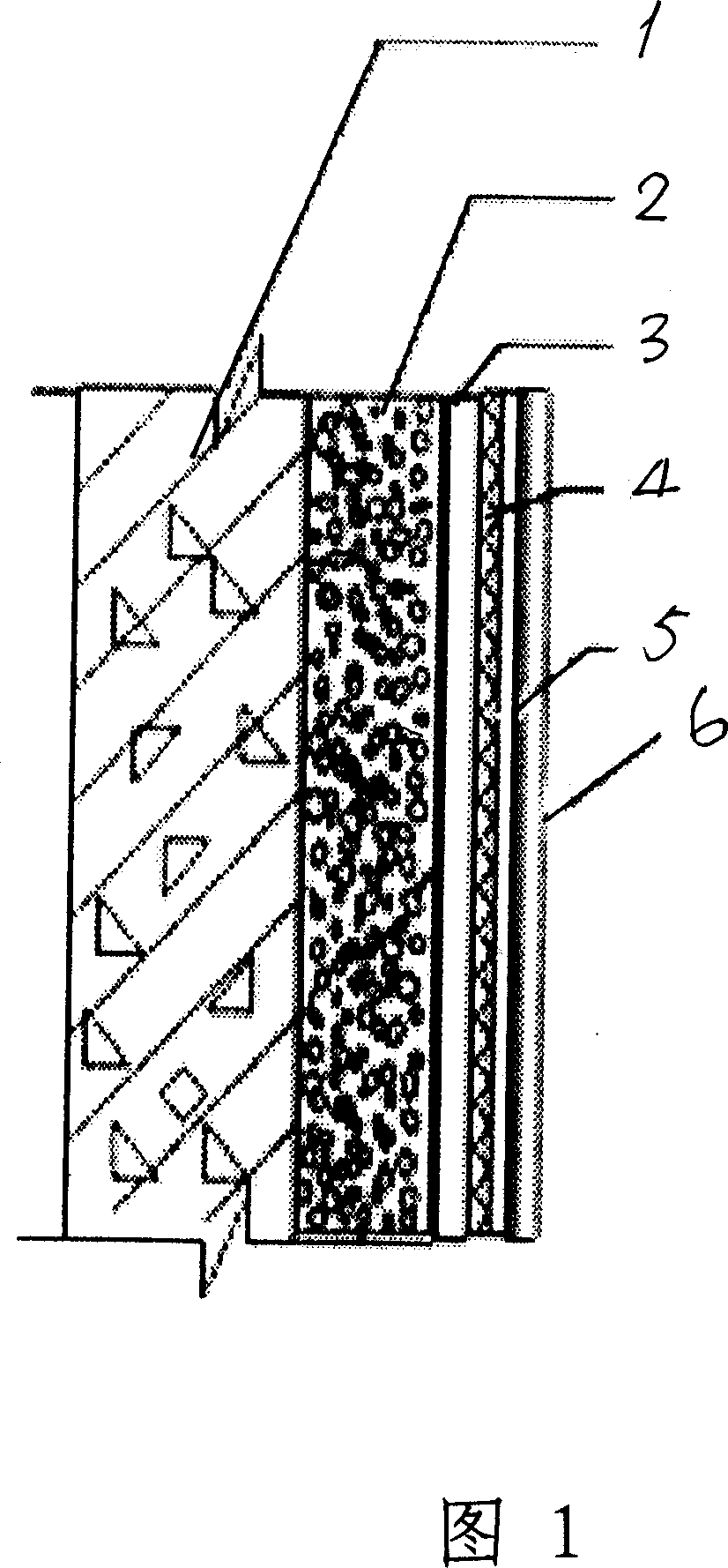

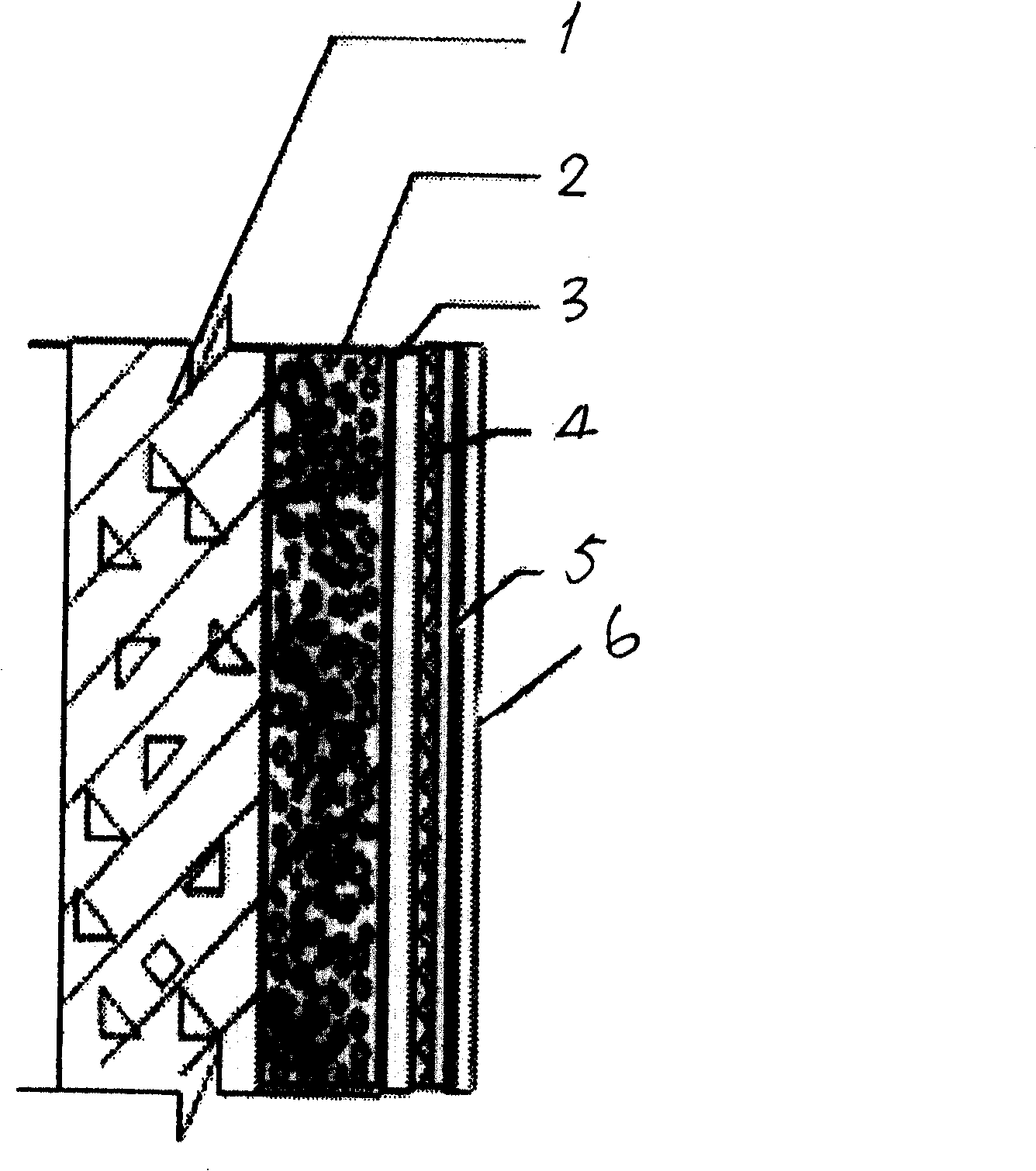

Method for making self-temperature-regulating phase-change heat-insulation wall and product thereof

InactiveCN101025037AAbility to raise room temperatureImprove the insulation effectCovering/liningsSolid waste managementFiberConstruction aggregate

The invention discloses a temperature-selfadjusting phase transition composite high temperature wall body manufacturing method, comprising: coating the wall body with temperature selfadjusting phase transition mortar, coating heat preservation putty and then coating elastic putty, and finally coating heat insulating paint, where the said temperature selfadjusting phase transition mortar is composed in weight percent of: temperature selfadjusting phase transition material 10-40%, hollow fiber material 5-35%, dispersible glue powder 8-38%, cement 12-42%, and lightweight aggregate 35-65%. And the invention provides a temperature-selfadjusting phase transition composite heat preservation wall body manufacturing method and the product. And the product has features of better heat preservation effect, high antifire performance, low wall body foundation requirements, high fastness of heat preservation layer, good decorative effect, no pollution, long service life, able to make large-area spreading and application, etc.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

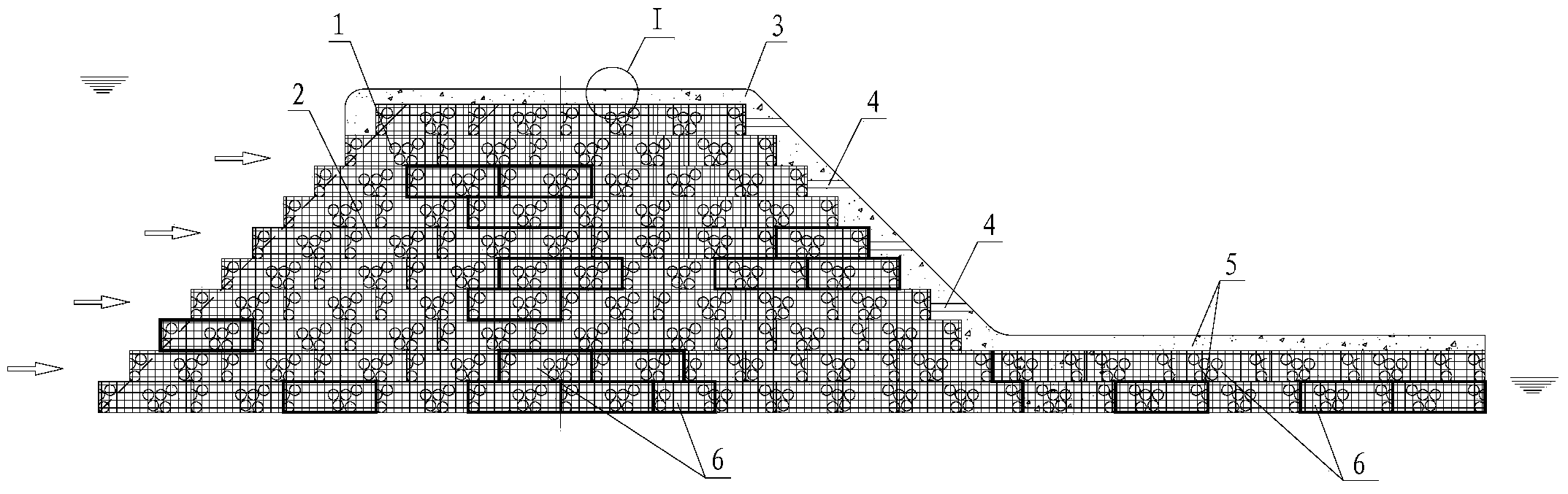

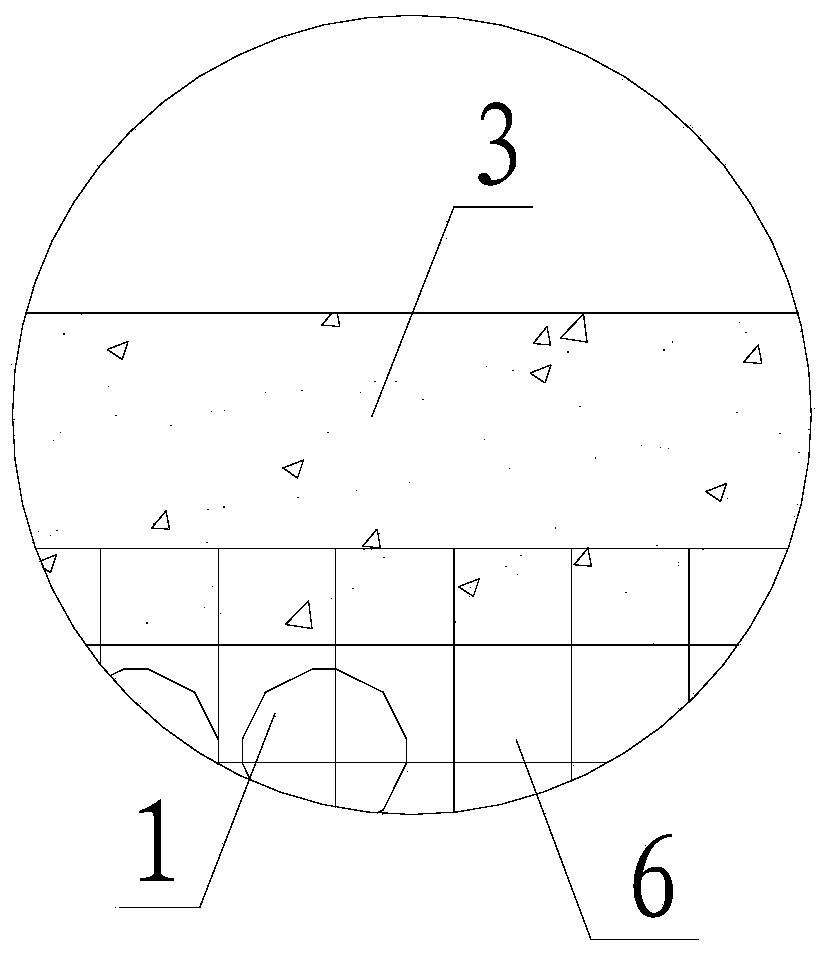

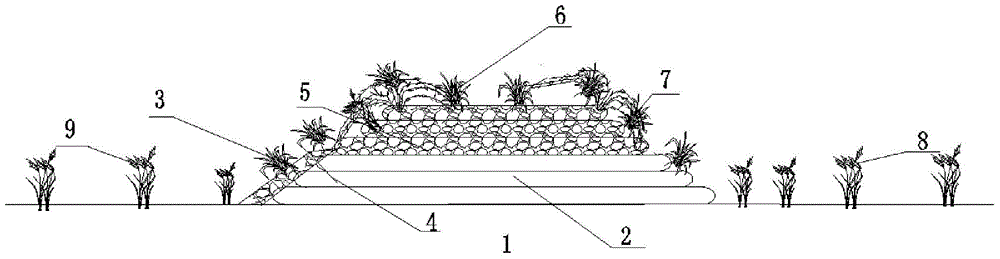

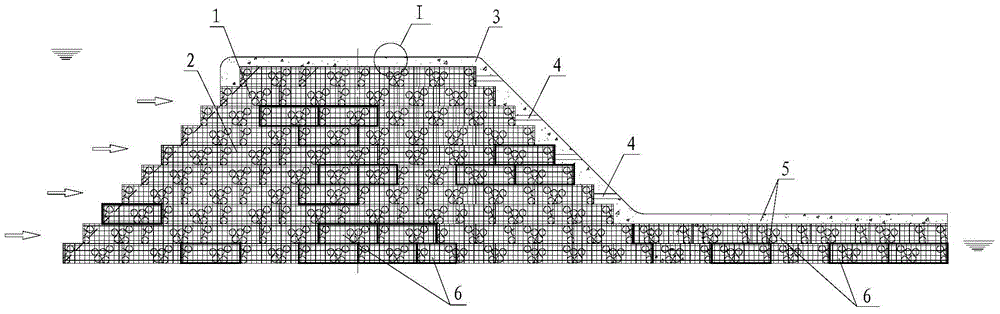

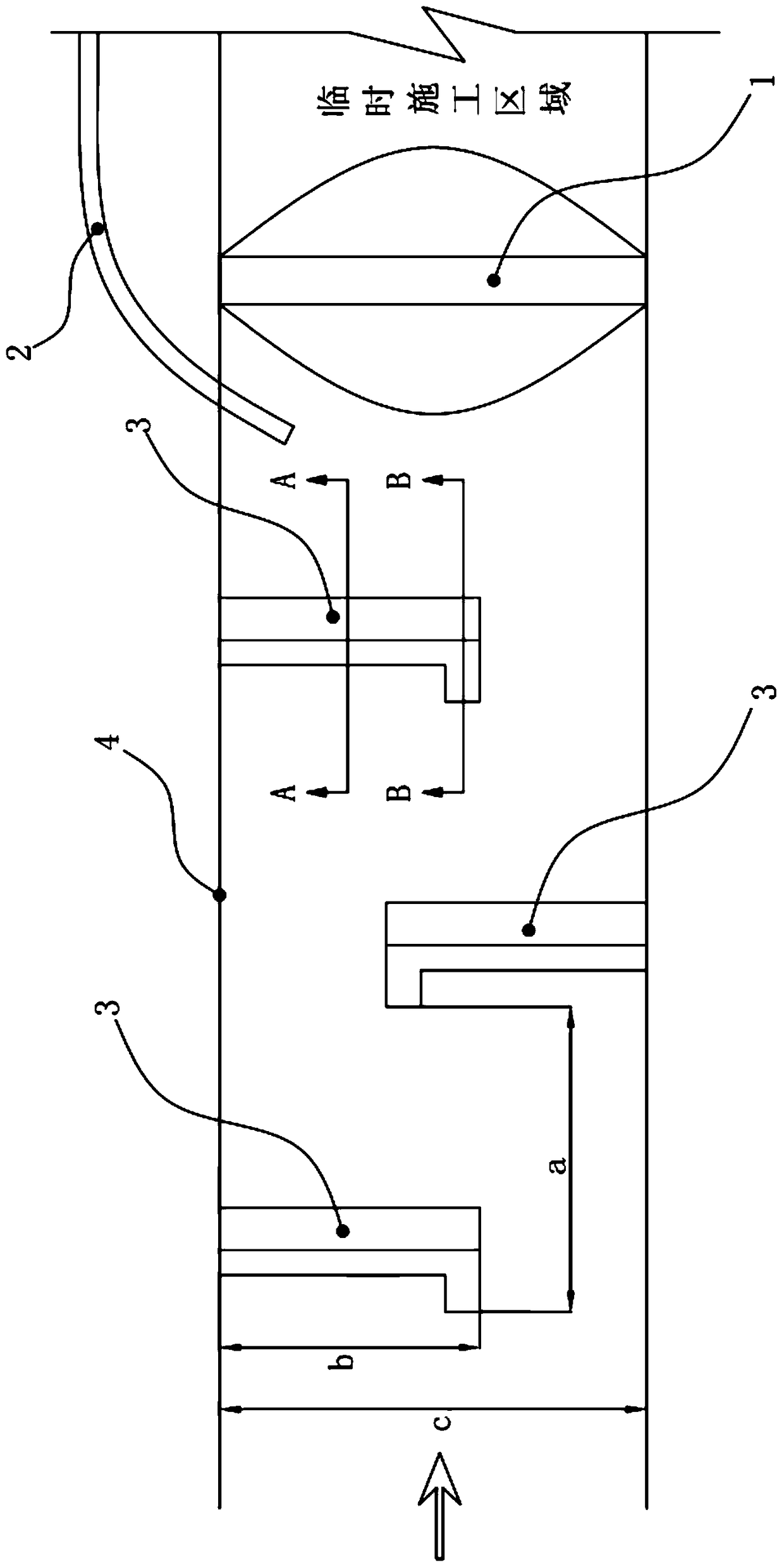

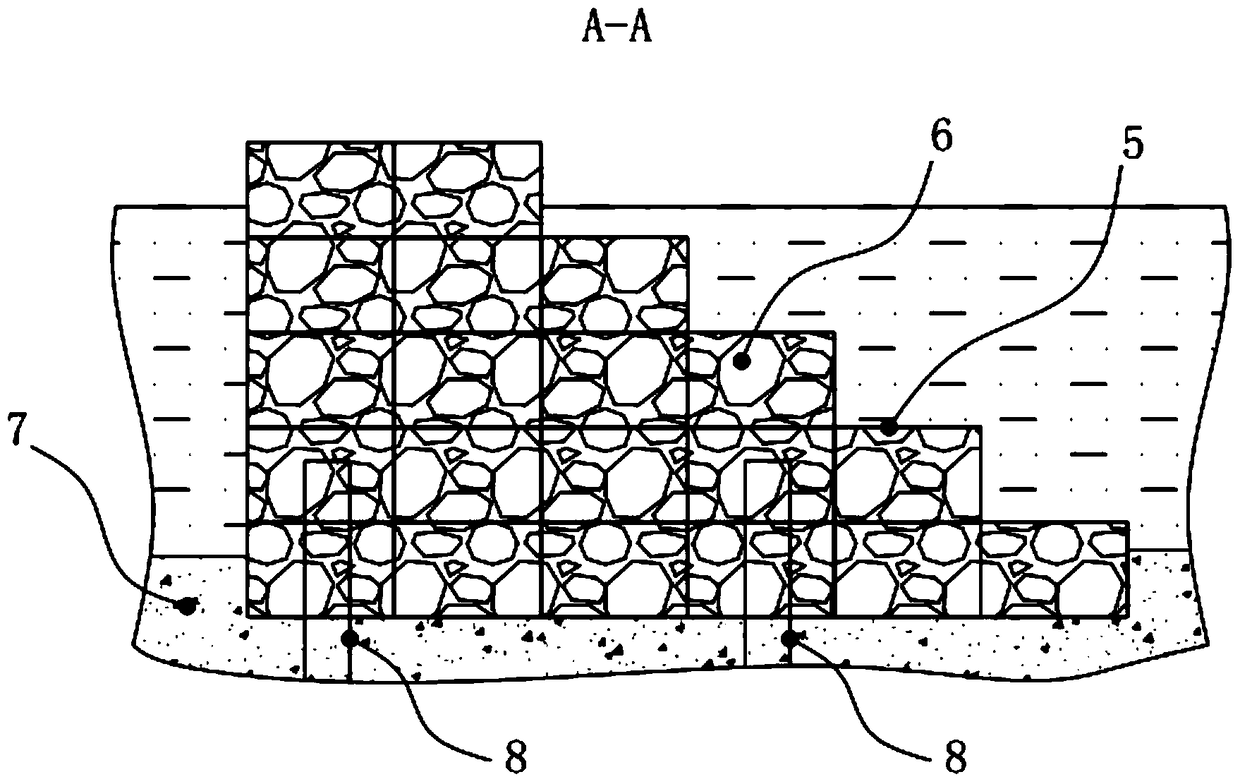

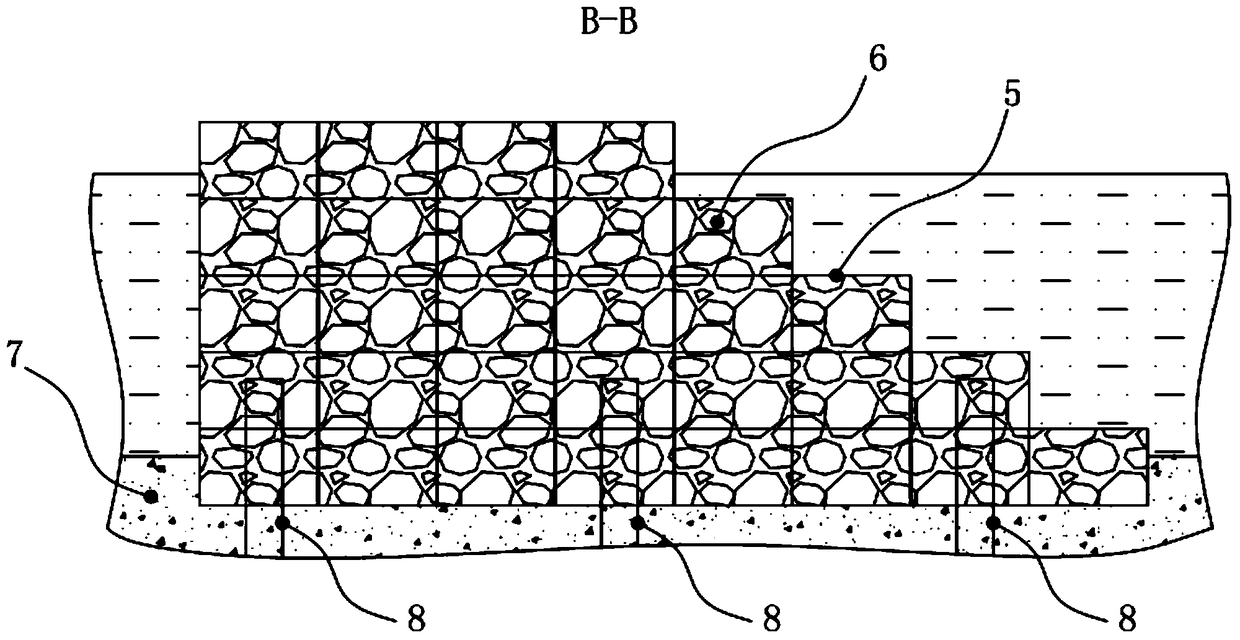

Arrangement method of ecological gabion chamber revetment type

InactiveCN102704441ARestoring Biodiversity TraitsRestoring Diversity TraitsCoastlines protectionReceptacle cultivationRiver routingEngineering

The invention relates to an arrangement method of an ecological gabion chamber revetment type, and belongs to a revetment structure type in river training works. A stepped sandstone cushion layer is laid on the revetment of a river; a sinuous ecological gabion chamber is arranged on the stepped sandstone cushion layer; and plants are planted in the sinuous ecological gabion chamber. The arrangement method has the advantages of novel structure, reliable operation, wide application range, capabilities of improving the engineering safety and favorably improving water eco-environments of rivers and lakes and great application prospect.

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

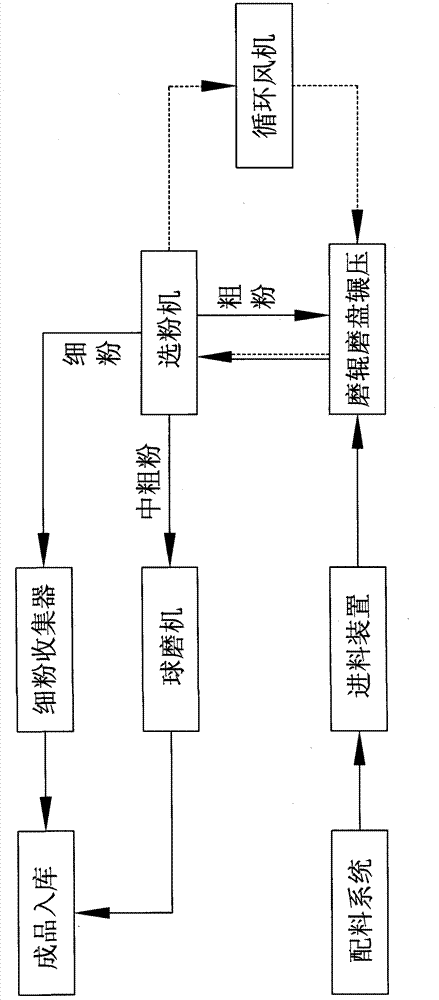

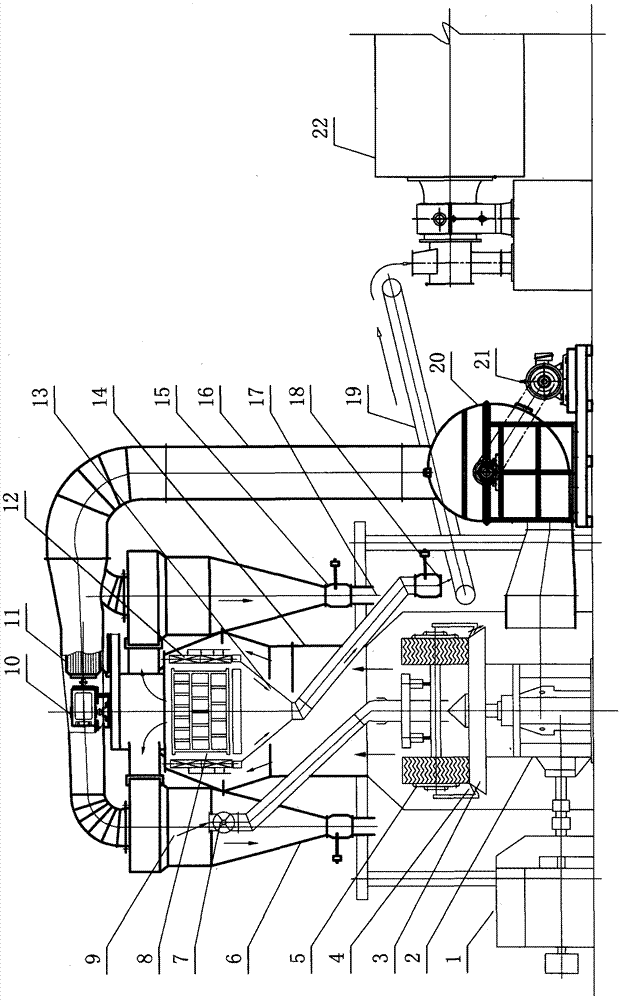

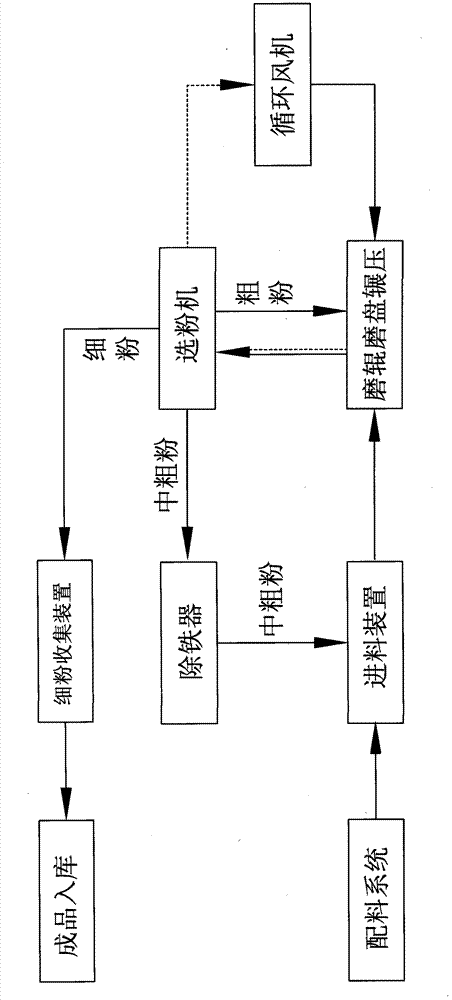

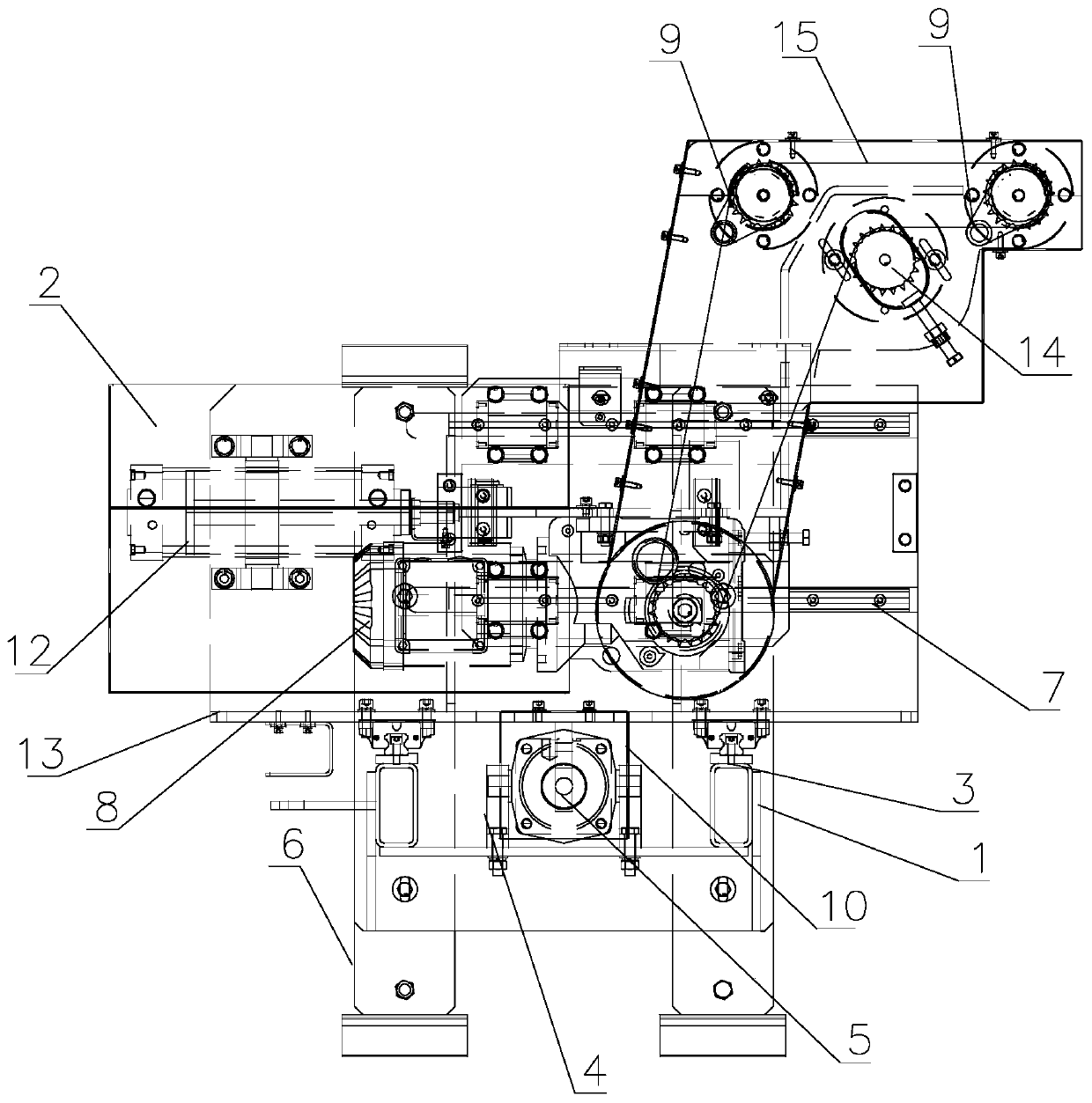

Parallelly-connected grinding technology and equipment thereof

Parallelly-connected grinding technology and equipment thereof belong to grinding technology and equipment thereof; the equipment comprises a vertical mill, a powder separator, a blower fan, and a ball mill; the powder separator is connected with the upper part of the vertical mill; fine powder collectors are disposed at the periphery of the powder separator; a crude powder outlet of the powder separator is connected with the ball mil through a middle crude powder conveying device; an air outlet of the blower fan is connected with the bottom of the vertical mill; a backwind pipe is connected with the top of the powder separator. The invention adopts the grinding technology combining the vertical mill with the ball mill and the material bed-rolling grinding technology; powder grading is realized inside the equipment; qualified materials are collected in advance, which reduces material underlay and over-grinding phenomena of the ball mill; a traditional mode in which the millstone rotates and the grinding roller is driven for a vertical mill is changed into a mode in which the millstone is fixed and the grinding roller rolls; powder grading is realized inside the equipment; the working efficiency is high; the fine grinding performance is good; the abrasion is less; the energy consumption is low; the investment is saved; and the maintenance is safe and simple.

Owner:YANCHENG JIDA MACHINERY MFG

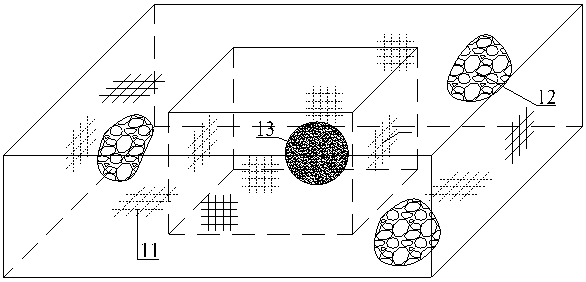

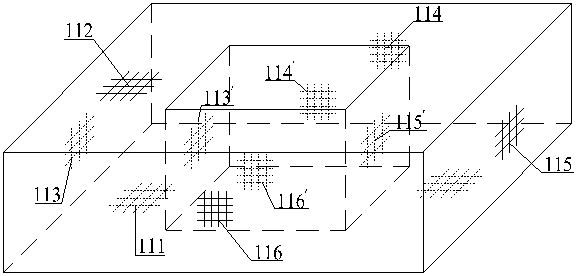

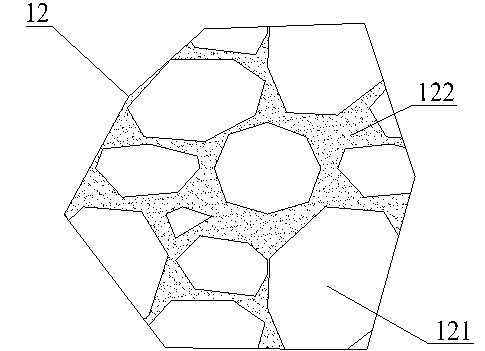

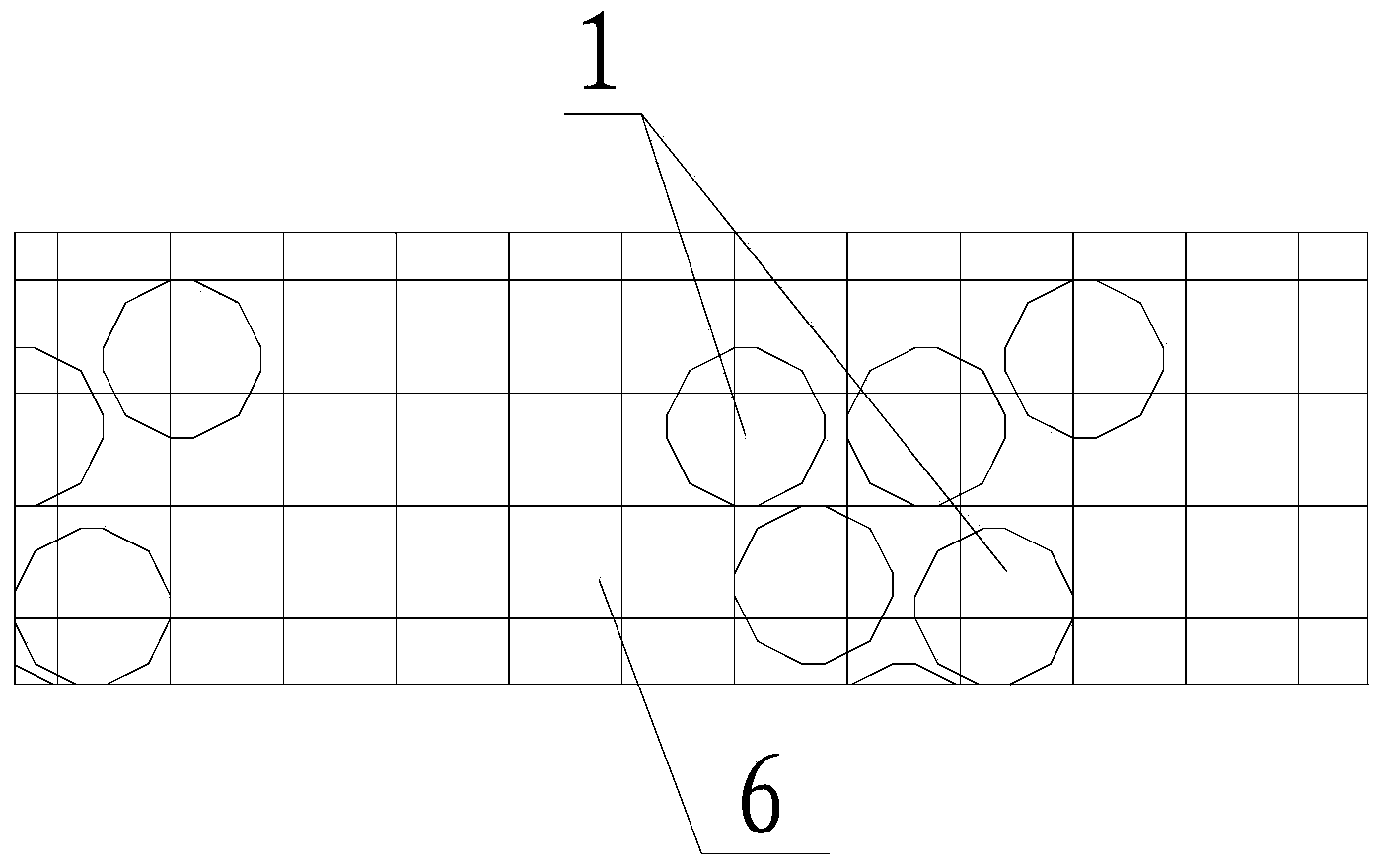

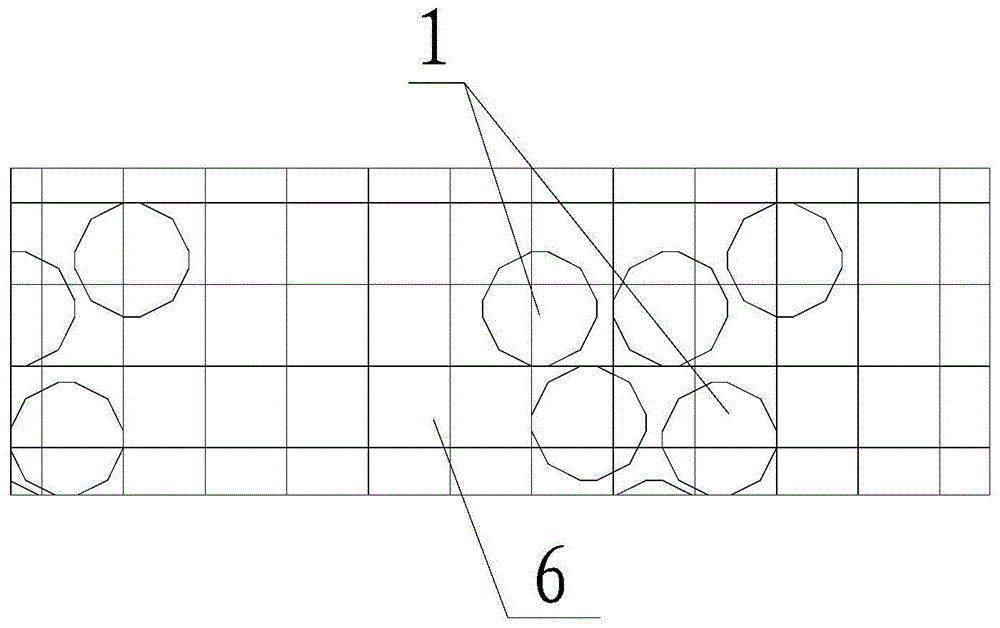

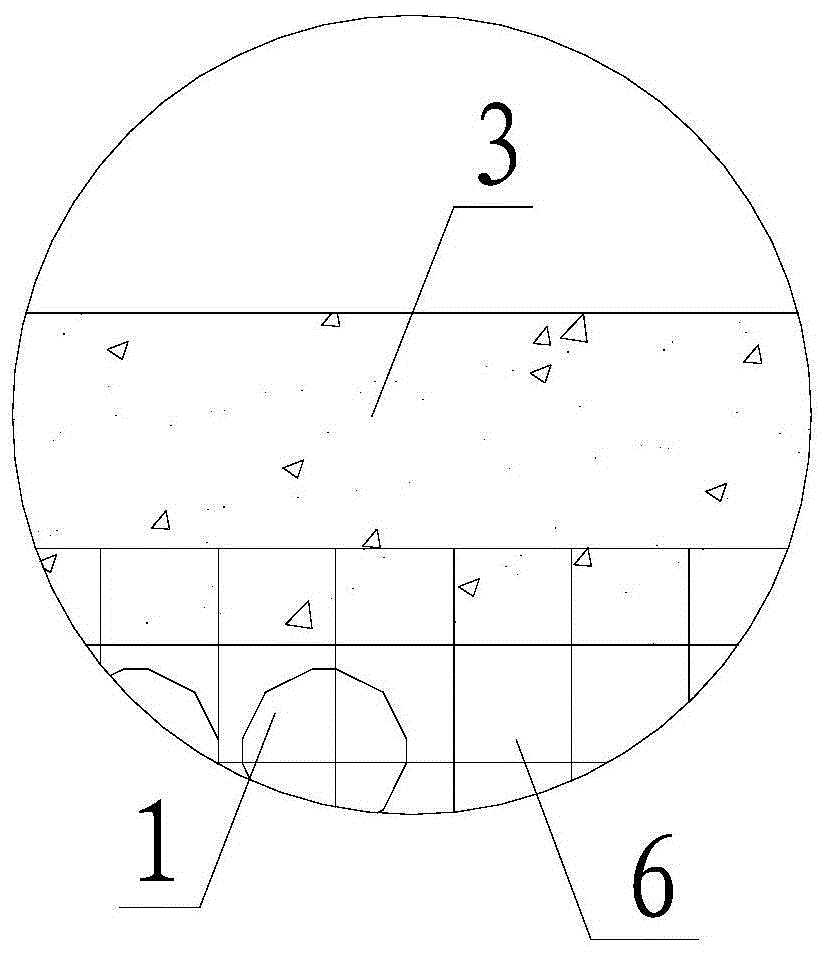

Blocking overflow dam structure

ActiveCN104018471ALow costLow basic requirementBarrages/weirsEarth-fill damsManufacturing technologyBed load

The invention discloses a blocking overflow dam structure and belongs to the technical field of design and manufacturing of hydraulic structures. The blocking overflow dam structure is low in requirement for infrastructures, simple in construction and low in building manufacturing cost. The blocking overflow dam structure comprises stone blocks and a meshed permeable framework, the stone blocks are arranged in the meshed permeable framework, and the blocking overflow dam structure is fixed in a river way or a ditch where the blocking overflow dam structure needs to be arranged outside through the meshed permeable framework; water flowing along the river way or the ditch permeates gaps between the meshed permeable framework and the adjacent stone blocks so as to flow through the blocking overflow dam structure, and solid matter or bed load mixed in water flow is filtered by the blocking overflow dam structure and is blocked at an upstream face of the blocking overflow dam structure.

Owner:POWERCHINA CHENGDU ENG

Three-in-one plastic sports ground, and preparation method thereof

InactiveCN105713269ALow costLong lasting bright colorsGround pavingsPolyurea/polyurethane coatingsEpoxyAdhesive

The invention discloses a three-in-one plastic sports ground. The three-in-one plastic sports ground is prepared from, by weight, 1.5 to 2.5 parts of epoxy resin, 70 to 90 parts of regenerated rubber, 10 to 14 parts of an adhesive, 1.5 to 2.5 parts of titanium dioxide, 0.1 to 0.3 part of a reinforcing agent, 1.5 to 2.5 parts of a coloring material containing inorganic pigments, 7 to 9 parts of quartz sand, 2.5 to 3.5 parts of a colorant, and 6 to 8 parts of polyurethane; the coloring material comprises 2 parts of a pigment powder, 0.21 part of titanium dioxide, 0.15 part of antioxidant 1010, 0.18 part of an anti-ultraviolet agent, and 0.15 part of a fortifier; the regenerated rubber is recycled waste rubber; the adhesive contains trimethylolpropane and hexamethylene diisocyanate; the anti-ultraviolet agent is phenyl salicylate; and the reinforcing agent is silicon dioxide. The invention also provides a preparation method of the three-in-one plastic sports ground. The preparation method comprises following steps: smearing of a water-proof layer, laying of an elastic layer, gap filling, and spraying of a wear-resistant layer. The cost of the three-in-one plastic sports ground is lower than that of conventional runways; the three-in-one plastic sports ground possesses permeability; and problems such as bulking, cracking, peeling, and discoloration are not caused.

Owner:梁意昌

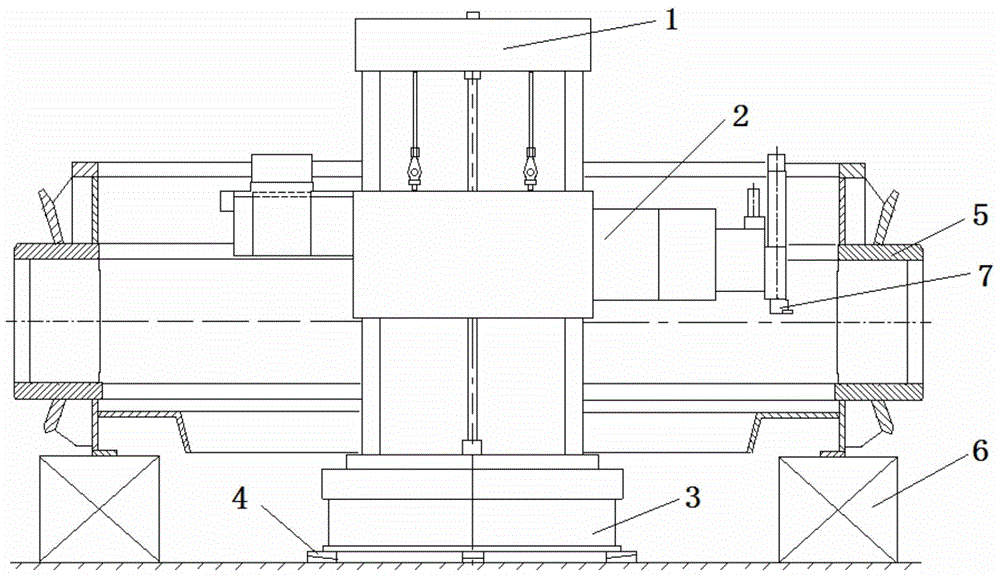

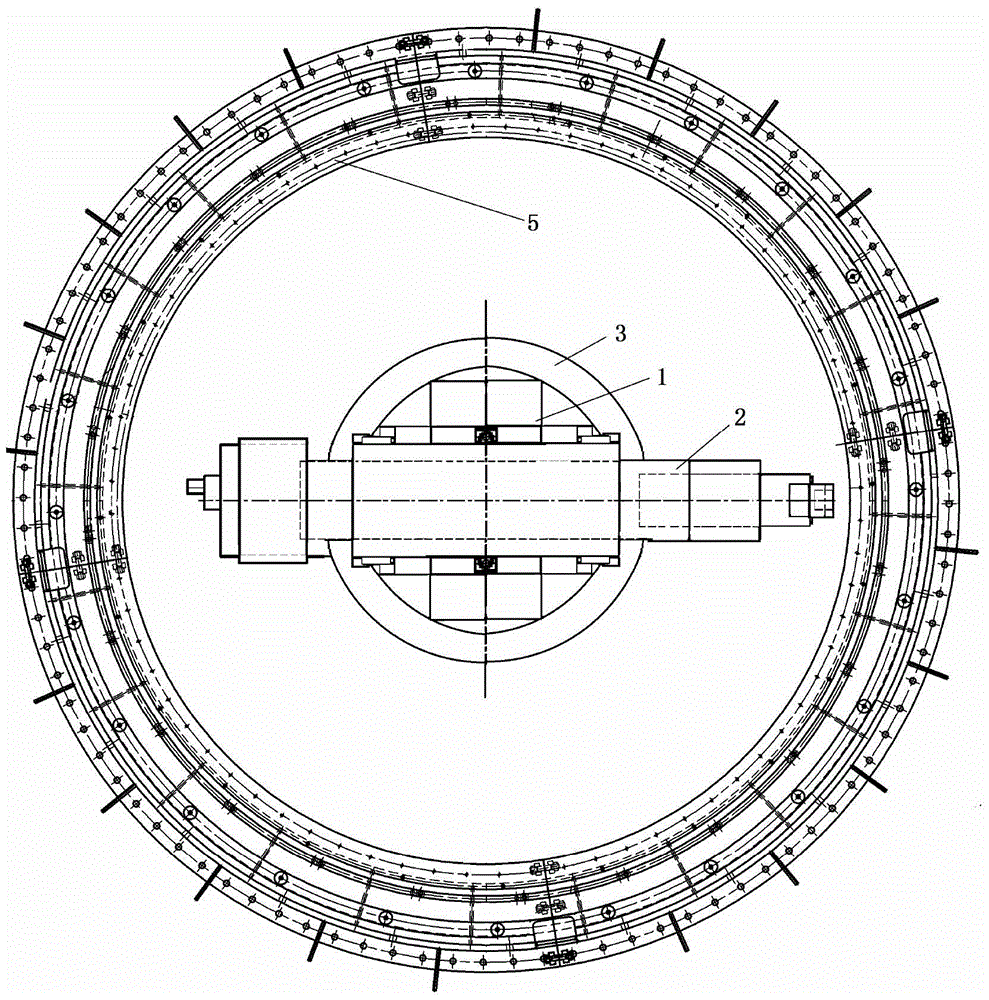

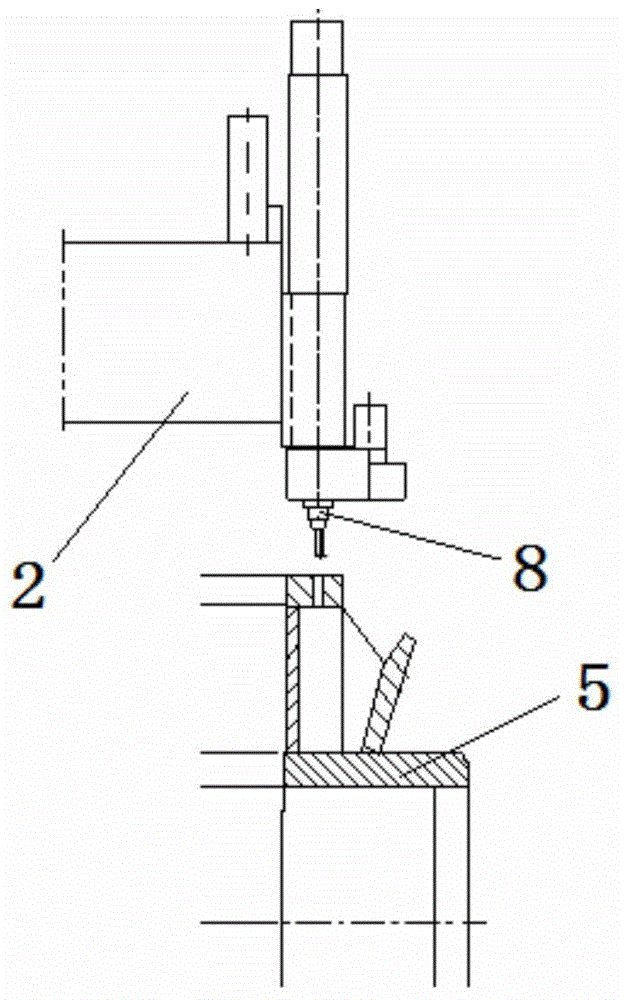

Machining process method of special machine for large stay rings

InactiveCN105215640AGuarantee processing qualityGuaranteed roughnessEngine manufactureReaction enginesWater turbineEngineering

The invention discloses a machining process method of a special machine for large stay rings of water turbines. According to the process method, the stay rings are assembled and machined on an assembly platform by adopting movable vertical lathe machining and accompanying fixture appliances. The process method comprises the following steps: adopting special machine equipment with a movable workbench, and realizing disassembly and carrying for the equipment in a manner of disassembling and assembling the equipment with vertical columns, cross beams and a tool rest; meeting an installation accuracy need by adopting special movable equipment for installing and adjusting adjustment tools; enabling the stay ring to meet an equipment machining stroke in a manner of fixing and supporting the machined stay ring by a square box; aligning and machining the stay ring by virtue of the convenience of movability of the equipment, and avoiding frequent movement and alignment for the stay ring workpiece with a heavy weight; driving the vertical-column tool rest by the rotation of the workbench of the equipment to machine the fixed stay ring workpiece, thus realizing a one-time installation and all-dimensional machining process. The process method disclosed by the invention has the advantages of being novel and unique in machining process, reasonable and concise in process, controllable in machining quality, high in accuracy, and the like.

Owner:HARBIN ELECTRIC MASCH CO LTD

External-circulation iron-removing grinding technology

An external-circulation iron-removing grinding technology belongs to grinding technology; the external-circulation iron-removing grinding technology integrates grinding, iron removal, and grading equipment as one body; materials after rolling are blown by high-speed air flow, and then are separated at a vortex grading part; fine powder is brought by the air flow to four cyclone separators distributed uniformly at the periphery for collection; middle-crude powder slides to the outside of the mill along a pipeline, and enters a pipeline iron-removing device below through an air-locking valve; iron impurities separated by the iron-removing device are discharged through a slag discharge port; other materials enters a circulating elevator, and are fed into the mill for grinding. With the material bed-rolling grinding technology and the external-circulation iron-removing technology, powder grading is realized inside the equipment, and iron impurities in the powder are removed in time, and thus steel loss is reduced. A traditional mode in which the millstone rotates and the grinding roller is driven for the vertical mill is changed into a mode in which the millstone is fixed and the grinding roller rolls; powder grading is realized inside the equipment; and thus the working efficiency is high; the fine grinding performance is good; the abrasion is less; the energy consumption is low; the investment is saved; and the maintenance is safe and simple.

Owner:YANCHENG JIDA ENVIRONMENTAL PROTECTION EQUIP

Heat insulation board capable of blocking hot and cold bridge, and preparation method thereof

The invention relates to the field of building materials, and particularly relates to a heat insulation board capable of blocking hot and cold bridge, and a preparation method thereof. At present, heat insulation materials used for outer walls are not ideal. The technical solution adopted by the invention is as follows: raw materials comprise, by weight, 40-45 parts of cement, 8-35 parts of redispersible rubber powder, 0.1-0.5 parts of cellulosic fiber, 10-15 parts of polyphenyl particles, 20-25 parts of fly ash, 5-10 parts of defoaming stone, 1-5 parts of light calcium carbonate, 1-5 parts of heavy calcium carbonate, 10-15 parts of a heat insulation material and 20-50 parts of expanded glass beads. The raw materials are distributed for three times and shaped in one time. The heat insulation board has the following beneficial effects of good flame retardant performance, incombustiblity, good heat insulation effect, good cohesiveness and high strength. Due to the board shape, the heat insulation board is convenient for construction and use, is reasonable in price, has the same service life with buildings, is suitable for being used by outer wall surfaces of various buildings, and has good economic benefits and social benefits.

Owner:陕西亿丰绿色建筑材料有限公司

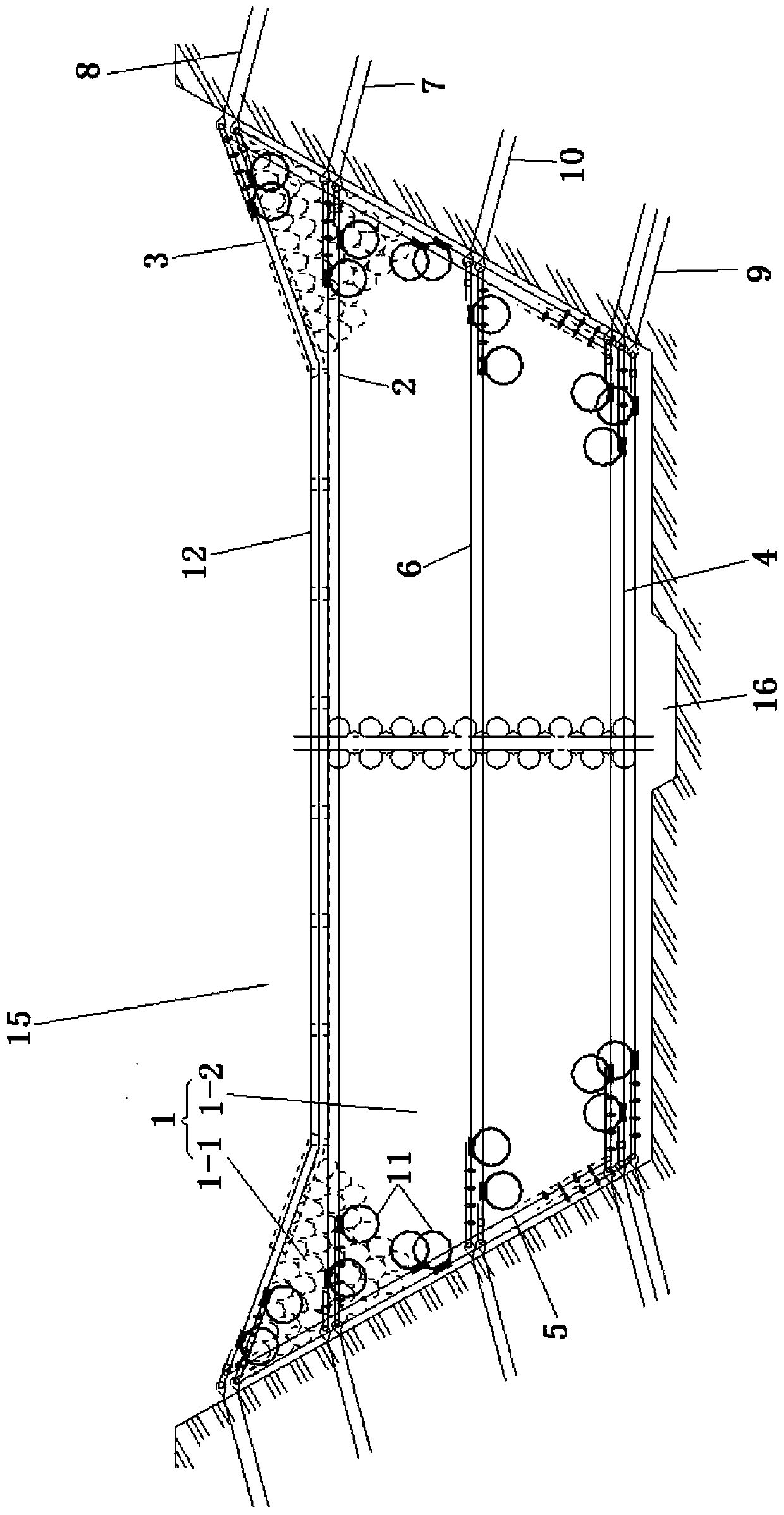

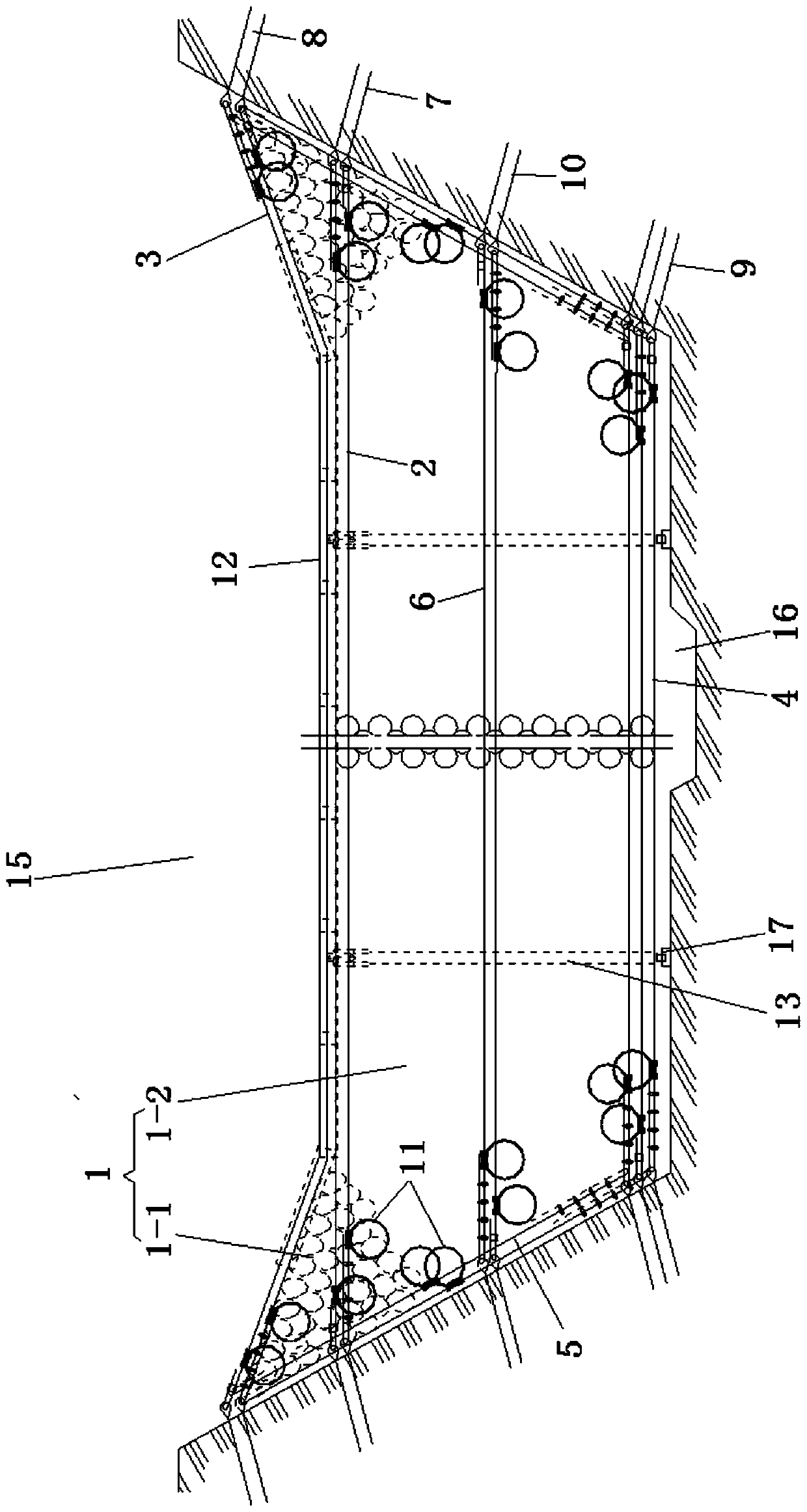

Flexible blocking screen for debris flow and flexible blocking dam for debris flow

PendingCN110344374ALess destructiveReduce transport volumeBarrages/weirsStructural engineeringMechanical engineering

The invention discloses a flexible blocking screen for a debris flow and a flexible blocking dam for the debris flow and relates to the field of blocking facilities, and provides the flexible blockingscreen for the debris flow convenient to construct and the flexible blocking dam for the blocking dam. The flexible blocking dam for the debris flow comprises the flexible screen, a top supporting rope, a wingspan rope, a bottom supporting rope and an edge rope; the flexible screen is transversely unfolded, two ends of the flexible screen upwarp to form a flexible wingspan part, and the rest partis a flexible screen main body; the top supporting rope is transversely stretched to the top of the flexible screen main body, and the upper edge mesh of the flexible screen main body is slidably connected to the top supporting rope; the wingspan edge is arranged along the upper edge of the flexible screen, and the upper edge of the flexible screen is slidably connected to the bottom supporting rope; the bottom supporting rope is transversely stretched to the bottom of the flexible screen, and the lower edge mesh hole of the flexible screen is slidably connected to the bottom supporting rope;edge ropes are arranged at two ends of the flexible screen, and a side edge mesh hole of the flexible screen is slidably connected to the edge rope. The blocking screen is mounted in a cheuch to obtain the blocking dam.

Owner:布鲁克(苏州)工程有限公司

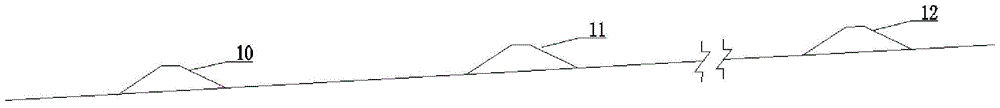

Step sand-blocking dam ecosystem for reservoir desilting and sand prevention

InactiveCN105064291ADredging realizedRealize comprehensive utilizationEarth-fill damsRock-fill damsVegetationEcological environment

Provided is a step sand-blocking dam ecosystem for reservoir desilting and sand prevention. According to topographical conditions, a reasonable position is selected, in the outer river segment of the upstream backwater area of the reservoir area, as a dam site where a sand-blocking dam is built. The dam site where the sand-blocking dam is built is leveled by areas. The lower filling bag dam body of the sand-blocking dam is built by segments and layers on a cleared and leveled river bed by adopting large reservoir desilting soil filling bag technology; the upper dam body of the sand-blocking dam is built by adopting gabion boxes. Ecological restoration and protection are conducted on the surface of the sand-blocking dam, and ecological restoration is conducted on rivers in the upstream and downstream areas of the sand-blocking dam. According to the step sand-blocking dam ecosystem for reservoir desilting and sand prevention, reservoir area desilting soil is used for building the dam and an ecological protection slope surface, so that not only is building cost reduced, but also ecological management and protection are combined into a whole by using local resources; water and soil loss in the reservoir area can be reduced, the ecological environment of the reservoir upstream area and surrounding areas is significantly improved. The step sand-blocking dam ecosystem for reservoir desilting and sand prevention is suitable for siltation prevention and treatment and ecological management work of reservoirs with heavy vegetation damage, ecological environment deterioration and heavy water and soil loss in large reservoir areas in central and western regions.

Owner:NANJING HYDRAULIC RES INST

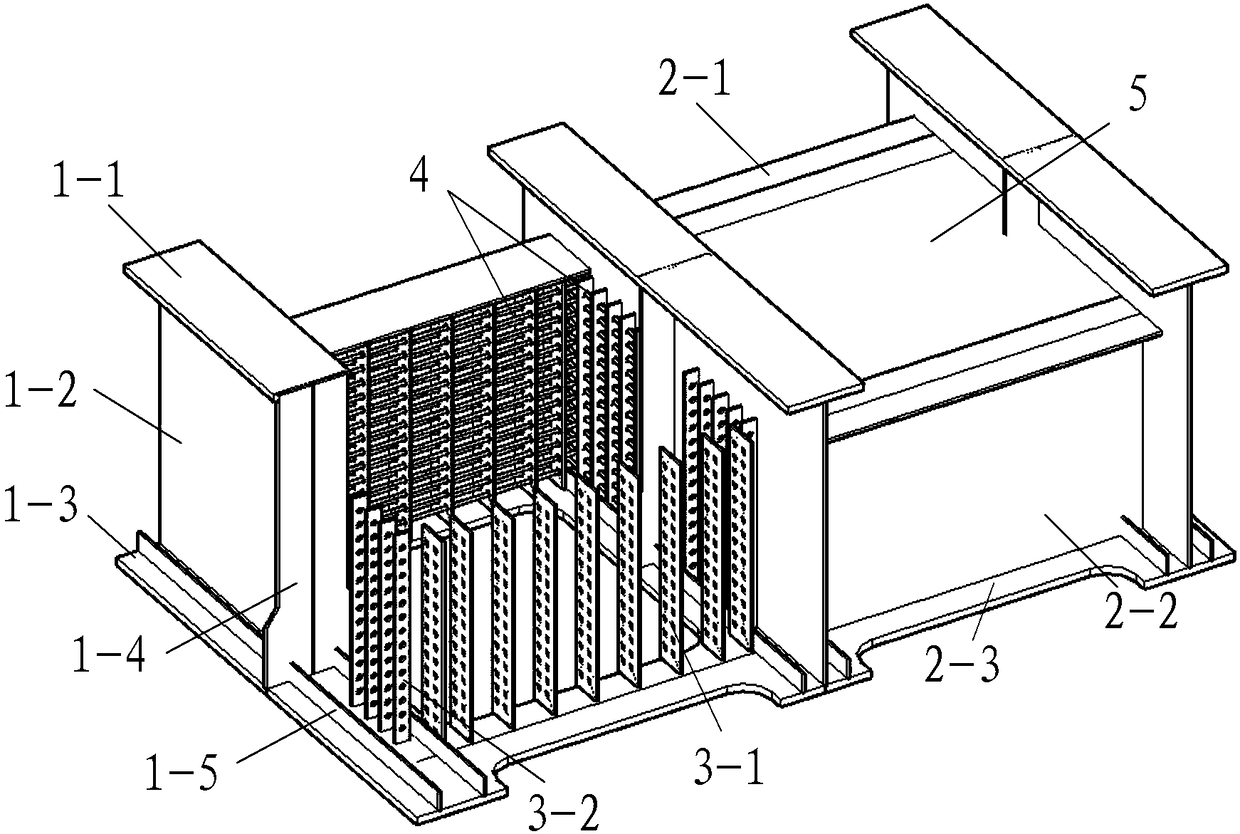

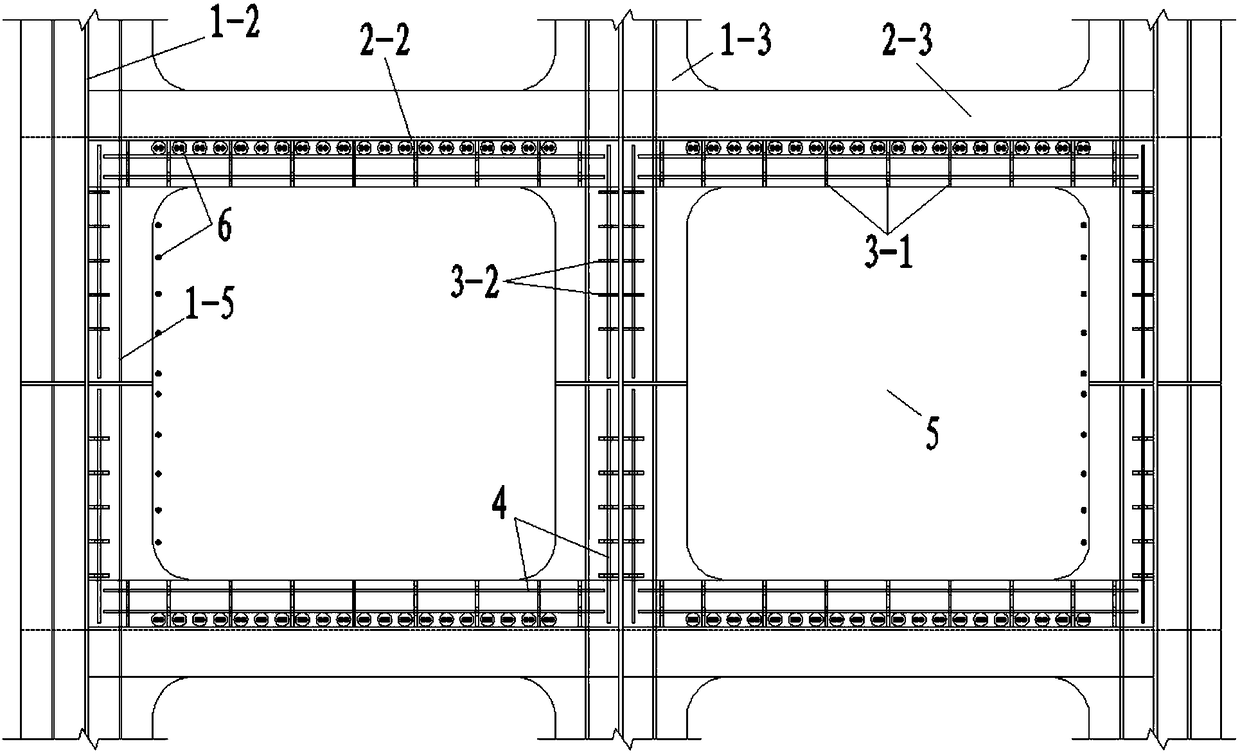

Combined rigid frame steel plate girder-pier girder solid structure

The invention discloses a combined rigid frame steel plate girder-pier girder solid structure. According to the structure, an I-shaped steel main girder and a crossbeam form a box-shaped grid room, perforated plate connection pieces are arranged inside web plates of the box-shaped grid room and penetrate through reinforcing bars and pour concrete, so as to solidify the pier girder. To ensure thatthe load born by the main girder is transmitted to the pier effectively, perforated plate connection pieces are arranged inside web plats of the steel main girder and the crossbeam of the box-shaped grid room, the perforated plates penetrate through common reinforcing bars and then concrete is cast so as to resist shear force, shaft force and bending moment of the pier girder solidified part; thesteel plate girder and the concrete pier are connected through the perforated plates, so that the structure is simple, bears forces reasonably and transmits force reliably, can meet various requirements of normal use and limit loading, improves the crossover capability of the bridge while the dead weight is reduced, is convenient and quick in construction, and solves main problems that the web plate concrete cracks, the middle span warps downwards and the anti-seismic performance is reduced in the existing concrete rigid frame bridge due to long-term load.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

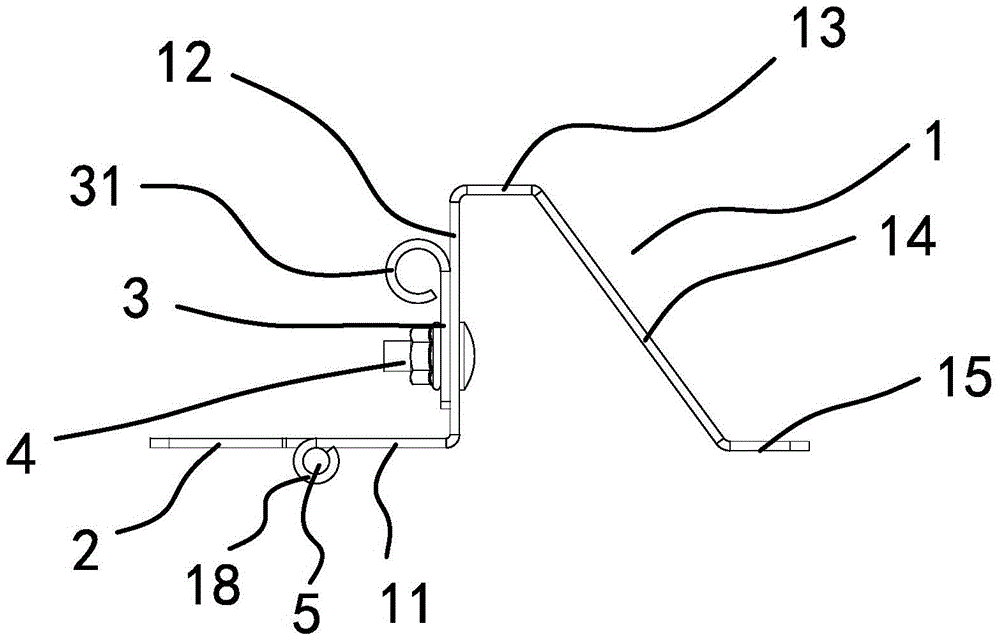

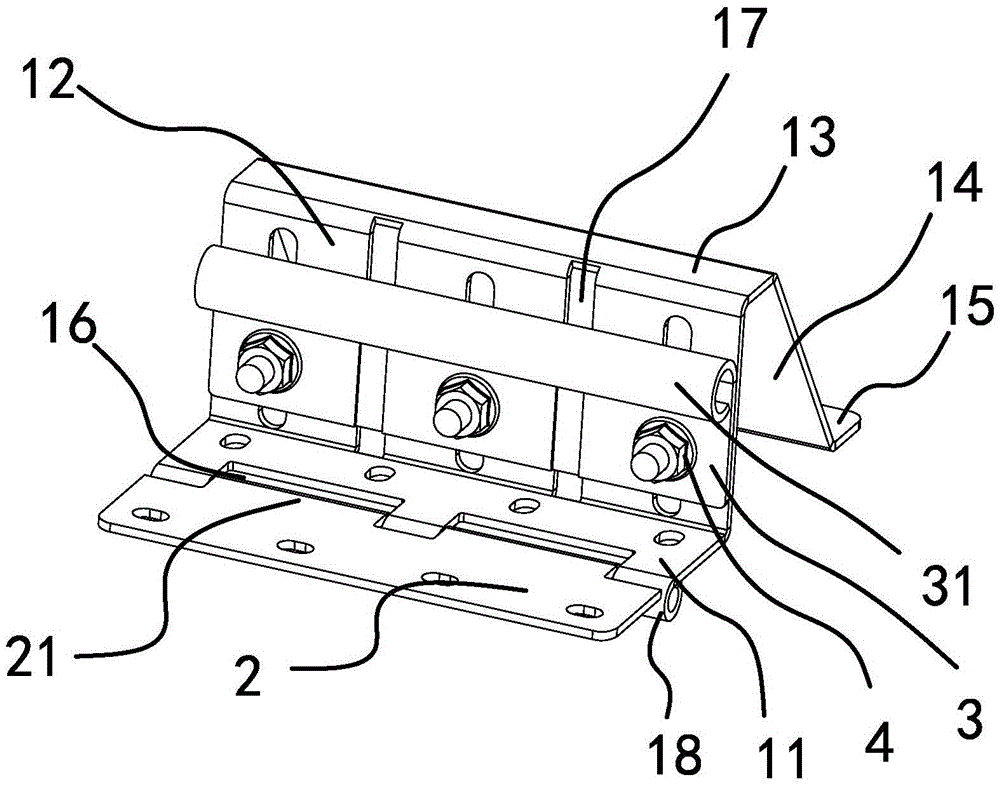

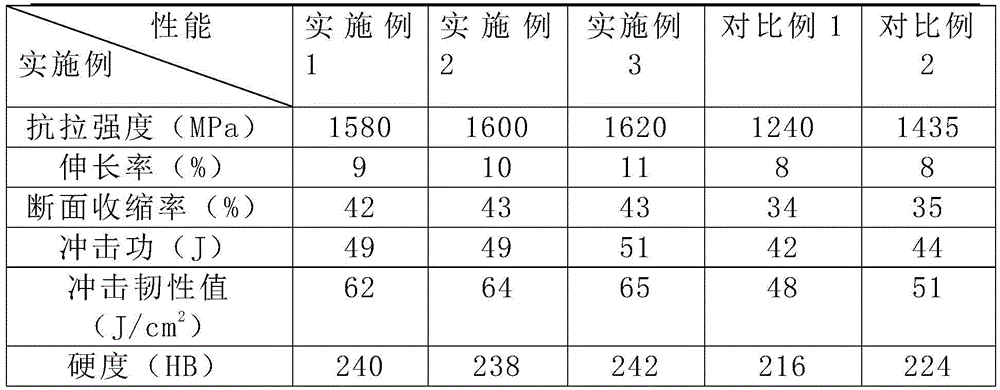

Anti-pinch hinge for industrial door

The invention provides an anti-pinch hinge for an industrial door, belongs to the mechanical technology field, and solves the problem of poor quality of the existing hinge for an industrial door. The anti-pinch hinge for the industrial door comprises an adjustment sheet, as well as a first hinge sheet and a second hinge sheet which are in hinge connection through a rotary shaft, wherein a winding drum is formed at the side of a first horizontal part of the first hinge sheet; a rotary shaft is arranged in the winding drum in a penetrating manner; strip-shaped holes are formed in a vertical part; location bolts are fixed in the strip-shaped holes in a penetrating manner; the first hinge part comprises a ceramic filling part and a metal layer arranged on the outer layer of the ceramic filling part; the ceramic filling part is formed by taking silicon carbide ceramic as a main body and at least partially arranging a silicon nitride ceramic surface layer on the outer layer of the main body; and the metal layer comprises the following composition ingredients in percentage by weight: 0.17-0.25% of C, 0.22-0.35% of Si, 1.2-1.3% of Cr, 0.05-0.2% of Ni, 0.3-0.8% of Mo, 0.3-0.8% of Mn, 0.06-0.12% of Ti, 0.05-0.3% of B and the balance iron. The anti-pinch hinge for the industrial door, which is provided by the invention, has the advantages of being simple in structure and high in safety.

Owner:宁波超亿门业有限公司

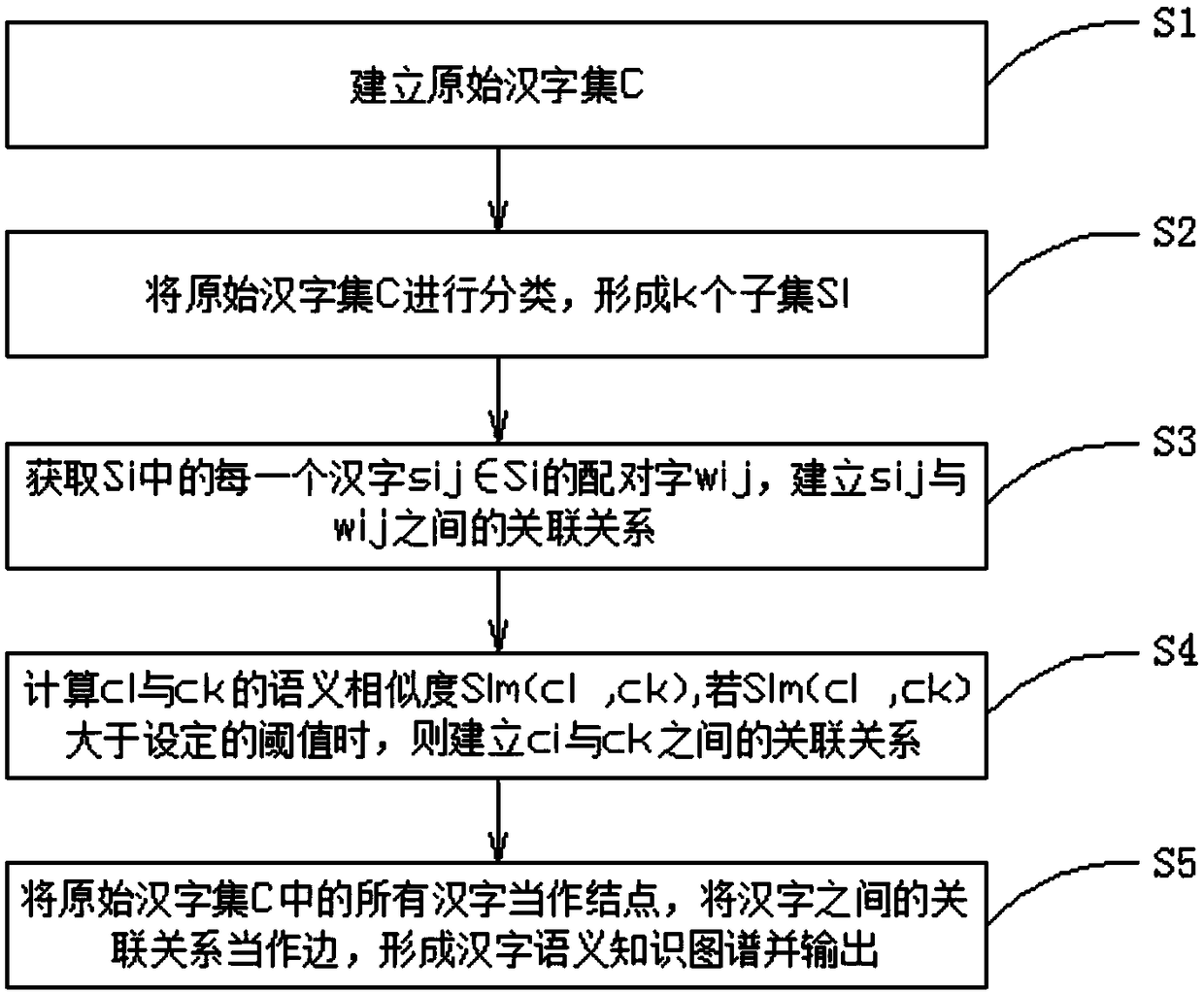

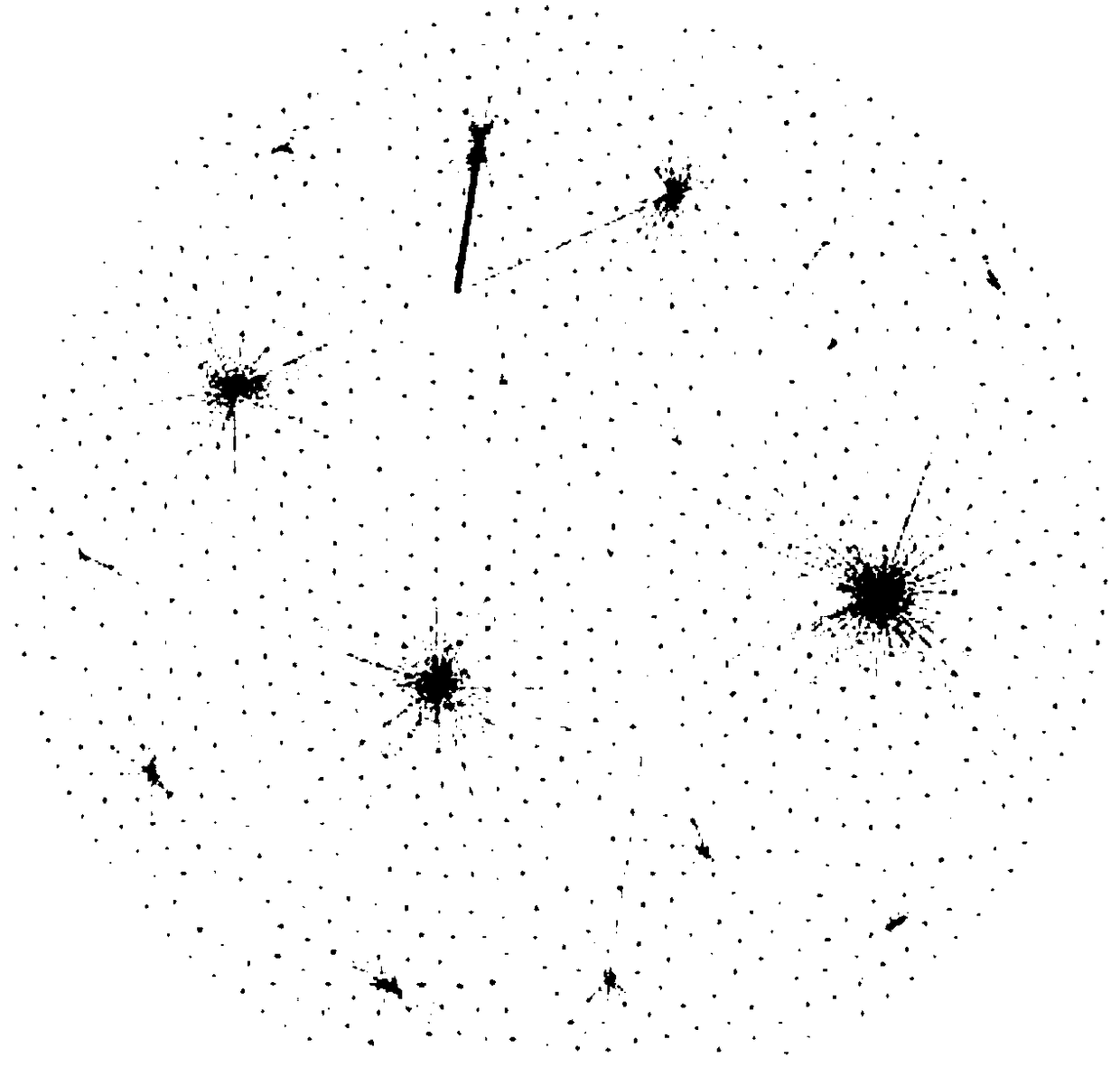

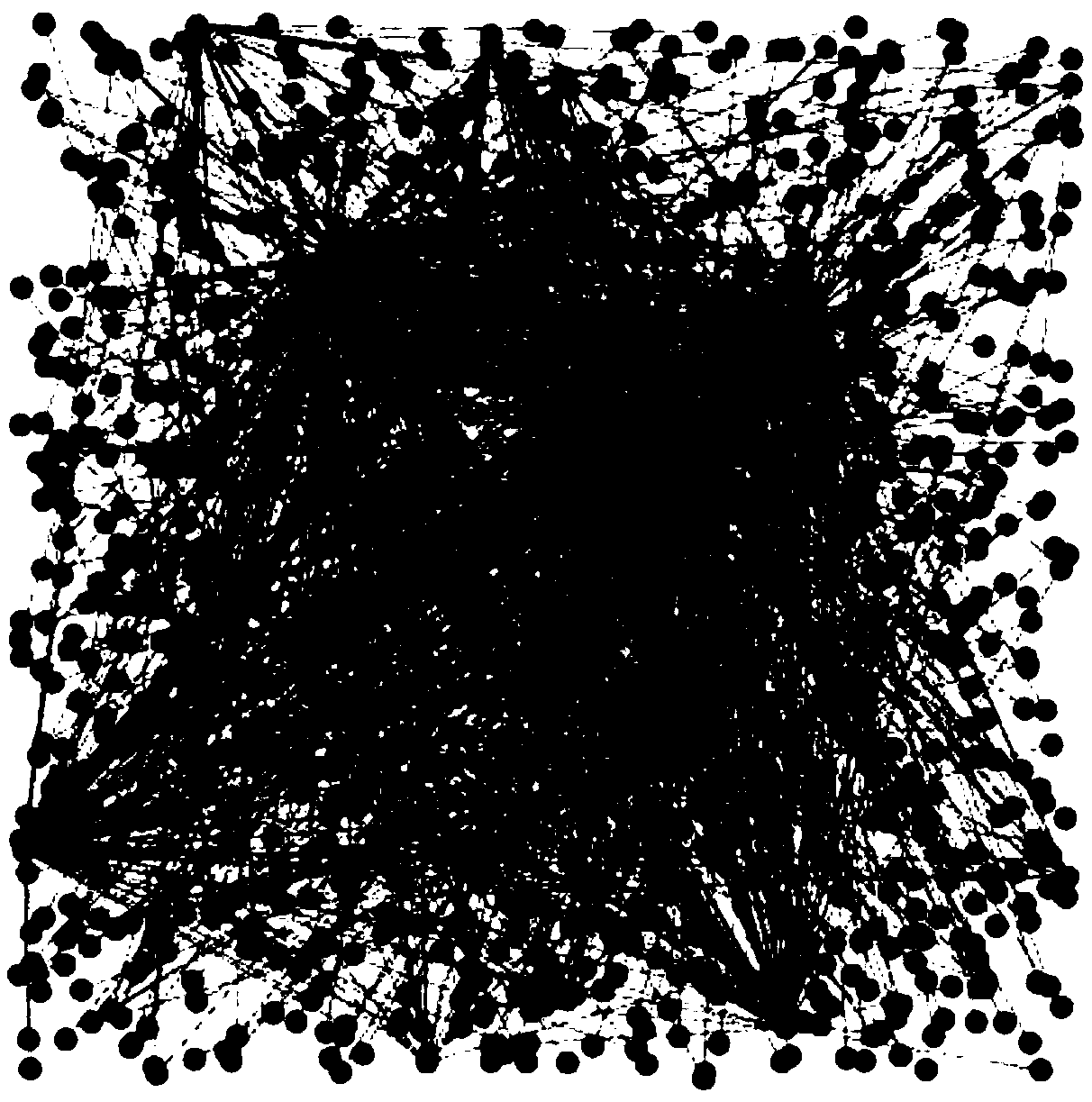

Chinese character semantic knowledge map construction method, device and apparatus, and storage medium

InactiveCN109189939AAvoid the problem of identifying and learning Chinese charactersEasy to masterText database clustering/classificationSemantic tool creationChinese charactersGlyph

The invention discloses a Chinese character semantic knowledge map construction method, device and apparatus, and storage medium, belonging to the technical field of Chinese language education. The method comprises the steps of: building an original Chinese character set C; classifiying the original Chinese character set C to form k sub-sets Si, wherein Si is a subset of C and i=1, 2, 3...k; obtaining a pairing word Wij of each Chinese character sij (is a member of) Si in Si, and if wij is an element of C, establishing the association between sij and Wij, and if Wij is not a member of C, adding wij to the Chinese character set C and establishing the relationship between sij and wij; calculating the semantic similarity Sim(ci, ck) between ci and ck; if Sim (ci, ck) is greater than the set threshold, establishing the correlation between ci and ck, wherein: ci is a member of C, ck is a member of C, and i is not equal to k; taking all the Chinese characters in the original Chinese character set C as nodes and the association relations among the Chinese characters as edges to form a Chinese character semantic knowledge map and outputting the map. The technical proposal of the example ofthe invention can quickly construct a Chinese character knowledge map, and various problems caused by learning Chinese characters based on character shape discrimination are avoided.

Owner:ANYANG NORMAL UNIV

Clay court and construction method thereof

The invention relates to the clay court construction filed and particularly relates to a clay court and a construction method thereof. The clay court is characterized by comprising a clay fragment layer and a clay fine sand surface layer which are paved from bottom to top on a court foundation, wherein the clay fragment layer is formed by bonding clay fragments and elastic particles through adhesives; the court foundation is any of a hard court foundation, a clay foundation, an elastic cushion or a semi-elastic cushion; the clay fragments and elastic particles are prepared according to a weight ratio of (10:4) to (10:0), and the adhesives and a clay fragment and elastic particle mixture are prepared according to a weight ratio of 1:(7-15). The clay court and the construction method thereof have the advantages that the structure is simple, and the permeable performance and the damping property are good; and the clay court is simple to construct and maintain, low in maintenance cost, good in anti-freezing and anti-cracking performances and long in service.

Owner:盐城速朗体育科技有限公司

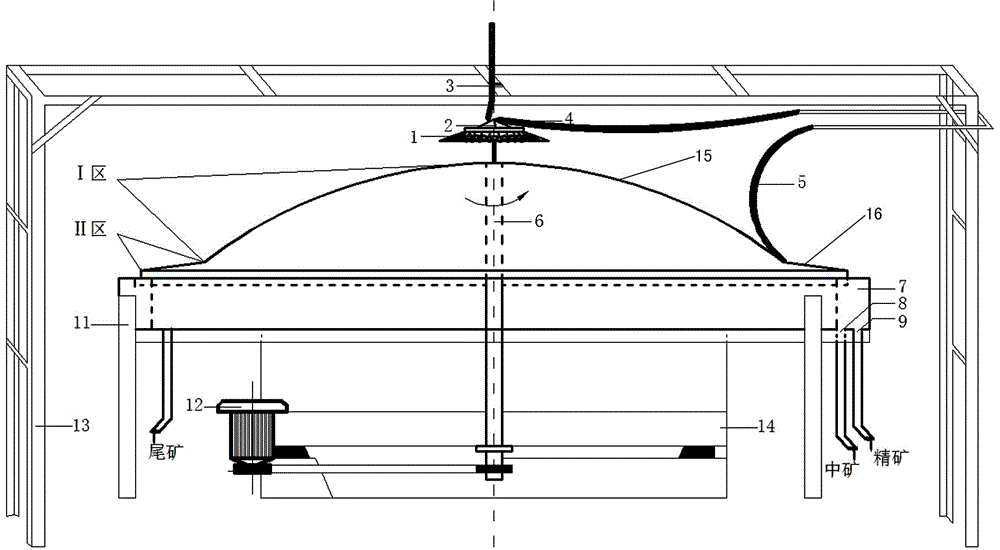

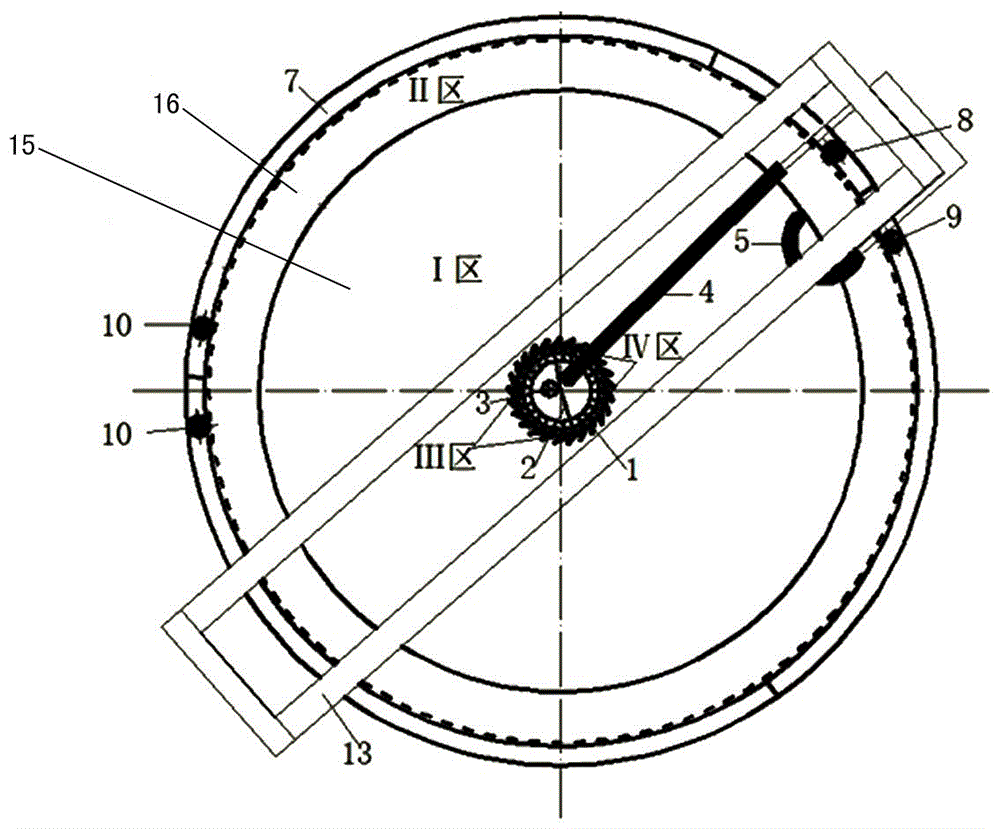

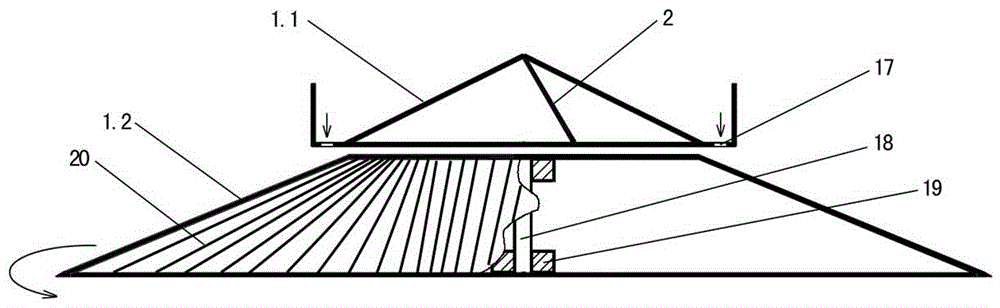

Arc surface spreading flow film sorting machine

ActiveCN106824500AIncrease centrifugal accelerationRaise the lower limit of granularityWet separationSurface spreadingEngineering

The invention discloses an arc surface spreading flow film sorting machine, and relates to equipment capable of continuously sorting fine-particle refractory minerals under combined effect of gravity and turning force. The equipment mainly consists of a rotary sorting disc driven by a driving device, an ore and water feeding device and an ore receiving and discharge device; the upper surface of the sorting disc is a spherical arc surface with a curvature radius of 0.58-2.27 m; the outer edge of the spherical arc surface is connected with a lap of annular inclined surface for forming an angle of 3-8 degrees with the horizontal plane; a flushing water pipe is mounted on the annular inclined surface; an ore receiving groove below the sorting disc in the flushing water pipe is provided with middling, concentrate and tailing discharge ports in sequence at intervals; an ore separation flushing disc is arranged rightly above the sorting disc; the upper part of the disc is a conical surface fixed disc, and the lower part is a movable disc provided with a rotating shaft; an ore feeding pipe mouth and a water feeding pipe mouth are aligned to the fixed disc; a series of leakage holes are formed in the bottom of the fixed disc, and are aligned to the movable disc; and a series of baffle plates aslant dispersed are arranged on the surface of the movable disc. The machine is suitable for environment-friendly, efficient, energy-saved and continuous sorting of 0.2-0.037 mm fine-particle valuable minerals.

Owner:昆明理工凯吉思科技有限公司

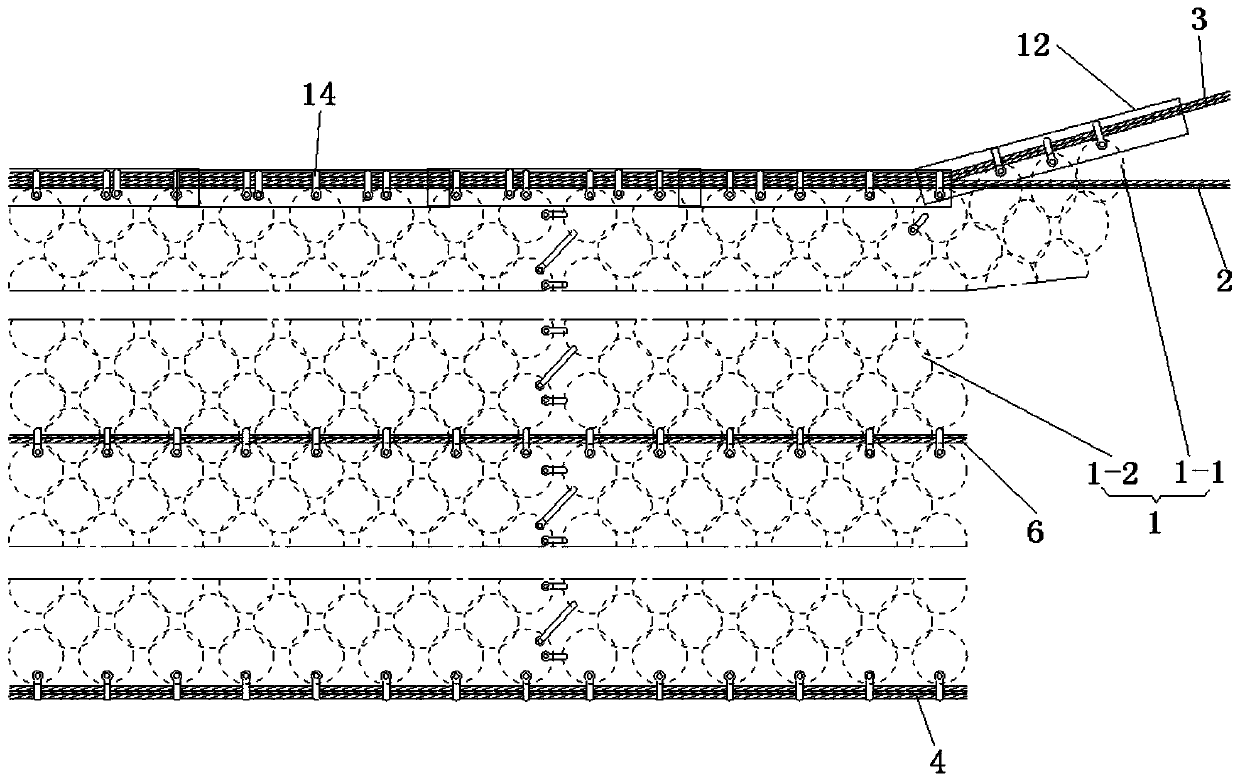

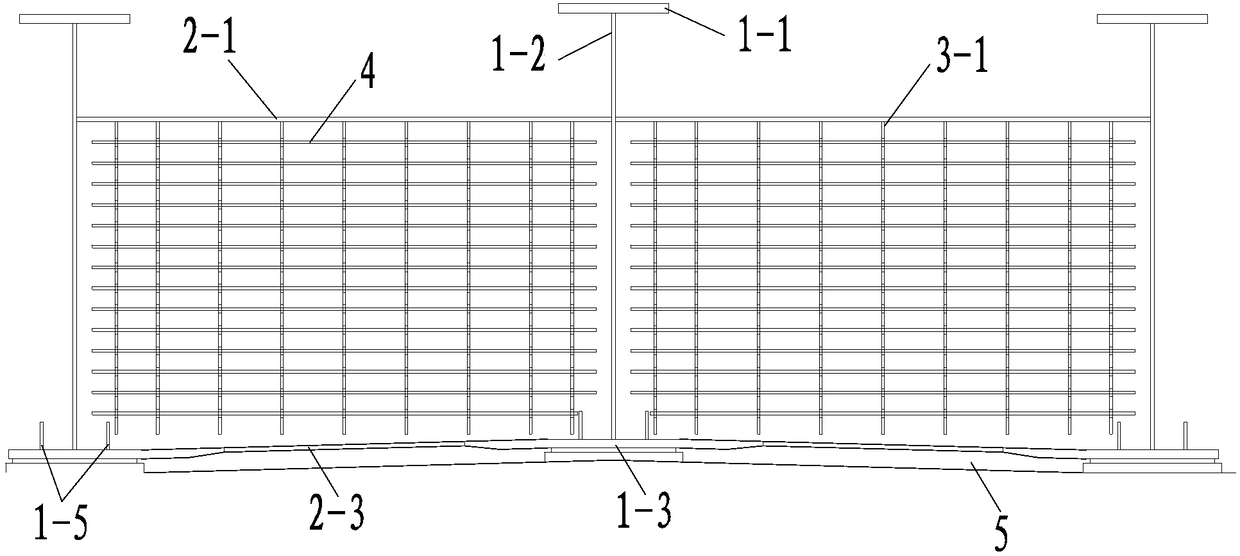

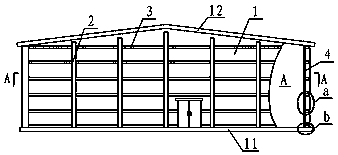

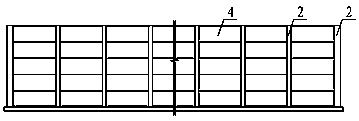

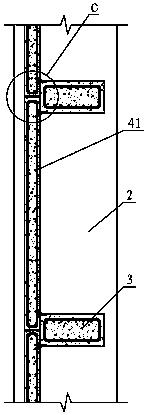

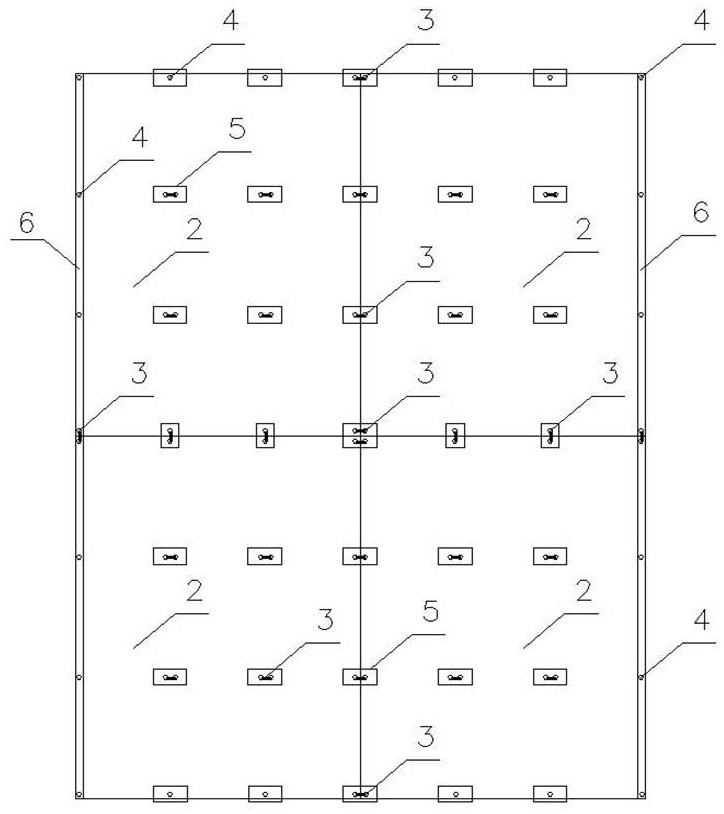

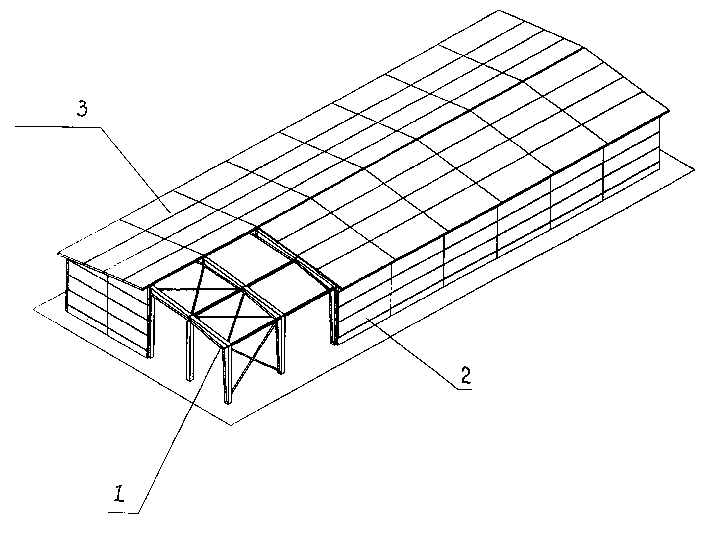

Assembled frame-type horizontal warehouse, prefabricated wallboard mould and construction method of horizontal warehouse

PendingCN110259237ALong construction periodBuild fastWallsMouldsSupporting systemReinforced concrete

The invention discloses an assembled frame-type horizontal warehouse, a prefabricated wallboard mould and a construction method of a horizontal warehouse. In recent years, steel plate silos develop rapidly due to the characteristics of the high construction speed, the short construction period, the low cost and the like, however, the fatal weakness of the steel plate silos is that the silo wall is thin, the temperature is greatly affected by the outside world, grain and other items which have strict requirements for the temperature and moisture are prone to mildewing, decaying and other phenomena in the storage process, it is difficult to store the grain for a long time, and the service life of the steel plate silos is short. The assembled frame-type horizontal warehouse comprises a frame-type warehouse body (1), the frame-type warehouse body is connected with a foundation (11) and a warehouse top (12), the frame-type warehouse body comprises a group of reinforced concrete stand columns (2) located at the four walls of a wall body, reinforced concrete connecting beams (3) are arranged between the reinforced concrete stand columns to form a supporting system of the warehouse top, and the reinforced concrete stand columns (2) and the reinforced concrete connecting beams (3) are connected with a reinforced concrete prefabricated wallboard (4). The assembled frame-type horizontal warehouse is used for horizontal warehouse construction.

Owner:刘全义

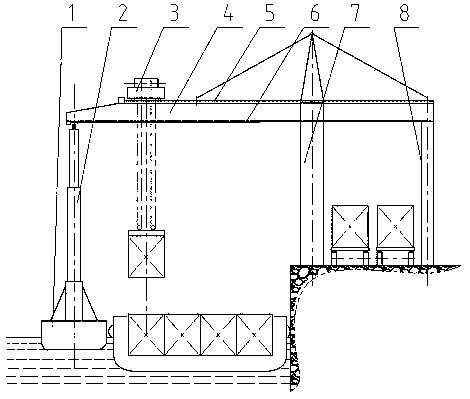

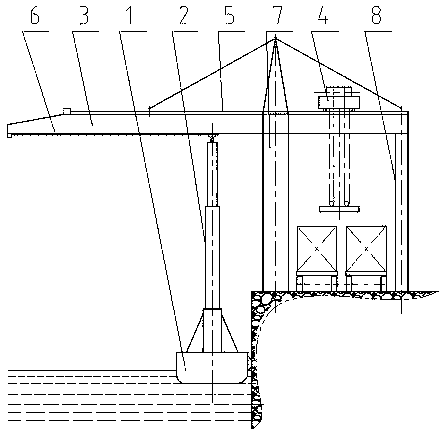

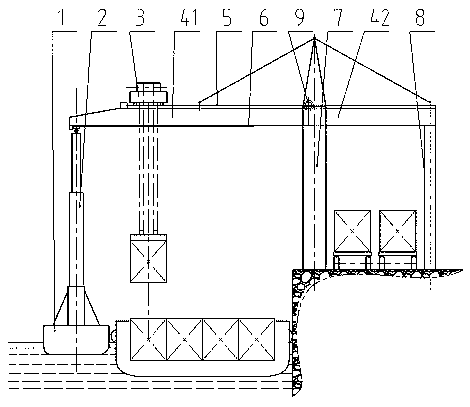

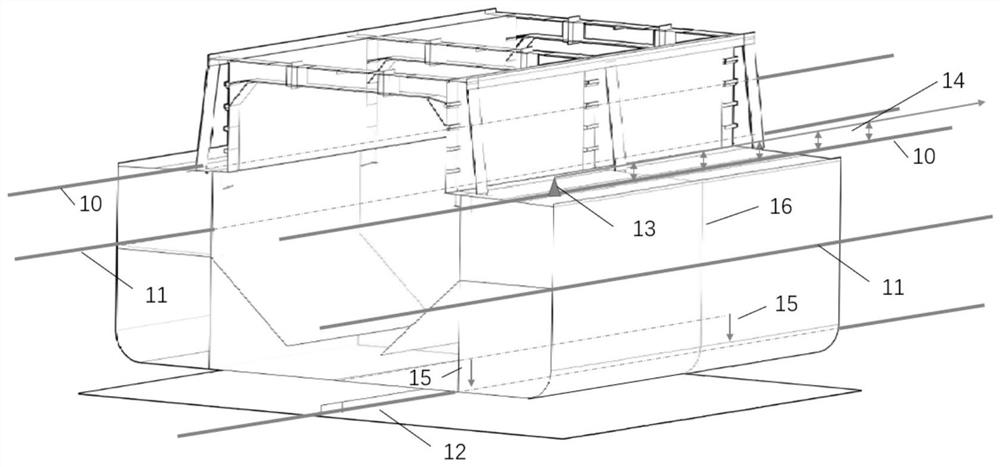

Portal crane with supporting floating body

InactiveCN108689308AMeet the requirements of liftingLow basic requirementTrolley cranesRunwaysGantry craneWaste management

The invention discloses a portal crane with a supporting floating body. The portal crane comprises a fixing portal and a track beam fixed to the fixing portal. A lifting guide rail is fixedly connected to the track beam. A crane car is movably supported in the lifting guide rail. The track beam is also connected with a floating portal. The floating portal is supported on a floating body on water.The floating portal comprises a floating portal body and a hydraulic oil cylinder mounted on the floating portal body. The floating body on water can be a ship-shaped structure or a pontoon type structure. By means of the portal crane with the supporting floating body, the requirement for transporting a container by crane in an inland wharf can be met; in addition, the requirement for the basis ofthe wharf is low; and the construction cost of the wharf and cranes thereof is lowered.

Owner:东台市富康机械有限公司

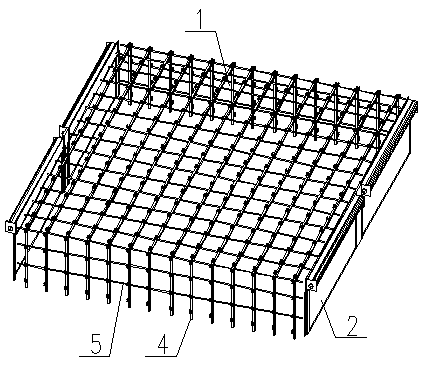

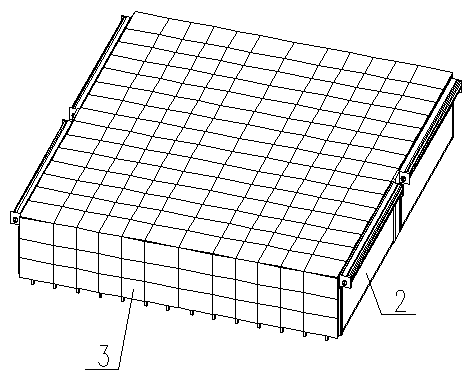

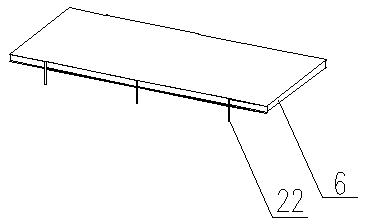

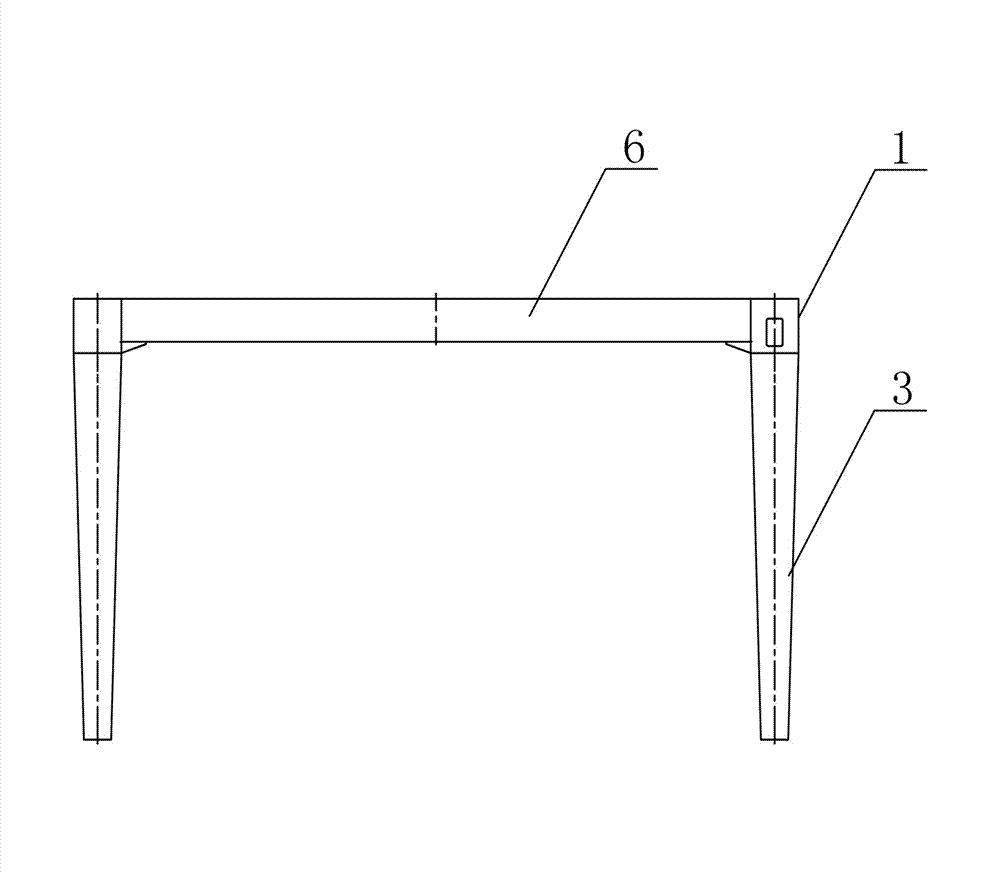

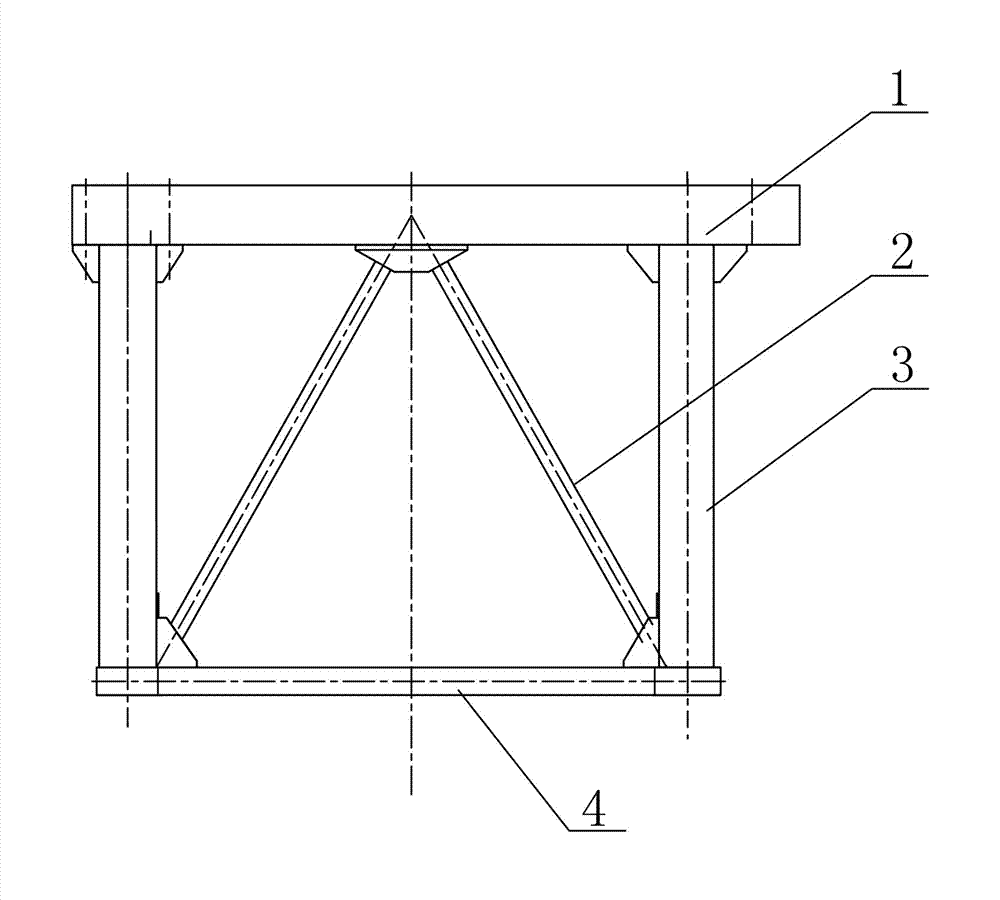

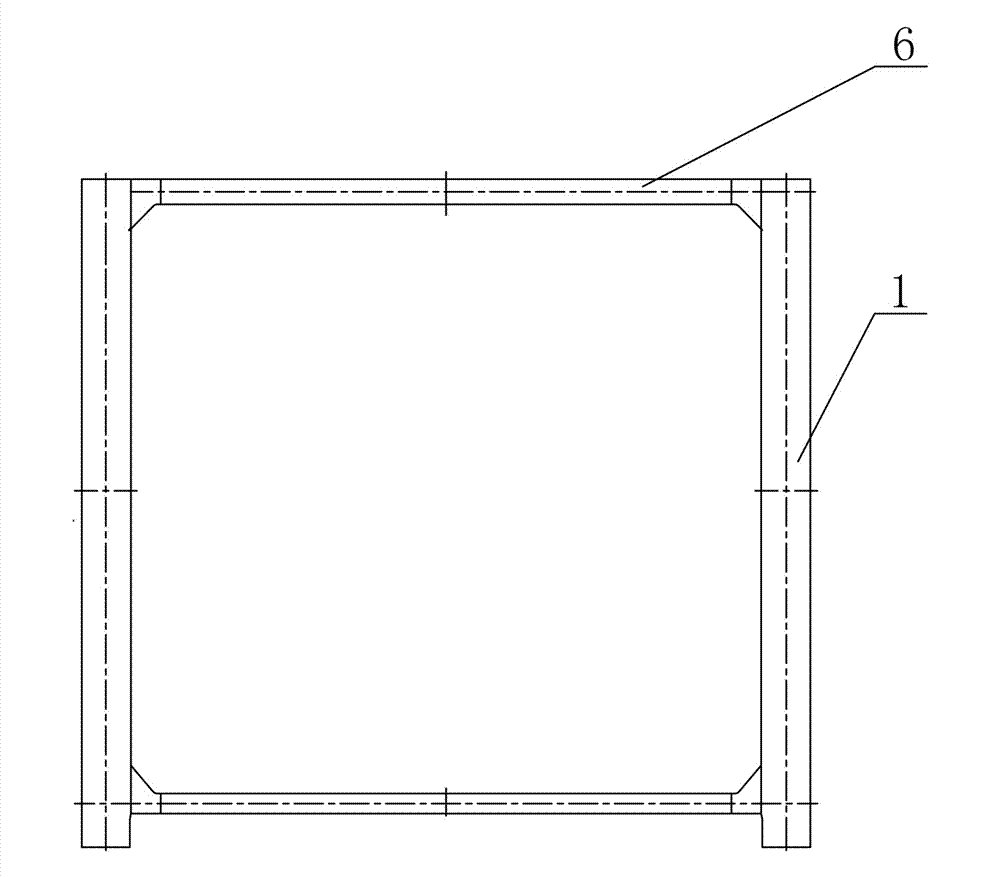

Movable prefabricated member sunlight temperature-rise maintenance system and method

The invention discloses a movable prefabricated member sunlight temperature-rise maintenance system and method. Fire coal and fuel gas are usually adopted for maintenance of existing prefabricated member maintenance kilns, while coal and other fossil resources belong to non-renewable resources, and combustion causes severe pollution while bringing heat. Although fuel gas belongs to clean energy, ventilation cannot be achieved in residence districts under construction. The movable prefabricated member sunlight temperature-rise maintenance system comprises a maintenance greenhouse, and the maintenance greenhouse is composed of a structural frame body (1), openable greenhouse doors (2) and a heat absorption and thermal insulation panel (3); the heat absorption and thermal insulation panel isinstalled on the structural frame body, and the structural frame body is a structure formed by connection of main keels (4) and subsidiary keels (5). The maintenance greenhouse is provided with an auxiliary heating device, and a movable production line is arranged outside the maintenance greenhouse.

Owner:湖北宇辉智能科技有限公司

Method for making self-temperature-regulating phase-change heat-insulation wall and product thereof

InactiveCN100447359CImprove insulation effectAchieve insulation effectCovering/liningsSolid waste managementFiberPhase change

The invention discloses a temperature-selfadjusting phase transition composite high temperature wall body manufacturing method, comprising: coating the wall body with temperature selfadjusting phase transition mortar, coating heat preservation putty and then coating elastic putty, and finally coating heat insulating paint, where the said temperature selfadjusting phase transition mortar is composed in weight percent of: temperature selfadjusting phase transition material 10-40%, hollow fiber material 5-35%, dispersible glue powder 8-38%, cement 12-42%, and lightweight aggregate 35-65%. And the invention provides a temperature-selfadjusting phase transition composite heat preservation wall body manufacturing method and the product. And the product has features of better heat preservation effect, high antifire performance, low wall body foundation requirements, high fastness of heat preservation layer, good decorative effect, no pollution, long service life, able to make large-area spreading and application, etc.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Frame structure for bridge type and door type combination type crane

InactiveCN102923580AImprove wind resistanceImprove seismic performanceBase supporting structuresBraking devices for hoisting equipmentsBridge typeEngineering

The invention discloses a frame structure for a bridge type and a door type combination type crane. The frame structure for the bridge type and the door type combination type crane is characterized by being formed by welding of a rail beam, inclined supports, pillar legs, a lower beam and contact beams. A lateral face framework is formed by welding of the rail beam, the lower beam and two pillar legs, and two lateral face frameworks form a doorframe type steel structure by welding of two contact beams. An upper plane framework is formed by welding of the rail beam and the contact beams, and the rail beam is a box type beam which is provided with a working channel and an illuminating system. The pillar legs are of box type pillar structures, and staircases or manned elevators which are arranged in the box type pillar structures are communicated with the rail beam. Compared with the prior art, the frame structure for the bridge type and the door type combination type crane is simple in structure, low in manufacturing cost, and convenient to install and maintain, avoids deformation of a structure due to non-synchronous operation, and particularly is suitable for a dockyard and a dock basin wharf, wherein a long-distance elevated trestle can not be arranged at the dockyard and the dock basin wharf.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

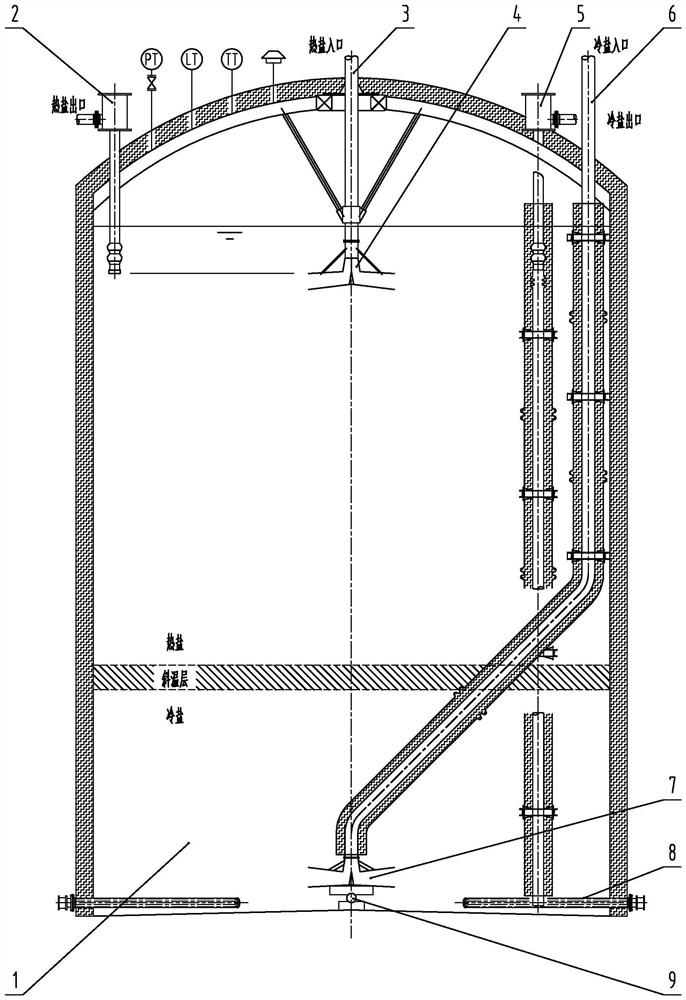

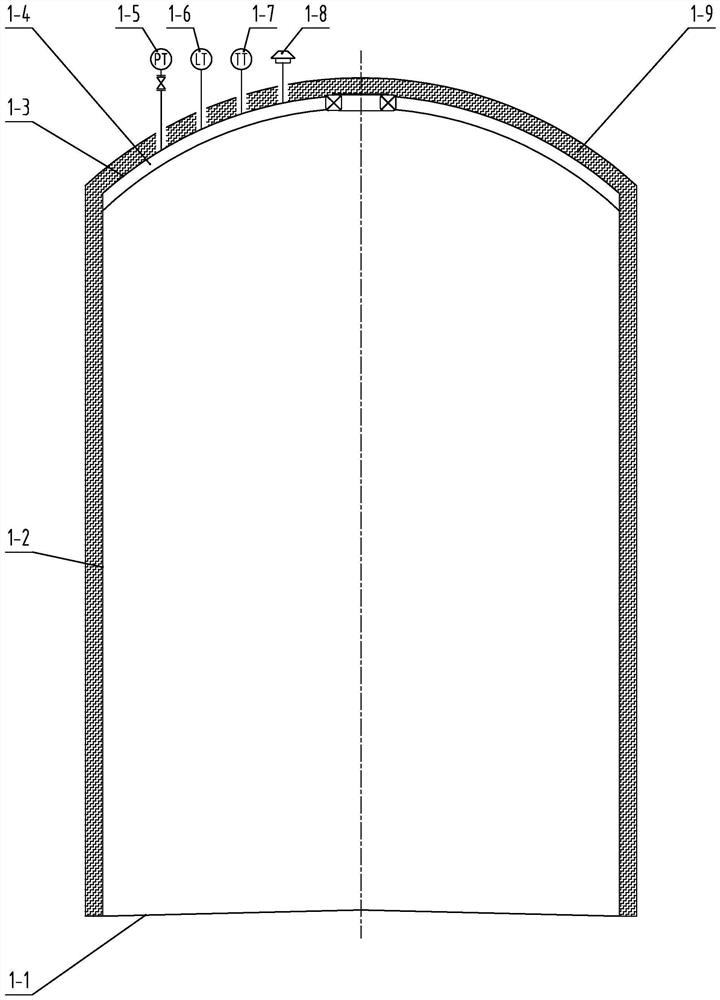

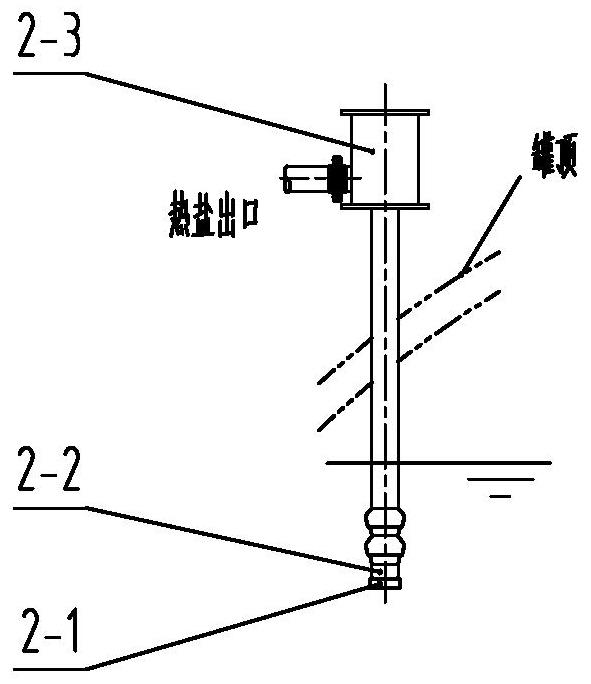

Storage tank for large-scale fused salt energy storage

PendingCN114132646AImprove reliabilityLow costHeat storage plantsLarge containersFreezing Point TemperatureHigh density

The invention discloses a storage tank for large-scale fused salt energy storage, and relates to the technical field of fused salt energy storage. In order to solve the problems that according to an existing fused salt storage tank, due to the fact that the freezing point temperature of fused salt is high, when the fused salt heat storage double tanks operate, the liquid level can change vertically, and the lowest liquid level is close to the bottom of the tank body, a pump shaft of a fused salt pump needs to be long and extends below the liquid level, and due to the fact that the pump shaft cannot be made to be too long, the tank body is limited to be too high. The technology that hot salt with low density is located on the upper portion, cold salt with high density is located on the lower portion, and a temperature gradient layer, namely a thermocline layer is arranged in the middle is adopted, through a salt distributor and a pipeline system, during heat storage, hot salt passes through a hot salt pipeline system and enters a tank body through a hot flat plate type salt distributor, cold salt is pumped out of the tank body through a cold salt pump, and the thermocline layer gradually moves downwards; the heat storage process is finished; during heat release, hot salt is pumped out of the tank body through a hot salt pump, cold salt enters the tank body from the cold flat plate type salt distributor through a cold salt pipeline system, and the thermocline gradually moves upwards. The method is suitable for the technical field of high-temperature fused salt energy storage.

Owner:HARBIN TURBINE AUX EQUIP ENG

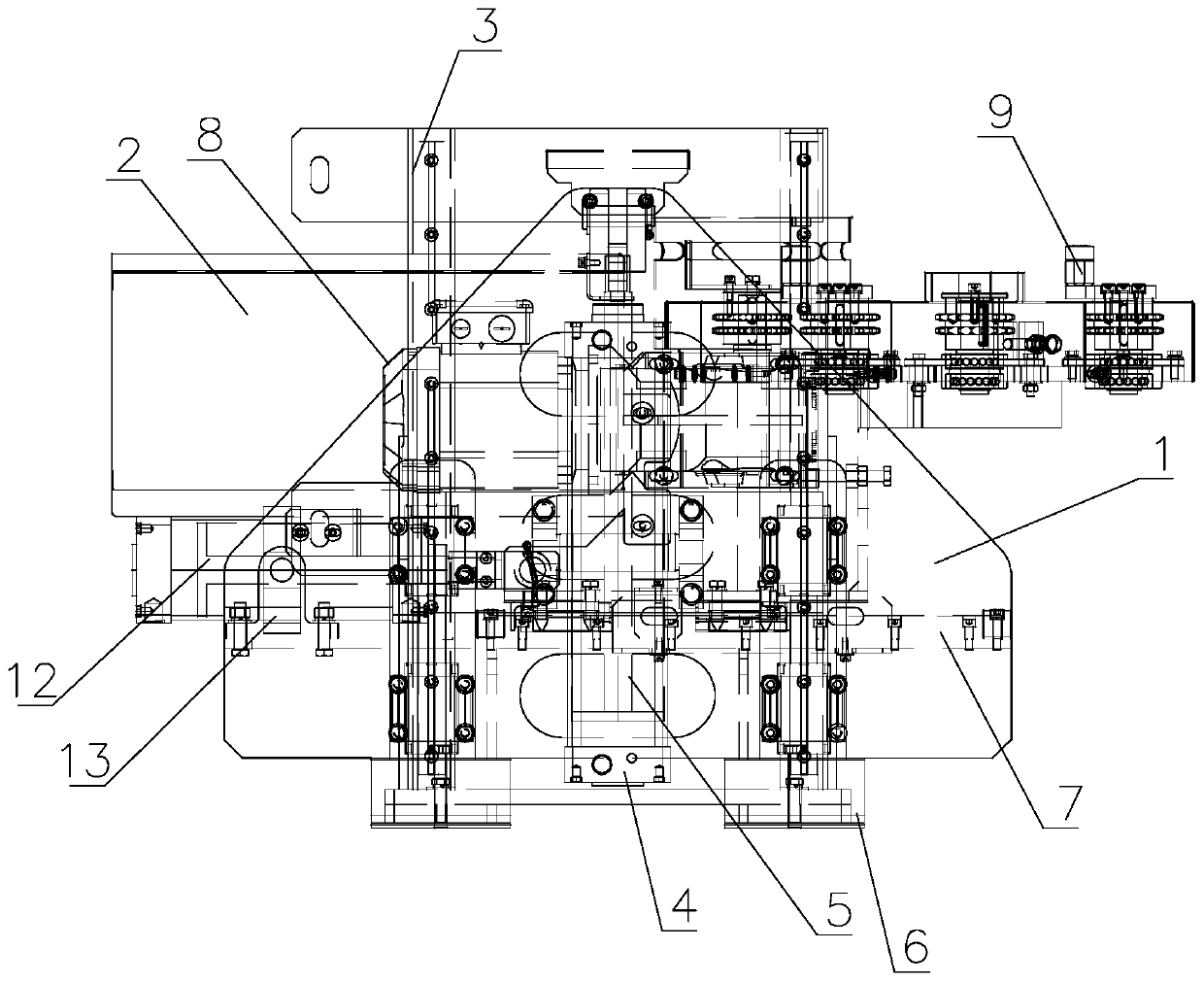

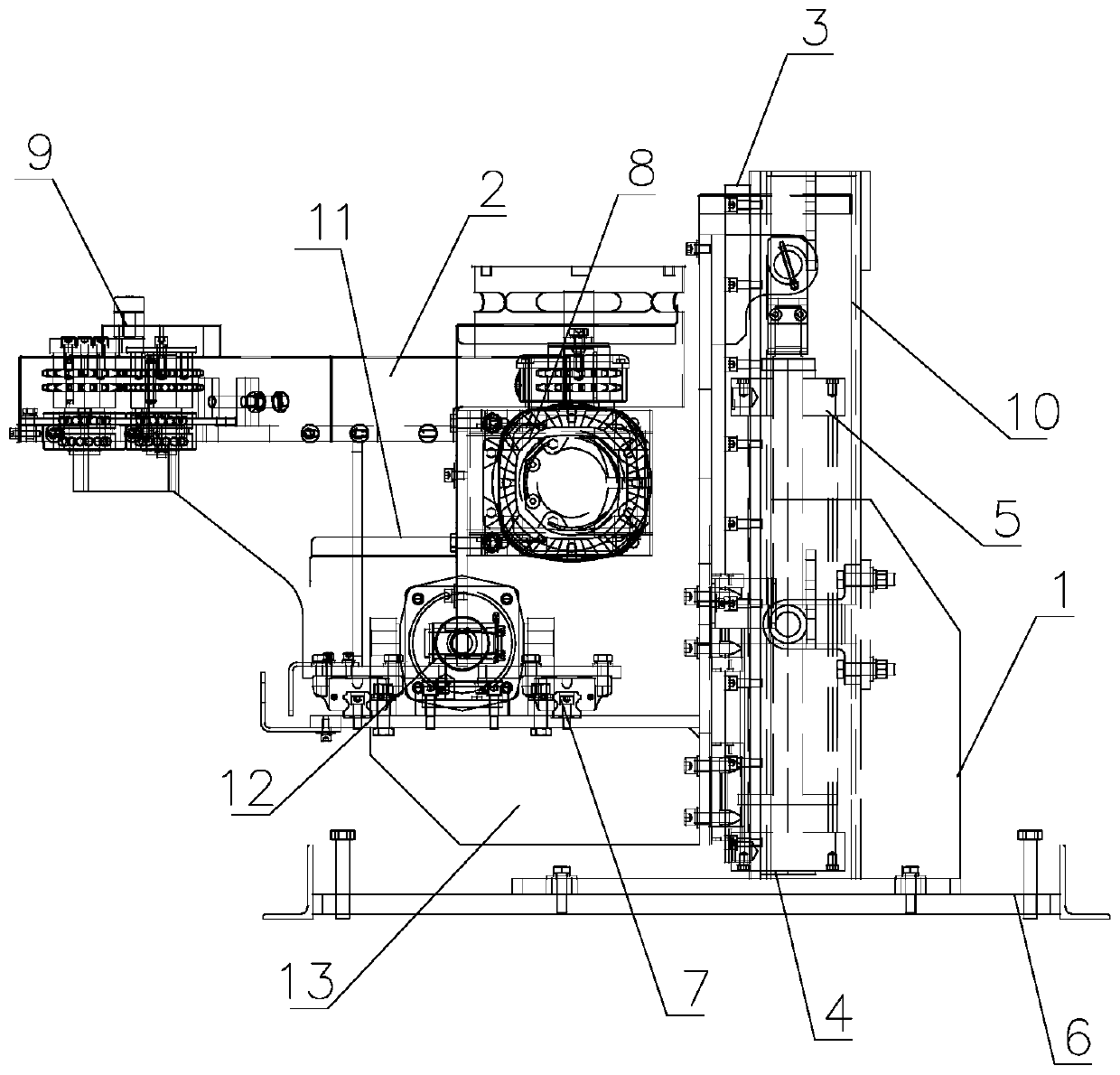

Coating locking and unlocking device

The invention belongs to the technical field of conveyor control, and particularly relates to a coating locking and unlocking device. The device comprises a bottom plate, a moving device and a lockingand unlocking device, the moving device is arranged on the bottom plate, and is used for adjusting the position of the locking and unlocking device, the locking and unlocking device is arranged on the moving device and comprises a motor and moving rotating devices, a chain wheel on a motor output shaft is in transmission connection with chain wheels on the moving rotating devices through a chain,the two moving rotating devices are arranged side by side, and a tensioning chain wheel is arranged on the outer side of the chain, and is arranged on the moving device and located between the two moving rotating devices. Two lifting appliance locking pins can be locked and unlocked at the same time, efficiency is greatly improved, the device is directly mounted on the ground, later-period maintaining is quite convenient, a pit does not need to be dug, the requirement for a plant foundation is low, chain transmission is adopted, the tensioning chain wheel is arranged, and the transmission effect is good.

Owner:MIRACLE AUTOMATION ENG CO LTD

Construction process of zero-leakage waterproof system

InactiveCN112343185AMaintain continuityGood self-healingBuilding insulationsBituminous coatingsMaterials scienceCoating

The invention relates to the technical field of construction of waterproof systems, in particular to a construction process of a zero-leakage waterproof system. The construction process is used for solving the problem that the construction process of the waterproof system in the prior art inevitably has a leakage phenomenon, so that the building quality is influenced. The construction process of the zero-leakage waterproof system comprises the following process steps of cleaning a base layer, painting a base layer treating agent, treating detail nodes, trial-paving a waterproof coiled material, spraying or blade-coating a waterproof coating, paving the waterproof coiled material, closed water detecting and the like. According to the construction process, the surface of the base layer is firstly coated with the treating agent, then the waterproof coating is sprayed or scraped, then the waterproof coiled material is laid on the waterproof coating, so that the waterproof coating and the waterproof coiled material can form a stable and integrally seamless waterproof layer, the waterproof layer can be self-repaired even if damaged in the construction and use process, water is preventedfrom flowing in the waterproof layer, the continuity of the waterproof layer is maintained, and the self-healing property is better, so that the zero-leakage effect can be achieved.

Owner:四川鑫桂湖防水保温节能科技有限公司

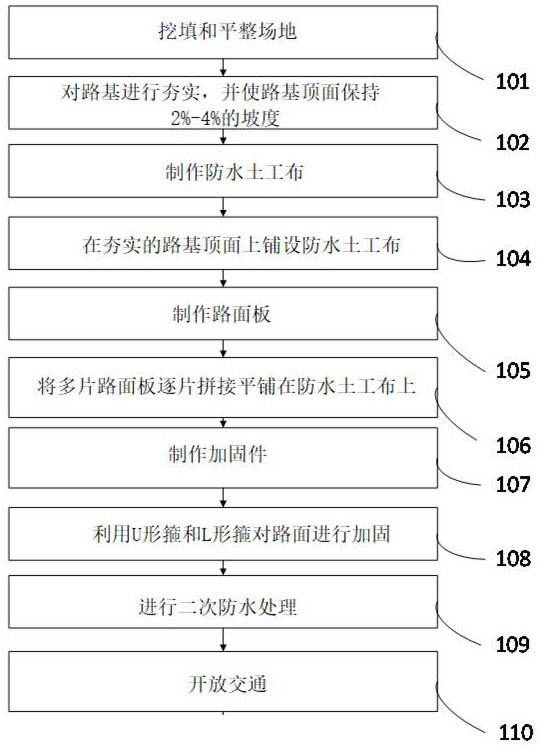

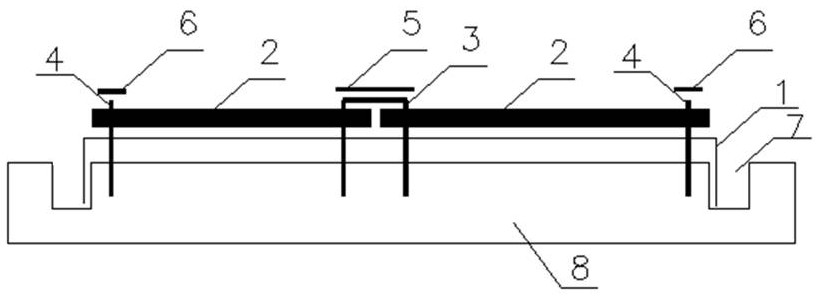

Construction method for quickly building road

InactiveCN112112022AEffectively drain stagnant waterNo pollution in the processSingle unit pavingsPaving detailsArchitectural engineeringStructural engineering

The invention discloses a construction method for quickly building a road. The construction method comprises the following step that a site is dug, filled and leveled; the roadbed is tamped; waterproof geotextile is manufactured; grooves are dug in the two sides of the roadbed, the top face of the compacted roadbed is flatly laid with the waterproof geotextile, the ends of the waterproof geotextile extend into the grooves, then the grooves are backfilled with natural plain soil layer by layer, and compaction is conducted layer by layer; road slabs are manufactured, and a plurality of anchoringholes are formed in the middles and the edges of the road slabs; the road slabs are installed, specifically, the multiple road slabs are spliced and flatly laid on waterproof geotextile one by one, anti-skid lines of the road slabs face upwards, and slab joints of the multiple road slabs and hole positions of the anchoring holes are aligned; reinforcing parts are manufactured, wherein the reinforcing parts are U-shaped hoops and L-shaped hoops; the U-shaped hoops and the L-shaped hoops are used for reinforcing the road surface; secondary waterproof treatment is carried out; and the traffic isput into service.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

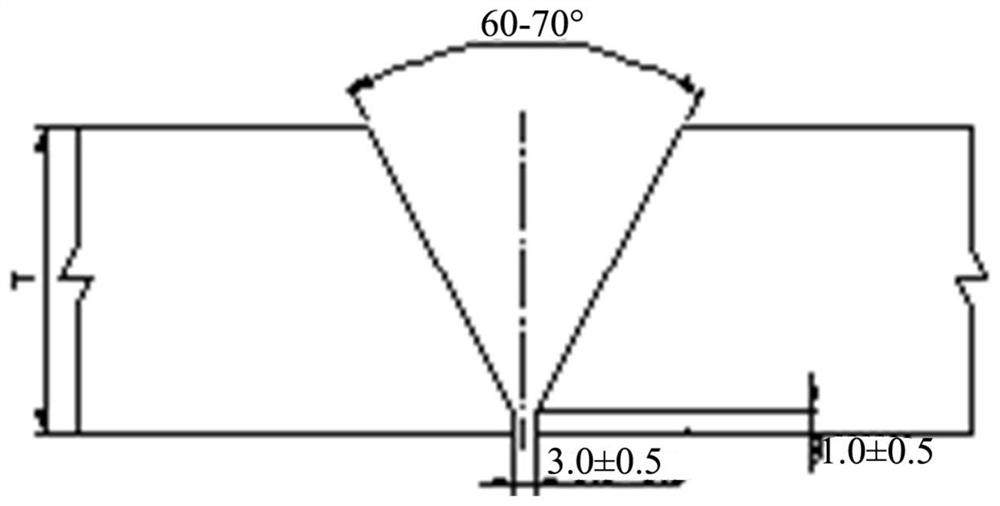

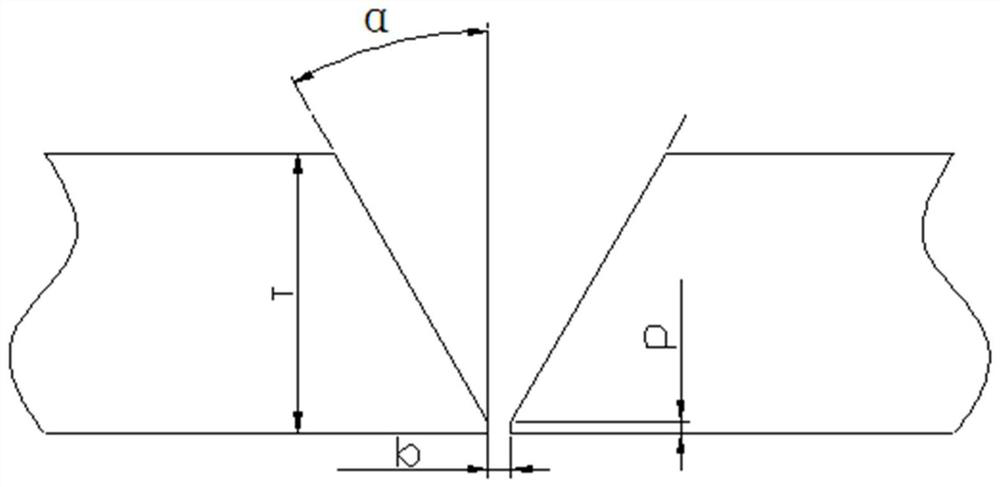

All-position gas shielded flux-cored wire downward semi-automatic welding method for long-distance pipeline

PendingCN113770489AFast coolingImprove mechanical propertiesArc welding apparatusWelding/cutting media/materialsThermodynamicsShielding gas

The invention provides an all-position gas shielded flux-cored wire downward semi-automatic welding method for a long-distance pipeline. The all-position gas shielded flux-cored wire downward semi-automatic welding method comprises the steps of performing groove machining and alignment on the long-distance pipeline, and then welding the pipeline by adopting a multi-layer multi-pass welding manner, wherein tungsten inert gas welding is adopted for a root welding layer; gas shielded flux-cored wire downward semi-automatic welding is adopted for a hot welding layer, a filling welding layer and a cosmetic welding layer; pure CO2 is used as a shielding gas for gas shielded flux-cored wire downward semi-automatic welding; an alkaline flux-cored wire is used as a welding material; the welding direction is downward welding; direct current straight polarity is used; the welding current is 110-170A; the welding voltage is 16-20V; welding positions comprise straight sections and mountainous area sections; the diameter range of the long-distance pipeline is more than 300 mm; and the wall thickness range of the long-distance pipeline is more than 8 mm. The all-position gas shielded flux-cored wire downward semi-automatic welding method for the long-distance pipeline is capable of improving the welding efficiency and the welding seam toughness, and is suitable for all-position, all-terrain and multiple-groove-type long-distance pipeline welding.

Owner:SICHUAN GASOLINEEUM CONSTR ENG

retaining overflow dam structure

ActiveCN104018471BLow costLow basic requirementBarrages/weirsEarth-fill damsManufacturing technologyHydraulic structure

The invention discloses a retaining overflow dam structure, which belongs to the technical field of design and manufacture of hydraulic structures. The invention provides a retaining overflow dam structure with low requirement on foundation setting, simple construction and low construction cost. The retaining overflow dam structure includes block stones and a mesh permeable framework, the block stones are filled in the mesh permeable skeleton, and the retaining overflow dam structure is fixed on the mesh through the mesh permeable skeleton In the river channel or channel where the retaining overflow dam structure needs to be installed on the outside; the water flowing along the channel or channel flows through the gap between the mesh permeable framework and adjacent stones and flows through the retaining overflow The dam structure, the solid matter or displacement substance trapped in the water flow is filtered through the intercepting overflow dam structure and blocked on the water-facing side of the retaining overflow dam structure.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

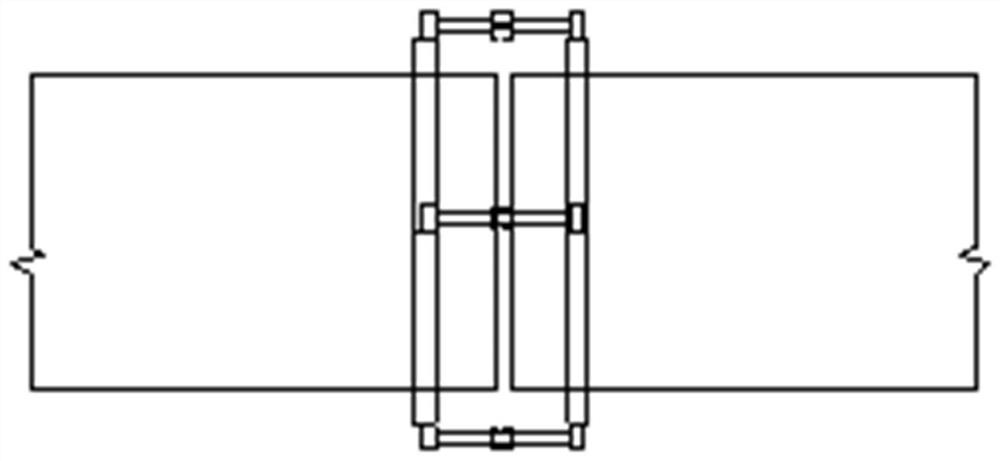

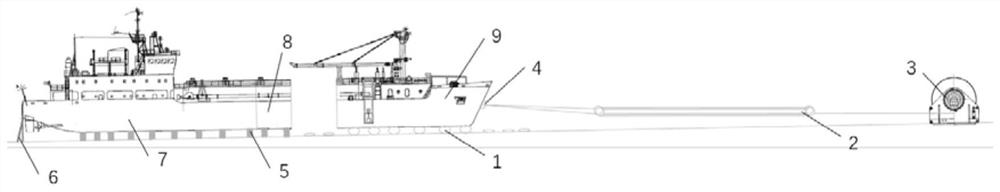

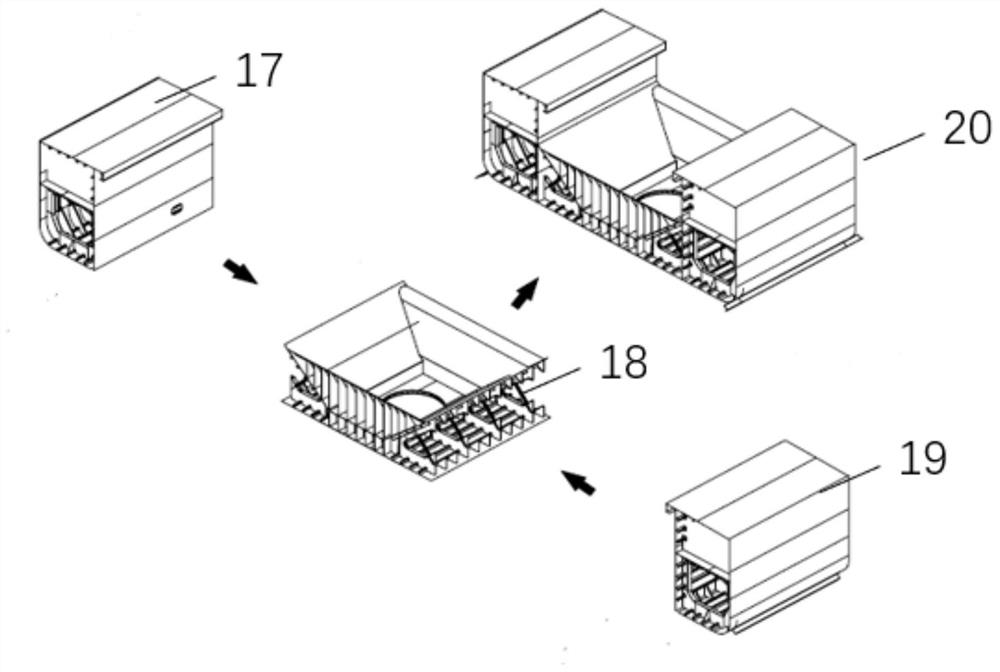

Ship lengthening and reconstruction method

PendingCN113895588AReduce extra investmentLow basic requirementWaterborne vesselsErbium lasersReconstruction method

The invention discloses a ship lengthening and reconstruction method, and belongs to the technical field of ship lengthening and reconstruction, and the method comprises the following steps of ship surveying and scribing, cutting, bow section pulling, segmented carrying, bow section folding and corollary equipment refitting. Displacement of the bow section is achieved through the method that the air bag and the traction device are matched, the difficulty that shipyard infrastructures are insufficient is overcome, meanwhile, cost is greatly reduced, the requirement for a shipyard foundation is not high, the method is suitable for the dock and the slipway, the applicability is wide, cost is low, and the period is controllable; according to the five-segment line inspection method, five segments are matched with a laser device to measure and record the deflection value of the ship position, a small segment carrying method is adopted for segmentation, the carried and folded segments can be finely adjusted in time, and the lengthening and reconstruction precision is improved; the large opening position and the weak structural strength position of the bow section are supported and reinforced after segmented lineation, the cut plane is perpendicular to the center line of the ship, and it is further guaranteed that the precision of the ship is controllable.

Owner:NANJING CHANGJIANG WATERWAY ENG BUREAU

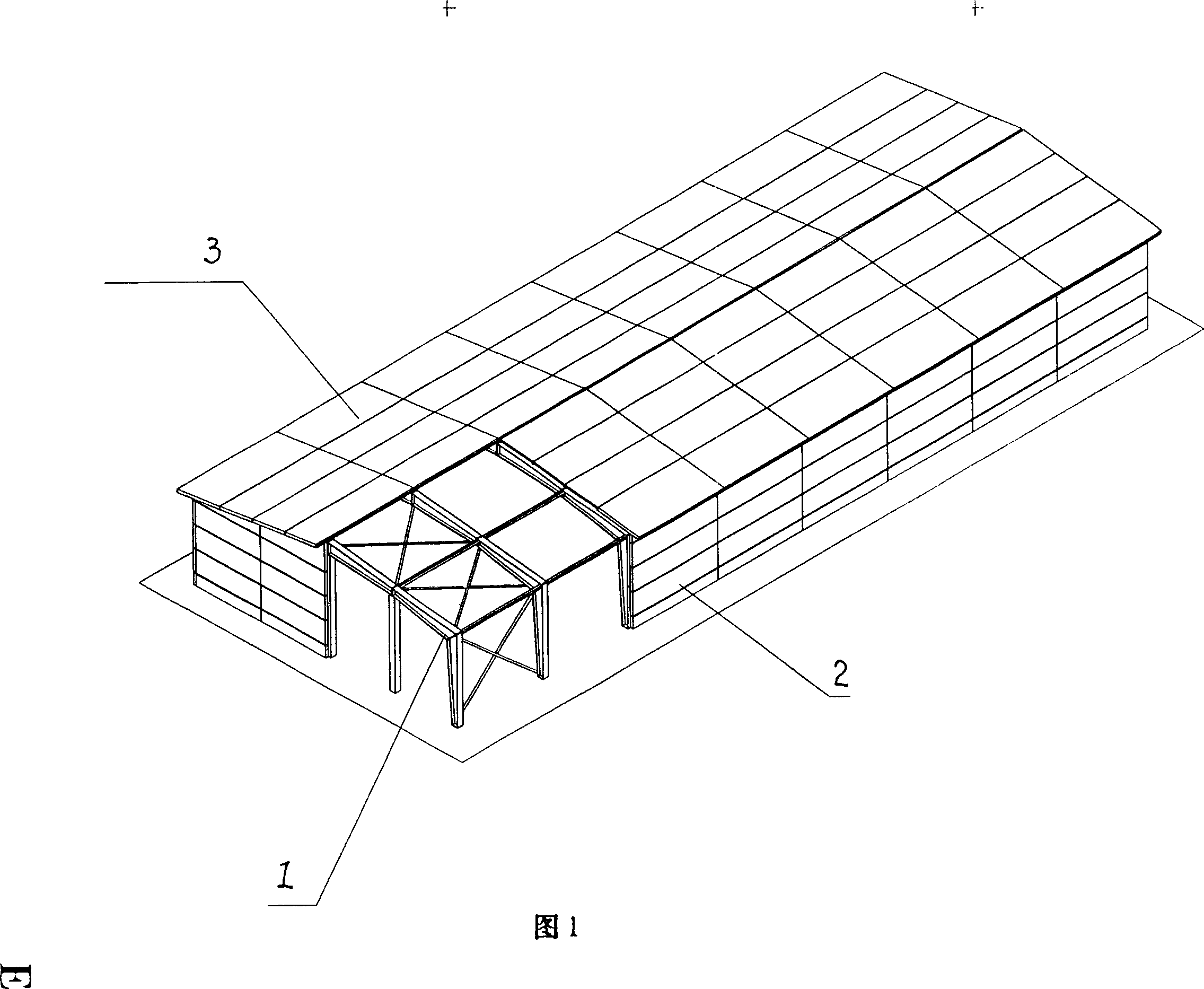

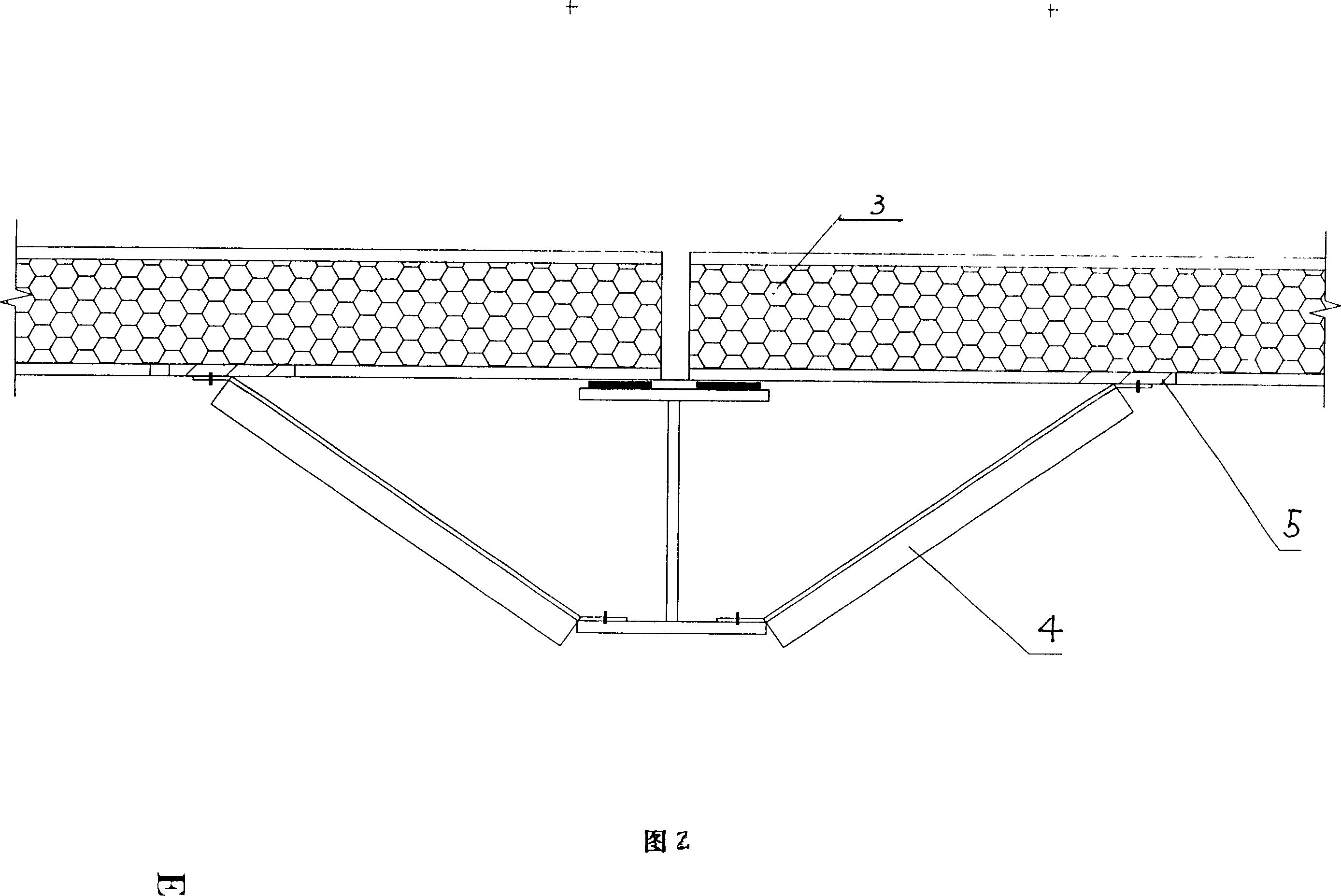

Construction process of plant building in goal type steel frame structure

InactiveCN1124395CImprove carrying capacityIncrease stiffnessIndustrial buildingsSteel barSteel frame

The technological scheme of the present invention includes interval between columns less than 9m, braced frame without purlins, and building comprising portal steel frame, wall panels hung directly onto and welded to steel column of the frame, roof slabs connected to the steel beams in the frame through built-in welding parts, and corner braces with one end connected to the frame and the other end cnnected to the connecting part in roof slab and wall panel. The present invention is superior in that by means of the integrated bearing, heat maintaining, fireproof, waterproof and decorative boards of the present invention and varying decoration, the building needs no structural frame and thus not high requirement to foundation, fast and simple construction speed and low cost. the present invention is especially suitable for construction of building shorter than six storeys.

Owner:CUBIC DIGITAL TECH CO LTD

High-moisture vertical mill drying in-series grinding process

The invention discloses a high-moisture raw material vertical mill drying in-series grinding process. The process solves the long-term problems of a traditional vertical mill treatment of high-moisture raw material, and greatly expands the application scope of a vertical mill. At the same time, the vertical mil-ball mill in-series grinding process and a rolling compaction material bed grinding process are adopted, the particle size of the majority of sorted fine powder is controlled in the range of 60-200 [mu]m, ball mill material cushion and overgrinding phenomena are reduced, and powder classification is achieved in the devices. The process is high in grinding efficiency, good in fine crushing performance, small in abrasion, low in energy consumption and safe and simple in maintenance.

Owner:TONGLING HAIYUAN SUPERFINE POWDER

Barrier combination structure and method for ditch water treatment and debris flow protection

ActiveCN106320252BAvoid blockageAvoid Impact HazardsBarrages/weirsHydraulic engineering apparatusNatural disasterEngineering

The invention provides a blocking composite structure and method for gully water treatment and debris flow protection, which can effectively treat all-year-round running water of gullies and resist debris flow, and belongs to the field of water conservancy and hydropower constructions. The blocking composite structure comprises a water retaining dam and a drainage tunnel making an upstream riverway of the water retaining dam communicate with a downstream riverway, and further comprises an intercepting dam which is located on the upstream side of the water retaining dam. One end of the intercepting dam is connected with the edge of the riverway and the other end extends into the riverway. While the water retaining dam and the drainage tunnel are arranged, the intercepting dam is arranged on the upstream side of the water retaining dam, so that the blocking composite structure can perform effective blocking and drainage treatment on all-year-round running water of gullies, provide a temporary construction area for a downstream area, resist special natural disasters such as debris flow and prevent the damage to the water retaining dam caused by debris flow.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com