Construction process of plant building in goal type steel frame structure

A portal frame and industrial factory building technology, applied in the field of building construction, can solve the problems of difficult secondary decoration, high anti-corrosion requirements, poor wind resistance, etc., achieve low ground endurance and foundation requirements, and improve The effect of enhanced anti-collision ability and anti-leakage ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments of the specification.

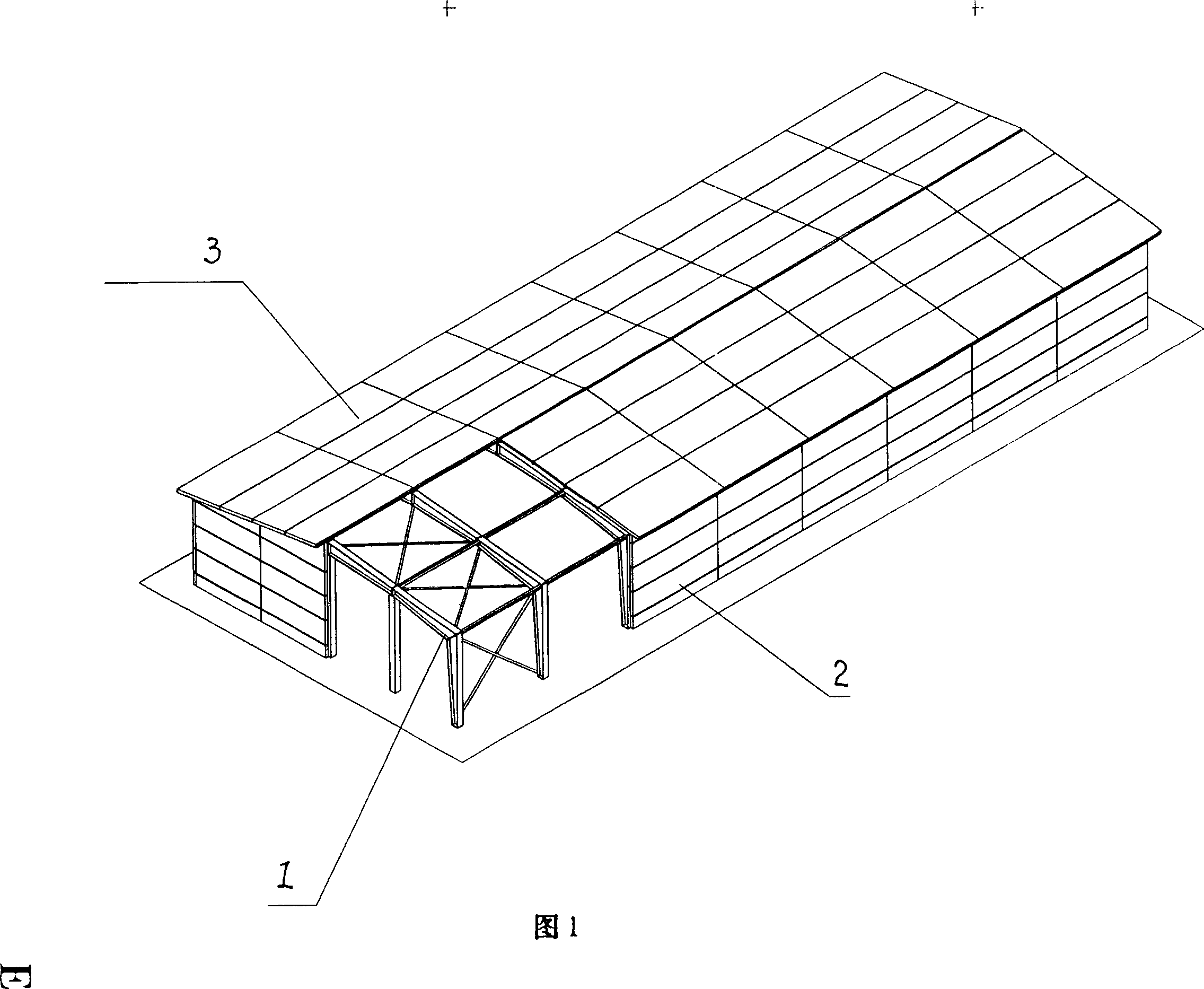

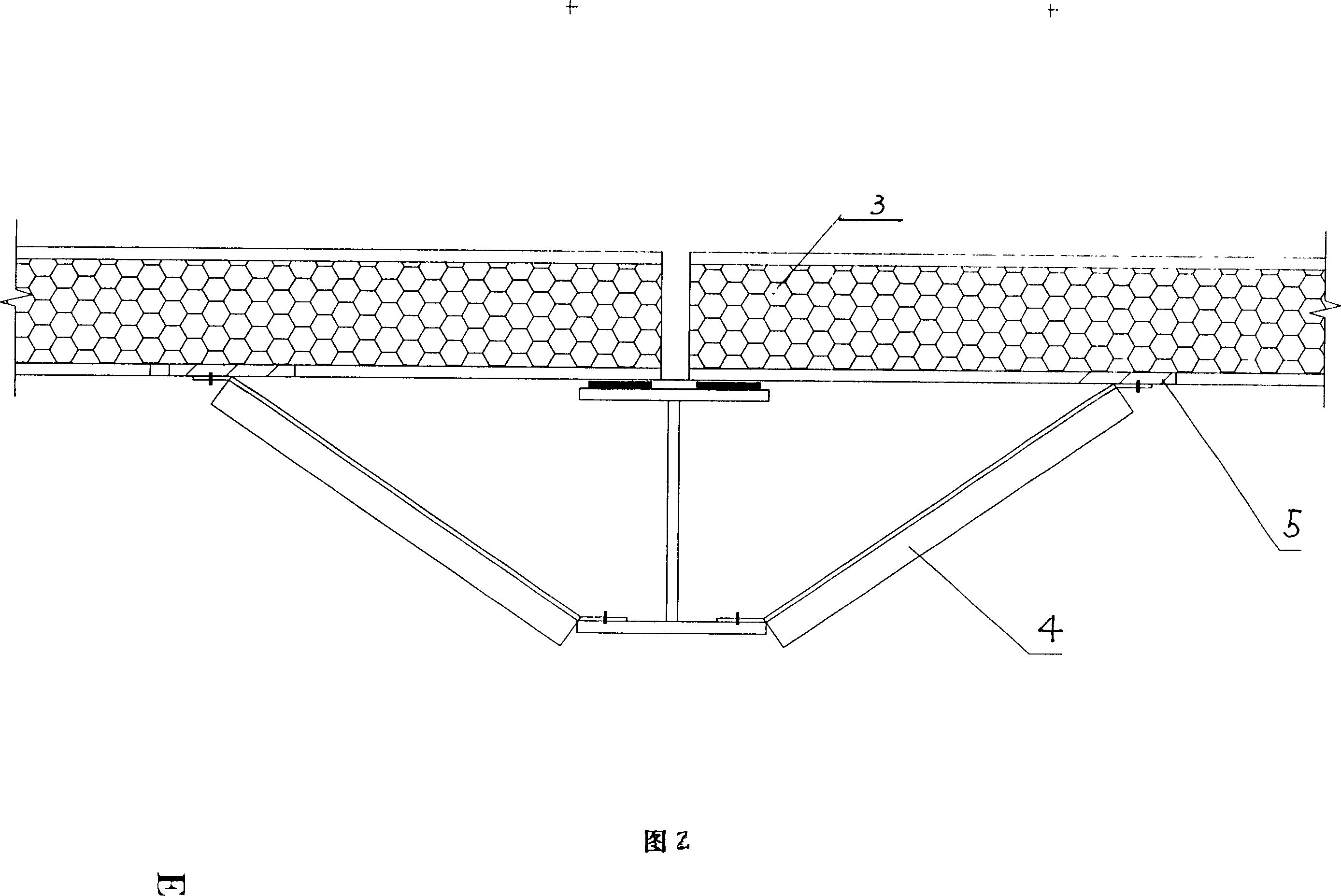

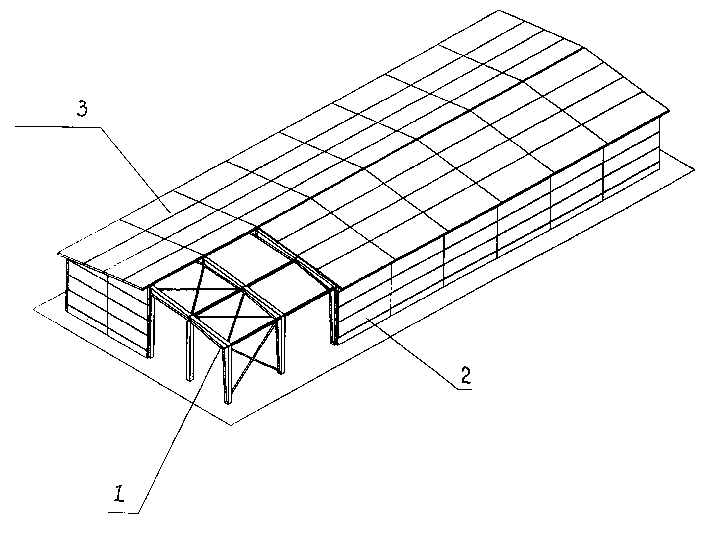

[0018] As shown in Figures 1 and 2, the technical solution of the present invention is: it is composed of a portal frame structure system 1, supporting wall panels 2, roof panels 3 and corner braces 4; the roof panel 3 is directly placed on the door on the steel beam 5 of the portal frame, and the embedded parts set in the roof panel 3 are welded to the steel beam; the wall panel 2 is directly hung on the steel column of the portal frame, and the wall panel 2 The embedded parts set in the above are welded and connected to the steel column; one end of the corner brace 4 is connected to the portal frame according to the specification, and the other end is directly fixed on the corner brace connector of the roof panel 3 and the wall panel 2.

[0019] The sheet material involved in the present invention, its performance parameter is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com