Combined rigid frame steel plate girder-pier girder solid structure

A steel plate girder and structure construction technology, which is applied in the field of composite steel plate girder bridge pier girder solid structure, can solve the problems of high maintenance cost, poor seismic performance, cracking and mid-span deflection, etc., and achieve low requirements and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

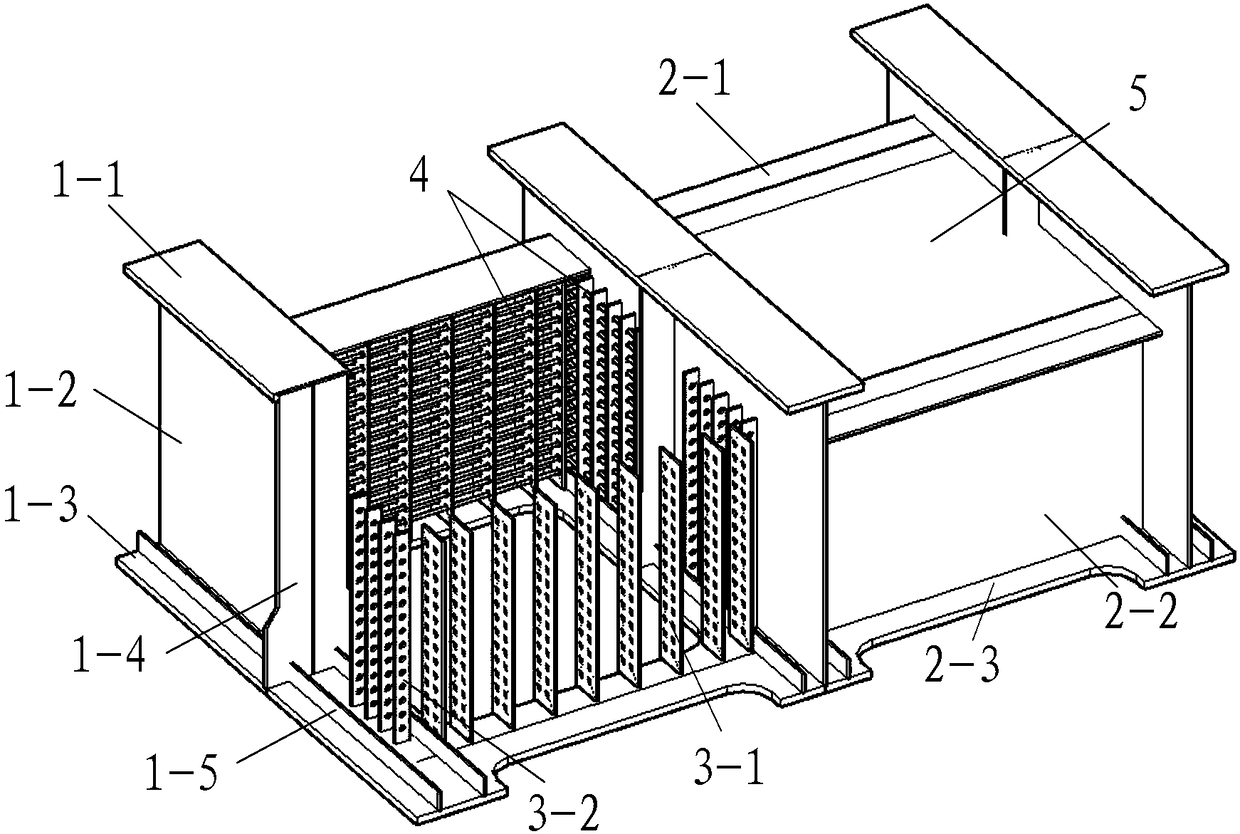

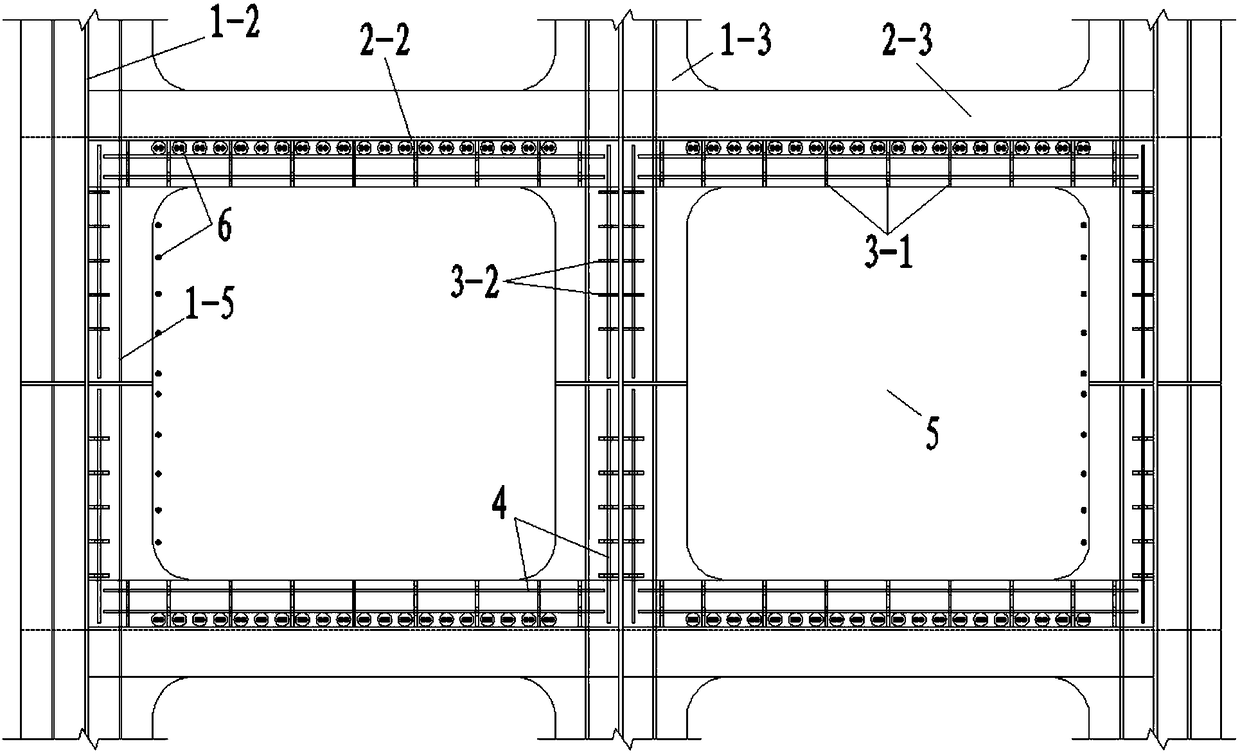

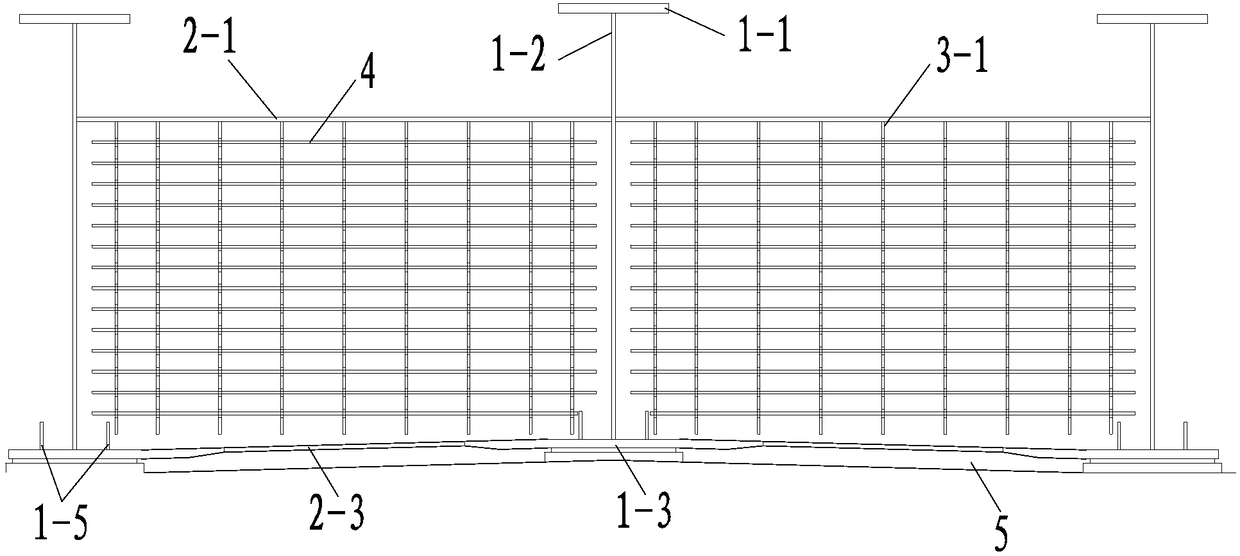

[0029] Such as Figure 1 ~ Figure 3 As shown, the composite steel plate girder bridge pier girder solid structure of the present invention includes an I-shaped steel girder and a beam arranged between the steel girders. The steel girder includes an upper flange plate 1-1, a web 1-2, Lower flange plate 1-3, transverse stiffener plate 1-4, longitudinal stiffener plate 1-5; beam includes upper flange plate 2-1, web plate 2-2, lower flange plate 2-3; passed value According to the analysis, the contact between the lower flange plate 1-3 of the main girder and the outer edge of the pier bears a relatively large local pressure. The lower flange plate 1-3 is equipped with longitudinal stiffening ribs 1-5; the inner sides of the main girder web 1-2 and the beam w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com