Portal crane with supporting floating body

A technology of gantry cranes and floating bodies, which is applied in the direction of trolley cranes, cranes, load suspension components, etc., and can solve problems such as limited application, high crane prices, and long overhangs of booms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

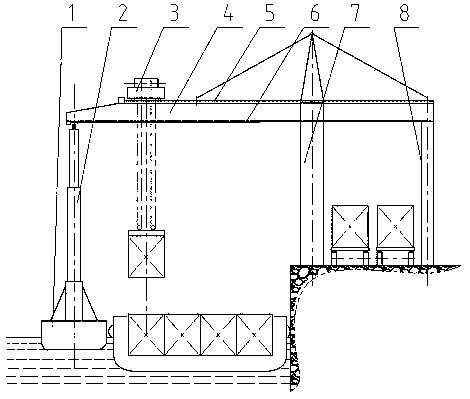

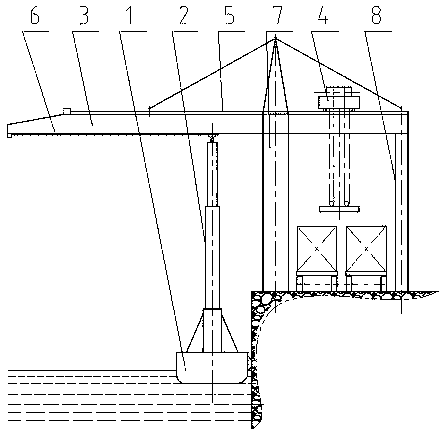

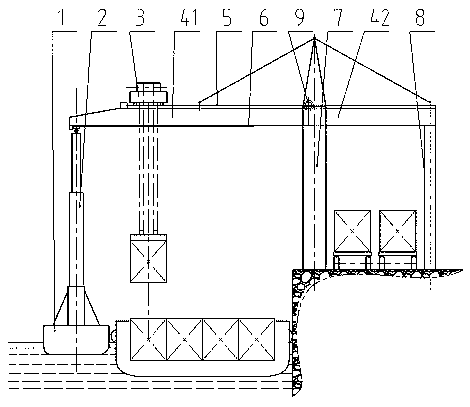

[0025] in figure 1 with figure 2 In the gantry crane with floating body support shown, the fixed gantry 7 is a steel frame member with a gate-shaped structure, and the fixed gantry 7 with a gate-shaped structure faces the river and is fixedly connected to the pier on the river bank. The door-shaped structure of 7 is fixedly supported by rail beams 4, and the rail beams 4 fixed on the fixed door frame 7 extend to both sides, and the rear door frame 8 is fixedly connected to the rear end of the door frame. The rear door frame 8 also has a door-shaped structure and is fixed Between the door frame 7 and the rear door frame 8 is the container transfer stacking space. The track beam 4 includes two beam frame bodies arranged parallel to each other. The two beam frame bodies are fixed in the fixed door frame 7 and the rear door frame 8 by the fixed door frame 7 and The two uprights of the rear door frame 8 are supported, and a heavy guide rail 5 is fixedly connected to each beam frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com