External-circulation iron-removing grinding technology

A technology of iron powder removal and external circulation, which is applied in the direction of grain processing, etc., can solve the problems of poor particle shape of the discharged material, affecting the operability of concrete, affecting the strength of clinker, etc., achieving good rigidity, high grinding efficiency, Reduce the effect of undue vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

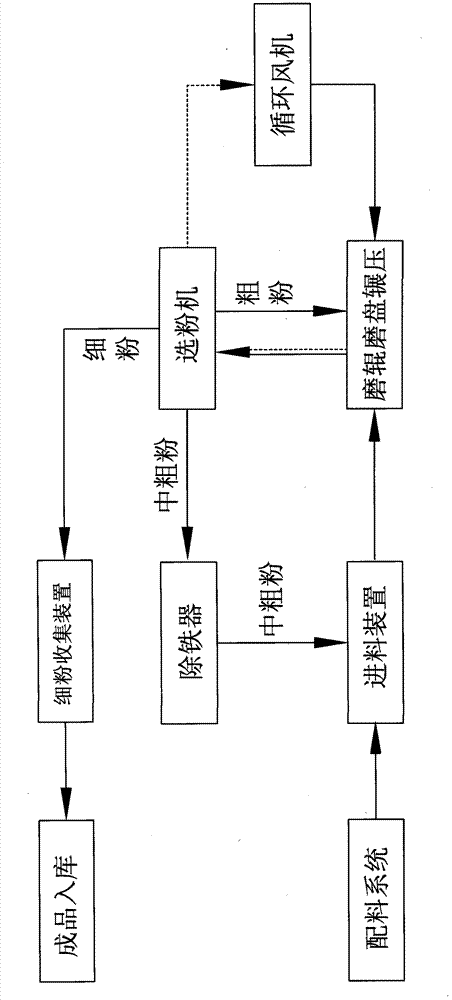

[0012] This embodiment is an external circulation iron removal and grinding process, the process flow is shown in the figure, and it is carried out according to the following steps:

[0013] (1) Feed the material prepared by the batching system into the elevator through the material conveying device, lift it up through the elevator, and drop it to the center of the millstone through the feeding pipe. The area is ground by high-pressure grinding rollers, and the material conveying device and the discharge pipe are equipped with iron removers for preliminary iron removal of the materials;

[0014] (2) The pulverized material is blown up by the high-speed airflow generated by the high-pressure fan at the edge of the millstone, and the coarse powder with large particles falls back to the millstone for regrinding. Under the action of the plane vortex in the dust air flow, the medium and coarse powder is subjected to centrifugal force, collides with the wall of the wind guide vane, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com