Motor rotation shaft assembly method and assembly machine implementing same

A technology of a motor shaft and an assembly method, which is applied to electromechanical devices, manufacturing motor generators, and assembling machines, etc., can solve the problems of high cost, difficulty in recruiting workers, and inability to cope with large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

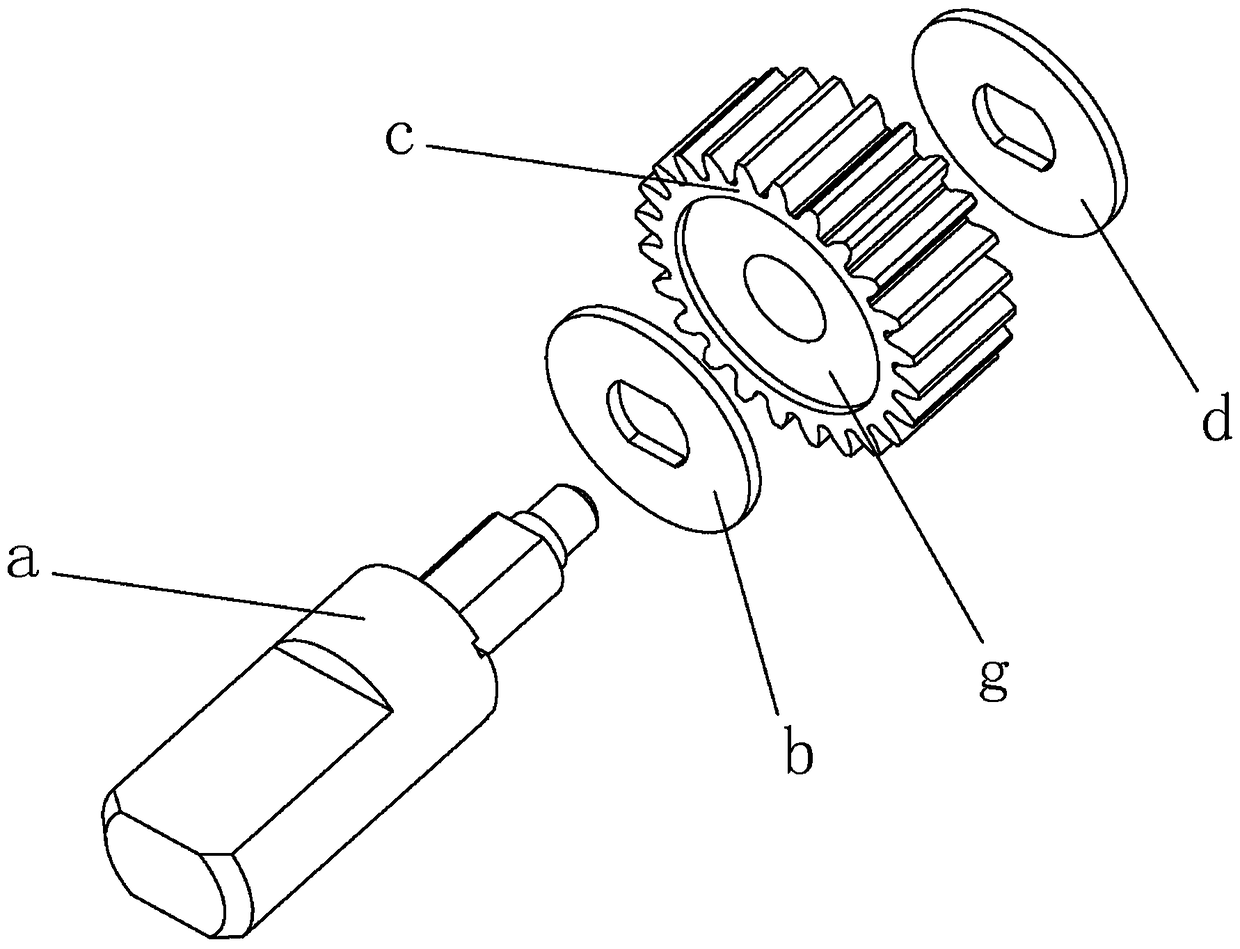

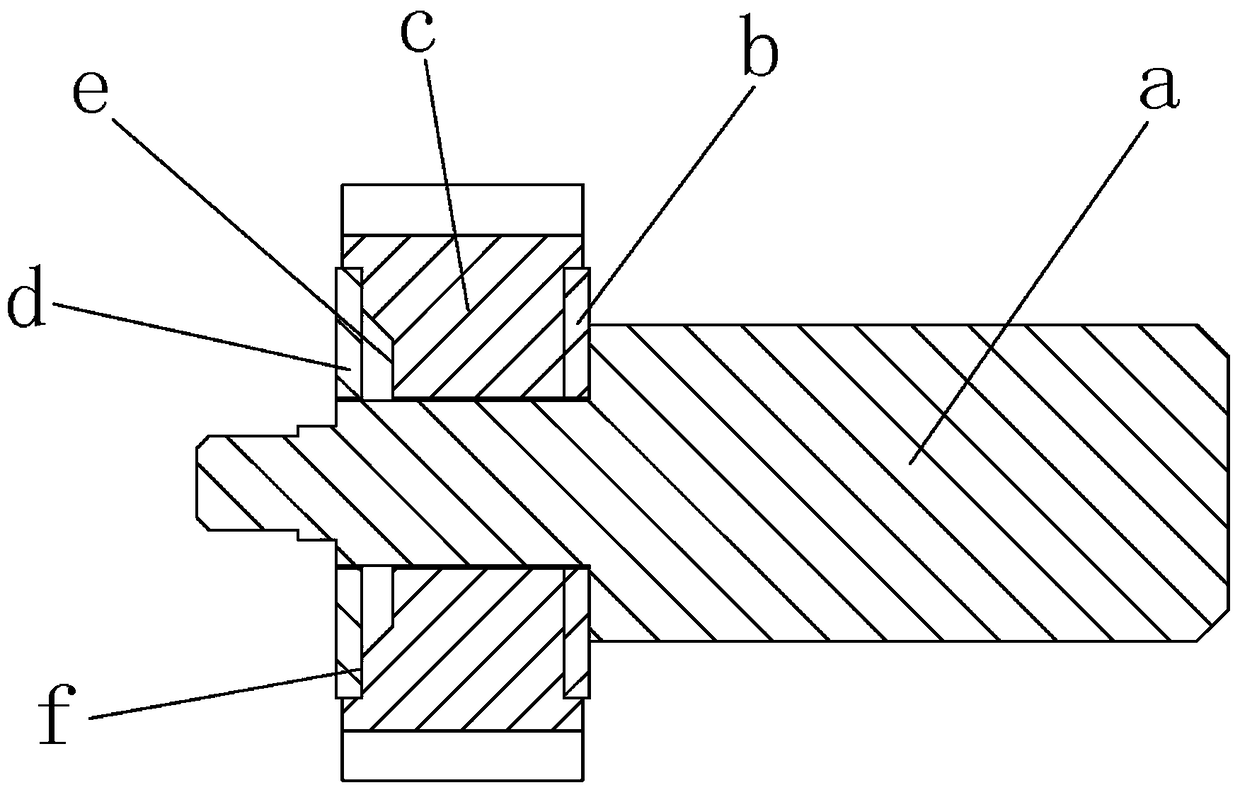

[0077] refer to Figure 1 to Figure 18 , an assembly method of a motor shaft, comprising the following steps:

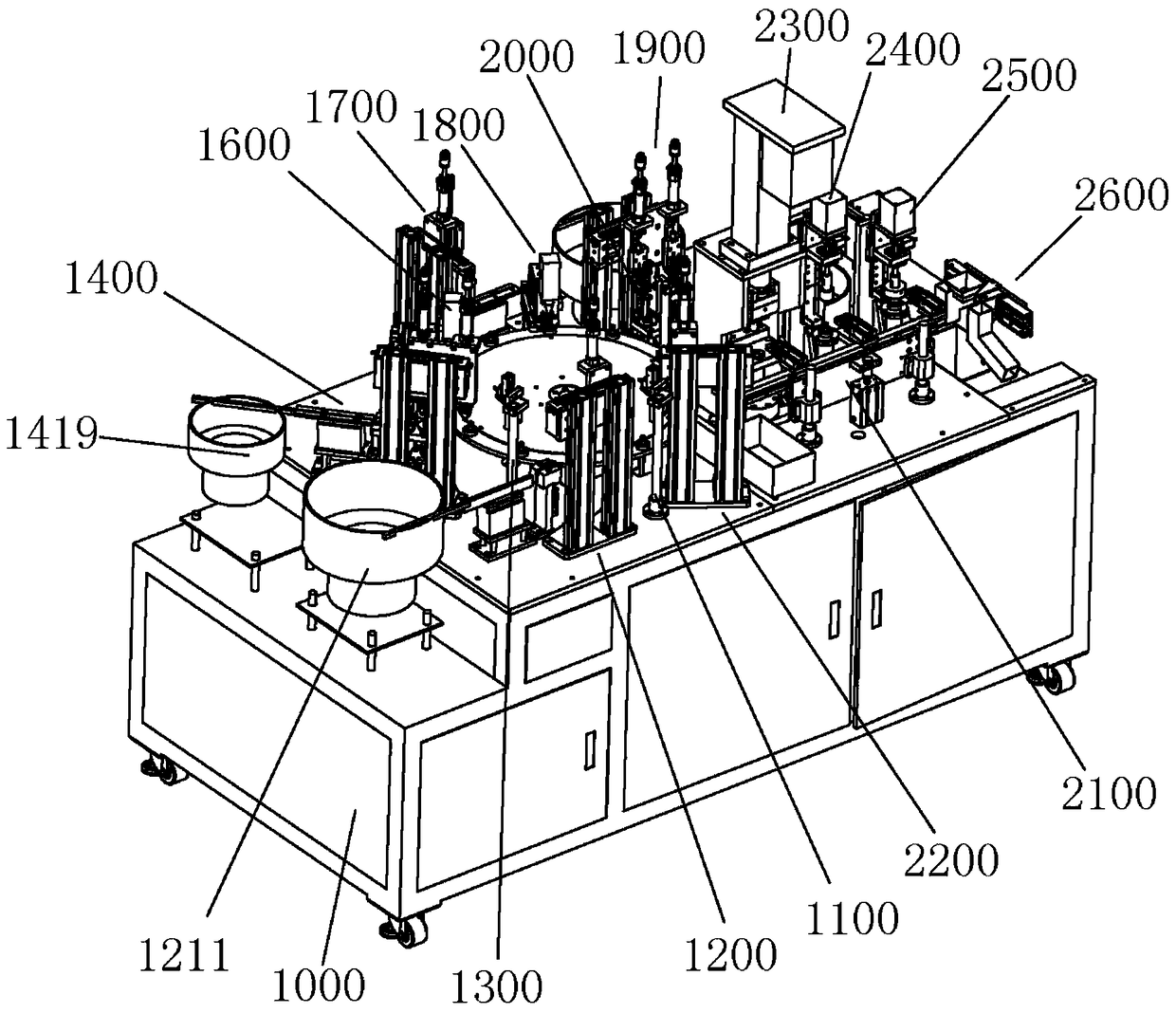

[0078] (1) A circular turntable is set on a machine table, and the turntable is connected with a first motor which drives it to rotate in the circumferential direction but not to move axially. The upper edge of the turntable is fixedly installed with several circularly arranged The shaft fixing seat for accommodating the lower end of the shaft is provided with a shaft fixing seat detection device around the turntable, a shaft delivery installation device, a shaft detection device, a lower pressure ring delivery installation device, a lower pressure ring detection device, and a second pressure ring detection device. An oiling device, a gear conveying and installing device, a second oiling device, an upper pressing ring conveying and installing device, an upper pressing ring detecting device, a finished product moving device and a defective product recovery device, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com