Assembled frame-type horizontal warehouse, prefabricated wallboard mould and construction method of horizontal warehouse

A technology of prefabricated wall panels and construction methods, applied in the directions of molds, manufacturing tools, building structures, etc., can solve the problems of clay bricks not meeting national environmental protection requirements, short service life of steel silo, and large silo-type silo wall thickness, etc. The effect of high construction difficulty, lower foundation cost and lower foundation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

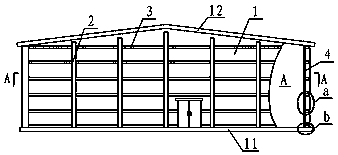

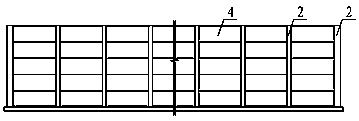

[0054] An assembled frame-type one-story warehouse, a prefabricated wall panel mold and a method for building a one-story warehouse, the composition of which includes: a frame-type warehouse body 1, the frame-type warehouse body connecting the base 11 and the warehouse roof 12, the frame-type warehouse body It includes a group of reinforced concrete columns 2 positioned on the four walls of the wall, and there are reinforced concrete connecting beams 3 between the reinforced concrete columns to form the support system of the warehouse roof. The reinforced concrete columns 2 and the The reinforced concrete connecting beam 3 is connected to the reinforced concrete prefabricated wall panel 4 .

Embodiment 2

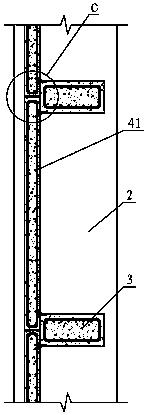

[0056] In the assembly frame-type bungalow warehouse, prefabricated wallboard mold and bungalow construction method described in Embodiment 1, the height of the reinforced concrete prefabricated wallboard 4 is 1m-3m, and the value is taken according to the storey height or integer multiples, and the length of the board is 5m-7m Integer multiples are taken according to the depth or bay of the warehouse body, the overall thickness of the reinforced concrete prefabricated wall panels including the insulation layer is 70mm-150mm, and the reinforced concrete prefabricated wall panels are distributed with steel mesh 41 .

Embodiment 3

[0058] For the assembly frame-type bungalow warehouse, prefabricated wallboard mold and bungalow construction method described in embodiment 1 or 2, the left and right ends of the reinforced concrete prefabricated wallboard 4 are embedded in the reinforced concrete columns 2 on both sides, or attached to the On the reinforced concrete column 2; the upper and lower ends of the reinforced concrete prefabricated wall panel 3 are attached to the reinforced concrete connecting beam 3, or embedded in the reinforced concrete beams on both sides; the upper and lower floors The reinforced concrete prefabricated wall panel 3 top connection or inlaid connection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com