Bridge expansion joint structure and construction technology thereof

A technology for expansion joints and bridges, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as increasing the adhesion between concrete and pre-embedded reinforcement, poor pre-embedding effect, welding point distribution spacing, and reducing maintenance time, etc. To achieve the effect of shortening the construction period, fast construction speed and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

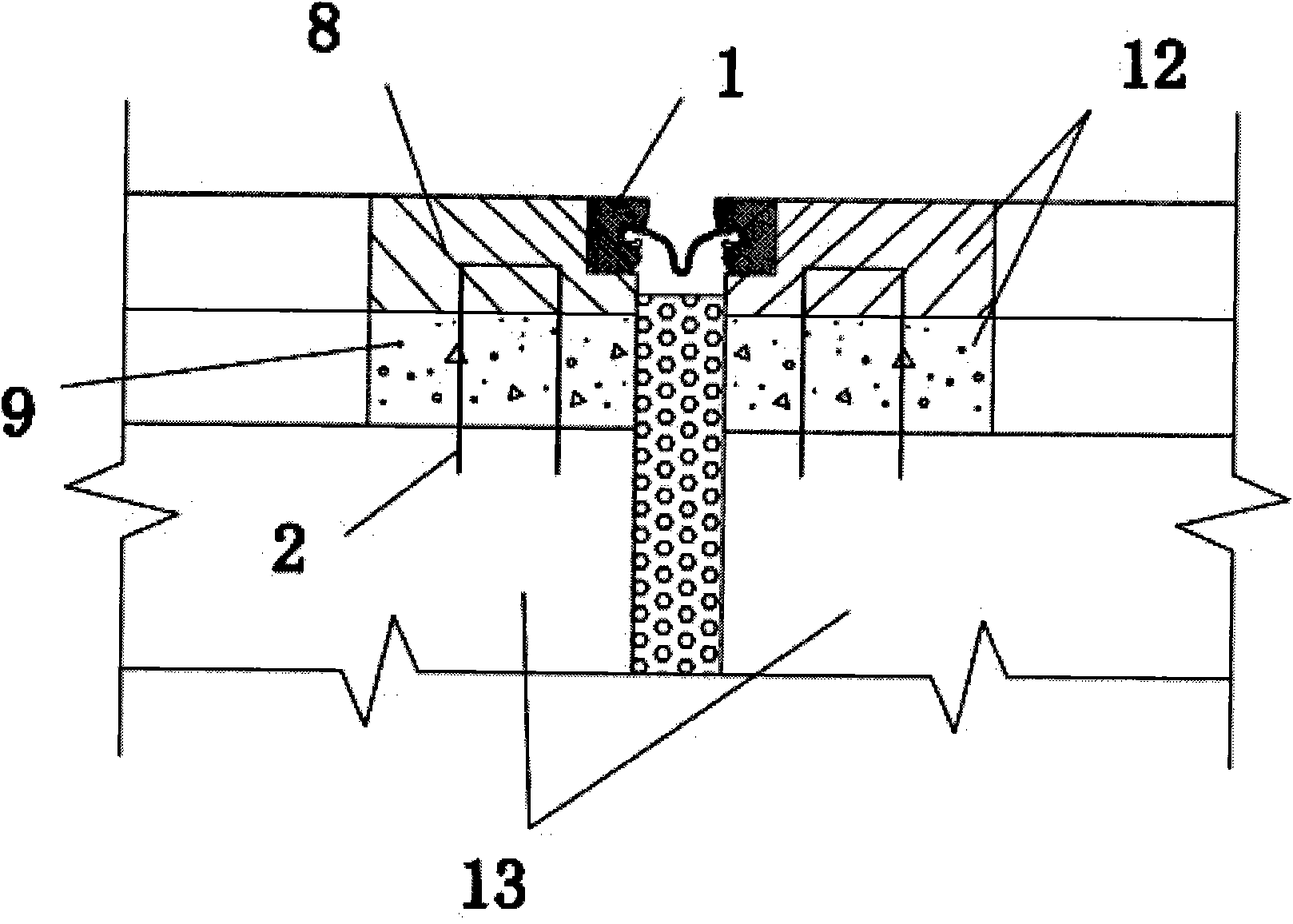

[0041] Such as figure 1 As shown, the bridge expansion joint structure described in this embodiment is located at the mid-span of the bridge, and it includes a concrete layer 12, section steel 1, pre-embedded reinforcement 2 and filling layer 15, and the pre-embedded reinforcement 2 is pre-embedded in the adjacent beam slab 13 Above, the exposed part is poured in the concrete layer, the filling layer 15 is located in the gap between the adjacent beams 13, the filling layer 15 is a foam board, and the concrete layer mainly includes the elastic concrete layer 8 and the epoxy resin concrete layer 9. The elastic concrete layer 8 is located above the epoxy resin concrete layer 9 , and the epoxy resin concrete layer 9 is arranged above the adjacent beam slabs 13 .

[0042] Of course, the filling layer 15 can also be other filling materials commonly used in construction, such as sponge and sponge board. Epoxy resin concrete layer 9 can adopt epoxy resin concrete commonly used in con...

Embodiment 2

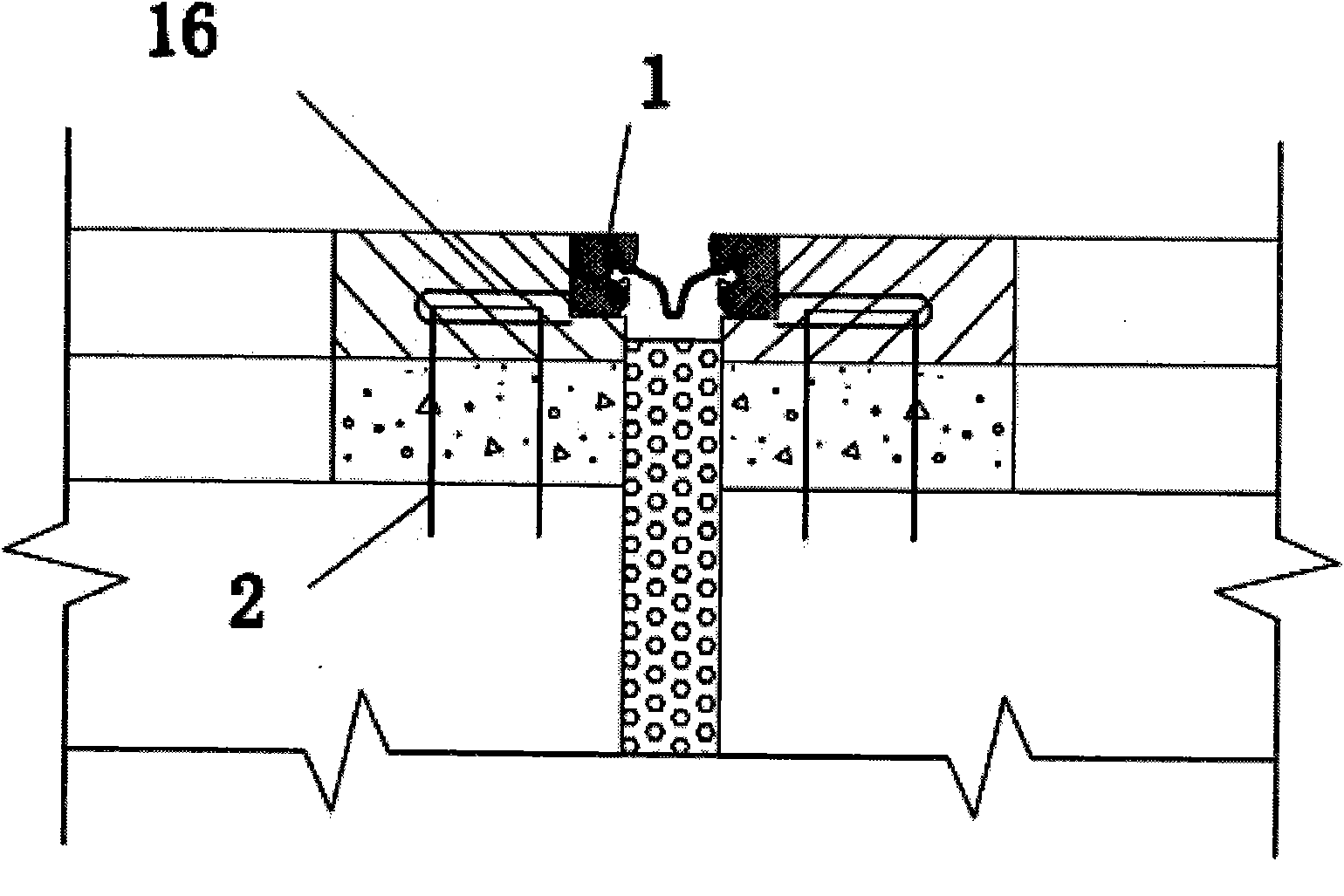

[0045] Such as figure 2 As shown, the bridge expansion joint structure described in this embodiment is different from Embodiment 1 in that a connecting rib 16 is provided between the pre-embedded reinforcement 2 and the section steel 1 to connect them. Connecting bar 16 also adopts reinforcing bar, and pre-embedded bar 2 is welded with section steel 1, increases strength.

Embodiment 3

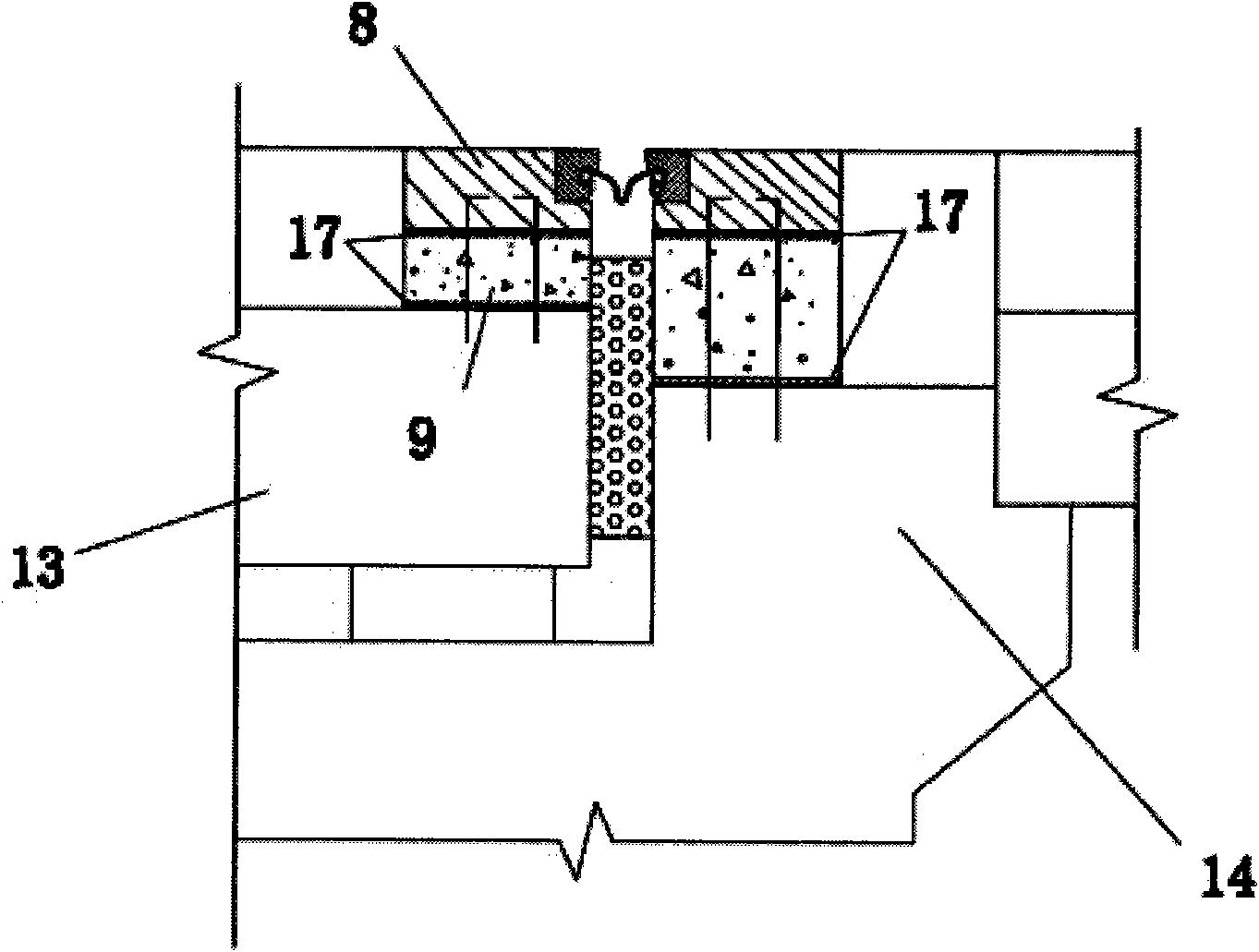

[0047] Such as image 3 As shown, the bridge expansion joint structure described in this embodiment is located at the junction of the bridge and the road surface, and it includes a concrete layer 12, profile steel 1, pre-embedded reinforcement 2 and filling layer 15, and the concrete layer mainly includes an elastic concrete layer 8 And the epoxy resin concrete layer 9, the elastic concrete layer 8 is located above the epoxy resin concrete layer 9, and the epoxy resin concrete layer 9 is arranged above the adjacent beam slab 13 and the platform cap back wall 14.

[0048] In order to effectively bond between the layers, an adhesive layer 17 is provided between the epoxy resin concrete layer 9 and the elastic concrete layer 8, and on the lower layer of the epoxy resin concrete layer 9, so that the epoxy resin The construction joints between the resin concrete layer 9 and the elastic concrete layer 8, and between the epoxy resin concrete layer 9 and the beam slab 13 and the platf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com