Method for carrying out dynamic compaction composite treatment on sludge soil foundation through gravel piles, drain board and upper filling body

A technology for compound treatment and gravel piles, which is applied in the fields of dynamic compaction and compound treatment of muddy soil foundations, drainage boards and gravel piles in the upper filling body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

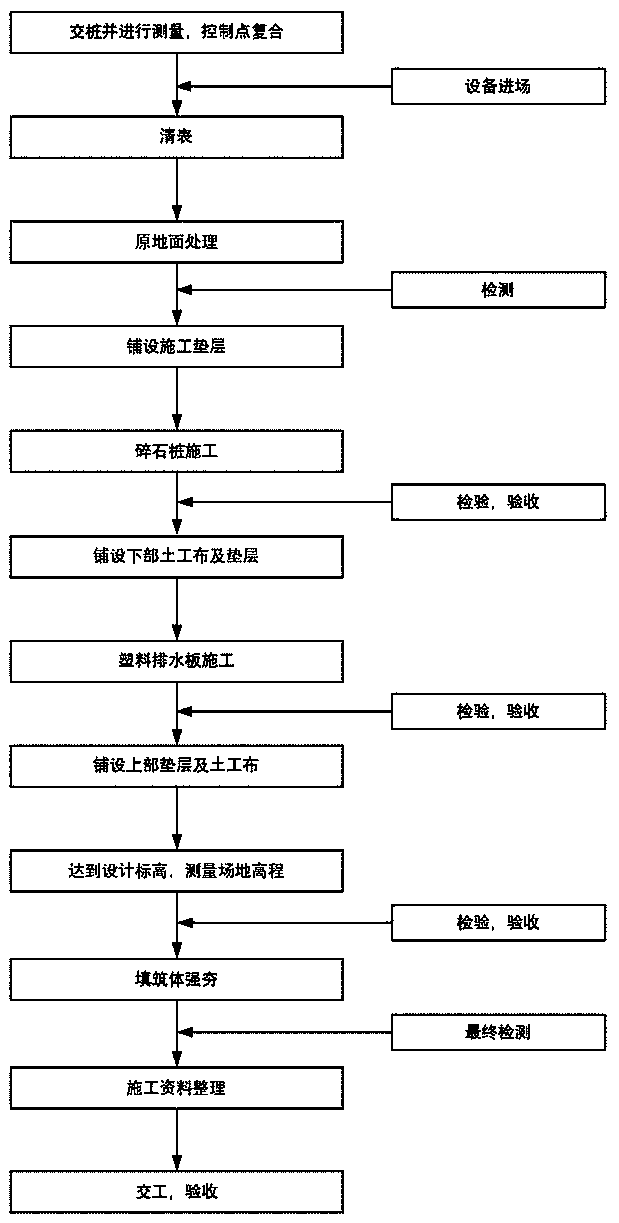

[0070] This embodiment provides a method for combined treatment of muddy soil foundation with gravel piles, drainage boards, and upper filling body dynamic compaction, including the following steps:

[0071] S1, laying construction cushion

[0072] After the surface of the site is cleared, a medium-weathered sandstone cushion with a preset thickness is laid and leveled, and compacted with a vibratory roller to meet the needs of the pile driver;

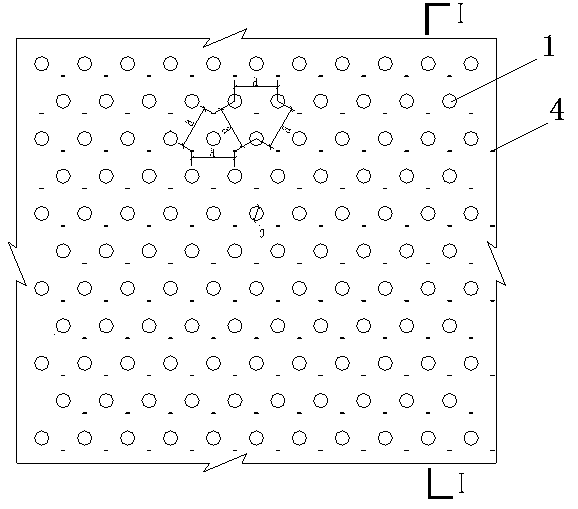

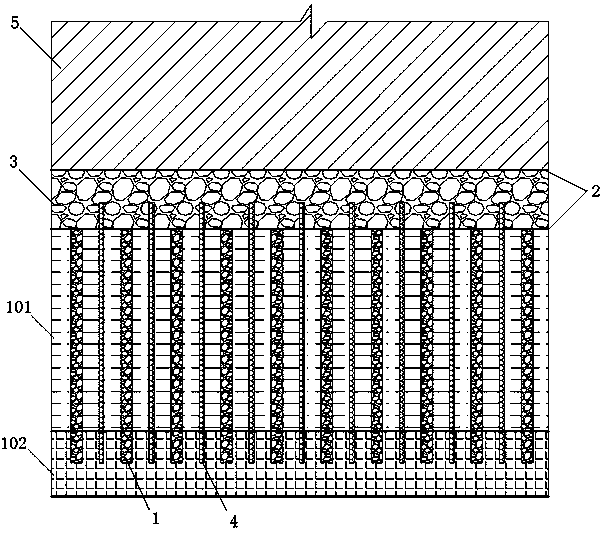

[0073] S2, for the construction of gravel pile 1, the vibrating pipe sinking method is used to form an artificial foundation in which the weak foundation soil and the vertical reinforcement of gravel pile 1 jointly bear the load;

[0074] S3, laying the geotextile and cushion under the gravel pile top, and laying the water-permeable geotextile 2 and the graded gravel cushion 3 on the artificial foundation to form the lower base of the horizontal drainage cushion;

[0075] S3.1, laying the geotextile under the drainage cushion

[007...

Embodiment 2

[0088] In the southwestern region of my country, there are engineering problems such as wide distribution range, large thickness, uneven distribution and large thickness variation of muddy soil foundation. Among them, the soft soil such as valley pond silt has a large buried depth, with an average of about 5m and a maximum buried depth of 13m. The silty soil has a water content greater than the fluidity limit, a large void ratio, low mechanical strength, and strong compressibility. Due to its complex structure and large amount of compression deformation, it is difficult to control the post-construction settlement of the road foundation.

[0089] 1. Construction procedures and parameters

[0090] 1.1 Laying construction cushion

[0091] After the surface of the site is cleared, a 50cm-thick medium-weathered sandstone cushion is laid and leveled, and compacted with a vibratory roller. The compaction degree is required to be ≥ 90% to meet the requirements of the pile driver.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com